Patents

Literature

39results about How to "Increase peripheral speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

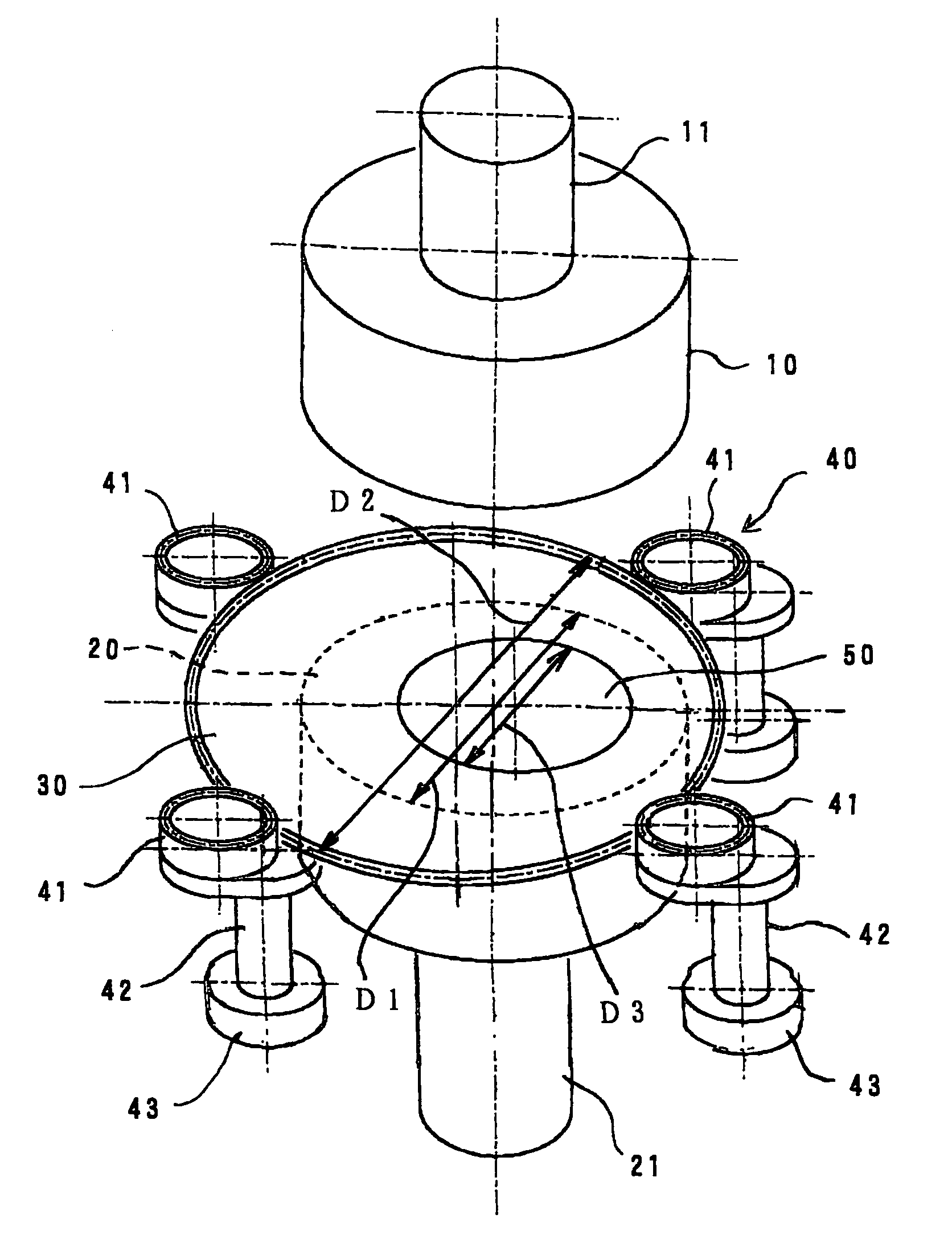

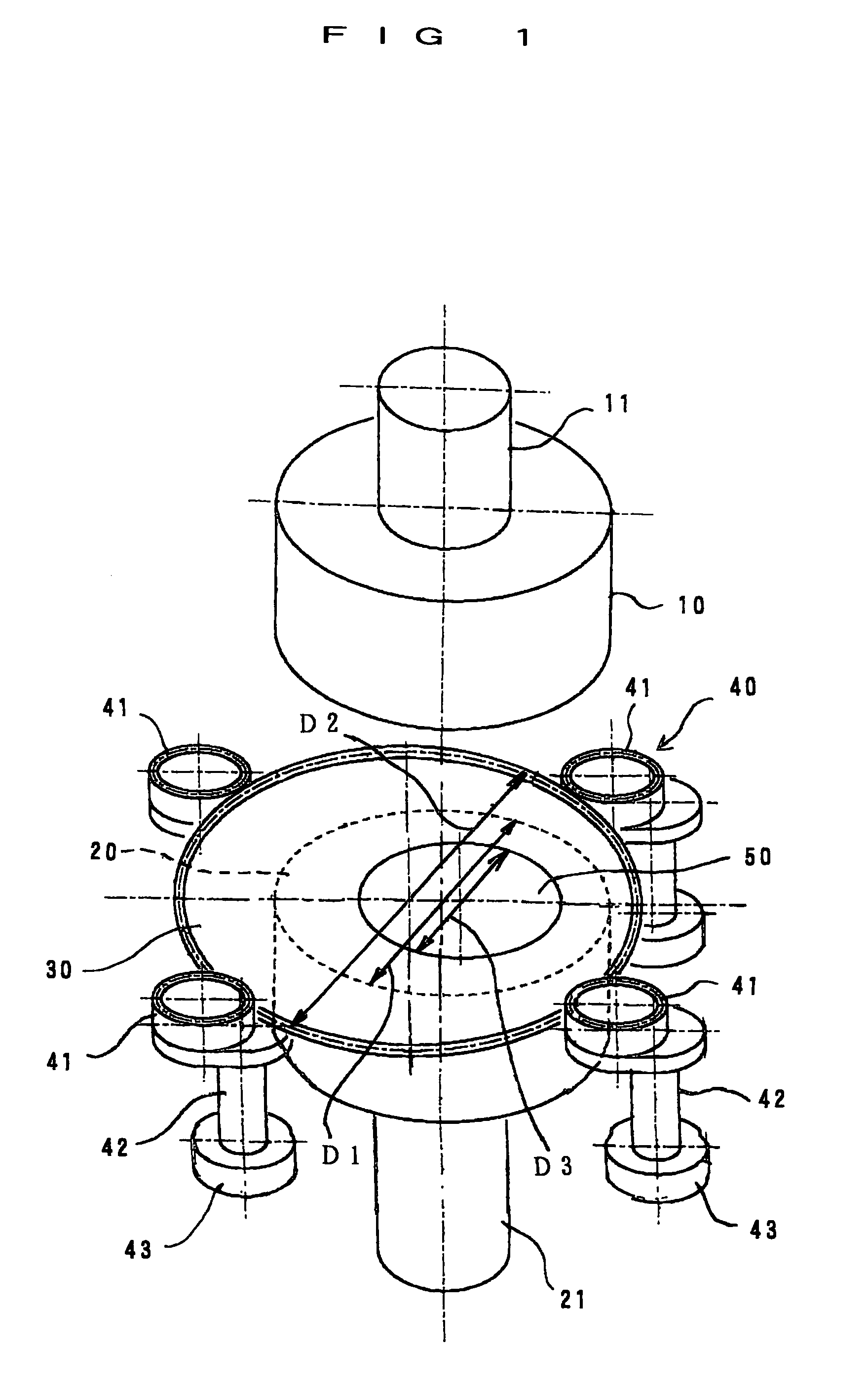

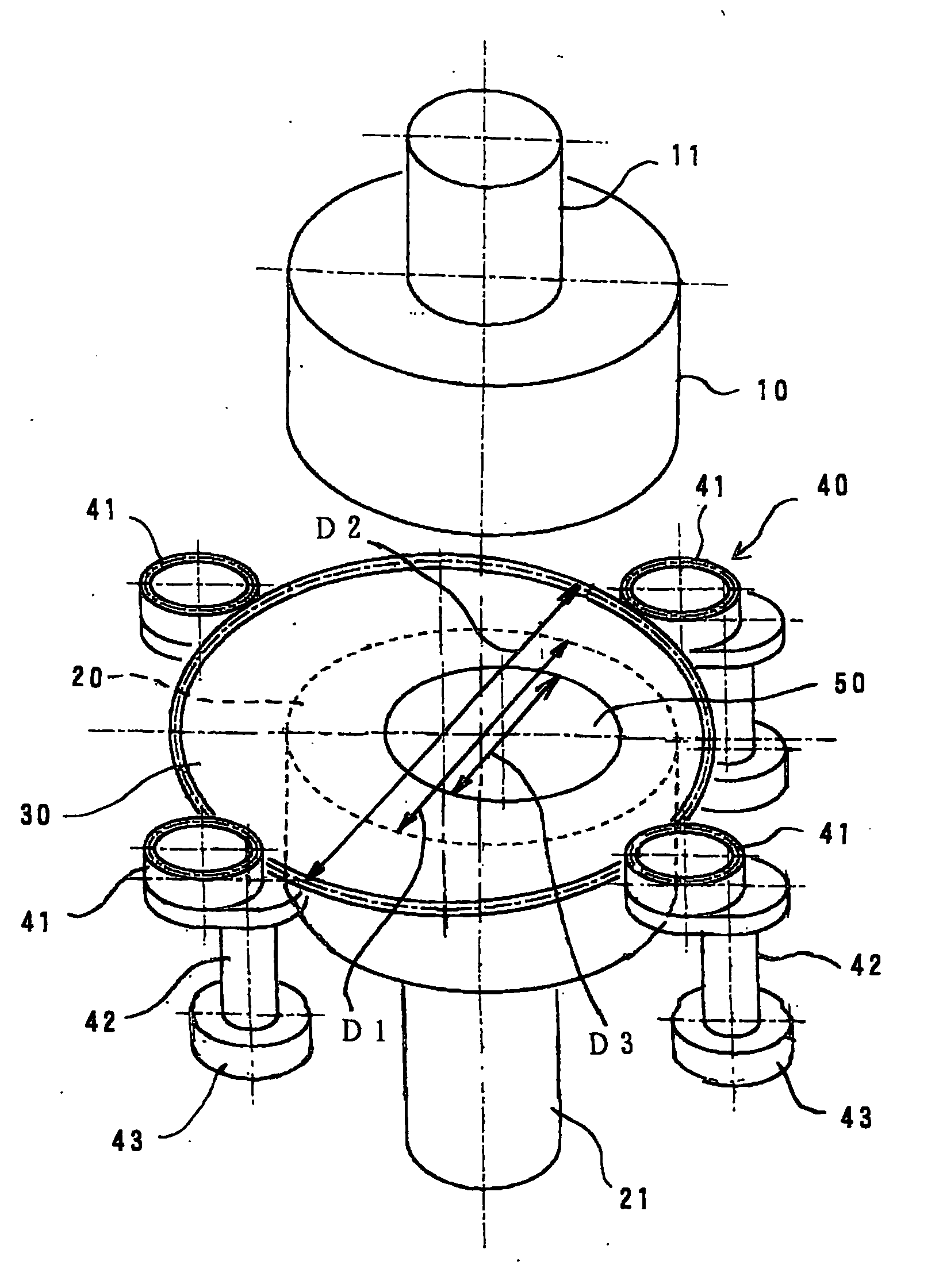

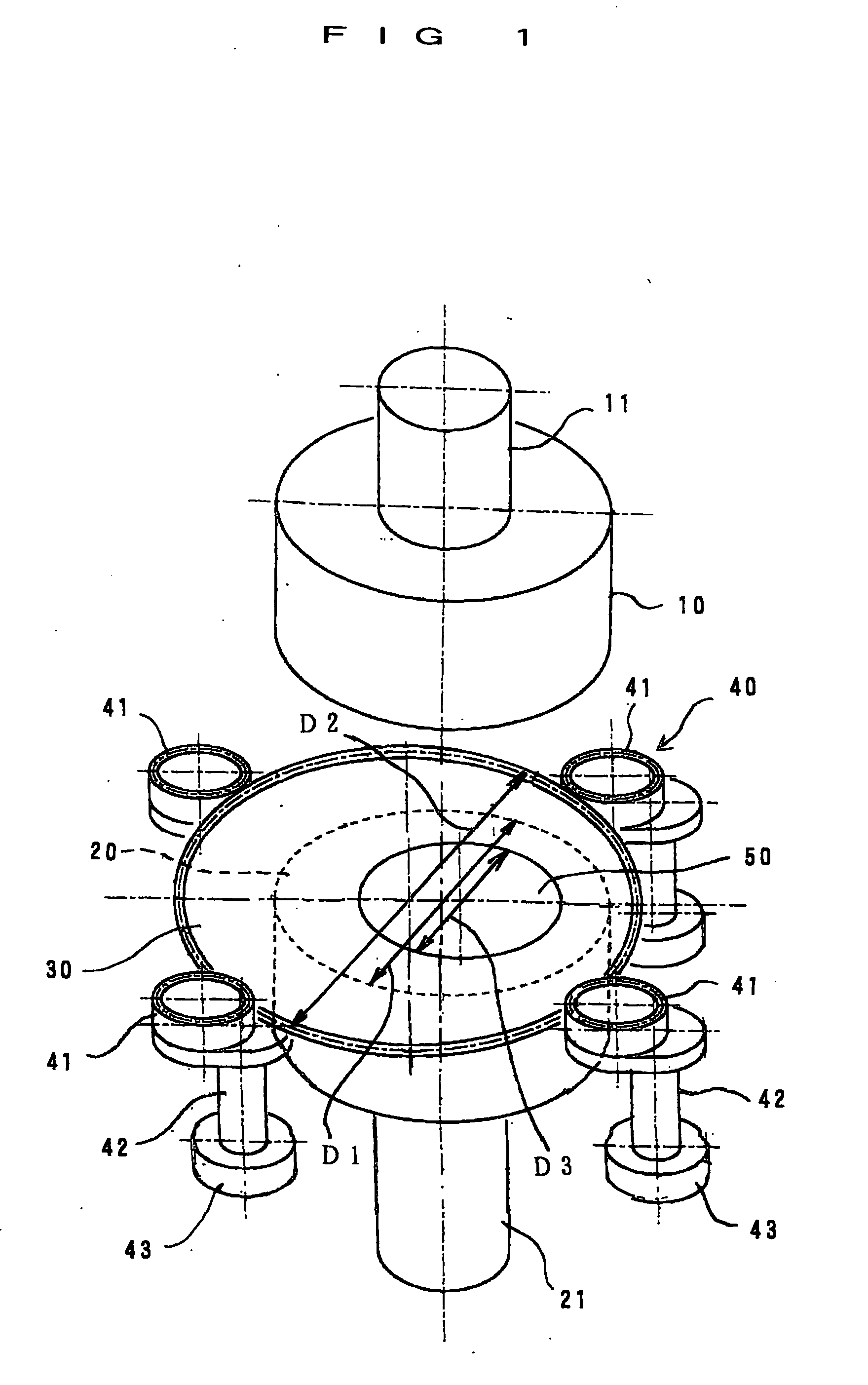

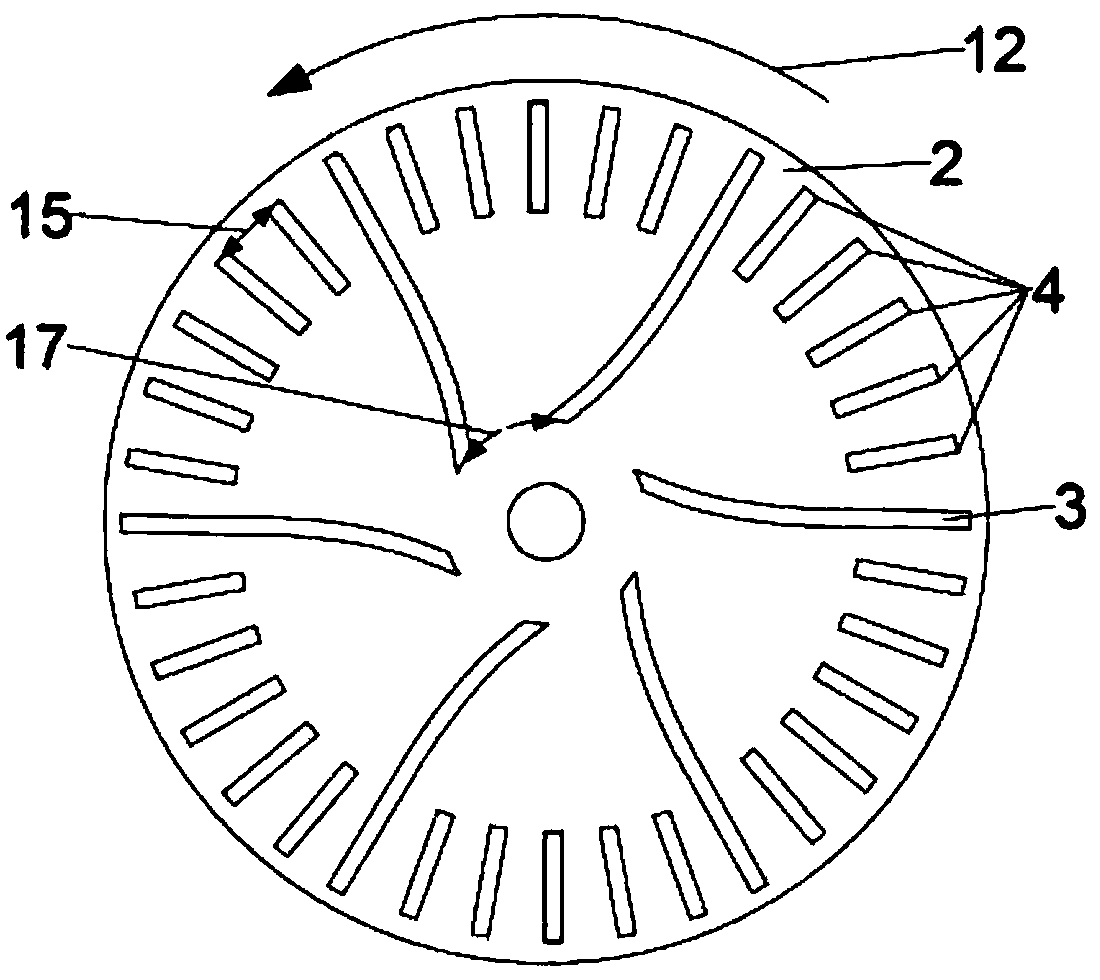

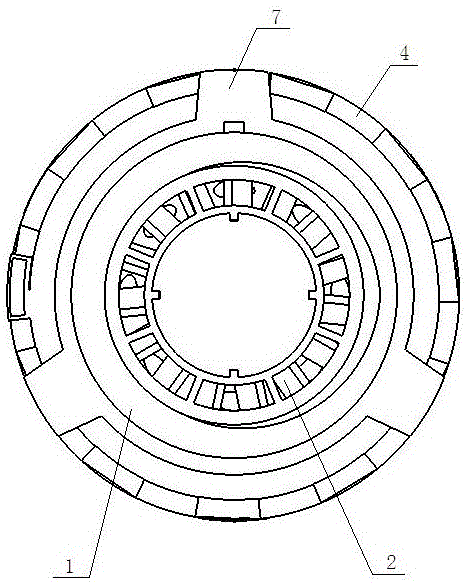

Double-side polishing method and apparatus

ActiveUS7029380B2Improve flatnessEasy constructionEdge grinding machinesRevolution surface grinding machinesReciprocating motionEngineering

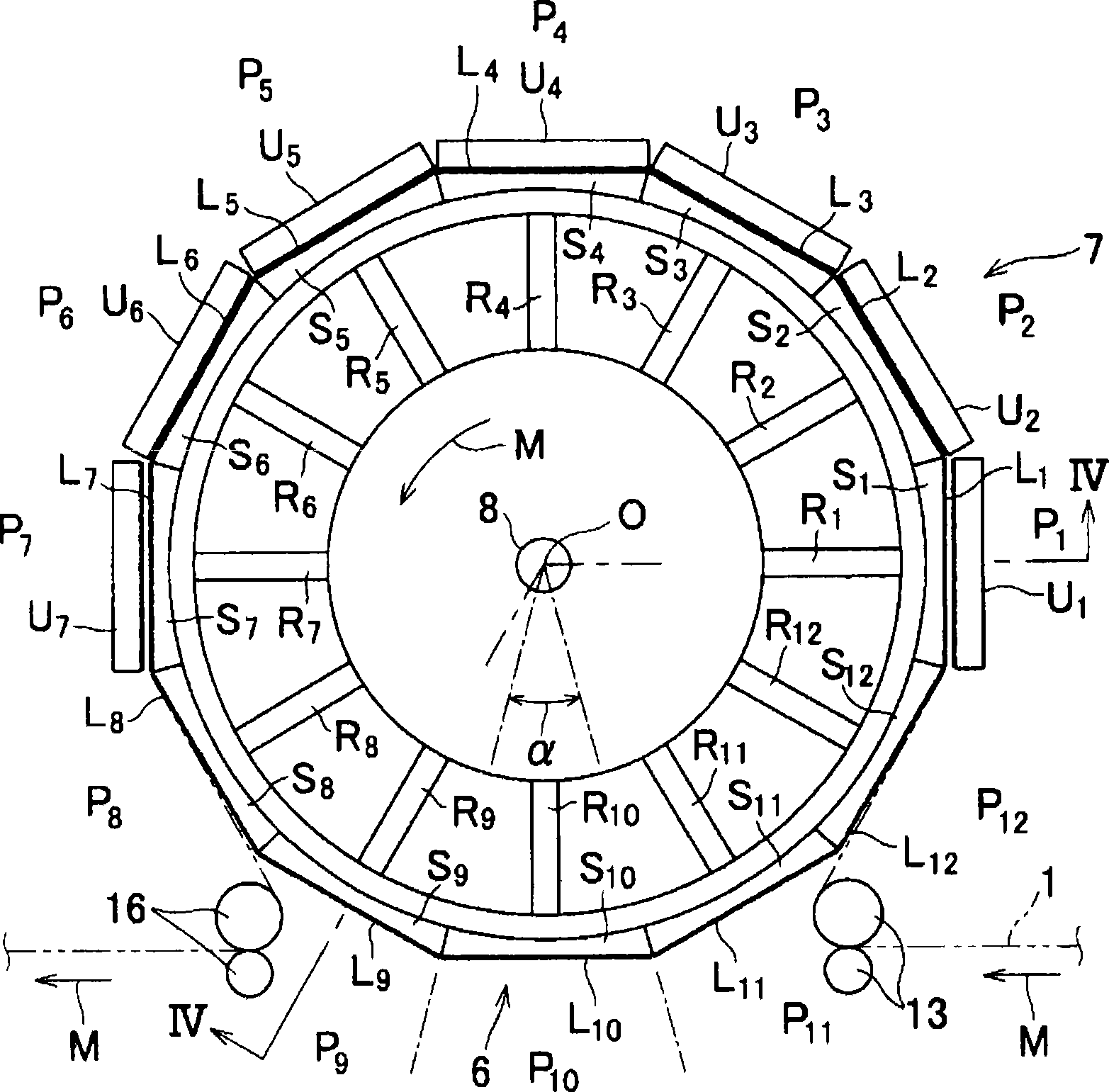

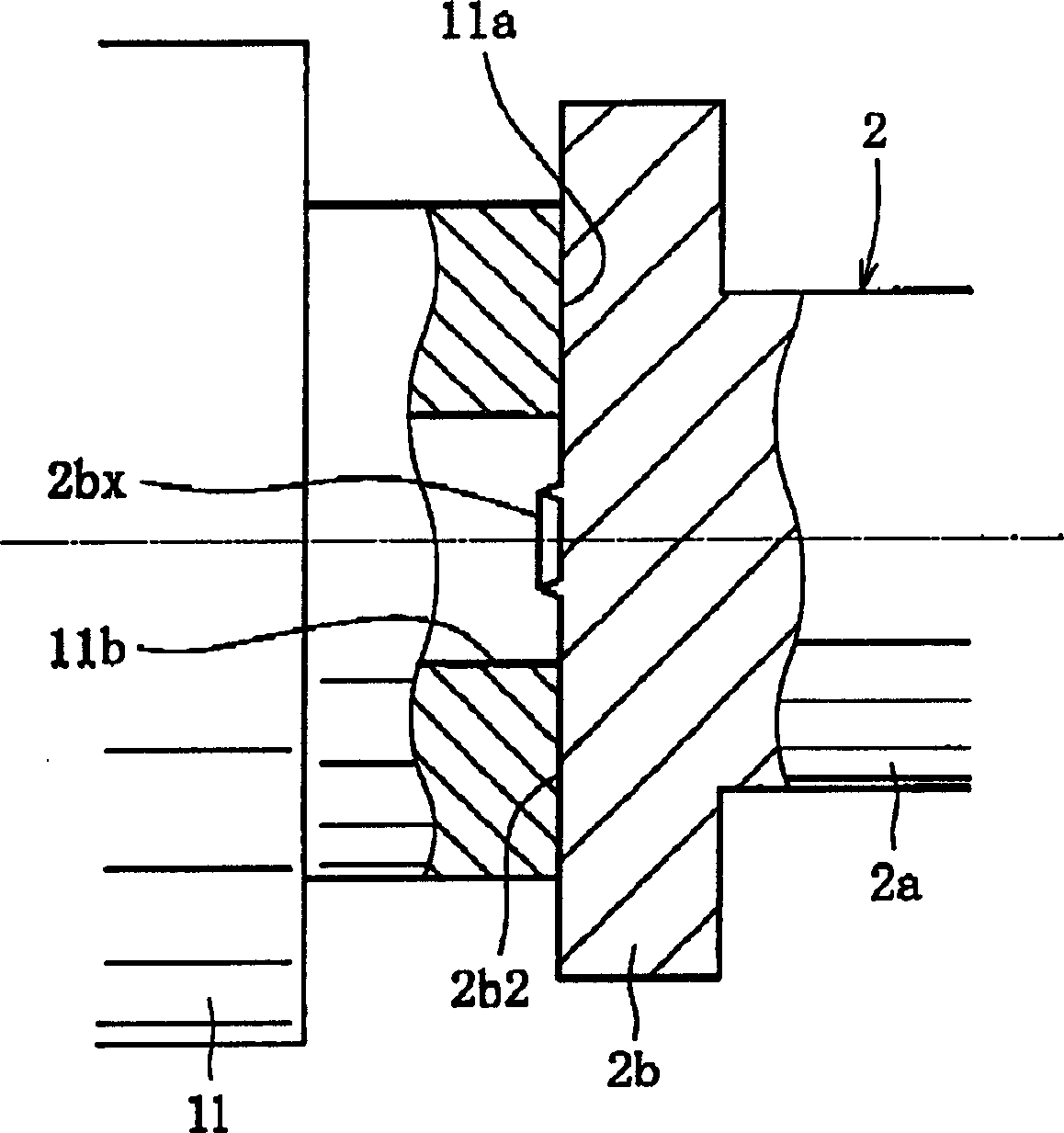

In order to improve a flatness of a work in single wafer type double-side polishing in which one wafer is polished with one carrier, a carrier larger in diameter than upper and lower surface plates that rotate is inserted between the surface plates, and a wafer smaller in diameter than the surface plates is held with the carrier. The carrier is rotated by plural eccentric gears that mesh with external gear teeth formed on the outer peripheral surface of the carrier at plural positions along a circumferential direction thereof and revolve around positions spaced from the centers as centers in synchronism with each other or one another at the plural positions of meshing. The carrier rotates about its center and moves circularly around the center of the surface plates spaced from the center thereof. The upper surface plate is reciprocated in a direction perpendicular to the central axis when required. Geometrical motion loci of points on the wafer are complex and peripheral speeds alter to large extents to thereby enhance equalization of peripheral speeds of points on the wafer to a higher level to thereby improve a flatness.

Owner:KASHIWARA KIKAI SEISAKUSHIYO +1

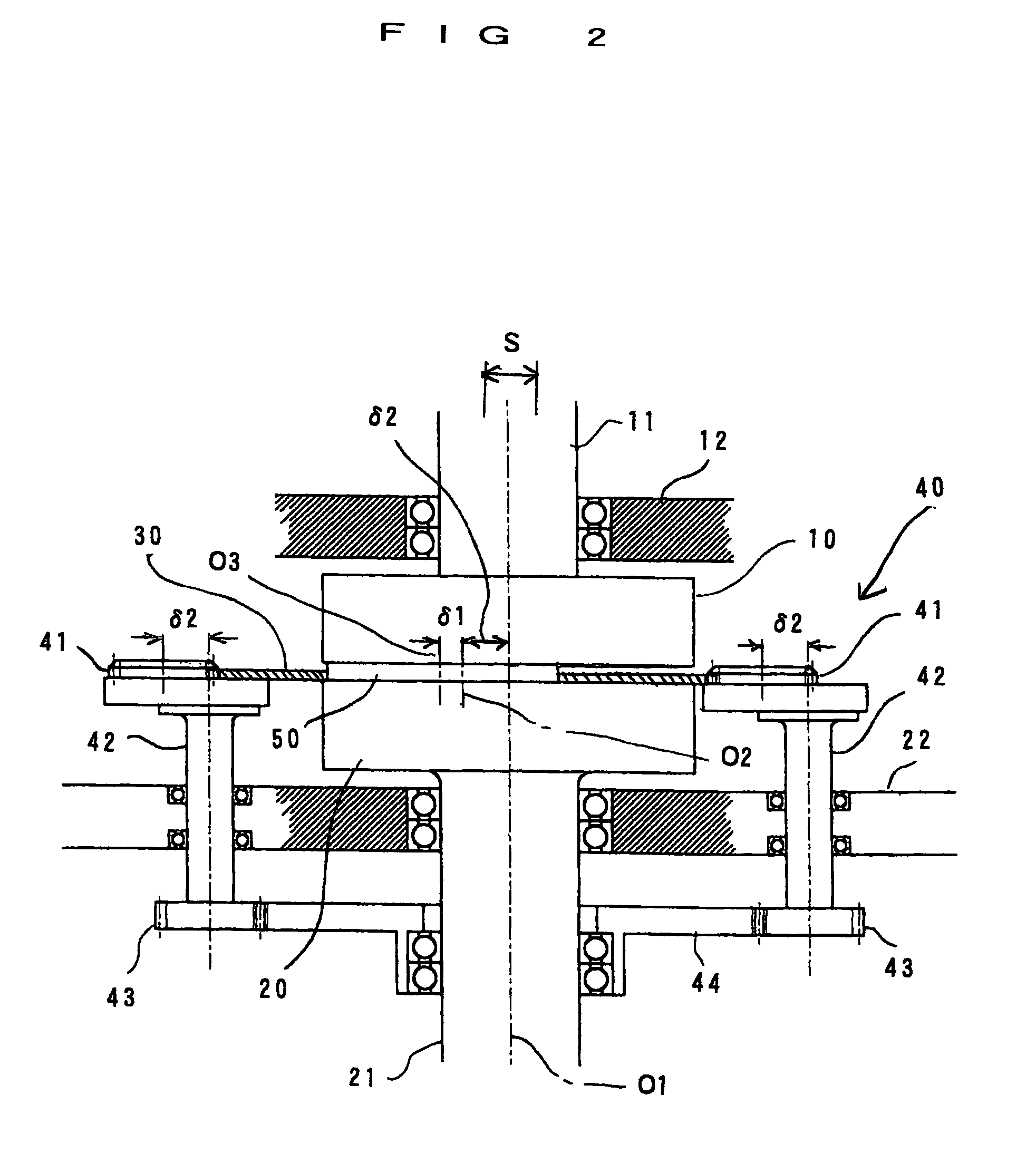

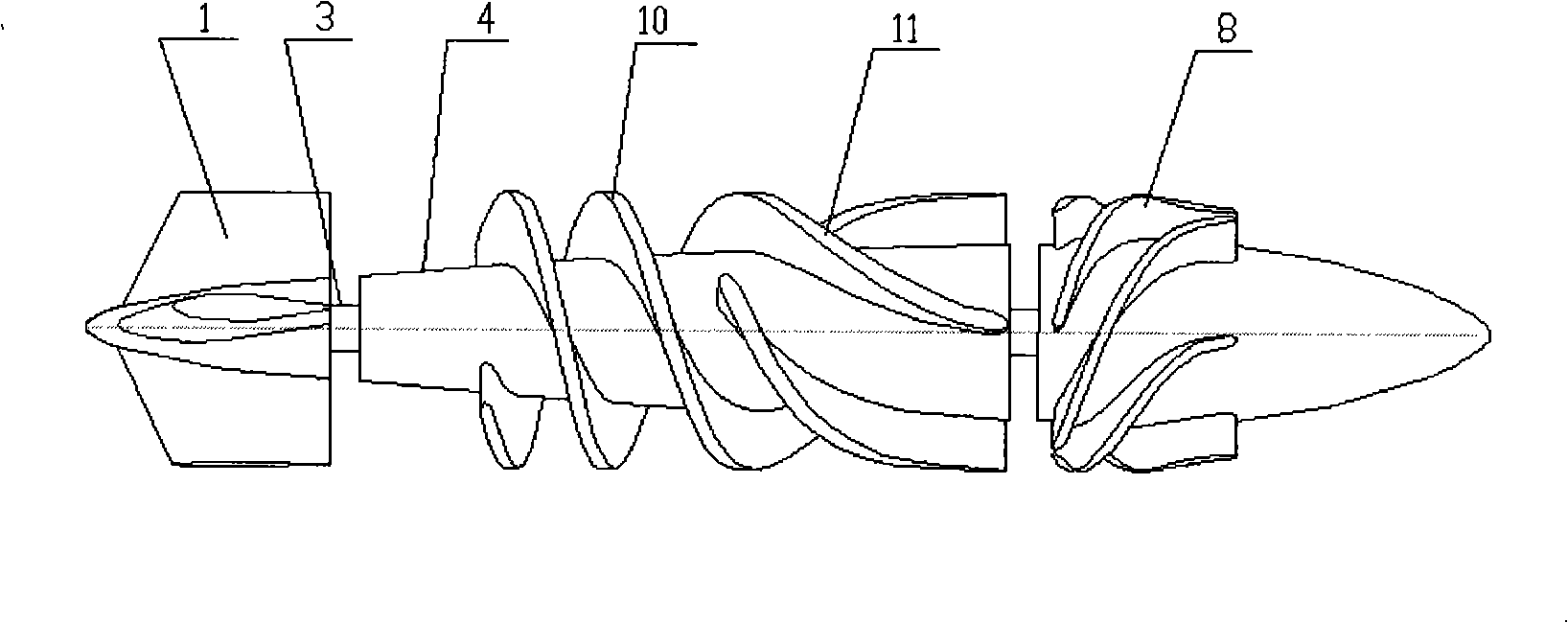

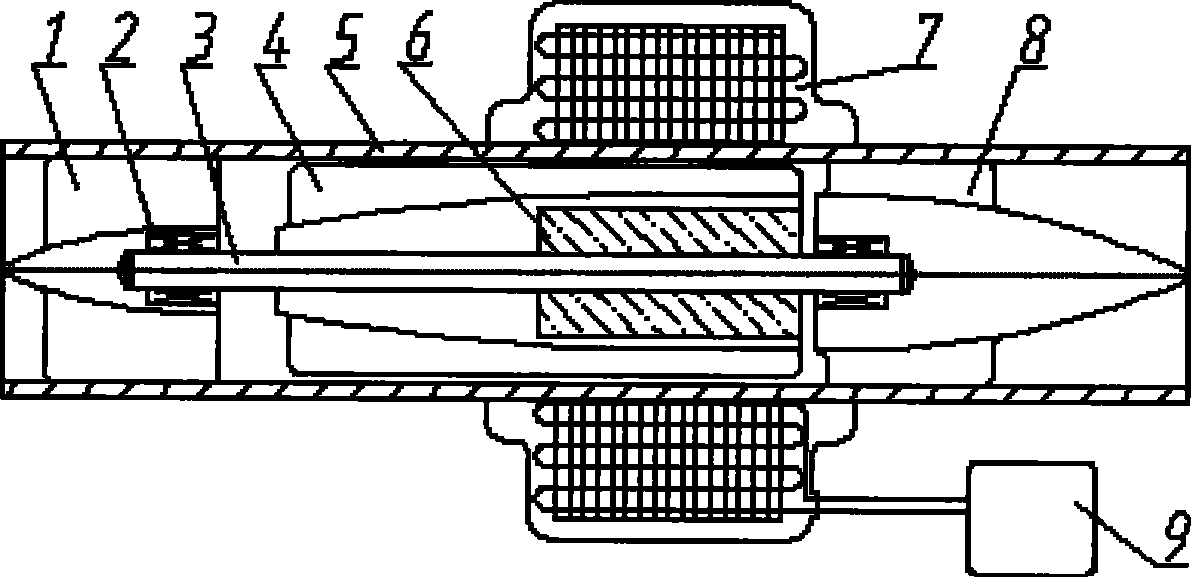

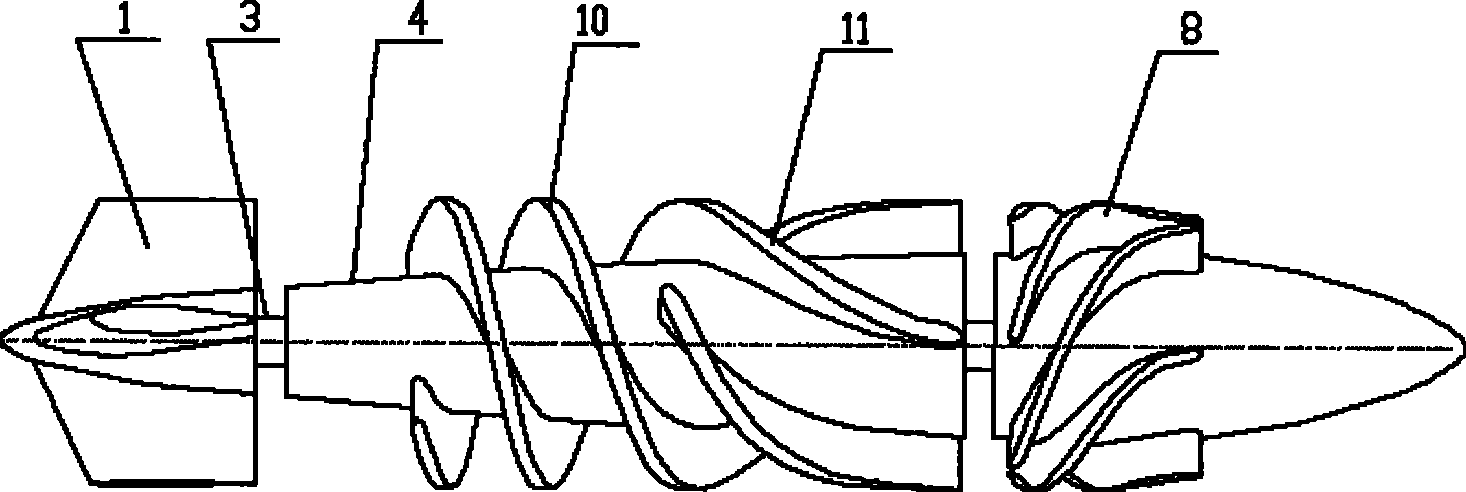

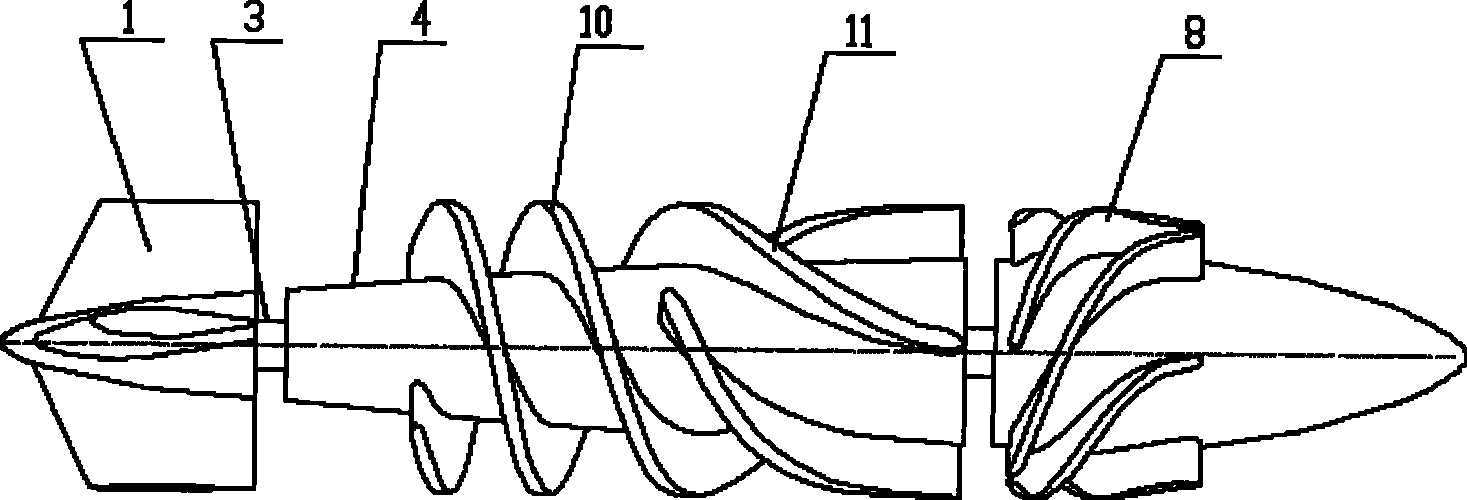

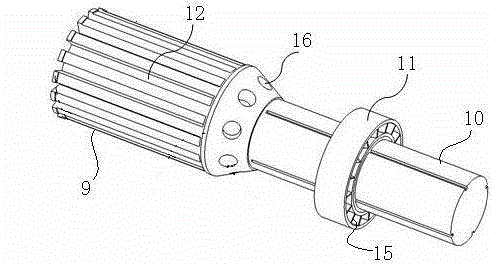

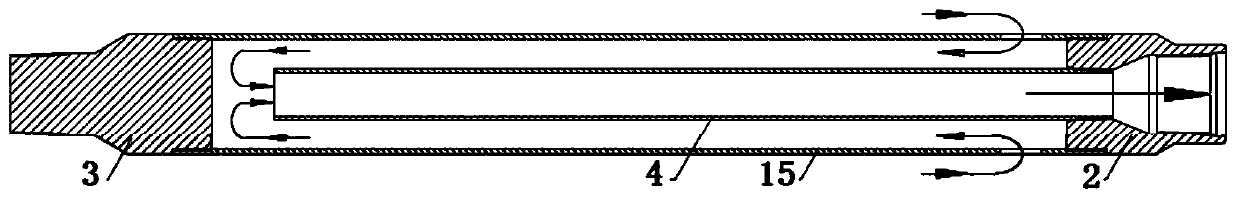

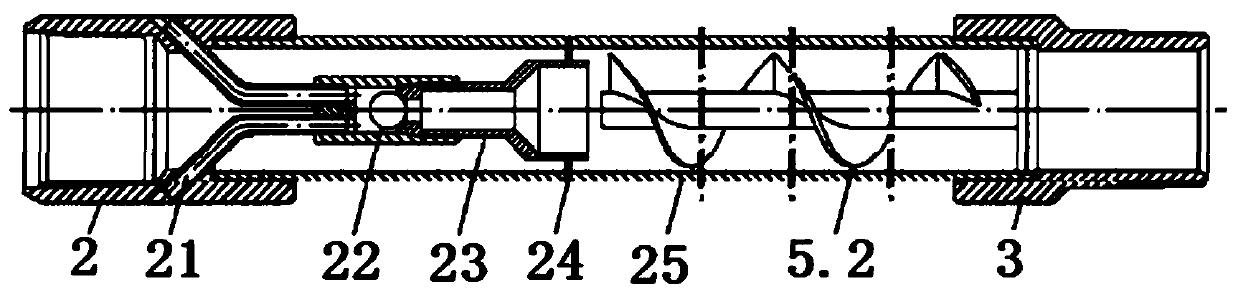

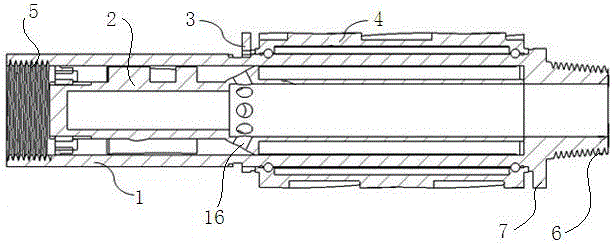

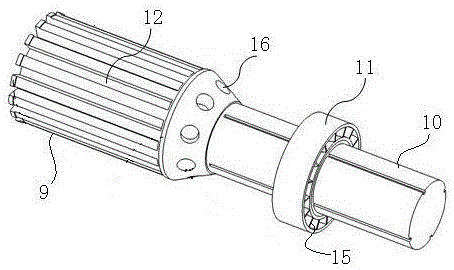

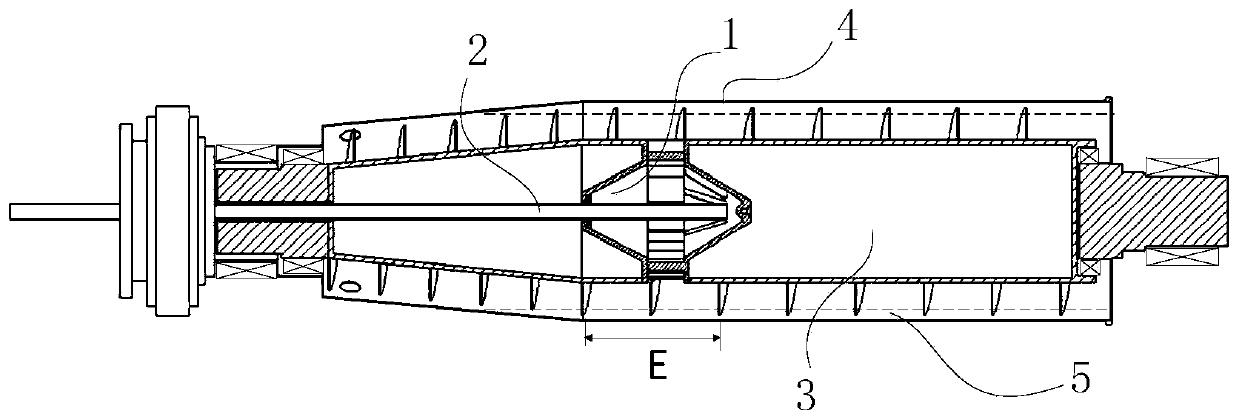

Implanted miniature streamlined shaft bloodshed pump

The invention relates to an embedded micro streamline axial flow blood pump, which can be used for assisting blood circulation of failed heart. The blood pump comprises a pump body arranged in a sleeve body and a driving device arranged outside the pump body, wherein the pump body comprises the sleeve body, a front guide vane, a rotor and a back guide vane; the hubs of the front guide vane, a rotor and the back guide vane are designed integrally in an integral streamline form; and the front half part of the rotor is provided with an inductive blade. The blood pump can reduce the on-way pressure loss of the blood in the flow channel of the blood pump, improve efficiency and reduce hemolysis; and can promote the circumferential speed of the blood after entering into a rotor area due to the inductive blade arranged on the front half part of the rotor, and avoids the occurrence of vacuole phenomenon.

Owner:中山好特人工心脏实验室有限公司

Double-side polishing method and apparatus

ActiveUS20050159089A1Improve flatnessEasy constructionEdge grinding machinesRevolution surface grinding machinesReciprocating motionEngineering

In order to improve a flatness of a work in single wafer type double-side polishing in which one wafer is polished with one carrier, a carrier larger in diameter than upper and lower surface plates that rotate is inserted between the surface plates, and a wafer smaller in diameter than the surface plates is held with the carrier. The carrier is rotated by plural eccentric gears that mesh with external gear teeth formed on the outer peripheral surface of the carrier at plural positions along a circumferential direction thereof and revolve around positions spaced from the centers as centers in synchronism with each other or one another at the plural positions of meshing. The carrier rotates about its center and moves circularly around the center of the surface plates spaced from the center thereof. The upper surface plate is reciprocated in a direction perpendicular to the central axis when required. Geometrical motion loci of points on the wafer are complex and peripheral speeds alter to large extents to thereby enhance equalization of peripheral speeds of points on the wafer to a higher level to thereby improve a flatness.

Owner:KASHIWARA KIKAI SEISAKUSHIYO +1

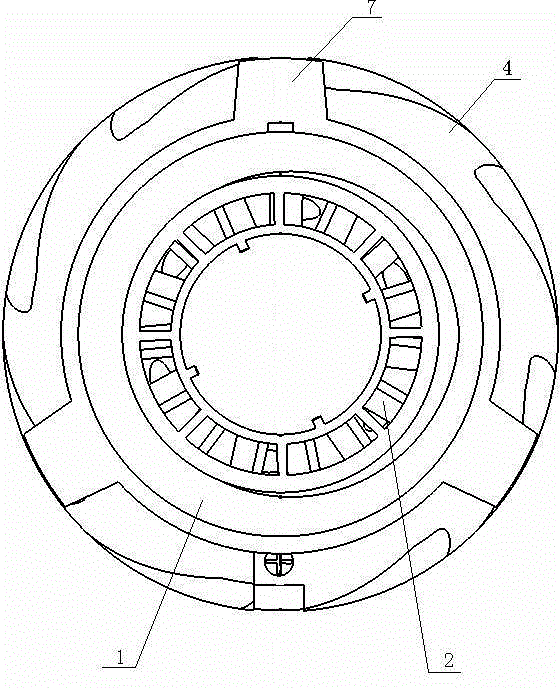

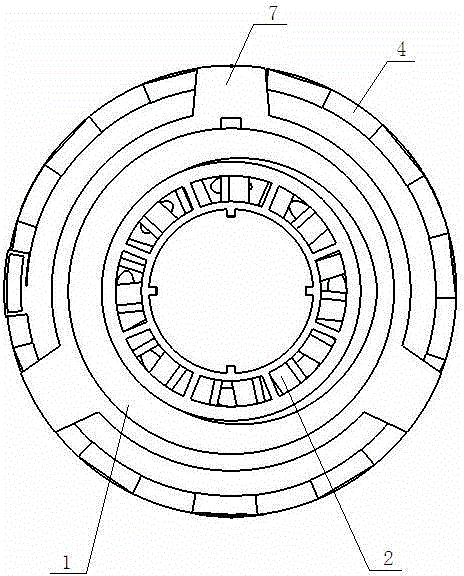

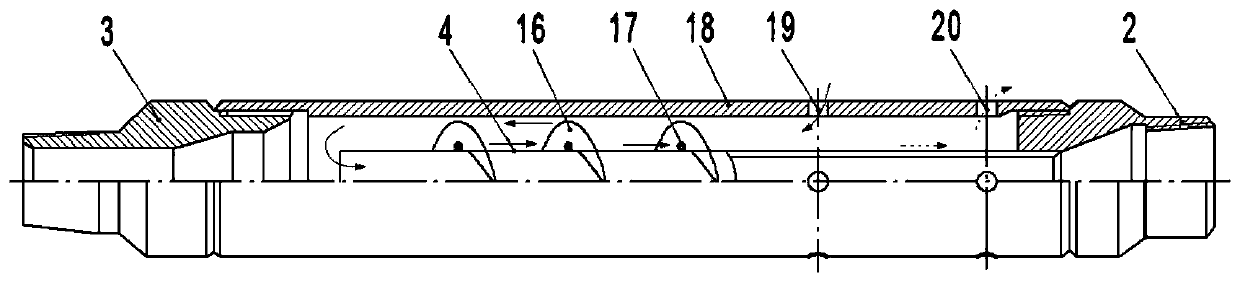

Split blade hydraulic-magnetic transmission well hole cleaning tool

ActiveCN104675346AIncrease peripheral speedImprove cleaning efficiencyFlushingAxial pressureCoupling

The invention relates to a split blade hydraulic-magnetic transmission well hole cleaning tool, which consists of a flow tube casing, a rotating magnetic core, an upper gauge protection body and a rotating blade, wherein the gauge protection body is arranged in a position, near the external screw thread part, of the outer wall of the flow tube casing, the outer wall of the flow tube casing is also provided with a position limiting ring, the upper gauge protection body is arranged at one side of the position limiting ring, the rotating magnetic core is integrally formed by a rotating tube and a rotating shaft, a transition connecting section of the rotating tube and the rotating shaft is provided with a drilling fluid hole, a hydraulic conversion device is fixedly arranged outside the rotating shaft, permanent magnets are uniformly distributed on the outer wall of the rotating tube, the two adjacent permanent magnets have the opposite magnetic pole directions, a rotating magnetic core is arranged in the flow tube casing, permanent magnets are uniformly distributed on the inner wall of the rotating blade tube body, and the two adjacent permanent magnets have the opposite magnetic pole directions; the hydraulic conversion device is a double-layer tubular body, and an axial pressure difference blade is arranged between the two layers of tubes; the rotating blade is split and dismountable. The split blade hydraulic-magnetic transmission well hole cleaning tool has the advantages that through the hydraulic-magnet coupling transmission, the limitation by the condition whether a drill rod rotates or not is avoided, the hydraulic-magnetic coupling transmission is realized under the condition of drilling fluid circulation, and the well hole cleaning efficiency is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

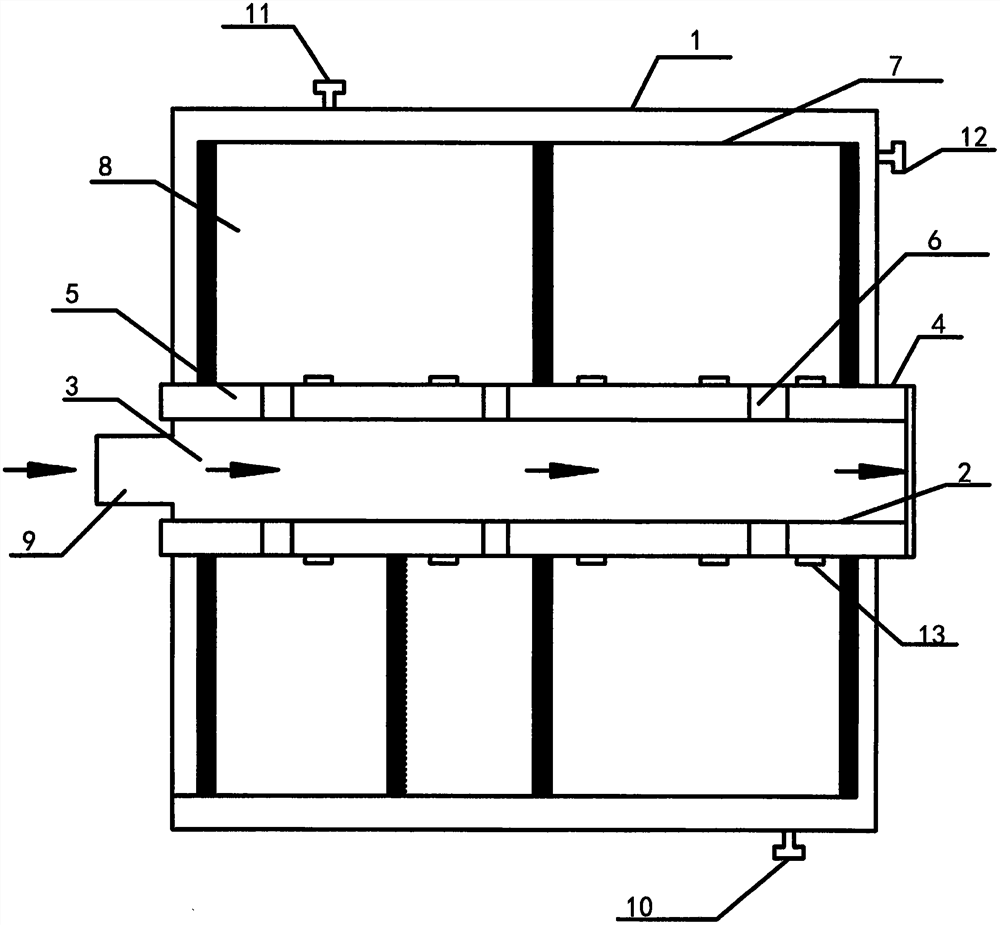

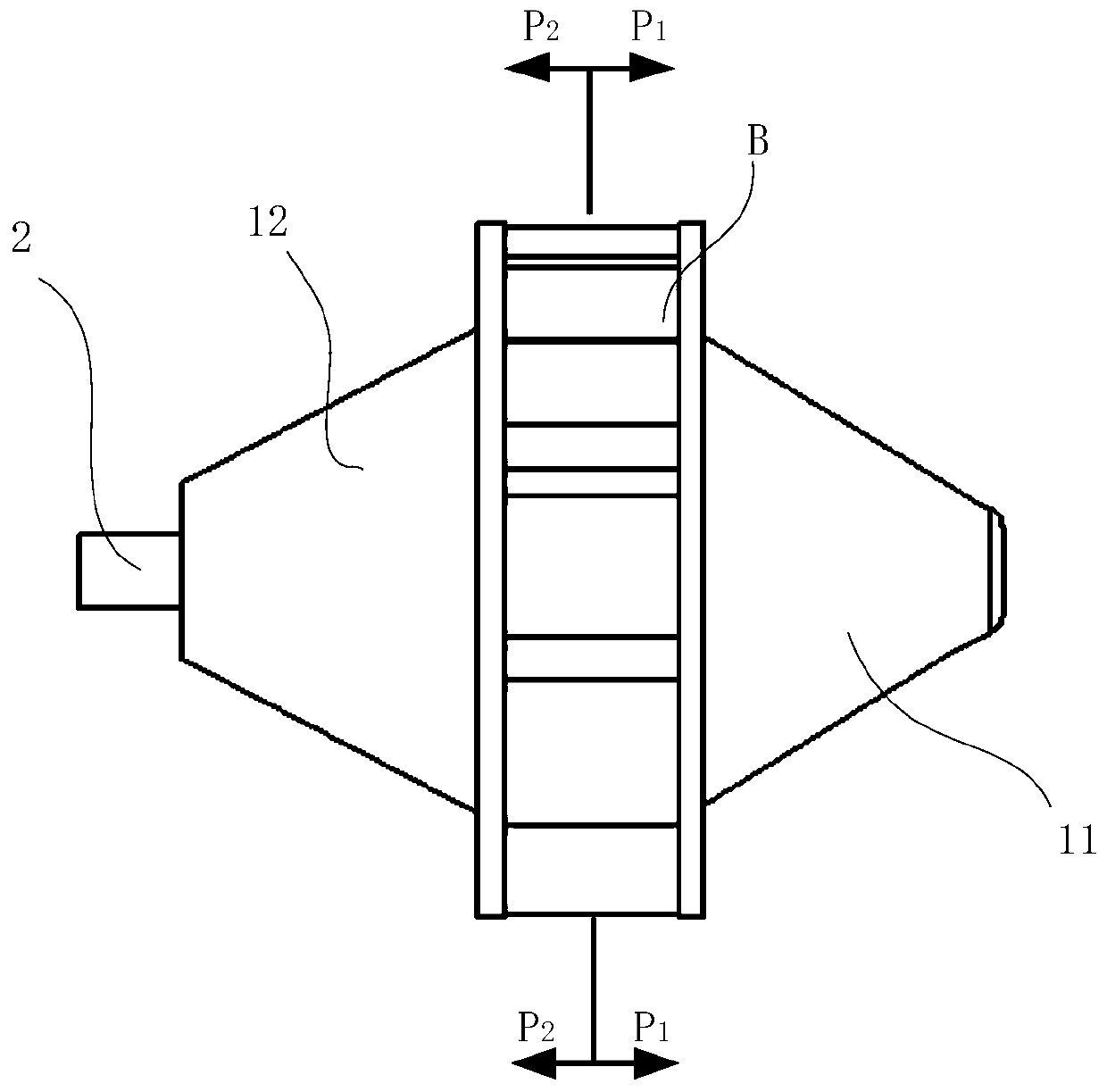

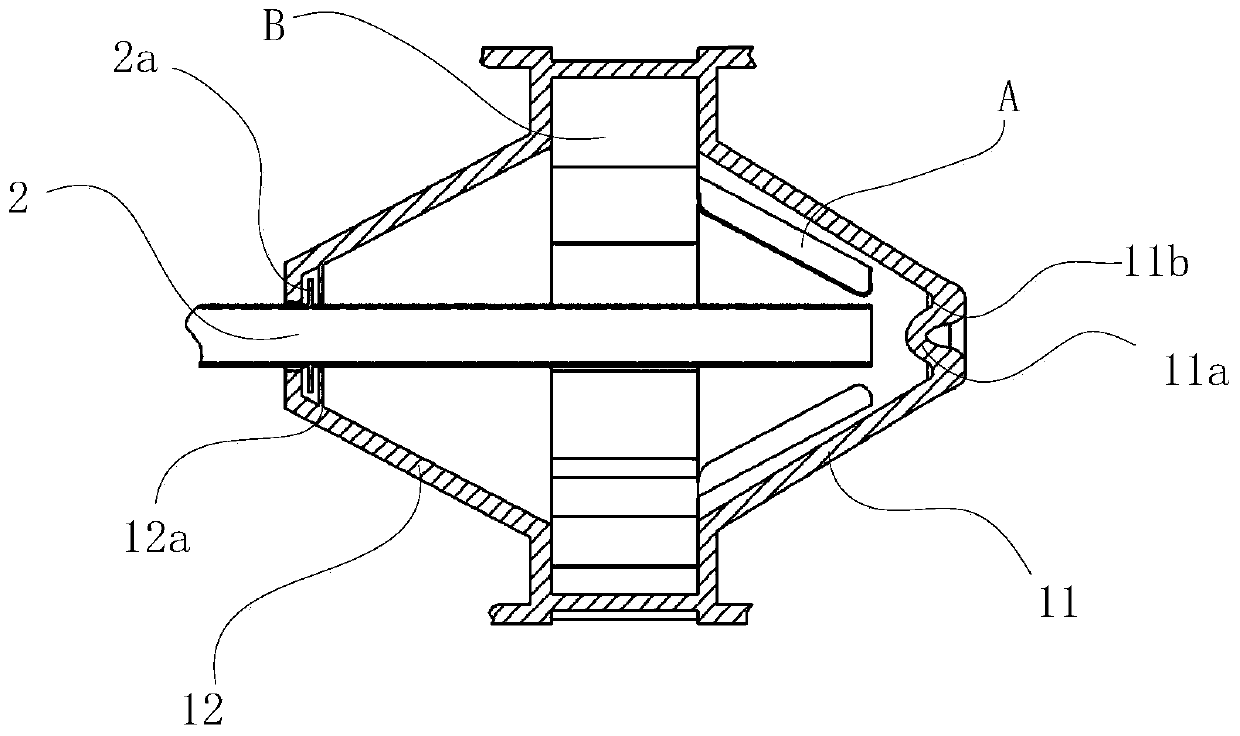

Sulfur tail gas super-gravity desulfurization device

ActiveCN106744705AAchieve partial oxidationImplement spin-inGas treatmentDispersed particle separationSulfurLiquid storage tank

The invention relates to a sulfur tail gas super-gravity desulfurization device and process thereof. The sulfur tail gas super-gravity desulfurization device comprises an alkali liquid storage tank and a super-gravity machine; the device utilizes alkali liquid to desulfurize sulfur tail gas, and a unique super-gravity machine structure is provided; in the structure, a hollow rotary shaft with a fluid channel is formed in a shell in a manner of penetrating through the middle axis of the shell, and a sleeve with a gas channel function sleeves the hollow rotary shaft; meanwhile, a rotary channel, which is communicated with a filling region and is provided with a spiral channel, is also formed on the basis; fluid passes through the hollow rotary shaft and then self rotation of the fluid is realized through the rotary channel, and then the fluid enters the filling region; the liquid is crushed and torn into small liquid drops under the action of a centrifugal force of liquid and is in sufficient contact with liquid reverse-flow small bubbles, and a phase interface, which is rapidly updated, is provided; crushing and tearing mixing of the fluid and gas is further realized by utilizing the self-rotation under a rotary state; the sufficient degree of gas-liquid contact is improved, and furthermore, the better sulfur tail gas desulfurization effect is obtained.

Owner:北京清大华亿科技有限公司 +2

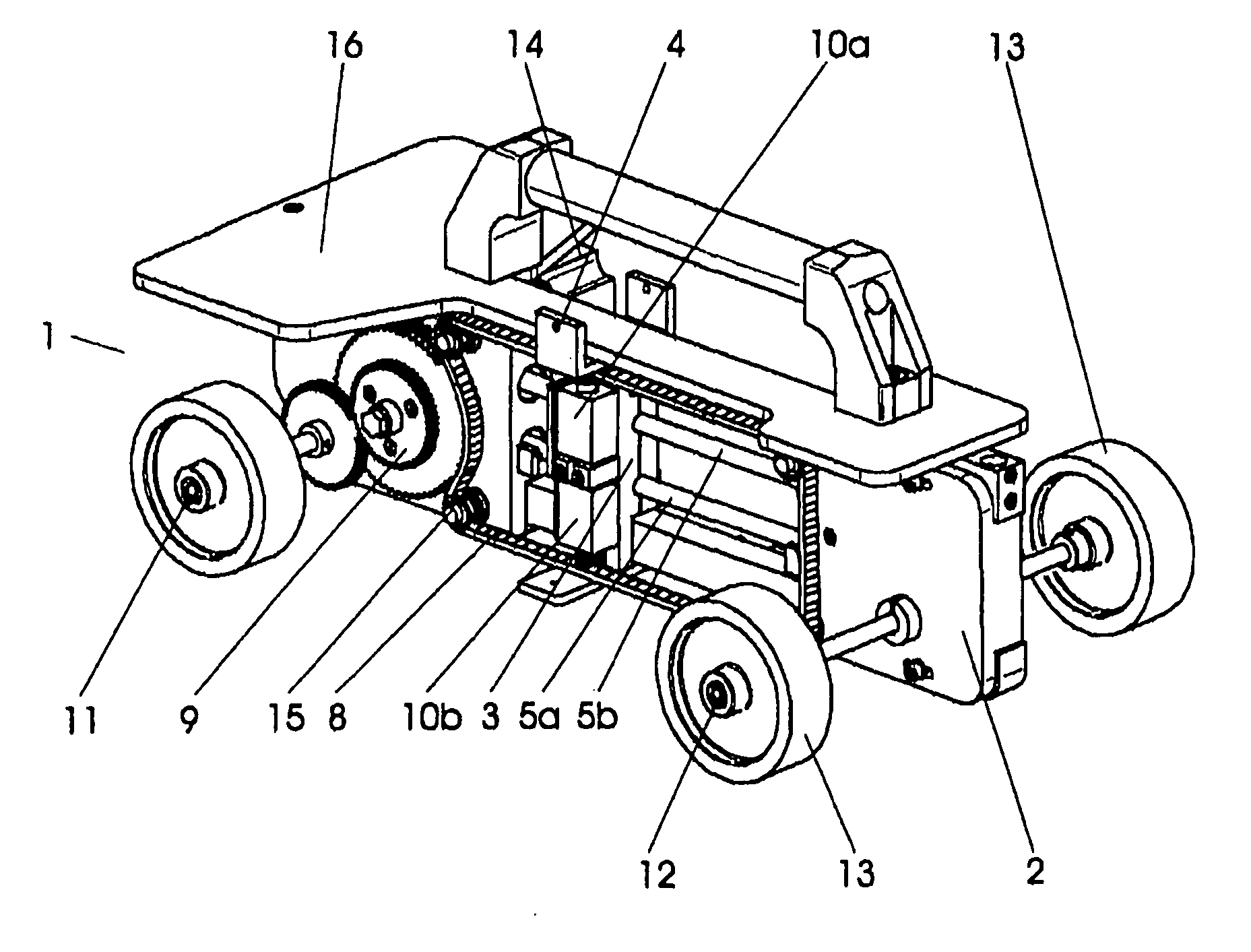

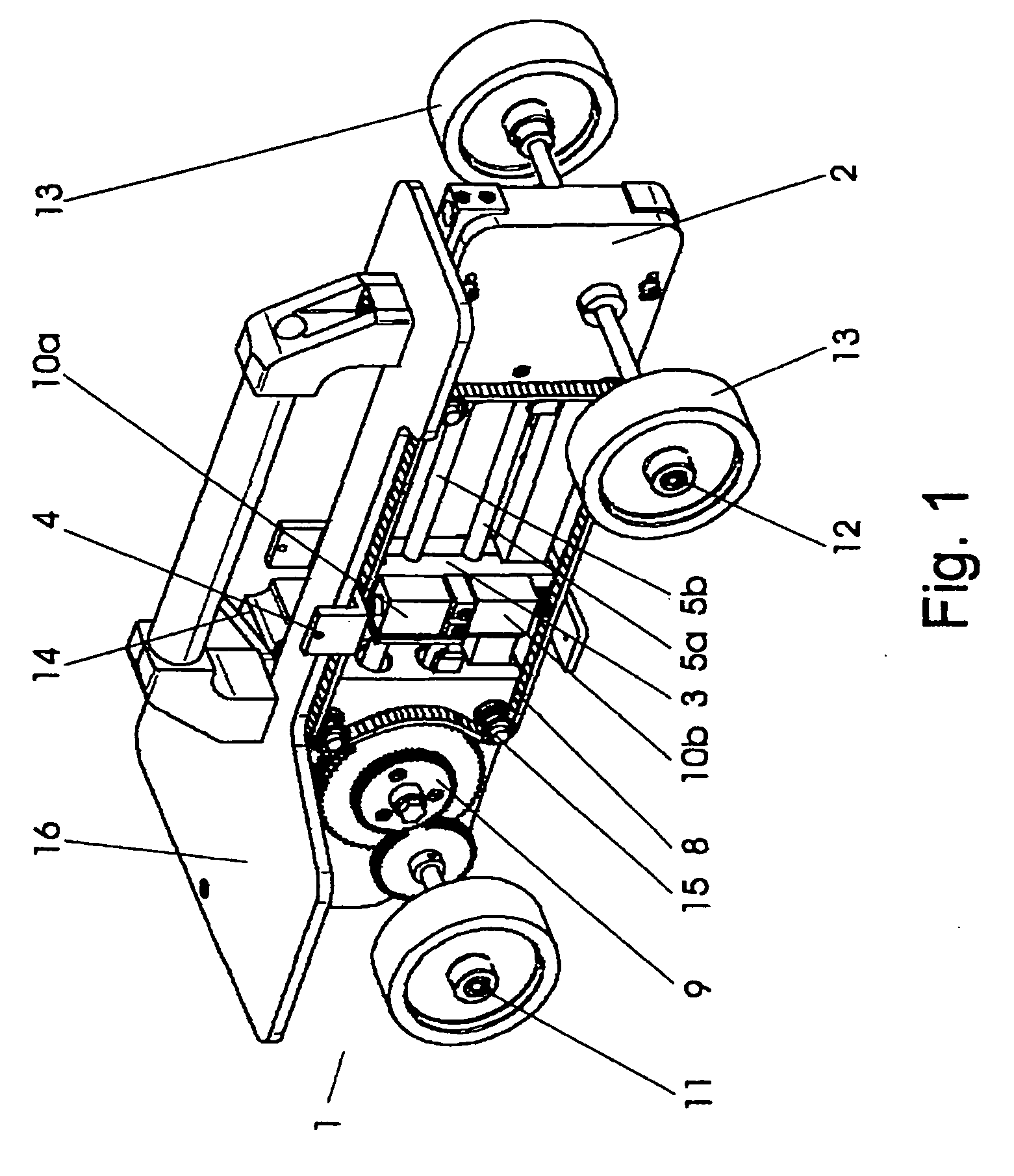

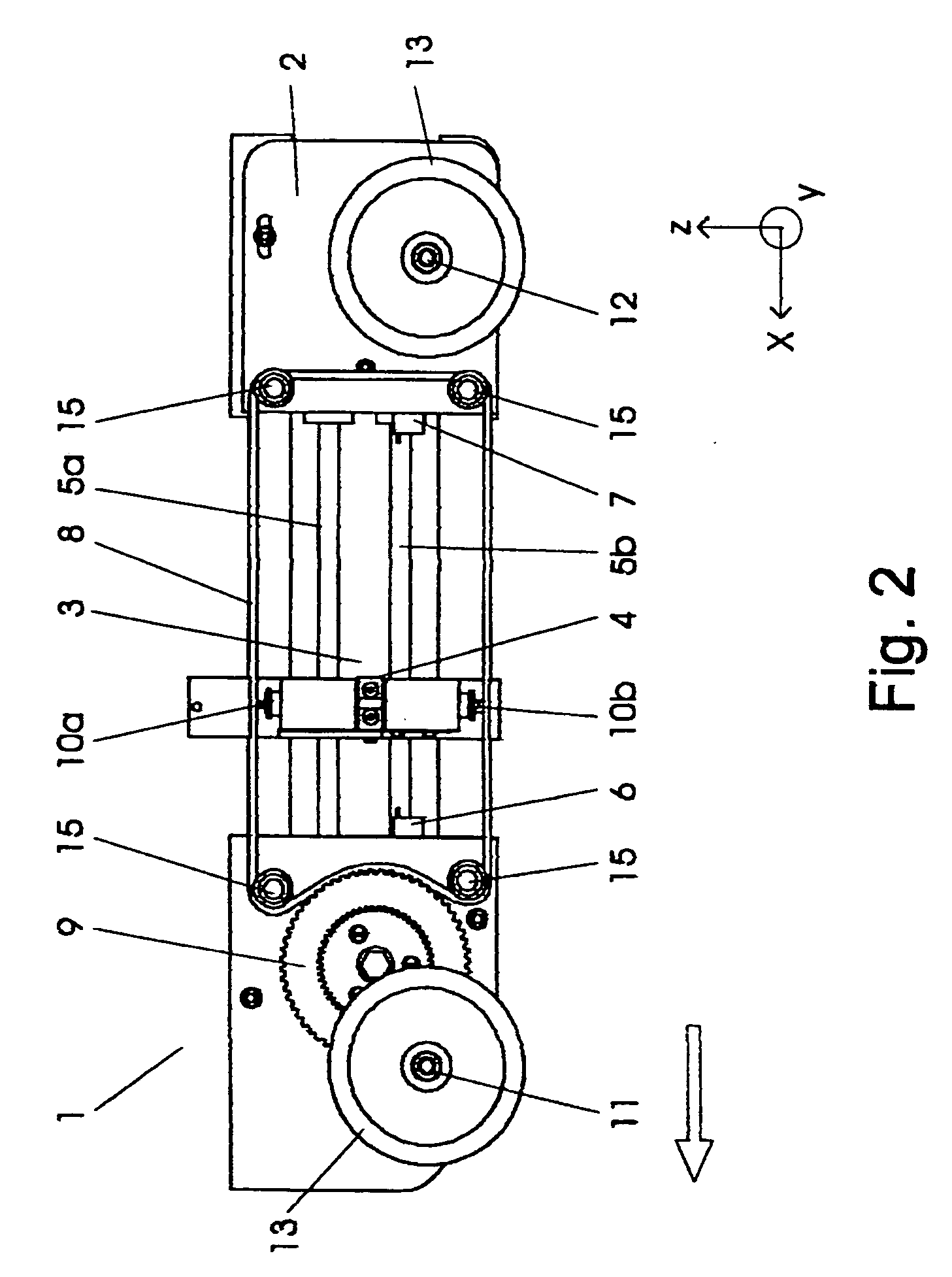

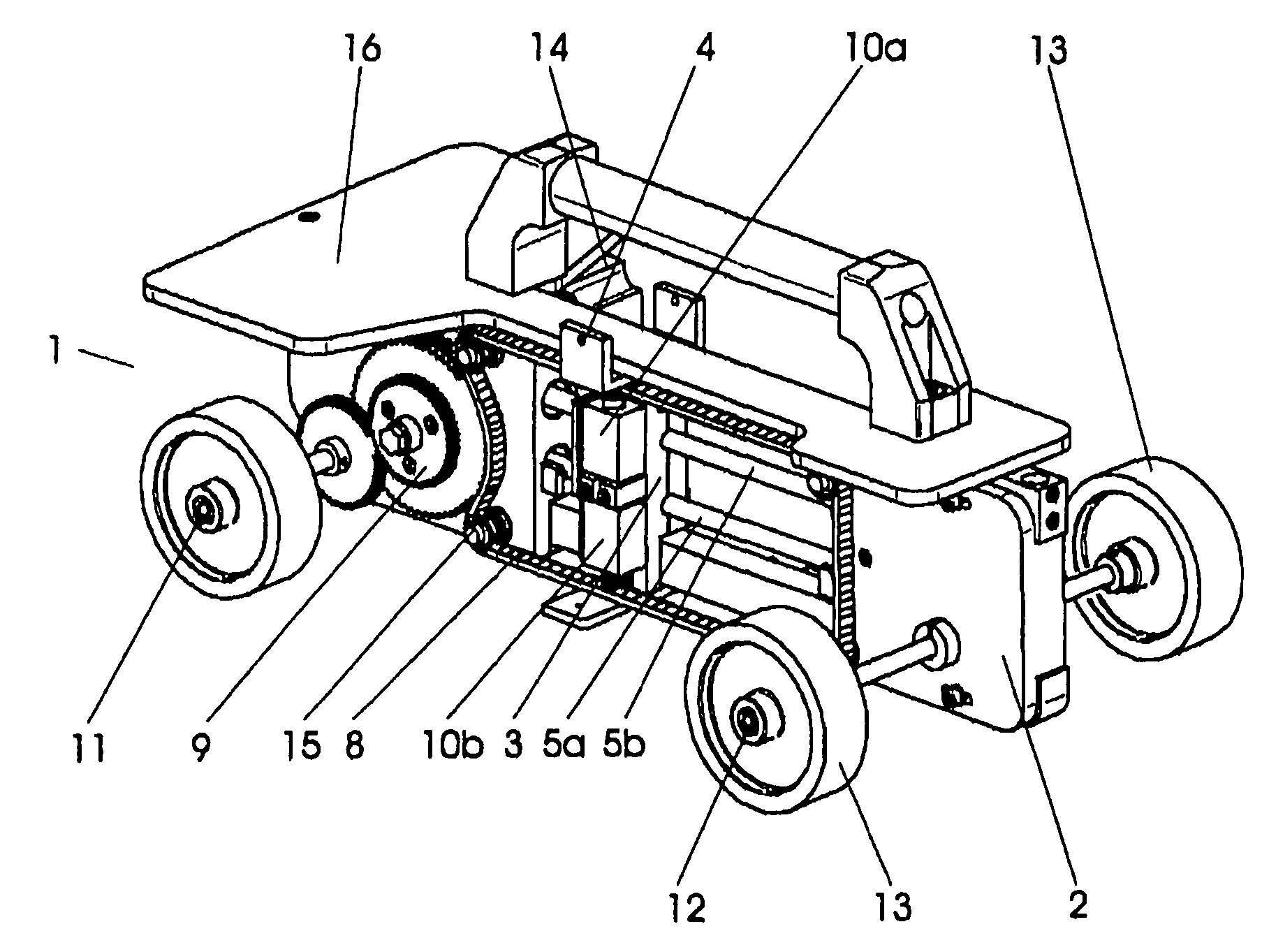

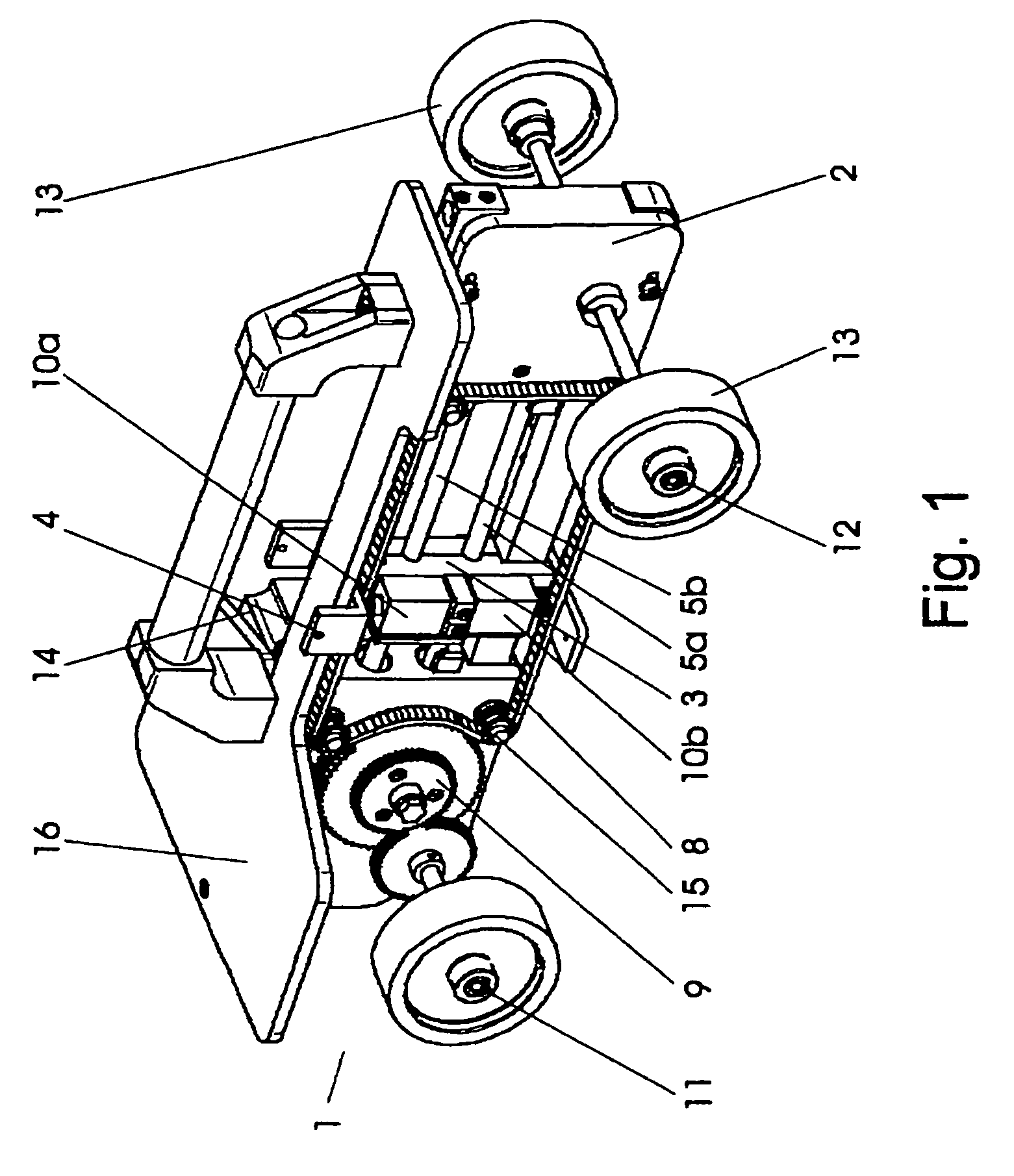

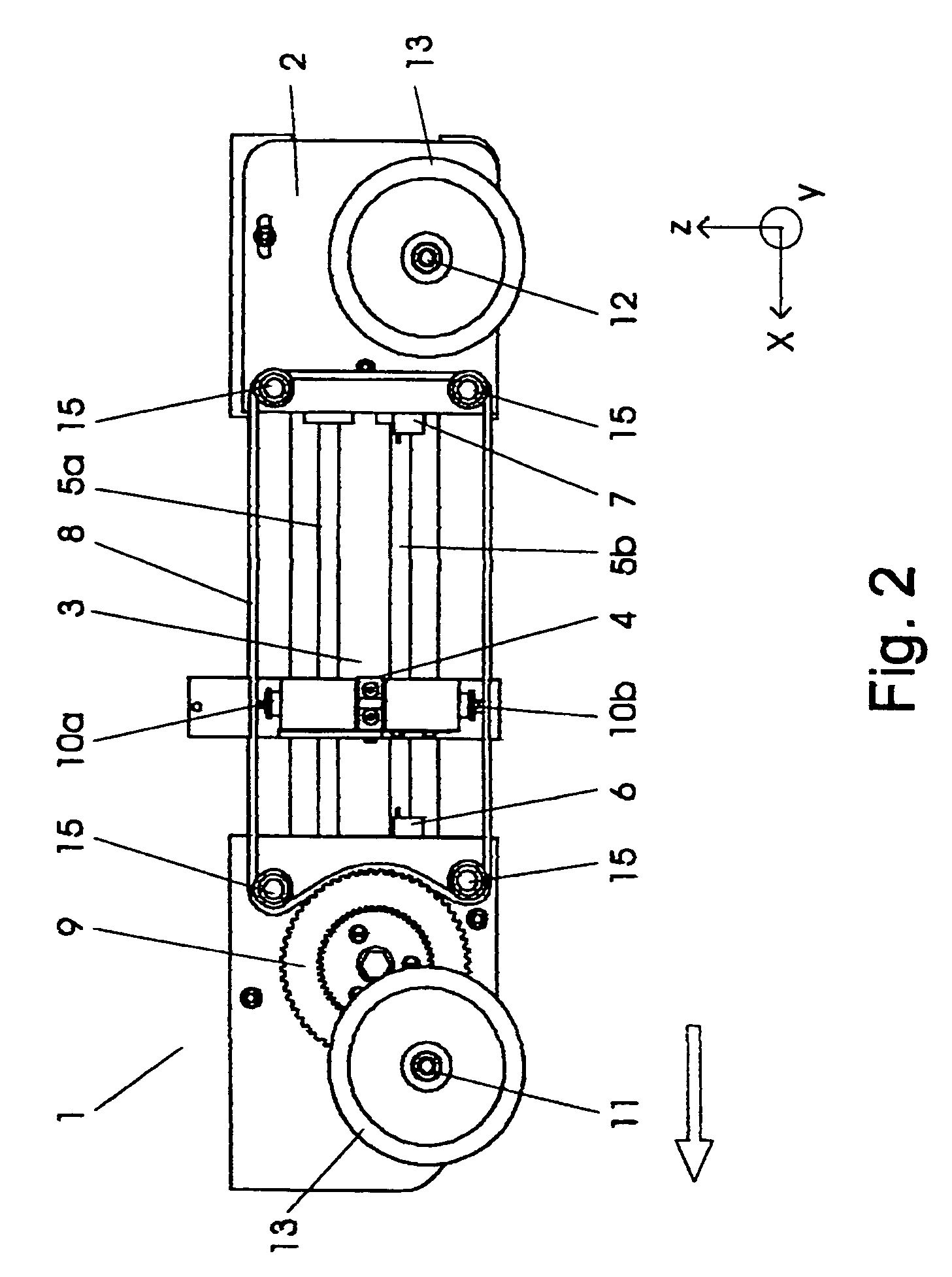

Positioning vehicle for positioning a test probe

InactiveUS20060191358A1Little effortExtensive and time-consumingAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement apparatus componentsTest probe

Described is a method for operating a positioning vehicle for positioning a test probe in defined intervals along a travel line, as well as to a positioning vehicle for carrying out the method. The positioning vehicle contains a traveling vehicle base part with a guide device and with a test probe carrier guided by this guide device in a guide. The guiding has a first reversal point and a second reversal point. The guide device comprises guide means in order on displacing the vehicle base part to guide the test probe carrier in the travel direction up to the first reversal point after it has reached the second reversal point, and in order to lead back the test probe carrier opposite to the travel direction up to the second reversal point after it has reached the first reversal point. In the phase of the return, the test probe carrier relative to the vehicle base part has the negative speed of the vehicle base part. Described is also a device which permits in particular objects having large surfaces to be scanned with little effort.

Owner:BAM

Implanted miniature streamlined shaft bloodshed pump

The invention relates to an embedded micro streamline axial flow blood pump, which can be used for assisting blood circulation of failed heart. The blood pump comprises a pump body arranged in a sleeve body and a driving device arranged outside the pump body, wherein the pump body comprises the sleeve body, a front guide vane, a rotor and a back guide vane; the hubs of the front guide vane, a rotor and the back guide vane are designed integrally in an integral streamline form; and the front half part of the rotor is provided with an inductive blade. The blood pump can reduce the on-way pressure loss of the blood in the flow channel of the blood pump, improve efficiency and reduce hemolysis; and can promote the circumferential speed of the blood after entering into a rotor area due to the inductive blade arranged on the front half part of the rotor, and avoids the occurrence of vacuole phenomenon.

Owner:中山好特人工心脏实验室有限公司

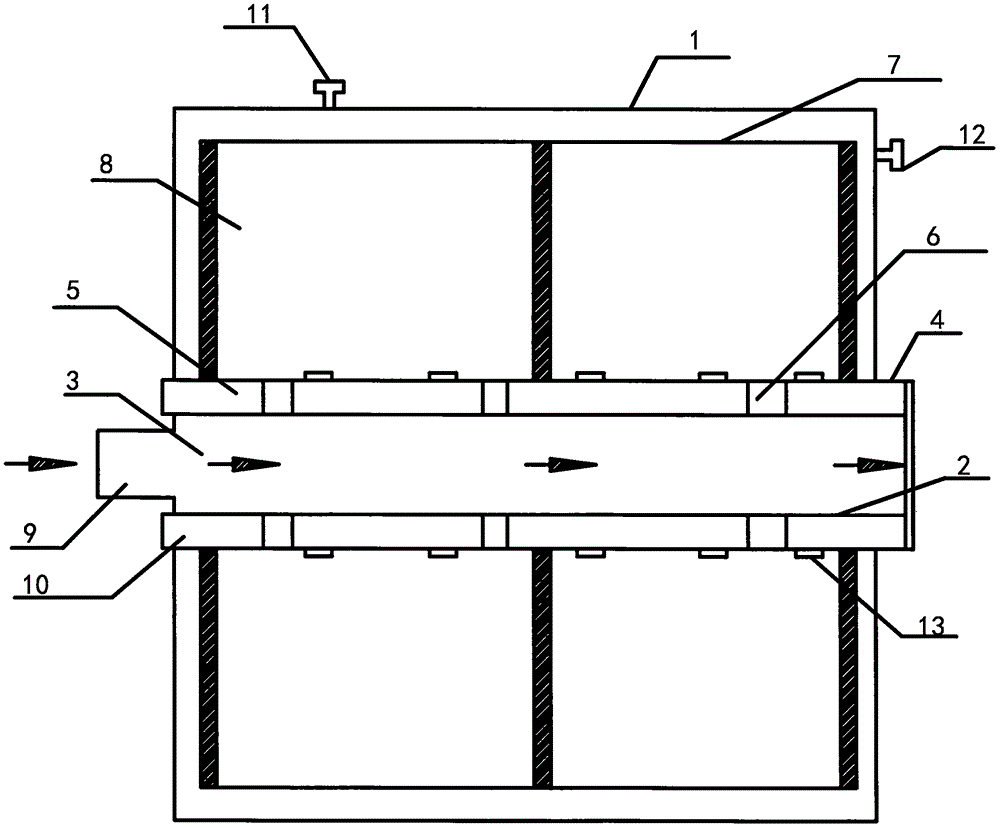

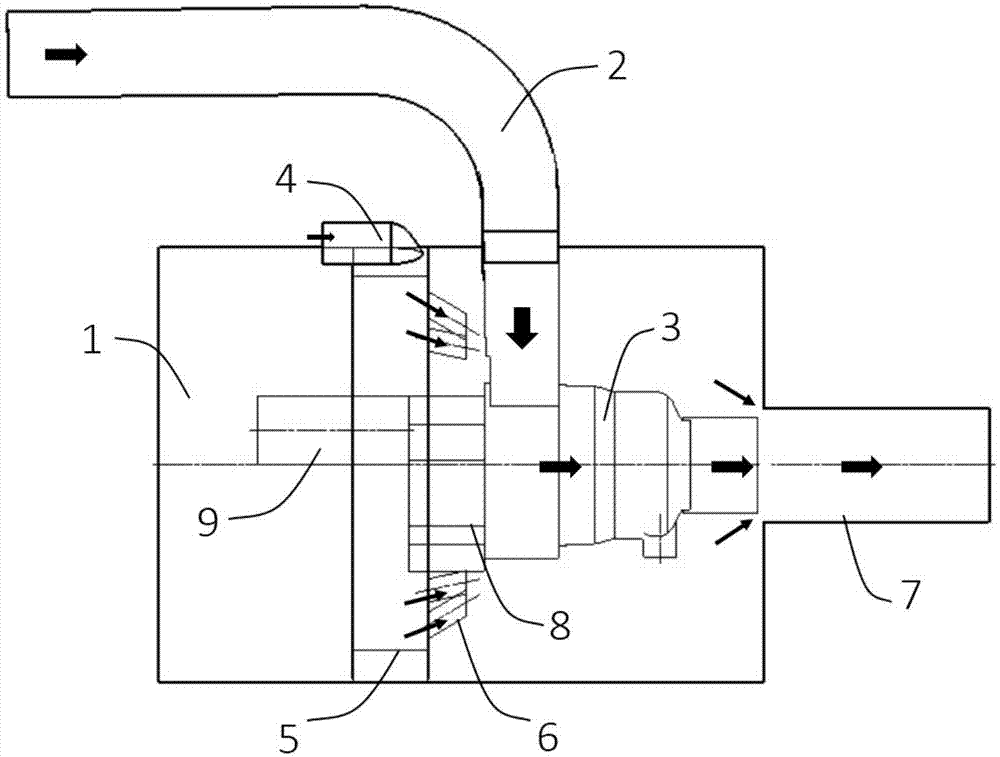

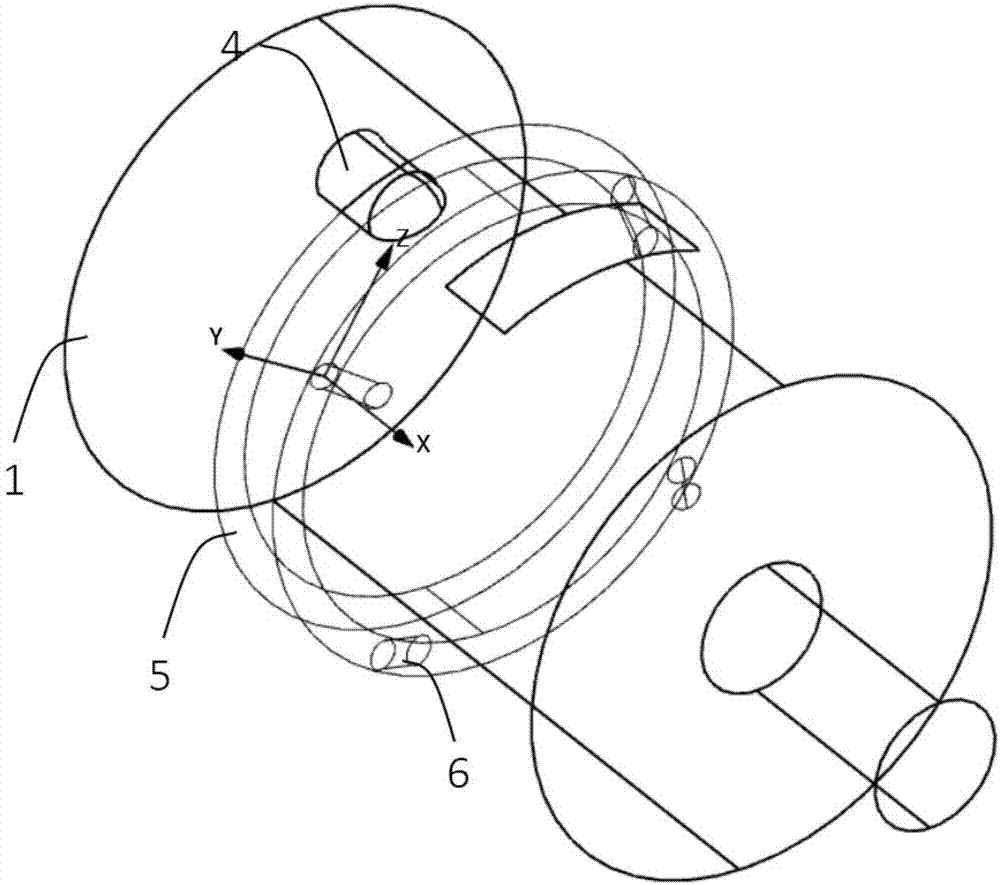

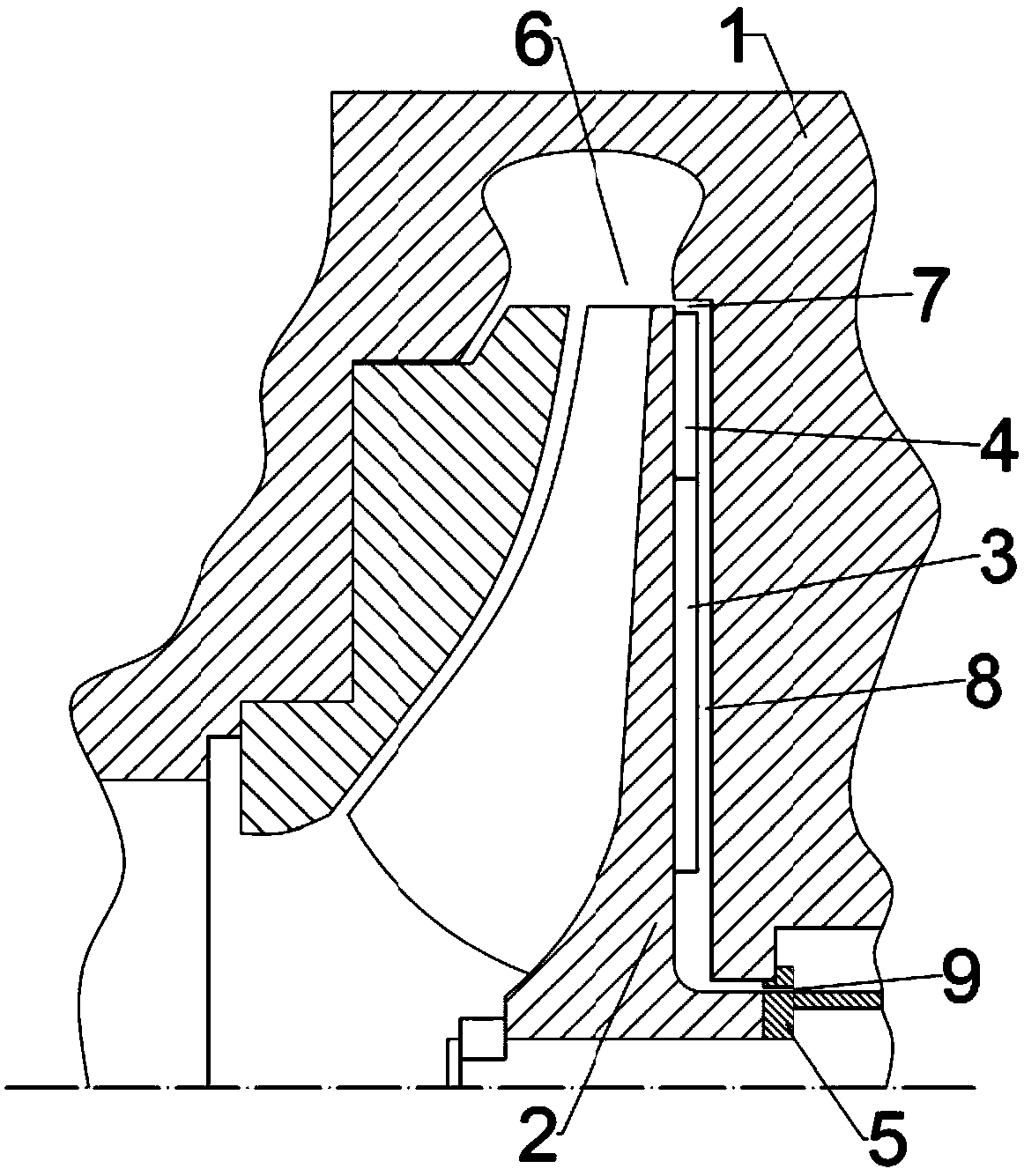

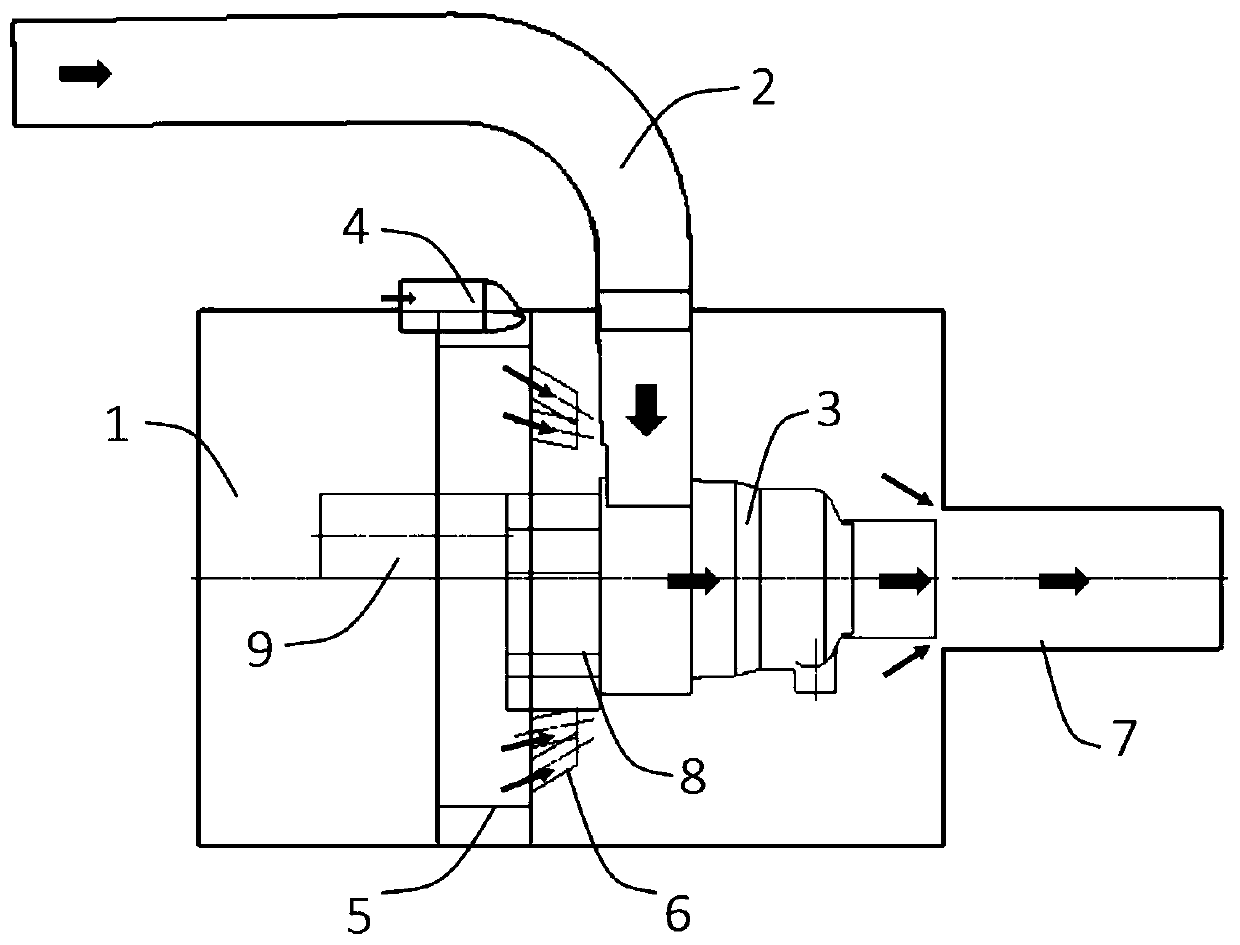

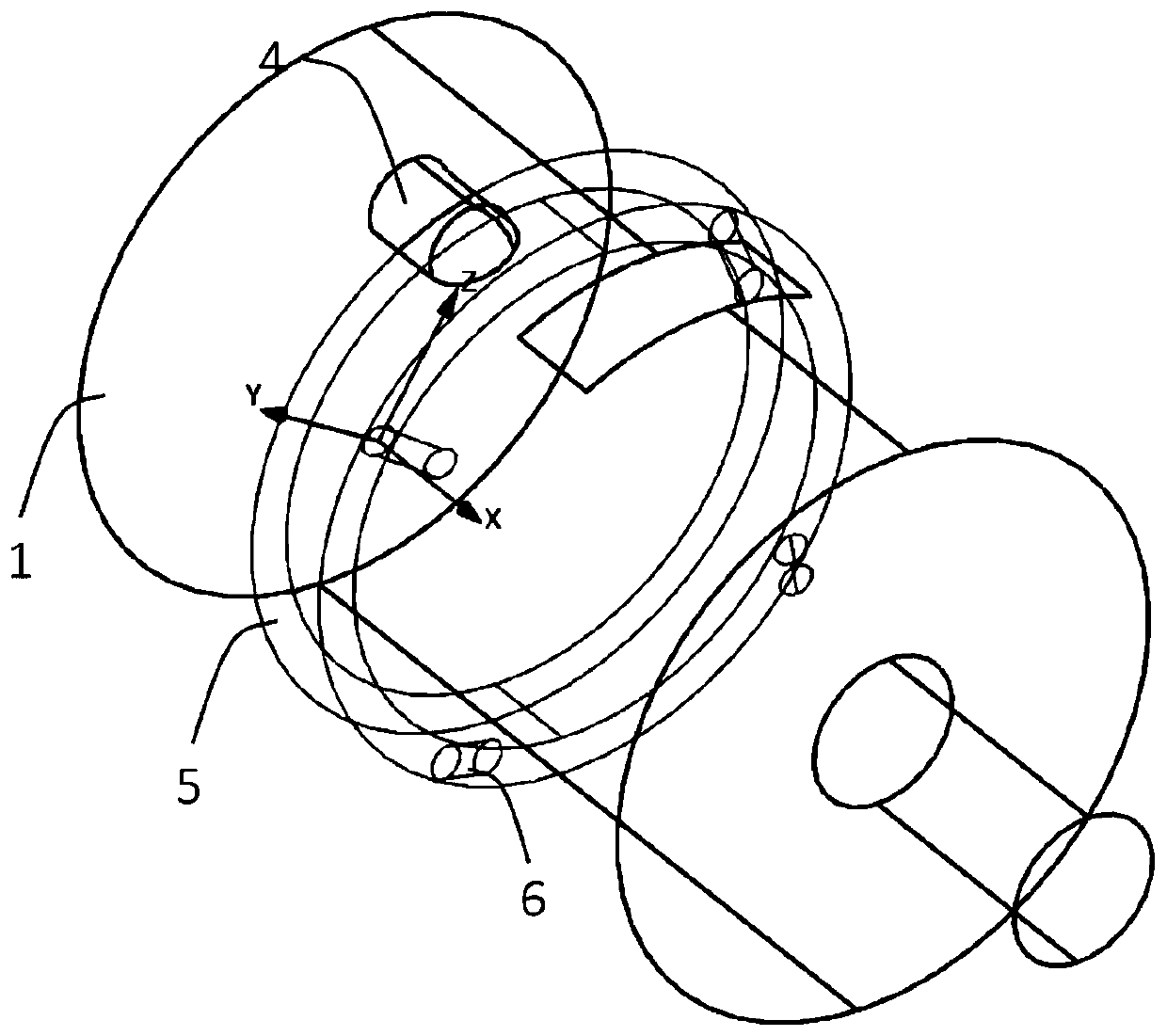

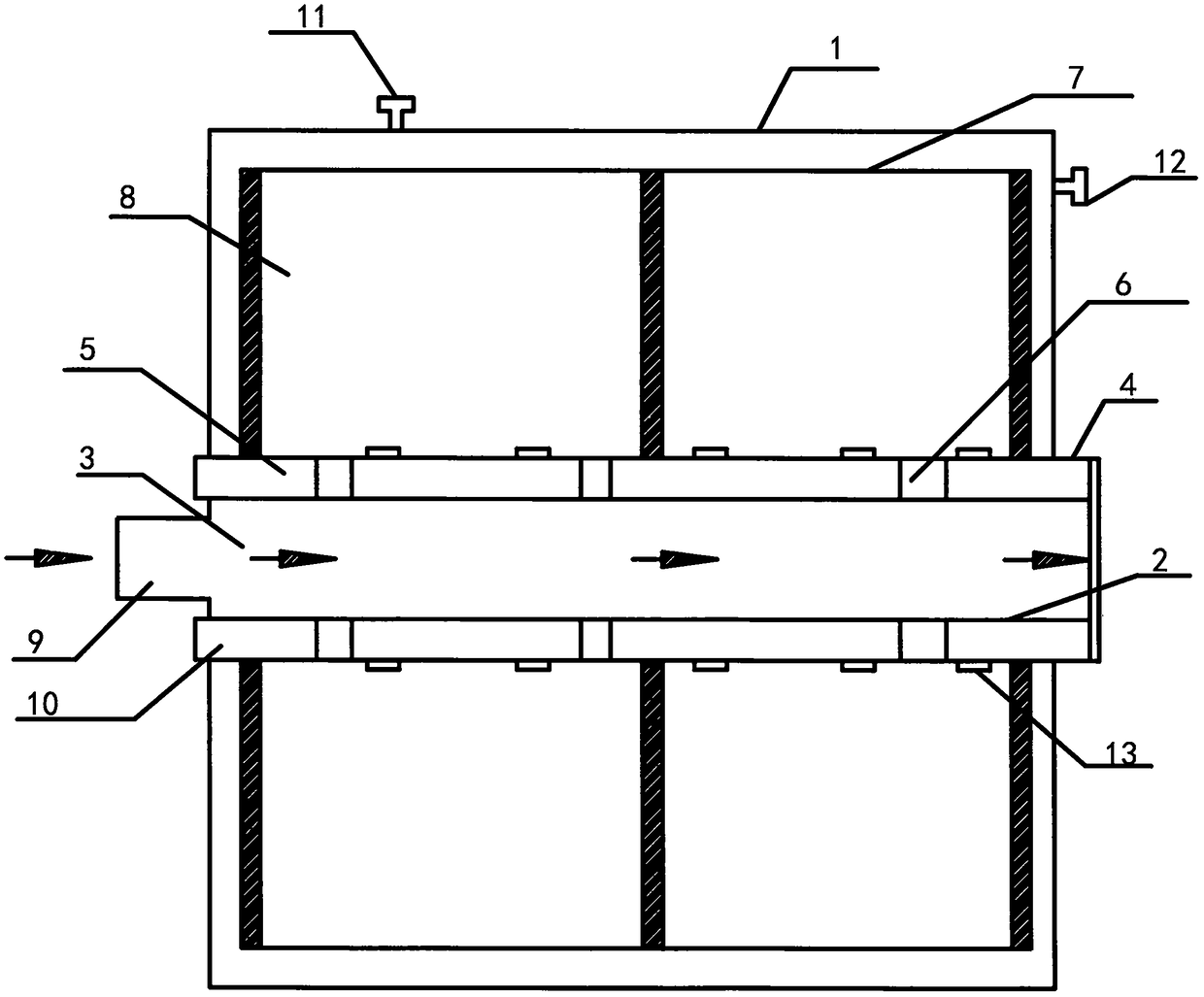

Air inlet ventilation structure used for aircraft auxiliary power system

ActiveCN107416214AIncrease peripheral speedEliminate backflowPower plant cooling arrangmentsPower installationsInlet channelSpray nozzle

The invention discloses an air inlet ventilation structure used for an aircraft auxiliary power system. The structure comprises an aircraft auxiliary power system cabin (1) and an air inlet channel (2) which is formed in the aircraft auxiliary power system cabin. An auxiliary power system body (3) is arranged in the aircraft auxiliary power system cabin and communicates with the air inlet channel. A closed type annular guide channel (5) is formed in the inner wall of the aircraft auxiliary power system cabin. A cat ear air inlet (4) is formed in the aircraft auxiliary power system cabin and communicates with the guide channel. Diversion spray nozzles (6) are arranged in the positions, perpendicular to the aircraft auxiliary power system cabin, of the guide channel, are located at the side, close to the auxiliary power system body, of the guide channel, and communicate with the guide channel. According to the air inlet ventilation structure provided by the invention, a single cooling air inlet is changed into a plurality of cooling air inlets based on a prior air inlet ventilation structure, and flowing and heat exchanging in the auxiliary power cabin are optimized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

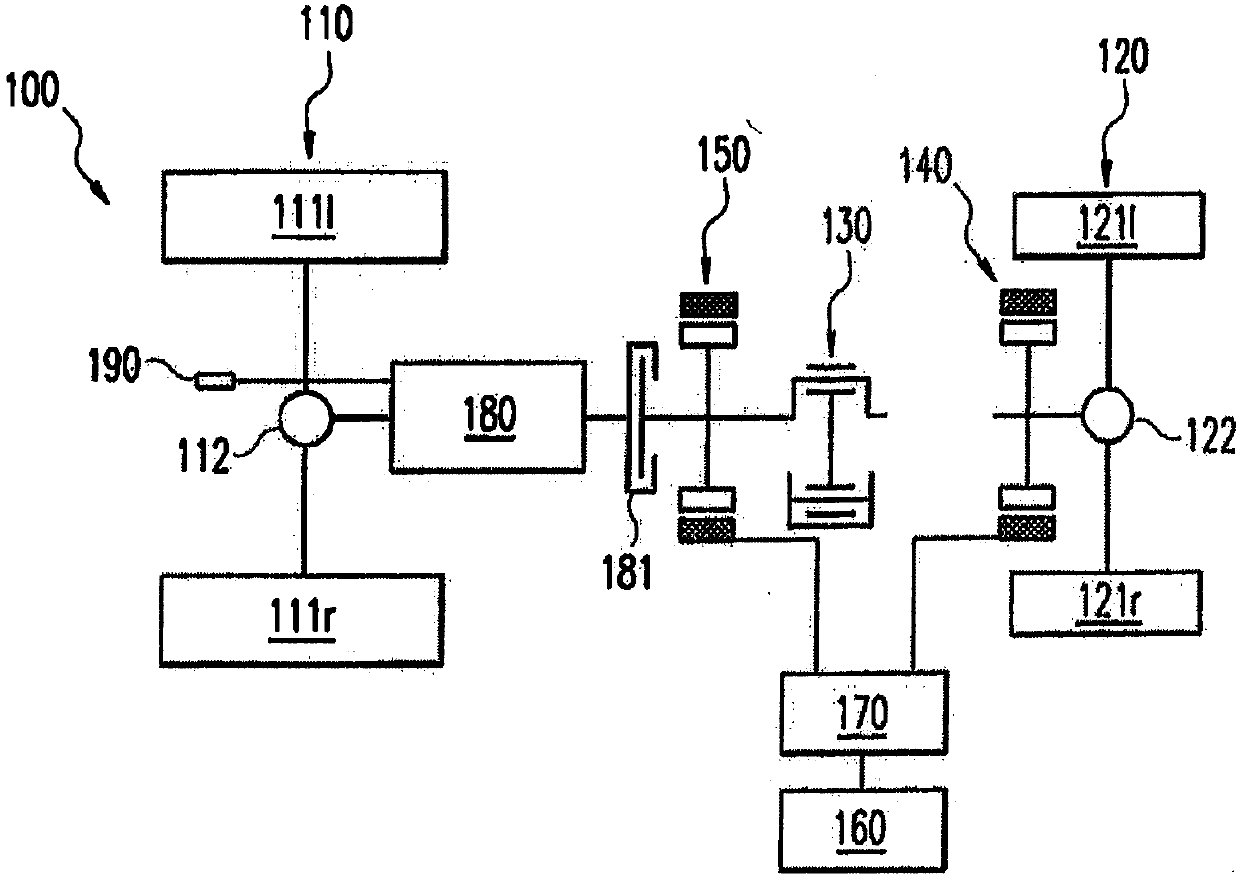

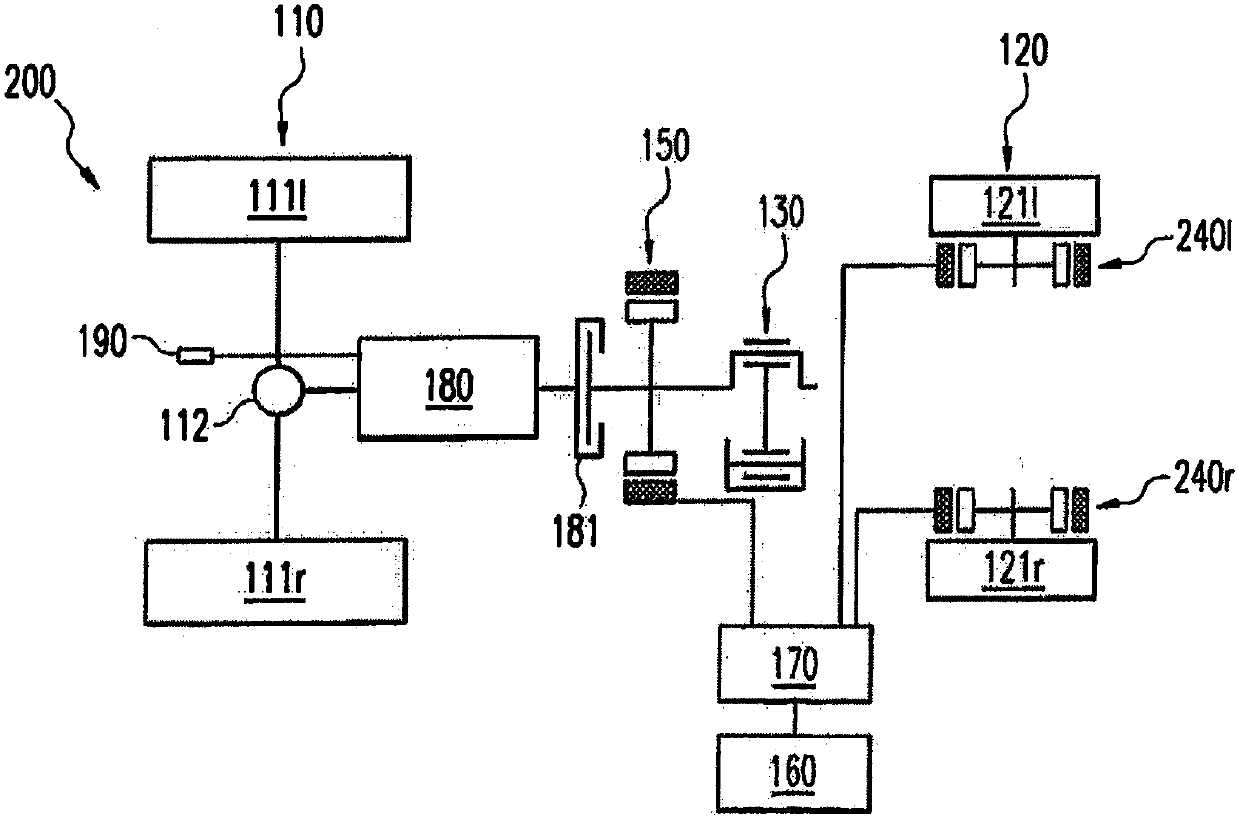

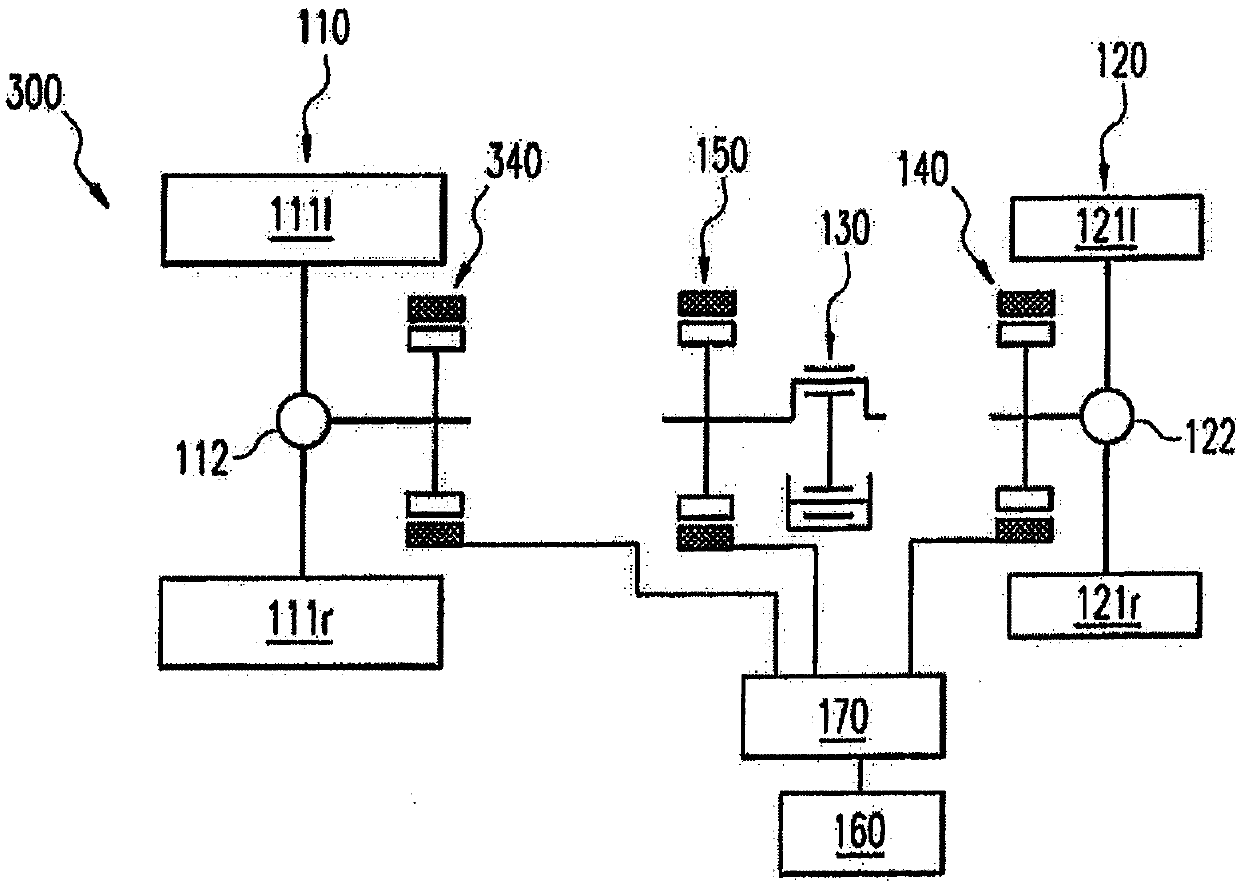

Method for controlling a wheel rotational speed of at least one wheel of a drivable axle of a two-track vehicle having two drivable axles, and two-track vehicle having at least two drivable axles

ActiveCN107848392AGreat tractionGuaranteed uptimeHybrid vehiclesGas pressure propulsion mountingState variableDrive motor

The invention relates to a method for controlling a wheel rotational speed of a wheel of a drivable axle of a two-track vehicle having two drivable axles and a corresponding vehicle, wherein the vehicle has a first drive motor for driving the first axle, a second drive motor for driving the second axle, a device for sensing driving state variables, and a control device. The method comprises the following steps: determining an actual rotational speed of the first axle, determining a target rotational speed for the second axle in dependence on the actual rotational speed of the first axle, and controlling the second drive motor in such a way that the determined target rotational speed is set at the second axle. In order to determine the target rotational speed, a synchronous target rotational speed at which the same wheel circumferential velocity is set at at least one wheel of the second axle as at the wheels of the first axle is determined in dependence on the actual rotational speed of the first axle. The target rotational speed for the second axle is then determined in dependence on the determined synchronous target rotational speed.

Owner:AVL LIST GMBH

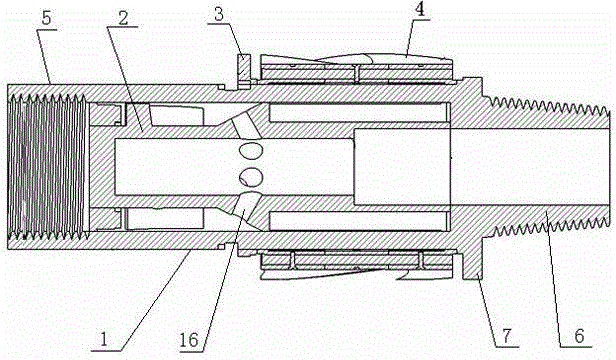

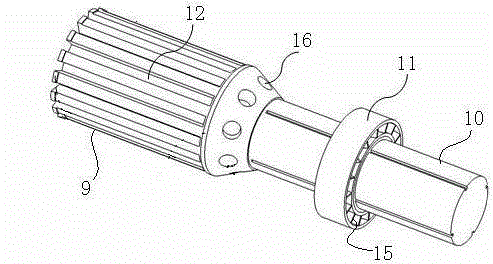

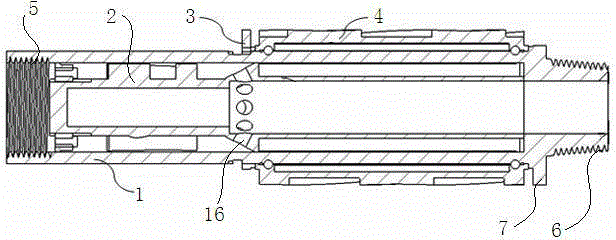

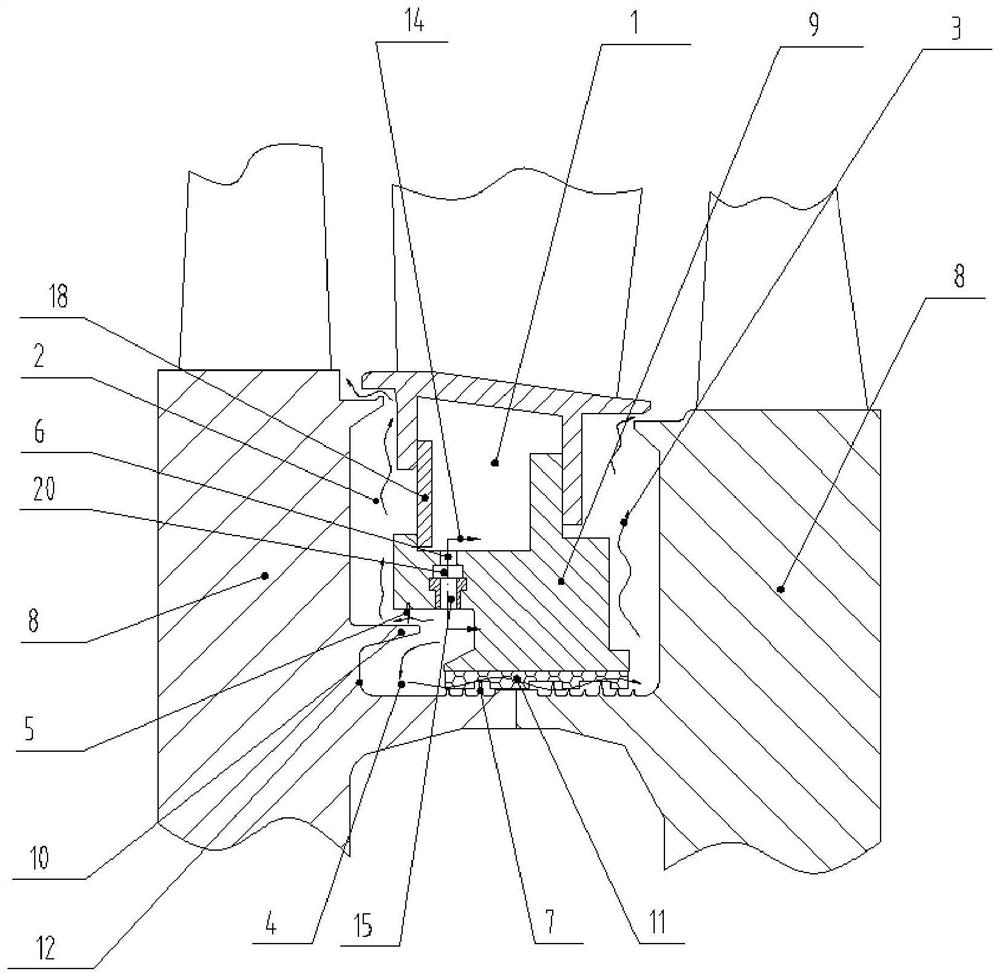

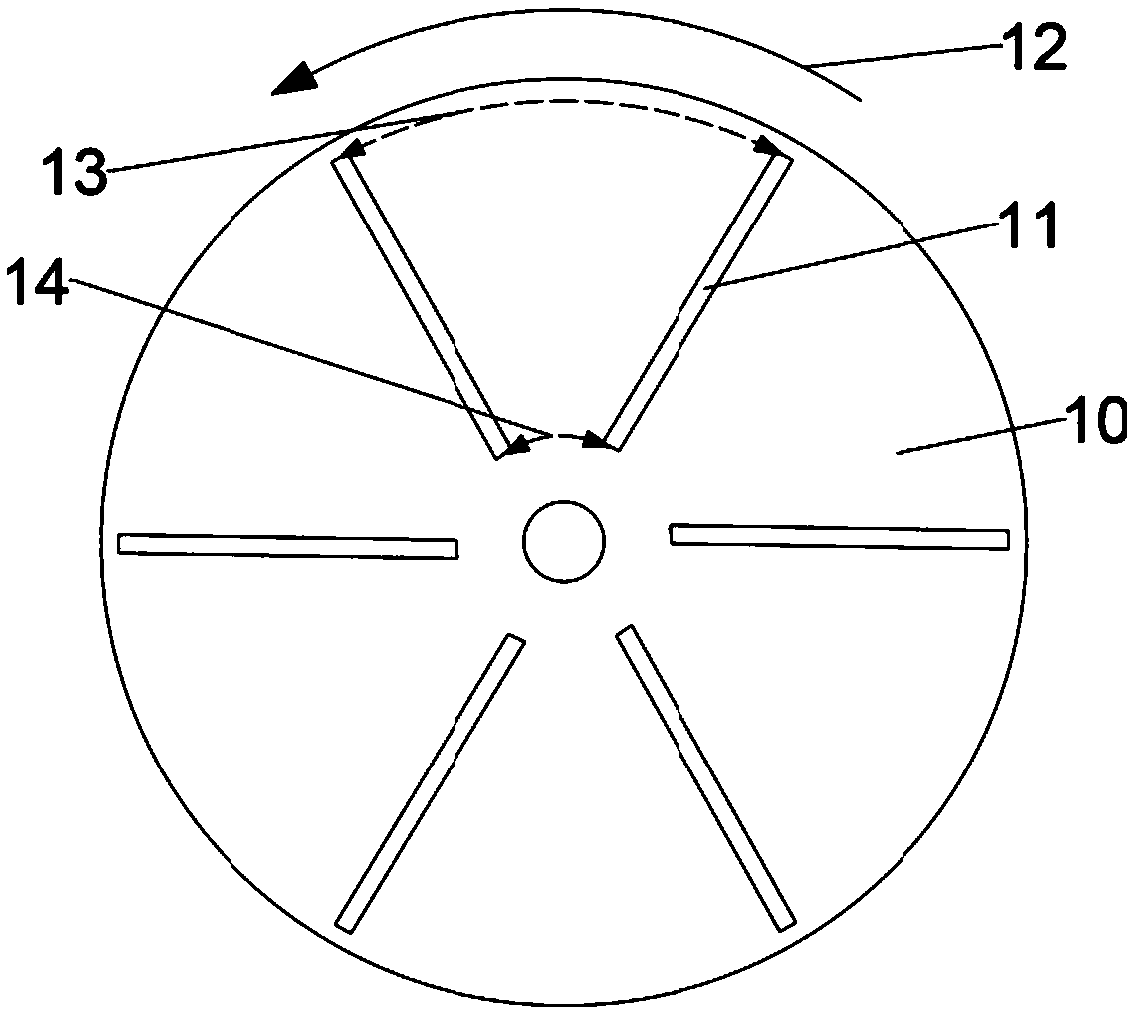

Integral vane hydraulic-magnetic driving borehole cleaning tool

ActiveCN104653130AIncrease peripheral speedInhibits the formation of cuttings bedsFlushingMagnetic coreCounter rotation

The invention relates to an integral vane hydraulic-magnetic driving borehole cleaning tool. The integral vane hydraulic-magnetic driving borehole cleaning tool consists of a flow barrel shell, a rotary magnetic core, an upper gauge protection body and a rotary vane, wherein the outer wall of the flow barrel shell is provided with a lower gauge protection body and a spacing ring; the upper gauge protection body is installed on one side of the spacing ring; the rotary magnetic core is integrally formed by a drum and a spindle; a transition connection section of the drum and the spindle is provided with drilling fluid holes; a hydraulic conversion device is fixedly arranged out of the spindle; the outer wall of the drum is evenly provided with permanent magnets; every two adjacent permanent magnets have opposite magnetic pole directions; the rotary magnetic core is installed in the flow barrel shell; the rotary vane sleeves the flow barrel shell; the outer wall of the flow barrel shell is also provided with a bearing raceway which corresponds to a bearing raceway of the rotary vane; a rolling body is installed in the bearing raceways; the outer wall of the flow barrel shell is also provided with a seal groove; the rotary blade is integrated; the inner wall of a drum body of the rotary blade is evenly provided with the permanent magnets; every two adjacent permanent magnets of the rotary blade have the opposite magnetic pole directions; the outer wall of the rotary vane is also provided with a storage oil sealing and compensating system. The integral vane hydraulic-magnetic driving borehole cleaning tool is free from the limitation whether a drill pipe rotates or not through hydraulic-magnetic coupling driving, and therefore, borehole cleaning efficiency can be drastically improved.

Owner:NORTHEAST GASOLINEEUM UNIV

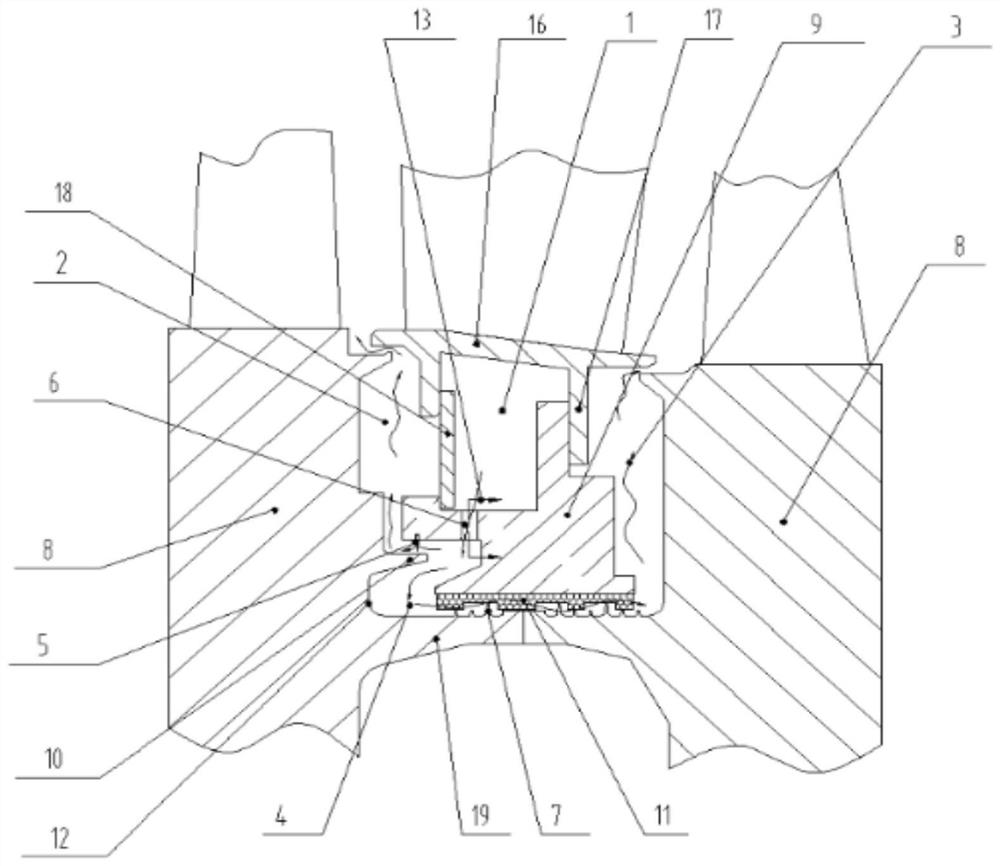

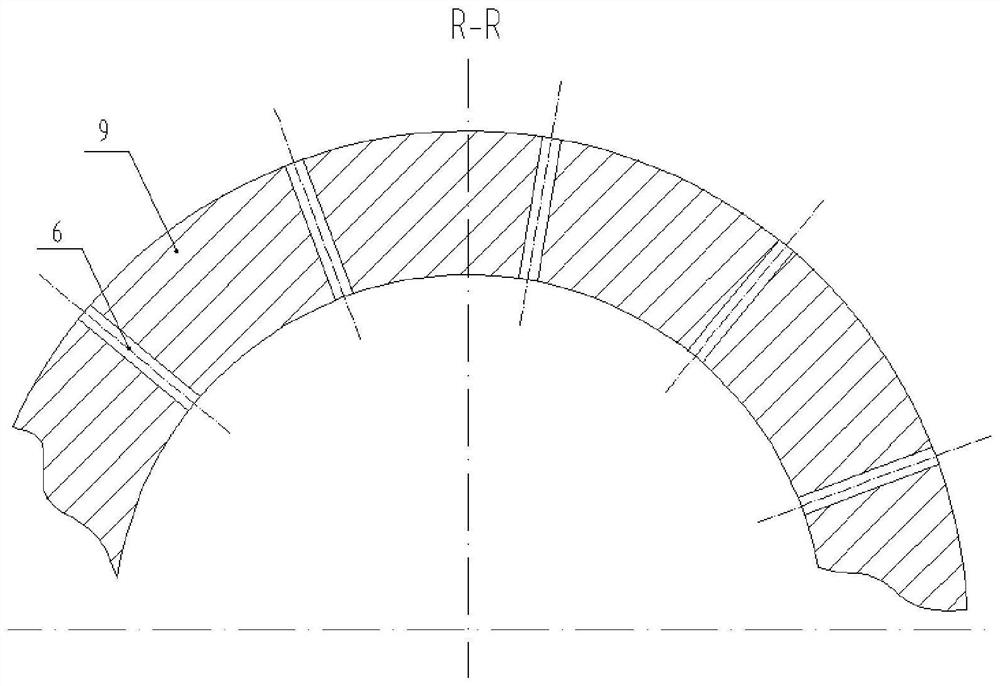

Gas turbine interstage sealing ring structure

ActiveCN111963320AReduce heat upIncrease peripheral speedTurbine/propulsion engine coolingLeakage preventionThermodynamicsEngineering

The invention provides a gas turbine interstage sealing ring structure, and belongs to the field of mechanical structure design. According to the gas turbine interstage sealing ring structure, the airinlet angle is increased in radial air supply holes in an interstage sealing ring. According to the gas turbine interstage sealing ring structure, a tangential angle structure is arranged in the radial hole of the interstage sealing ring, and the pre-rotation of airflow passing through the radial hole is increased, so that the circumferential speed difference between the airflow and the rotor surface is reduced, the temperature rise caused by the frictional resistance after the air flows through the rotor surface is weakened, and the use amount of cooling air is reduced under the same wheel disc cooling requirement. According to the gas turbine interstage sealing ring structure, on the premise that it is guaranteed that an original flow path structure is basically unchanged, optimizationis achieved, part machining is easy, installation is convenient, and the maintenance cost is low.

Owner:浙江燃创透平机械有限公司

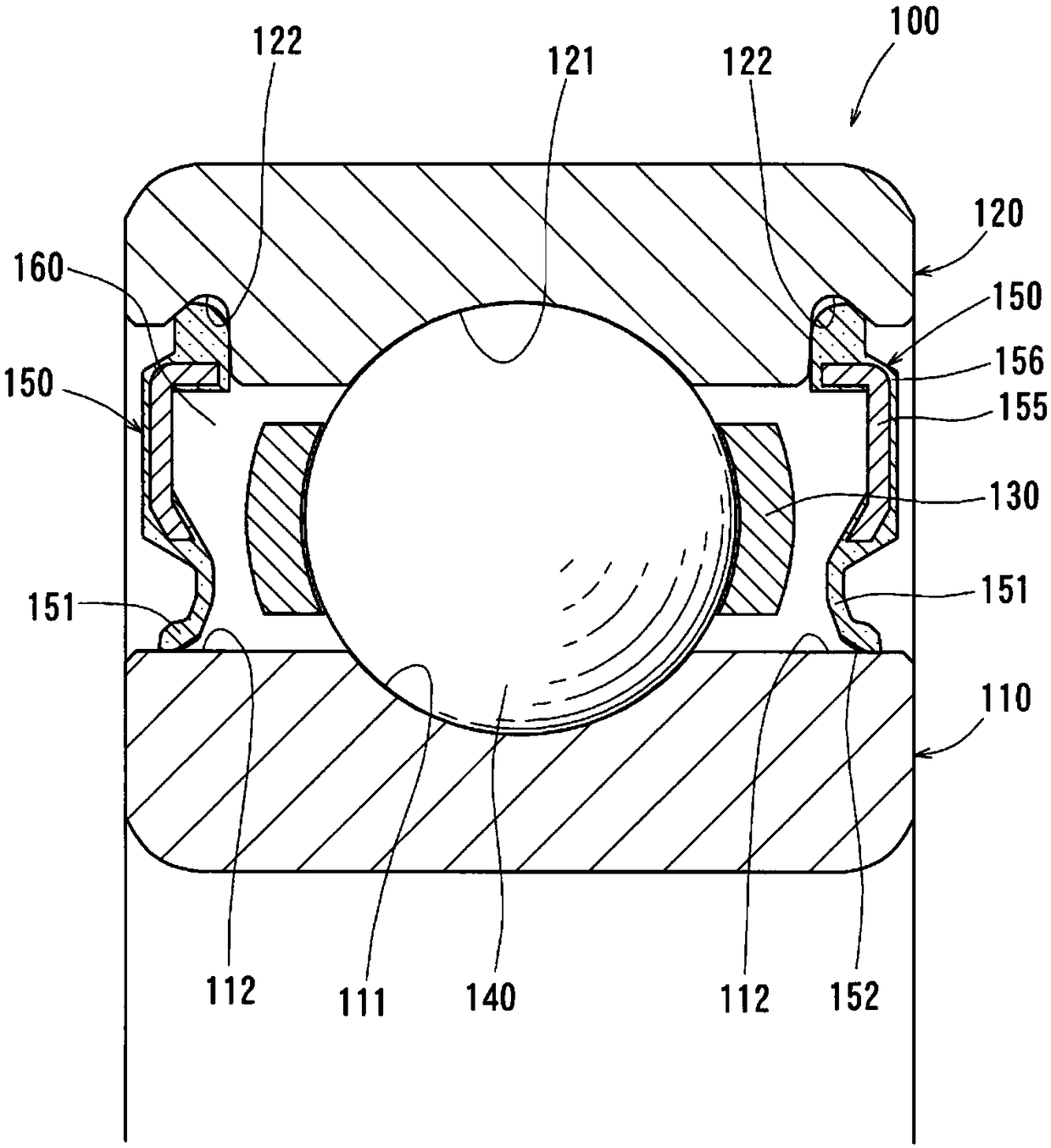

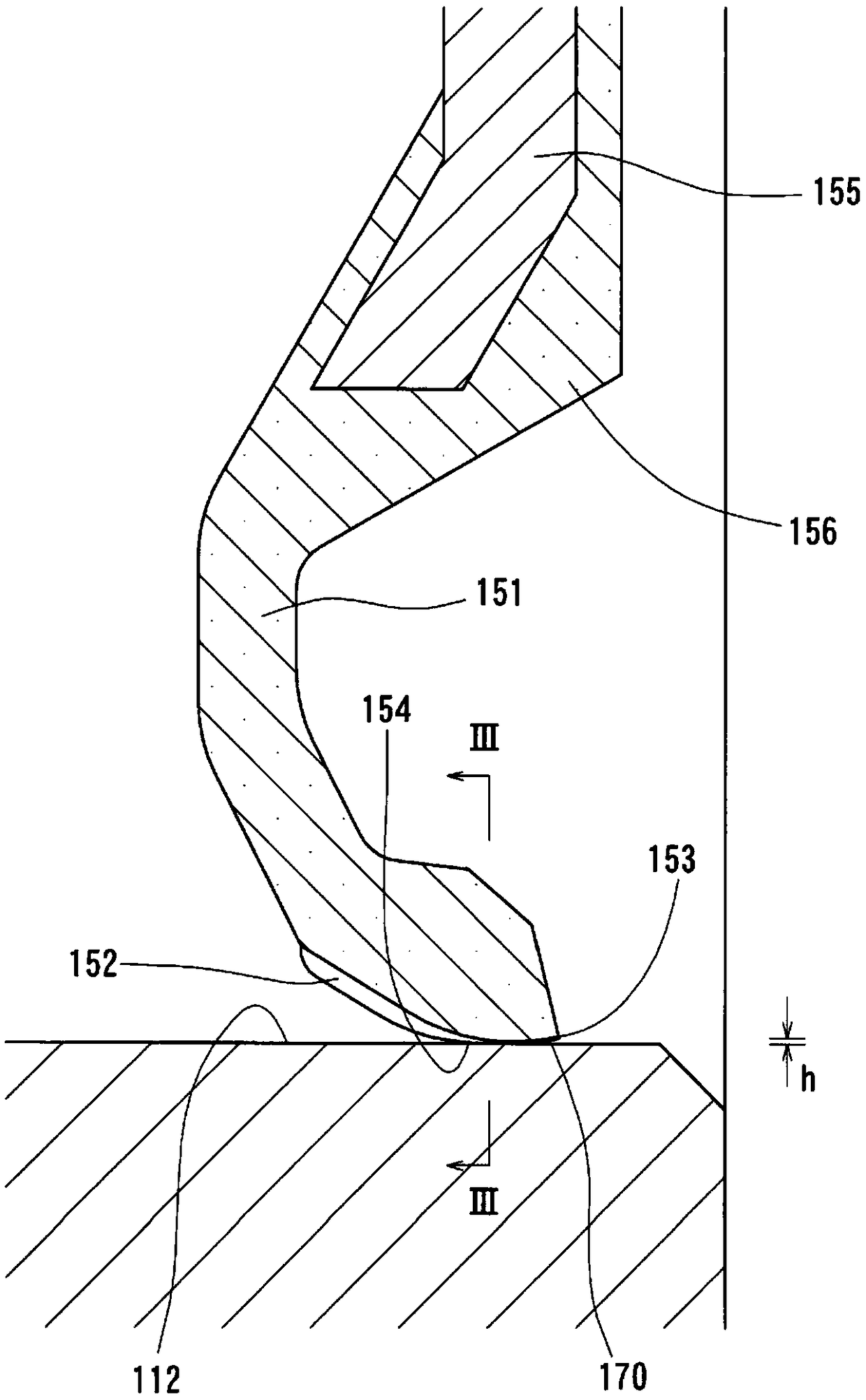

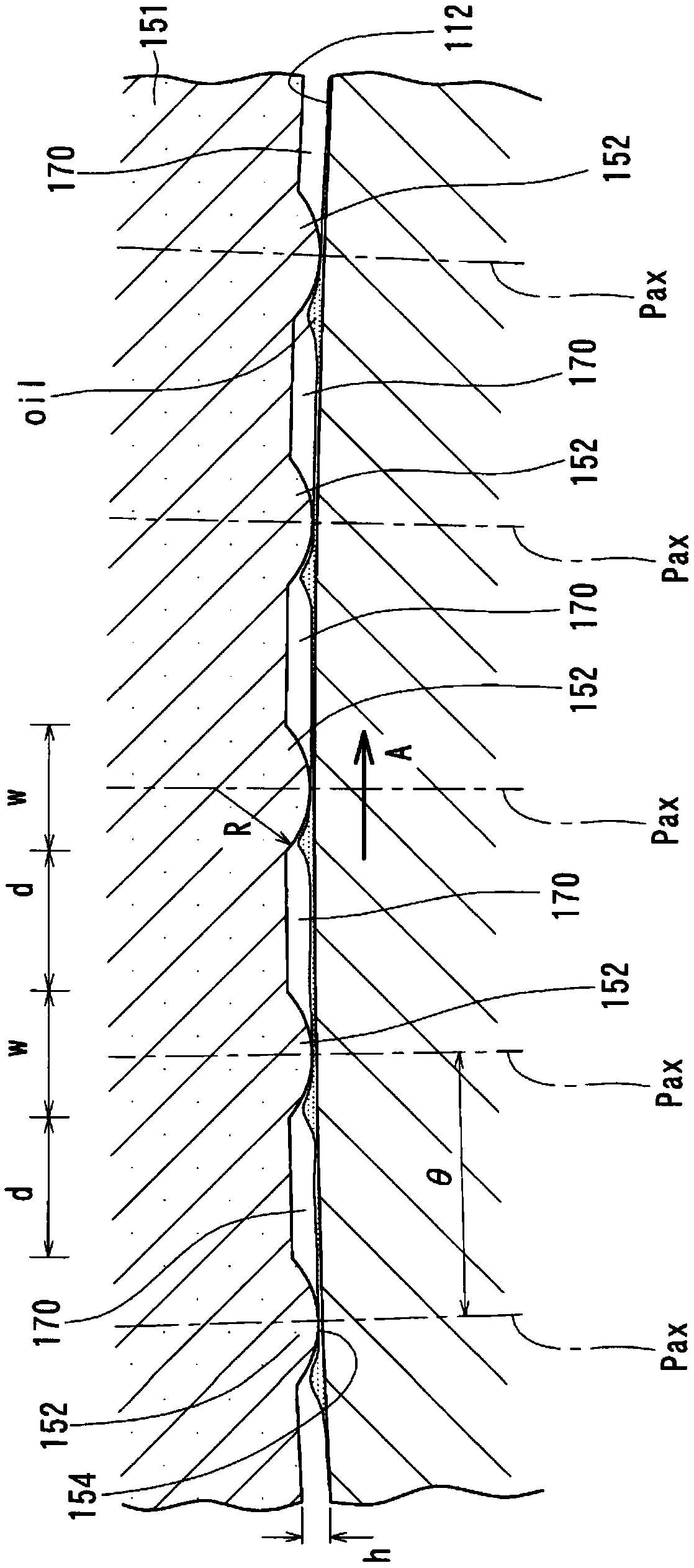

Seal-equipped bearing, and ball bearing

ActiveCN108713107APromote formationReduce coefficient of frictionEngine sealsBall bearingsForeign matterBall bearing

In the present invention, a plurality of protrusions (152) are formed by being arranged at intervals of 0.3-2.6 mm in the circumferential direction, on seal lips (151) of seal members (150). An oil passage (170), which interconnects a bearing inner space (160) and the outside and through which it is impossible for foreign matters of a prescribed particle size to pass, is generated between a seal sliding surface (112) sliding in the circumferential direction with respect to the protrusions (152), and the seal lips (151). Accompanying the rotation of a bearing, due to a wedge effect when the protrusions (152) draw lubricating oil into the oil passage (170) between themselves and the seal sliding surface (112), formation of an oil film is promoted between the seal lips (151) and the seal sliding surface (112), resulting in a fluid lubrication state.

Owner:NTN CORP

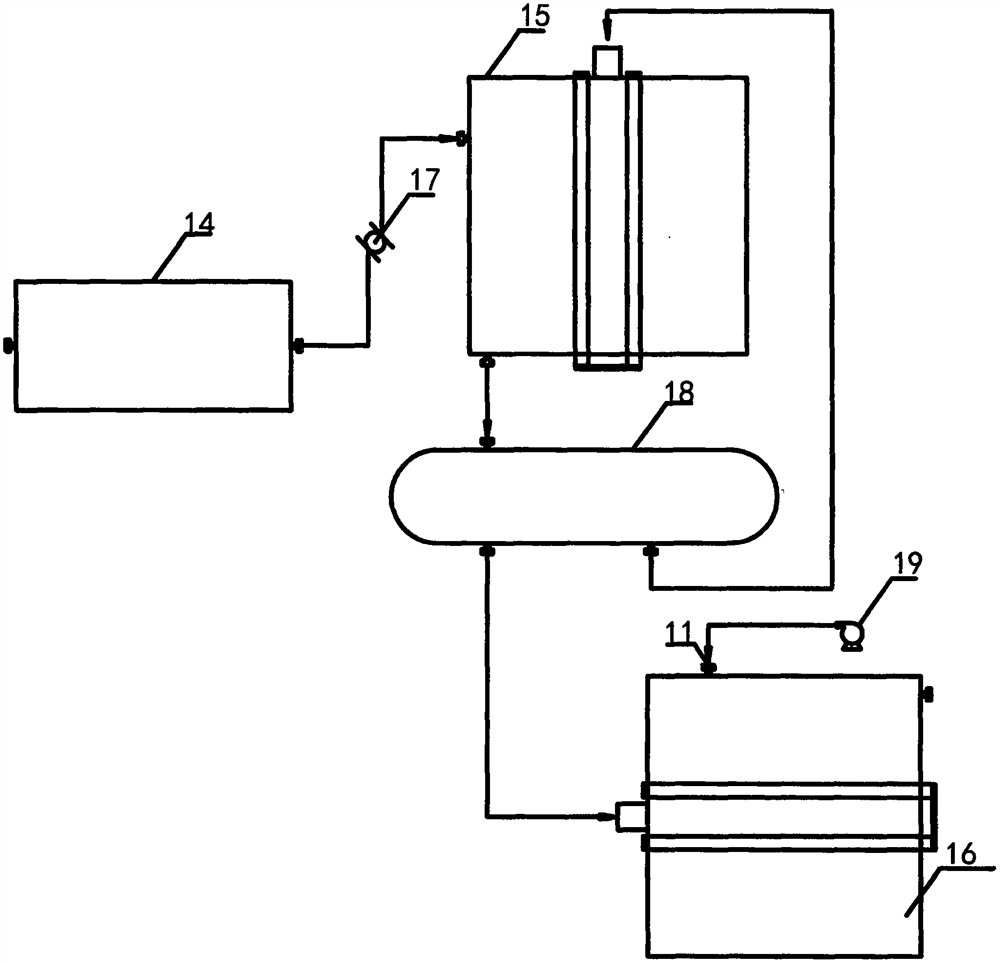

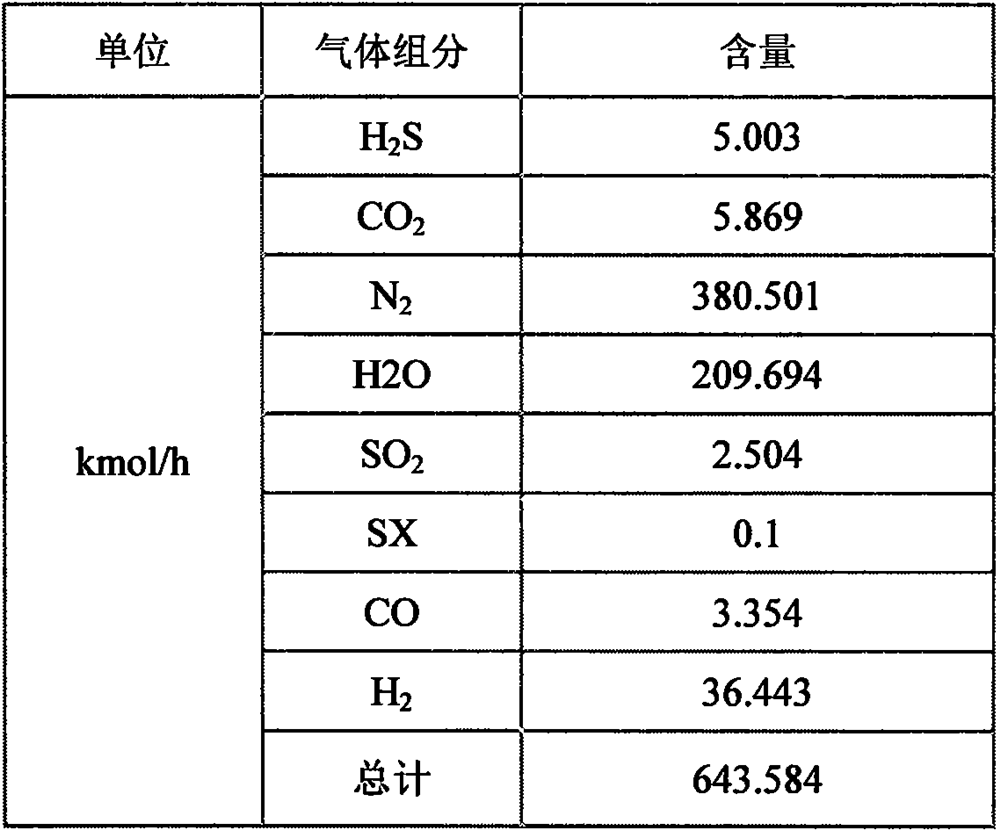

Supergravity oxidation machine and tail gas treatment device and process

PendingCN112973421AImplement spin-inImprove oxidation effectGas treatmentDispersed particle separationEngineeringCentrifugal force

The invention relates to a supergravity oxidation machine, a sulfur recovery tail gas treatment device and a process. The supergravity oxidation machine is characterized in that a hollow rotating shaft with a fluid channel is arranged on the central axis of a shell and penetrates through the shell, and a sleeve with a gas channel function sleeves the hollow rotating shaft; meanwhile, a rotating channel which is communicated with the packing area and is provided with a spiral channel is formed on the basis, self-spinning entering of fluid is achieved after the fluid passes through the hollow rotating shaft and then passes through the rotating channel, and the circumferential speed is increased under the rotating acting force, the shearing force and the self-spinning acting force of the fluid at the moment when the fluid enters the packing area; and the generated centrifugal force pushes the fluid to the outer edge, and the gas with oxidizing capacity is crushed, torn and mixed in the filler area, so that the gas-liquid contact sufficiency is improved, and a very good liquid oxidizing effect is obtained. In addition, the sulfur recovery tail gas treatment device and process can effectively reduce the sulfur content in the acid gas.

Owner:北京沃尔福环保科技有限公司 +1

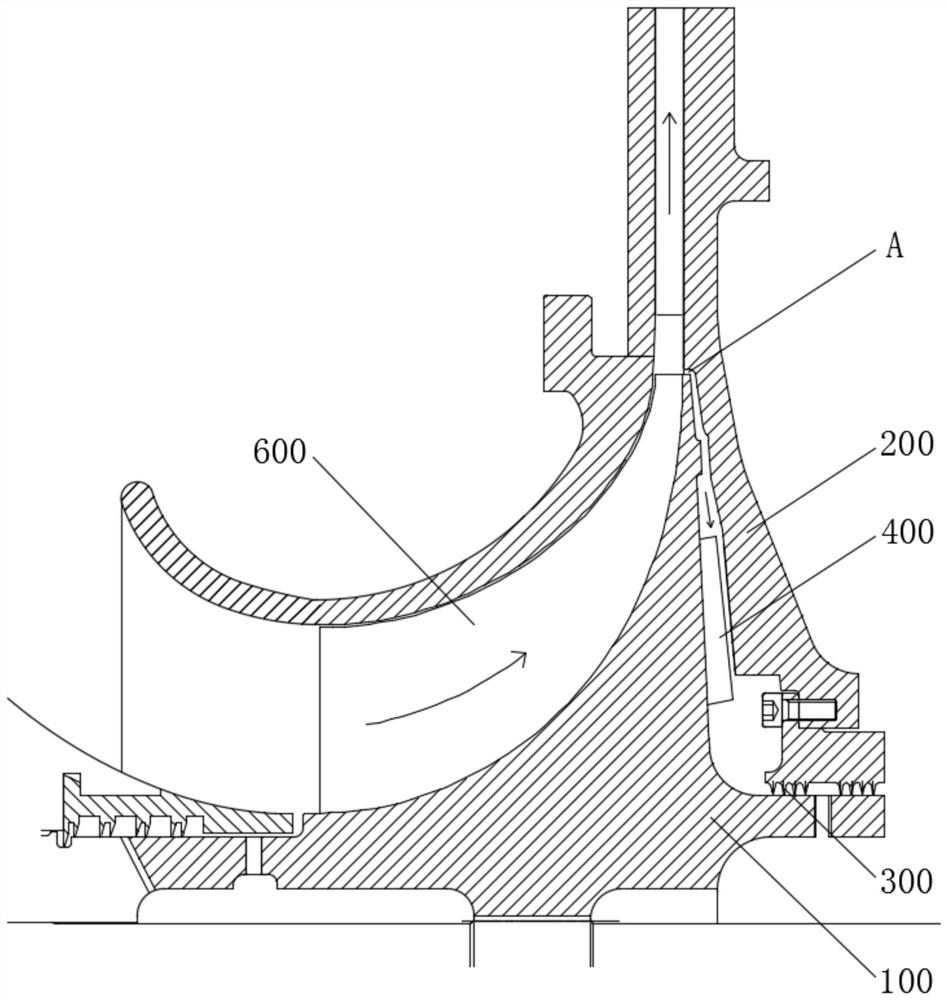

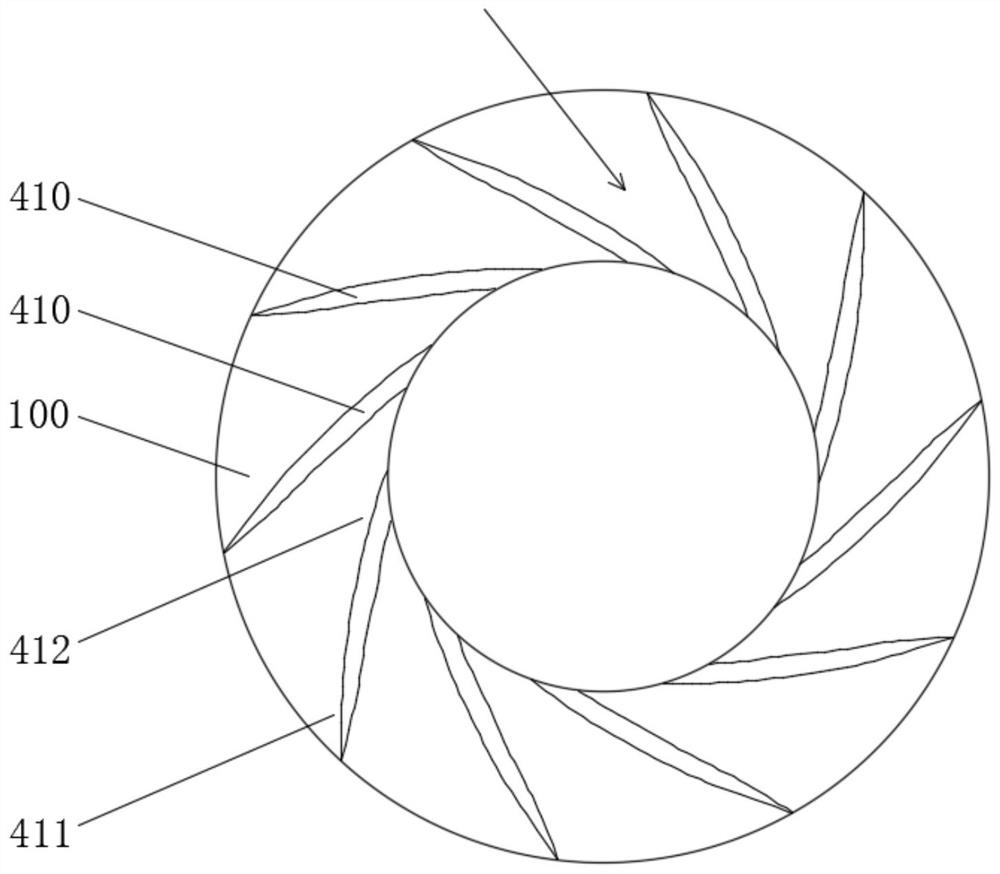

Radial flow type rotating mechanical impeller

InactiveCN109083864AThickenIncrease peripheral speedPump componentsBlade accessoriesImpellerEngineering

The invention discloses a radial flow type rotating mechanical impeller. The radial flow type rotating mechanical impeller comprises an impeller body, and a plurality of main blades and a plurality ofedge blades are arranged on the back surface of the impeller body. The main blades are uniformly distributed on the back surface of the impeller body in the peripheral direction of the impeller body,and the main blades are arranged in a protruding mode. The edge blades are uniformly arranged between the inlet sections of the adjacent main blades in the peripheral direction, and the edge blades are arranged in a protruding mode. According to the radial flow type rotating mechanical impeller, the blade consistency in an area with a larger radius on the back portion of the impeller body is significantly increased, meanwhile, the increase of the blade consistency of an area with a smaller radius is avoided, so that the circumferential velocity increases rapidly after leakage fluid enters a back clearance of the impeller body, the circumferential velocity of the leakage fluid further increases with the decrease of the radius under the drive of the blades on the back portion of the impeller body, the pressure is reduced at the same time, the reduction of fluid pressure in the area with the larger radius facilitates the reduction of the axial force on the back portion of the impeller body, and the axial force of the impeller body is balanced.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

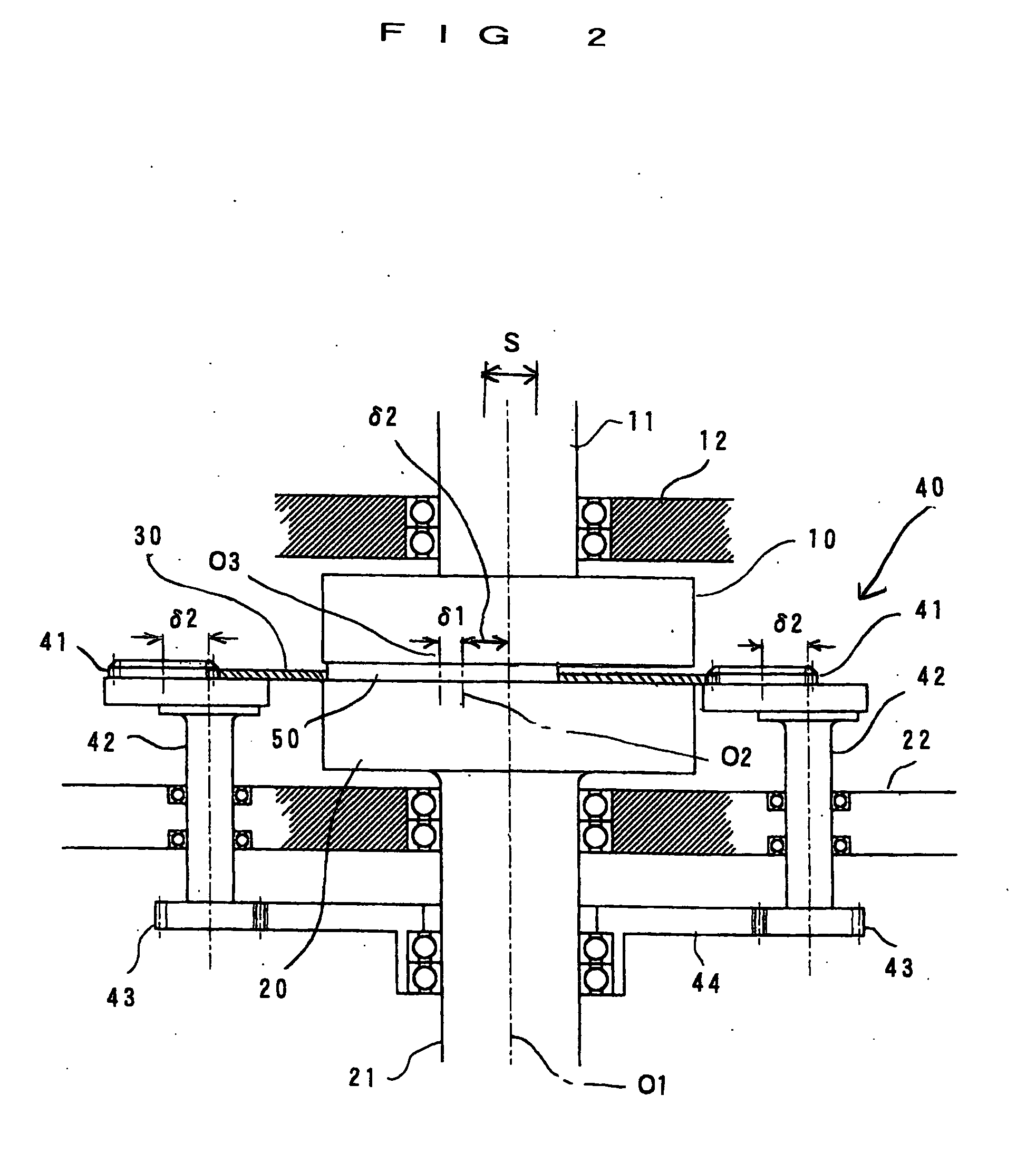

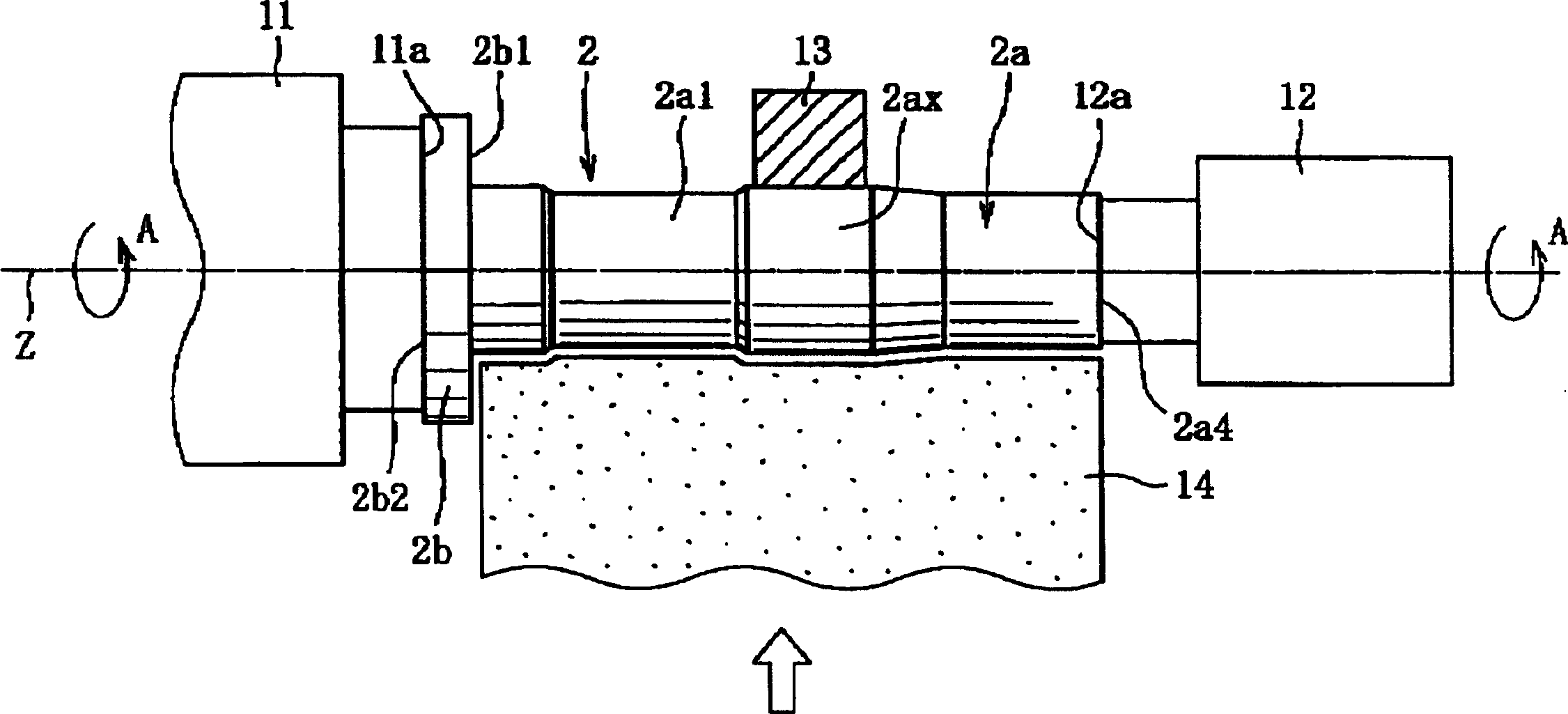

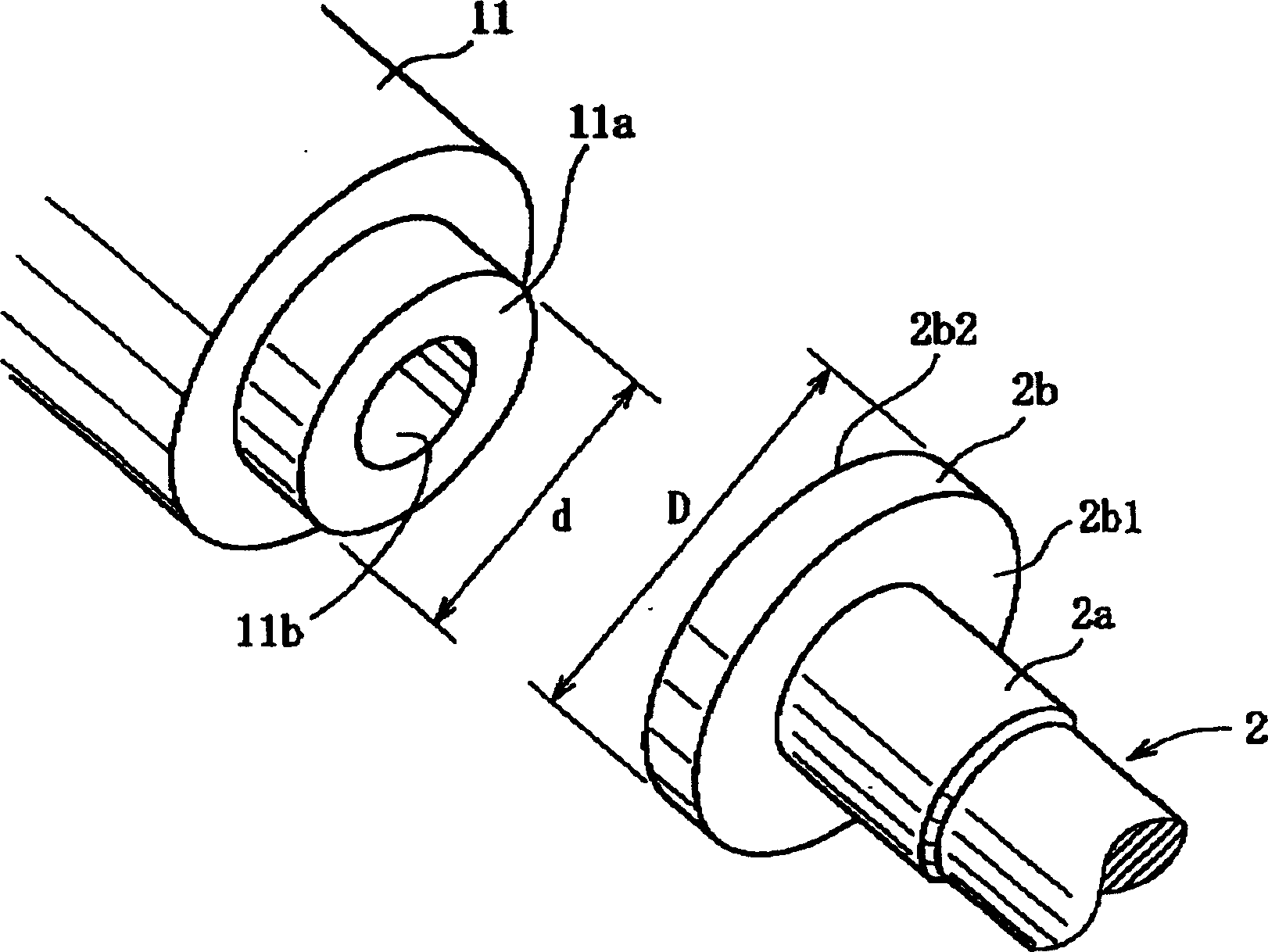

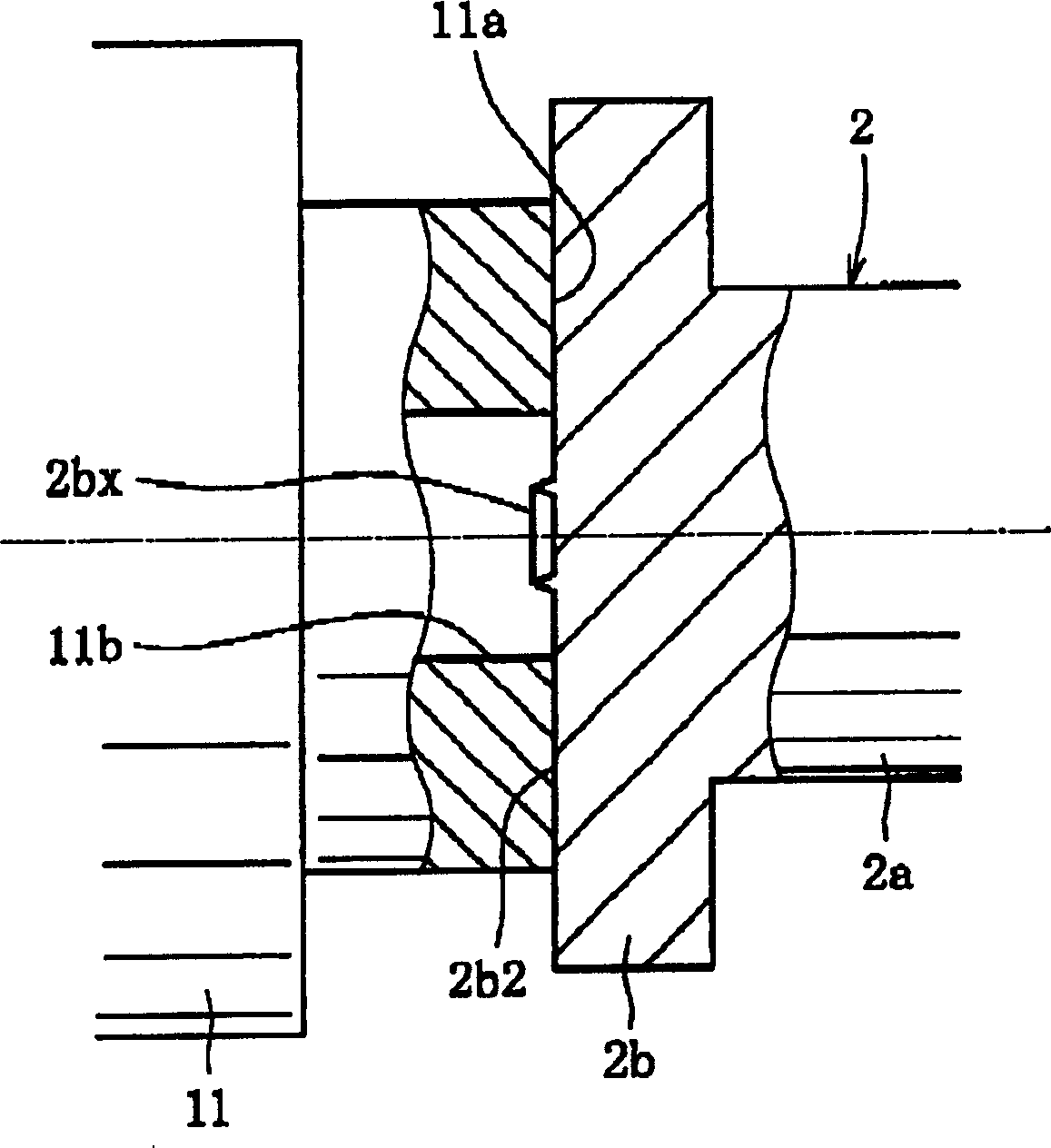

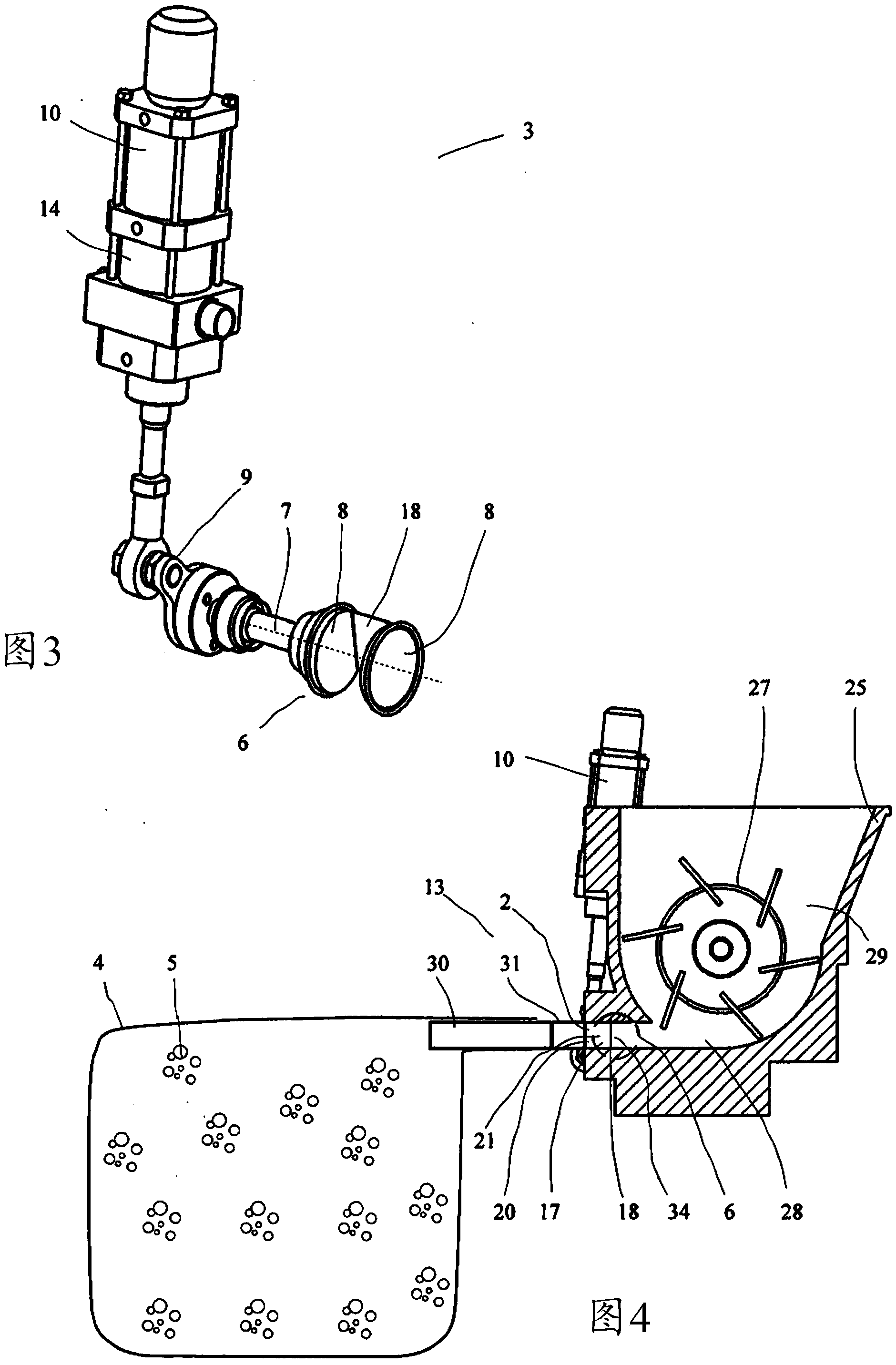

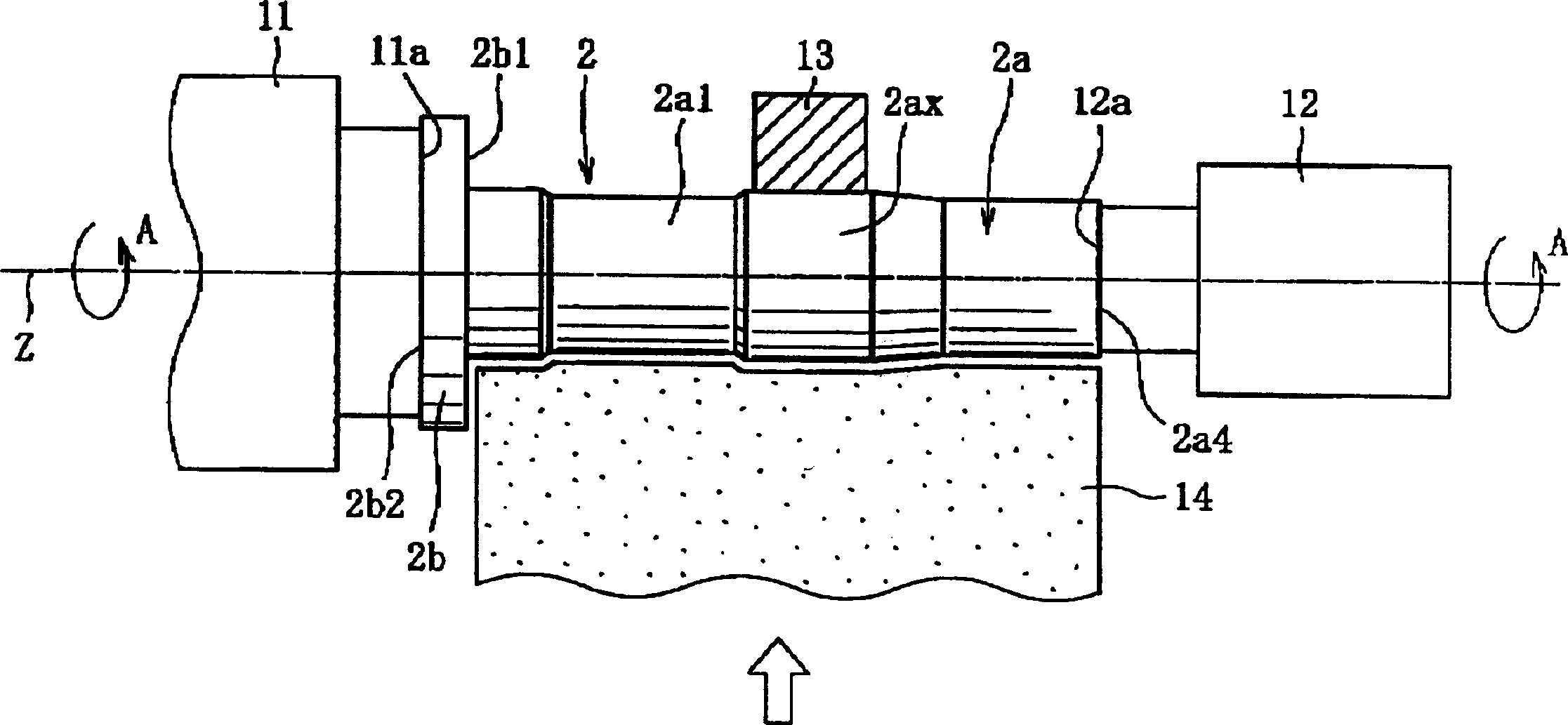

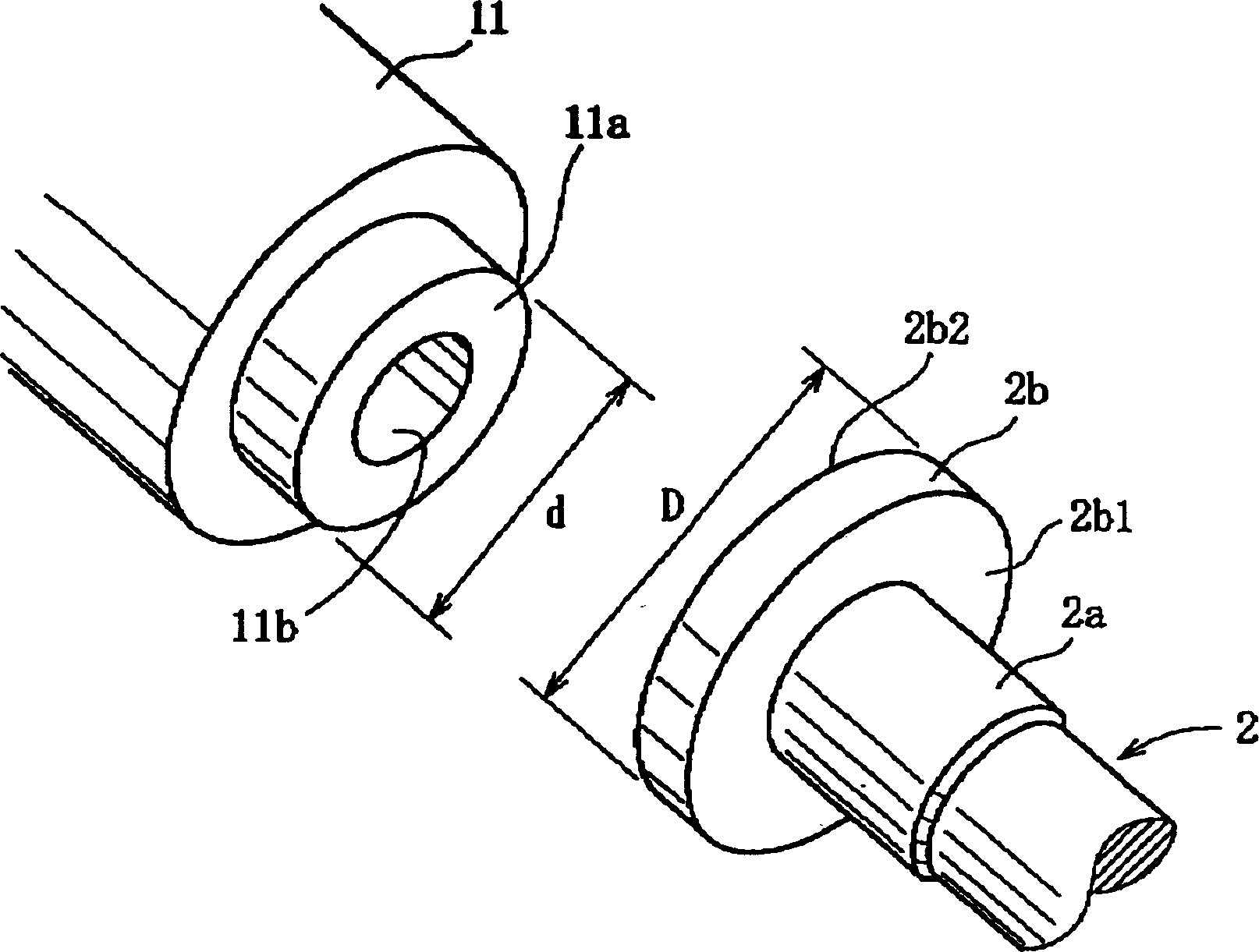

Method for mfg. hydraulic bearing device

InactiveCN1285841CIncrease peripheral speedPrevent centrifugal rotationLathesRevolution surface grinding machinesContact methodEngineering

Methods for making hydrodynamic bearing devices are provided. The method can effectively increase the peripheral speed when grinding the axial element which is the structural element of the hydrodynamic bearing device, and can prevent centrifugal rotation to improve grinding efficiency and work efficiency, and improve product quality at the same time. An axial member serving as a structural member of a hydrodynamic bearing device is supported at both ends in surface contact using a pair of plate members while rotating the axial member about its axis. The peripheral surface of the axial portion of the axial member is ground on a grinding stone while supporting the peripheral surface of the axial portion with a supporting member. Also, the plate member which is in surface contact with the flange portion of the axial member is formed with at least one recessed portion in a predetermined area of the center of rotation of the contact surface thereof. In addition, the contact portion of the plate member with the flange portion is elastically supported by an elastic member.

Owner:NTN CORP

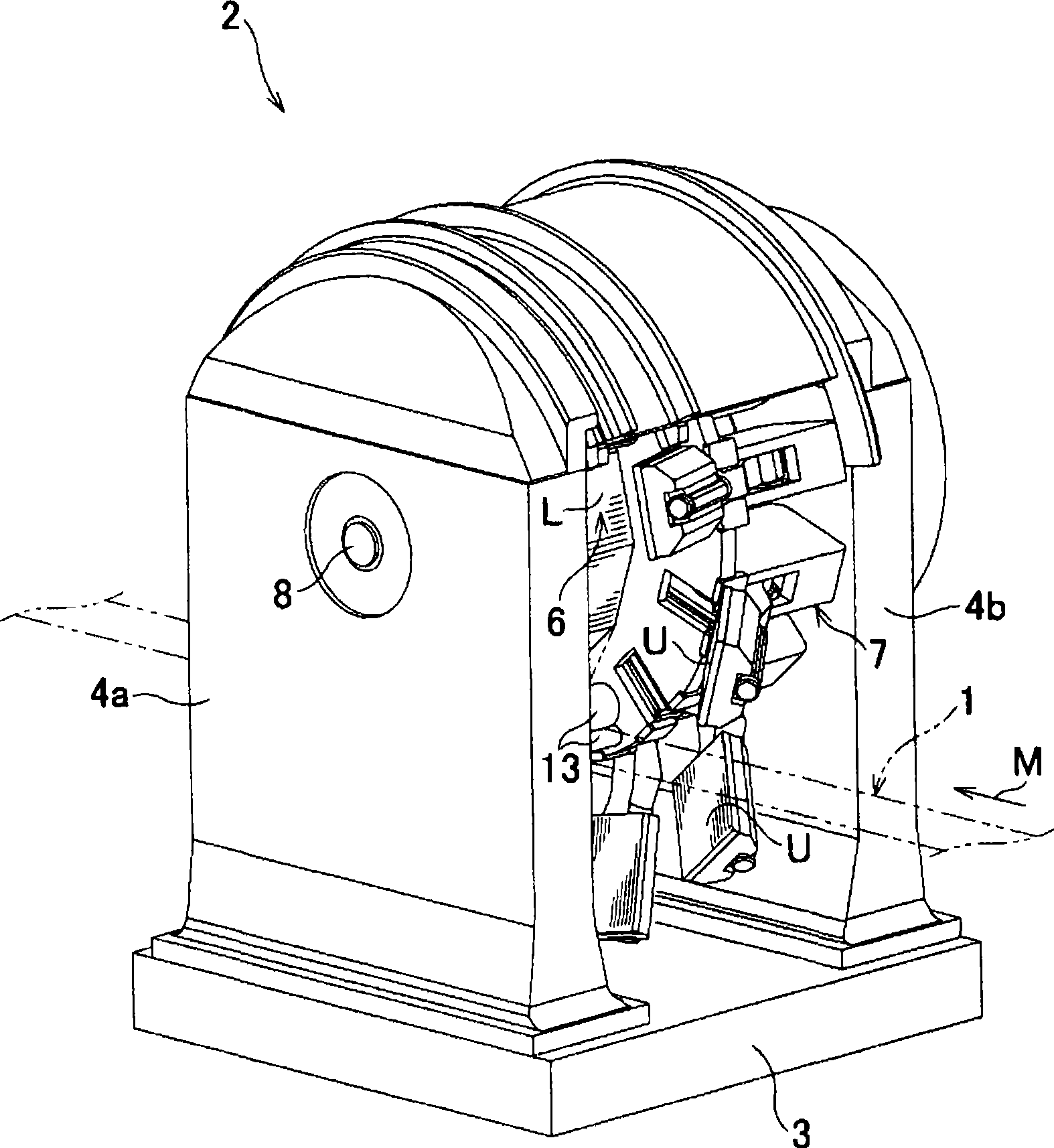

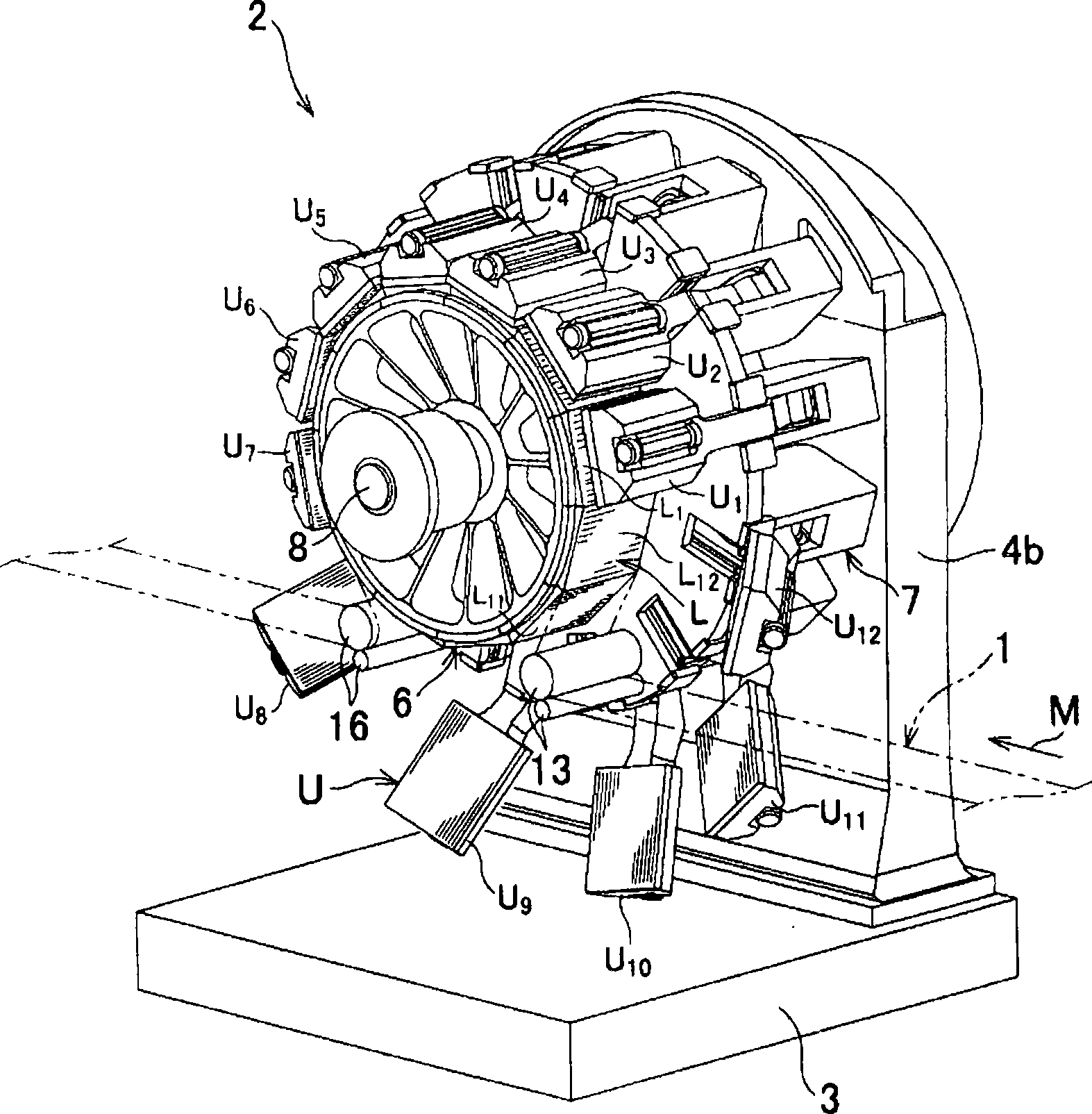

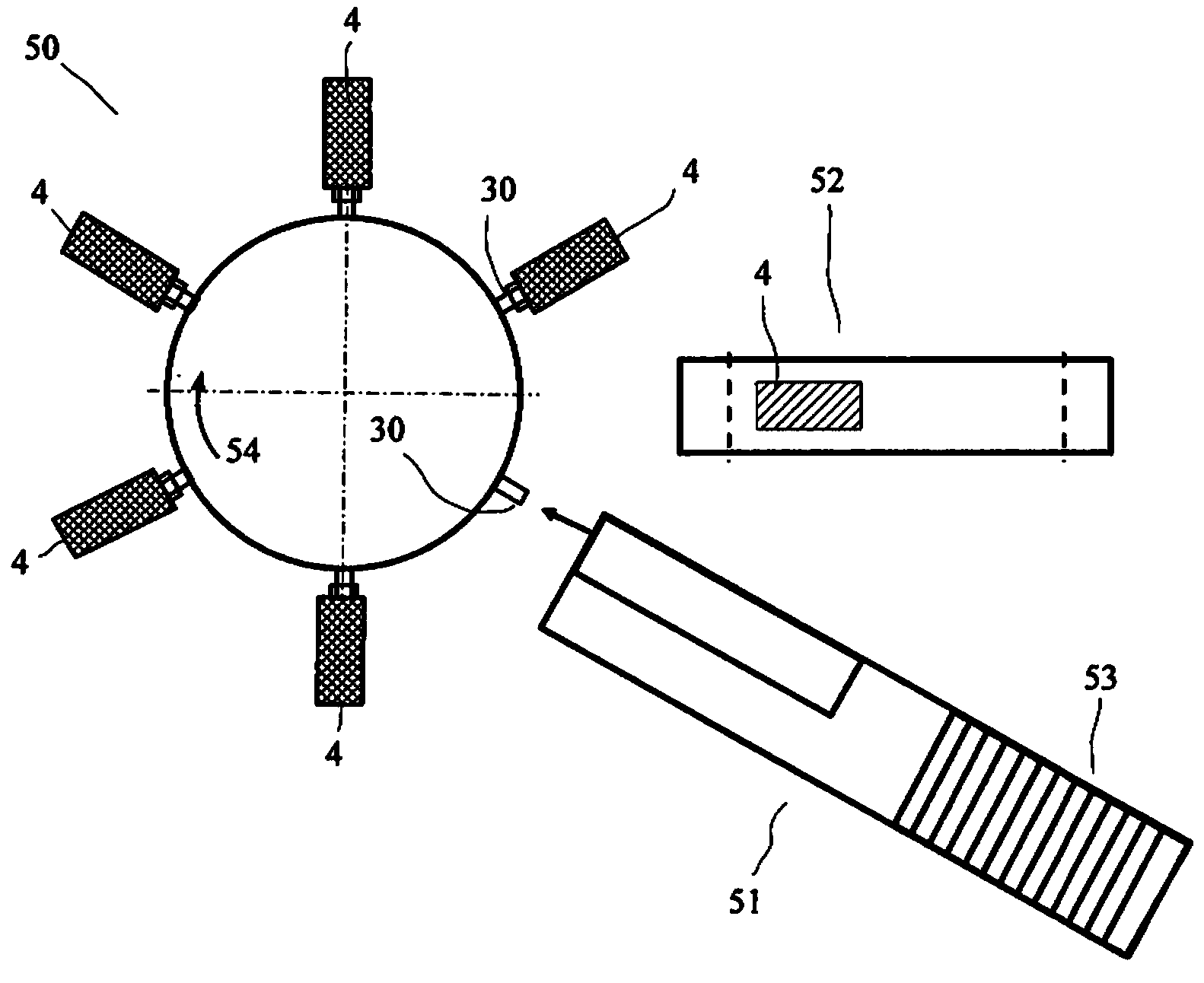

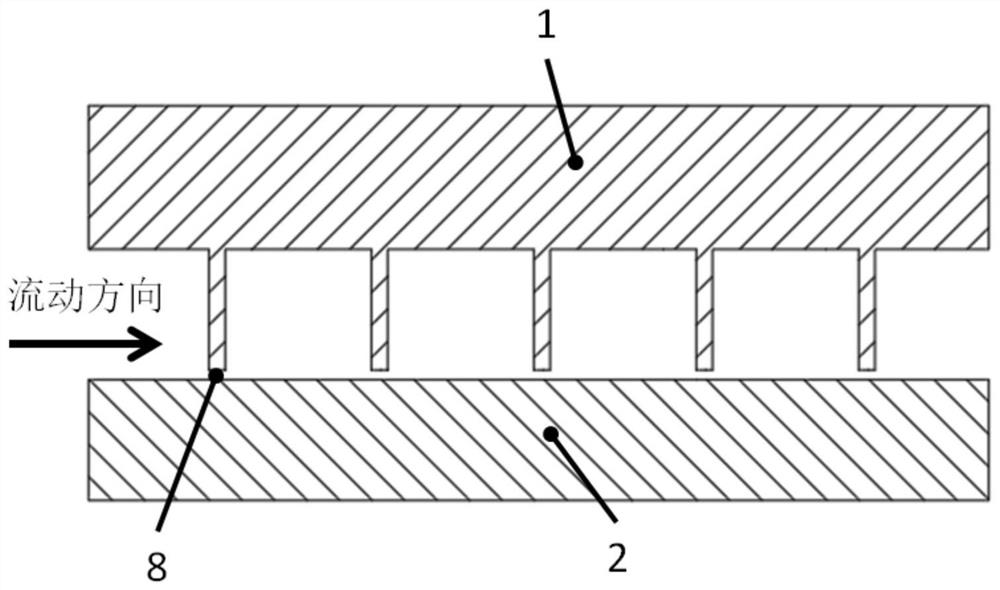

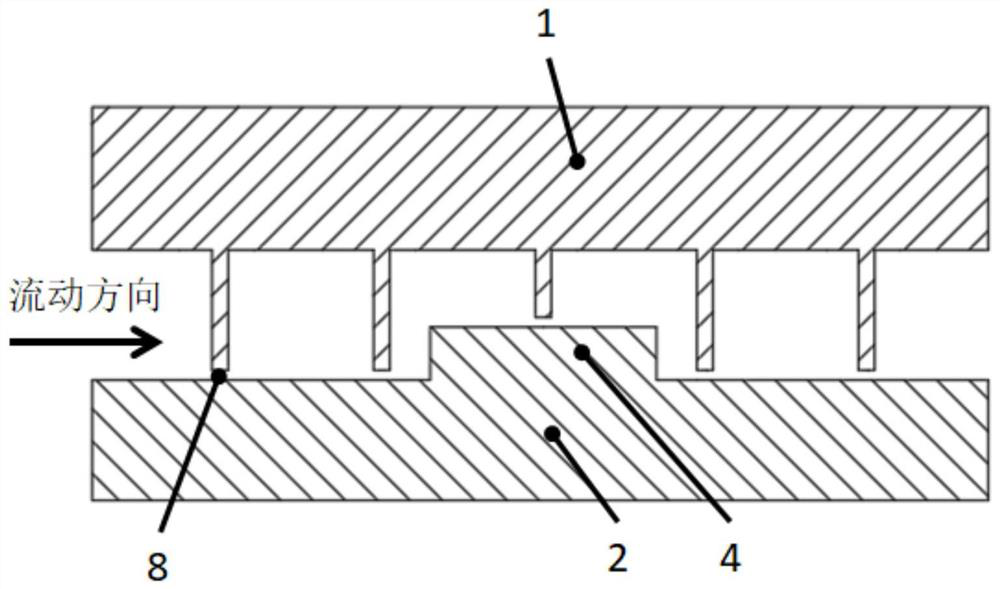

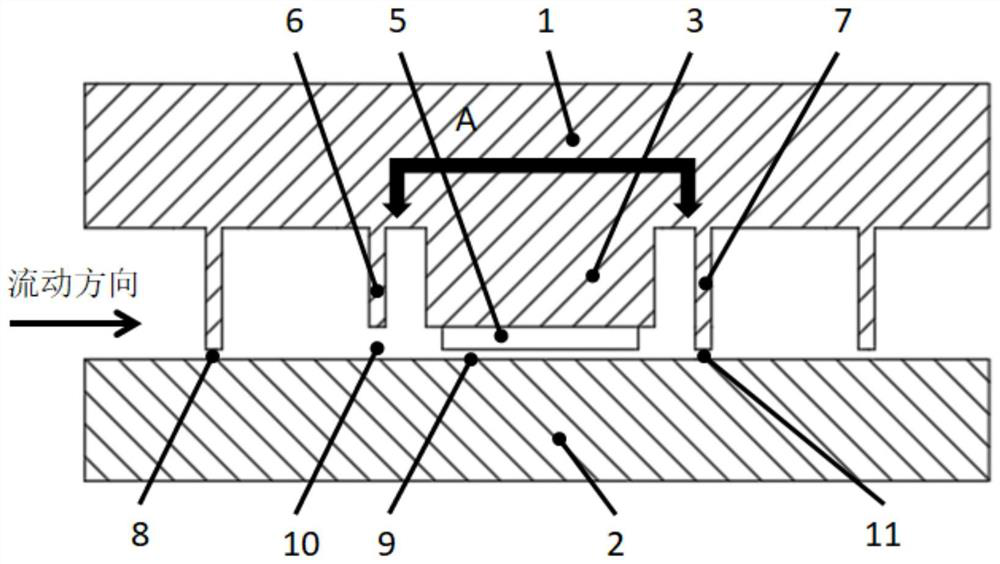

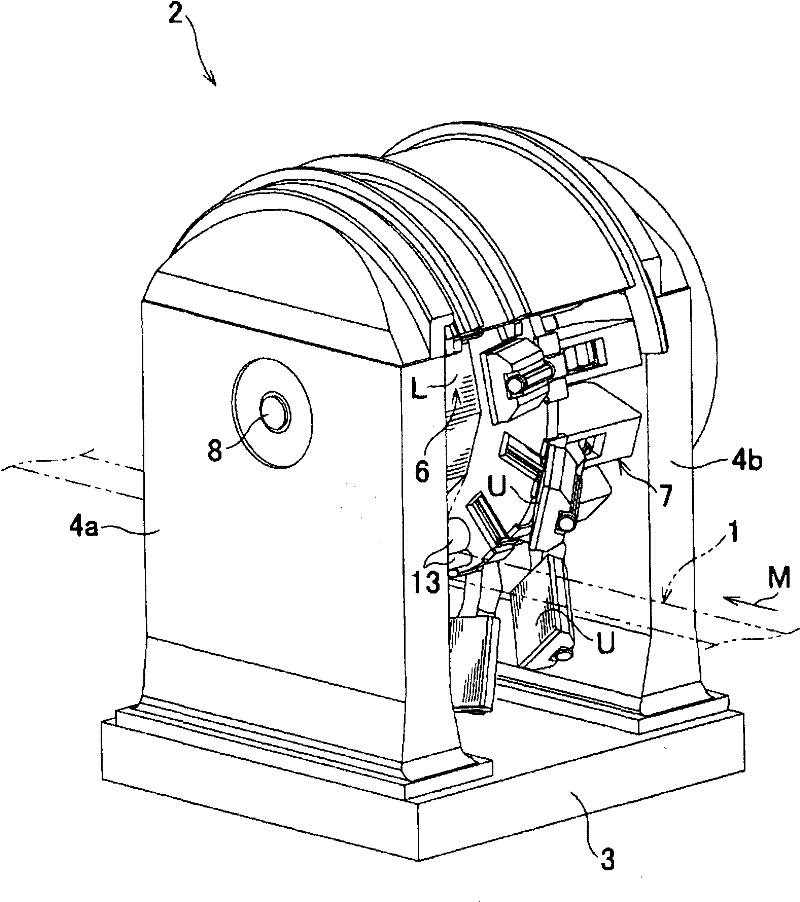

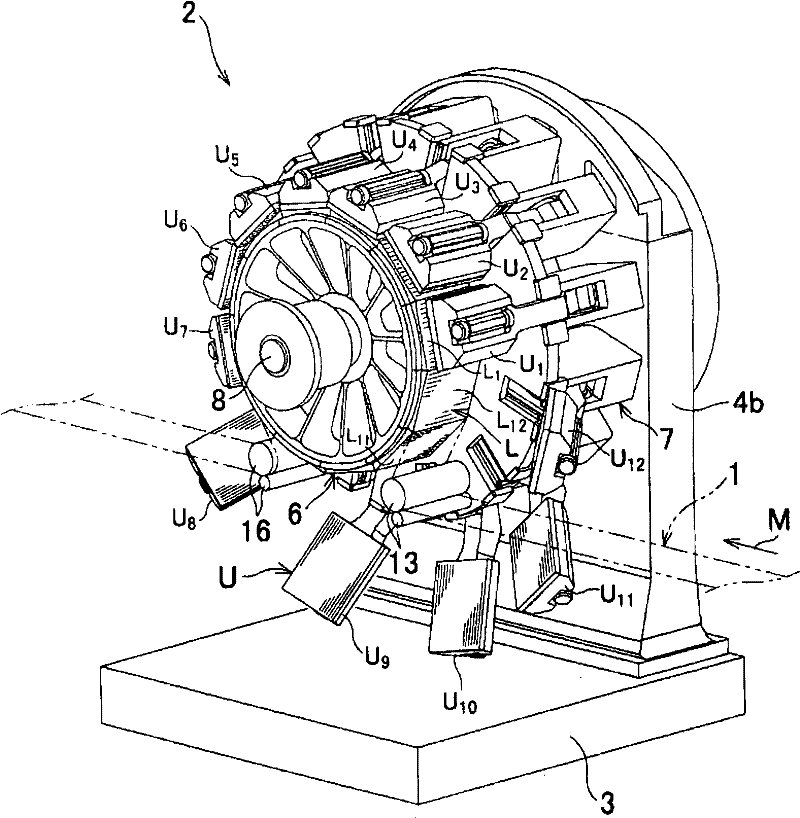

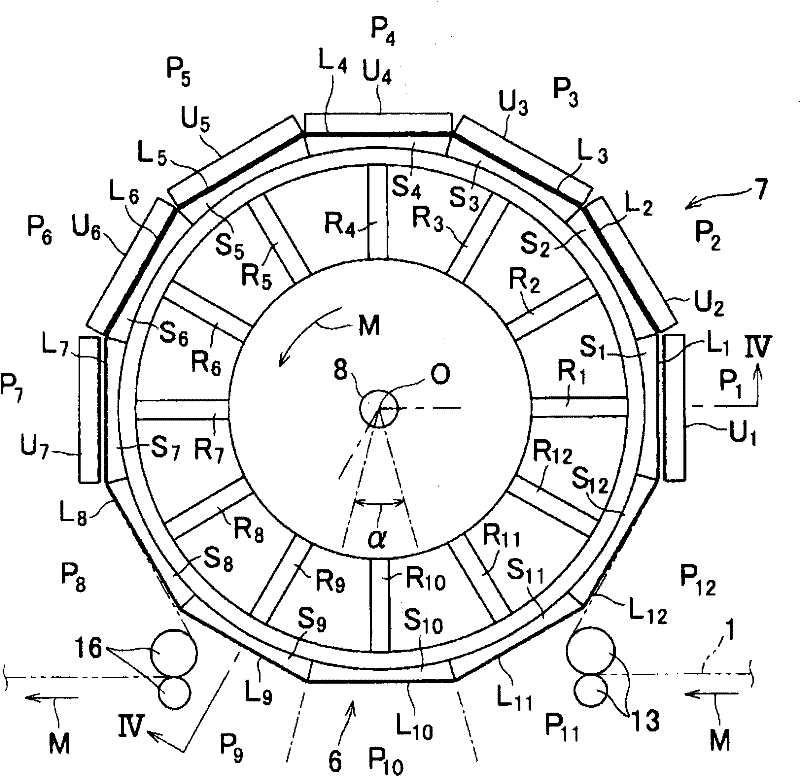

Device for stretching web formed of thermoplastic synthetic resin

InactiveCN101490328AIncrease peripheral speedWell formedNon-woven fabricsStretchingSynthetic resinSheet material

The invention provides a device for stretching a web formed of thermoplastic synthetic resin ove r its entire width. The device (2) for stretching a web (1) formed of thermo plastic synthetic resin comprises a plurality of first stretching members (L) arranged in the peripheral direction on the peripheral surface of a drum (6) rotating in a machine direction (M). A rotation element (7) rotating in t he same direction of and in synchronization with the drum (6) is provided on the rotation shaft (8) of the drum (6). A plurality of second stretching me mbers (U) respectively corresponding to the first stretching members (L) are provided on the rotation element (7). Portions, facing in the radial direct ion of the drum (6), of respectively corresponding first stretching member (L) and second stretching member (U) are formed by protrusions (31, 41) and r ecesses (32, 42) extending in parallel to the shaft (8) and alternately arra nged in the peripheral direction of the drum (6) to form a complementary sha pe meshing detachably in the radial direction of the drum (6). At least one of the first stretching member (L) and the second stretching member (U) is f ormed to be movable in the radial direction of the drum (6).

Owner:UNI CHARM CORP

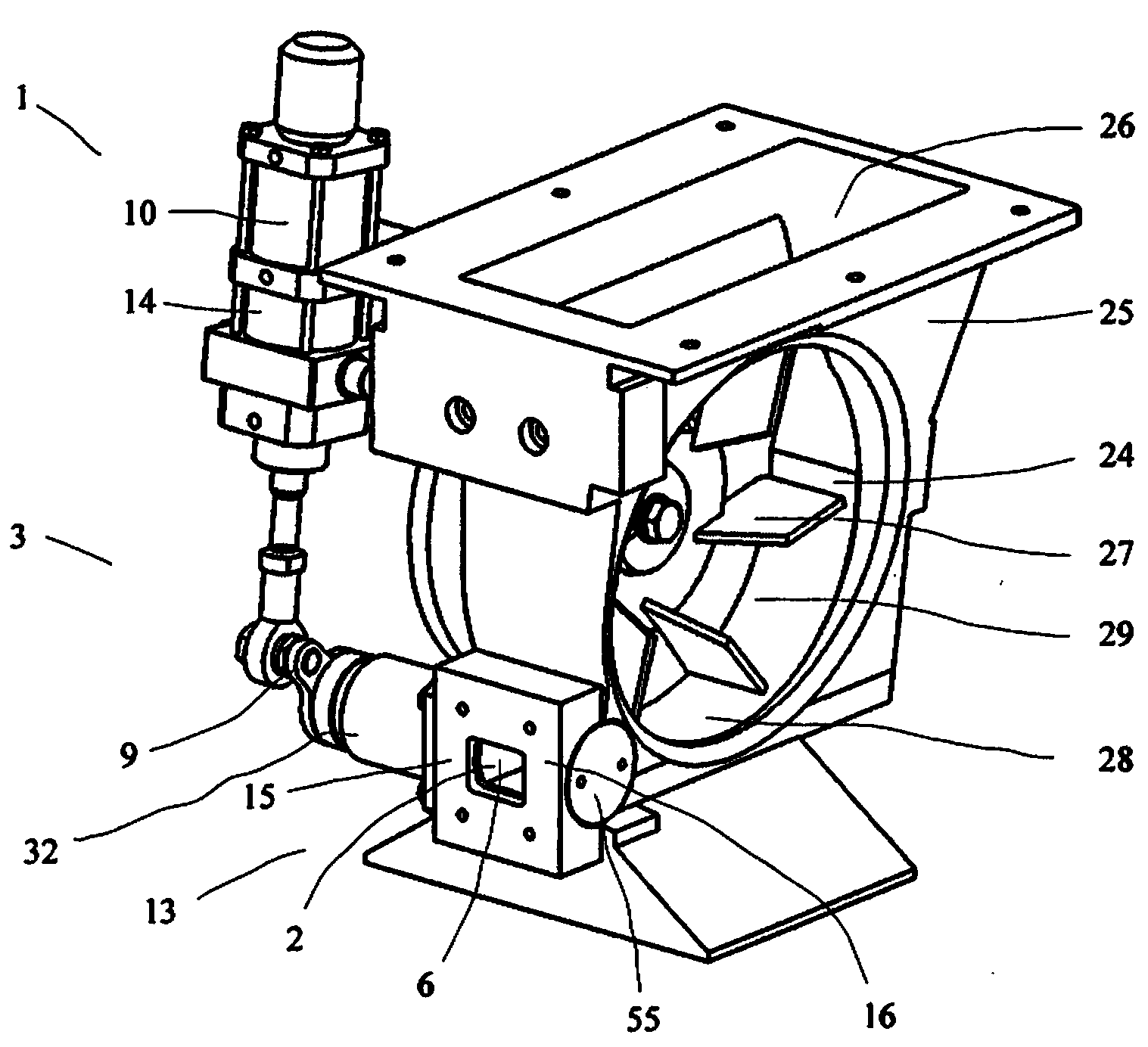

Filing device for packaging machine

ActiveCN104125917AIncrease peripheral speedCompact structurePlug valvesSolid materialEngineeringFill device

The invention relates to a filling device (1) for a packaging machine and to a packaging machine having a filling device that includes a filling channel (2) and a controllable channel closure (3) in order to control the flow through the filling channel of a bulk material (5) to be filled into a valve sack (4). The channel closure comprises a pivotable closure element (6) which is arranged within the filling channel and the pivot axis (7) of which extends transversely with respect to the filling channel in such a way that, when closed, the channel closure completely closes the filling channel and, when fully open, completely opens the filling cross section.

Owner:HAVER & BOECKER

Rotary spiral gas anchor

The invention discloses a rotary spiral gas anchor. The gas anchor comprises an anchor shell, an upper connector is arranged at one end of the anchor shell, a lower connector is arranged at the otherend of the anchor shell, a central pipe extending in the axial direction is arranged in the anchor shell, and a spiral body is rotatably arranged in the middle of the central pipe; one end of the spiral body is installed on the central pipe through a first rotating piece, and the other end of the spiral body extends towards the upper connector and is installed on the central pipe through a secondrotating piece; an annular installation step is arranged on the outer ring of the end, close to the lower connector, of the central pipe and abuts against the first rotating piece; and the outer ringof the end, close to the upper connector, of the central pipe is sleeved with a compression spring, one end of the compression spring abuts against the second rotating piece, and the other end of thecompression spring abuts against the upper connector. The rotary spiral gas anchor is impacted by gas and liquid fluid to rotate, and the gas and liquid can be separated more efficiently through the rotating spiral body.

Owner:YANGTZE UNIVERSITY

Positioning vehicle for positioning a test probe

InactiveUS7252304B2Extensive and time-consumingShorten the timeAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement apparatus componentsMobile vehicleSimulation

Described is a method for operating a positioning vehicle for positioning a test probe in defined intervals along a travel line, as well as to a positioning vehicle for carrying out the method. The positioning vehicle contains a traveling vehicle base part with a guide device and with a test probe carrier guided by this guide device in a guide. The guiding has a first reversal point and a second reversal point. The guide device comprises guide means in order on displacing the vehicle base part to guide the test probe carrier in the travel direction up to the first reversal point after it has reached the second reversal point, and in order to lead back the test probe carrier opposite to the travel direction up to the second reversal point after it has reached the first reversal point. In the phase of the return, the test probe carrier relative to the vehicle base part has the negative speed of the vehicle base part. Described is also a device which permits in particular objects having large surfaces to be scanned with little effort.

Owner:BAM

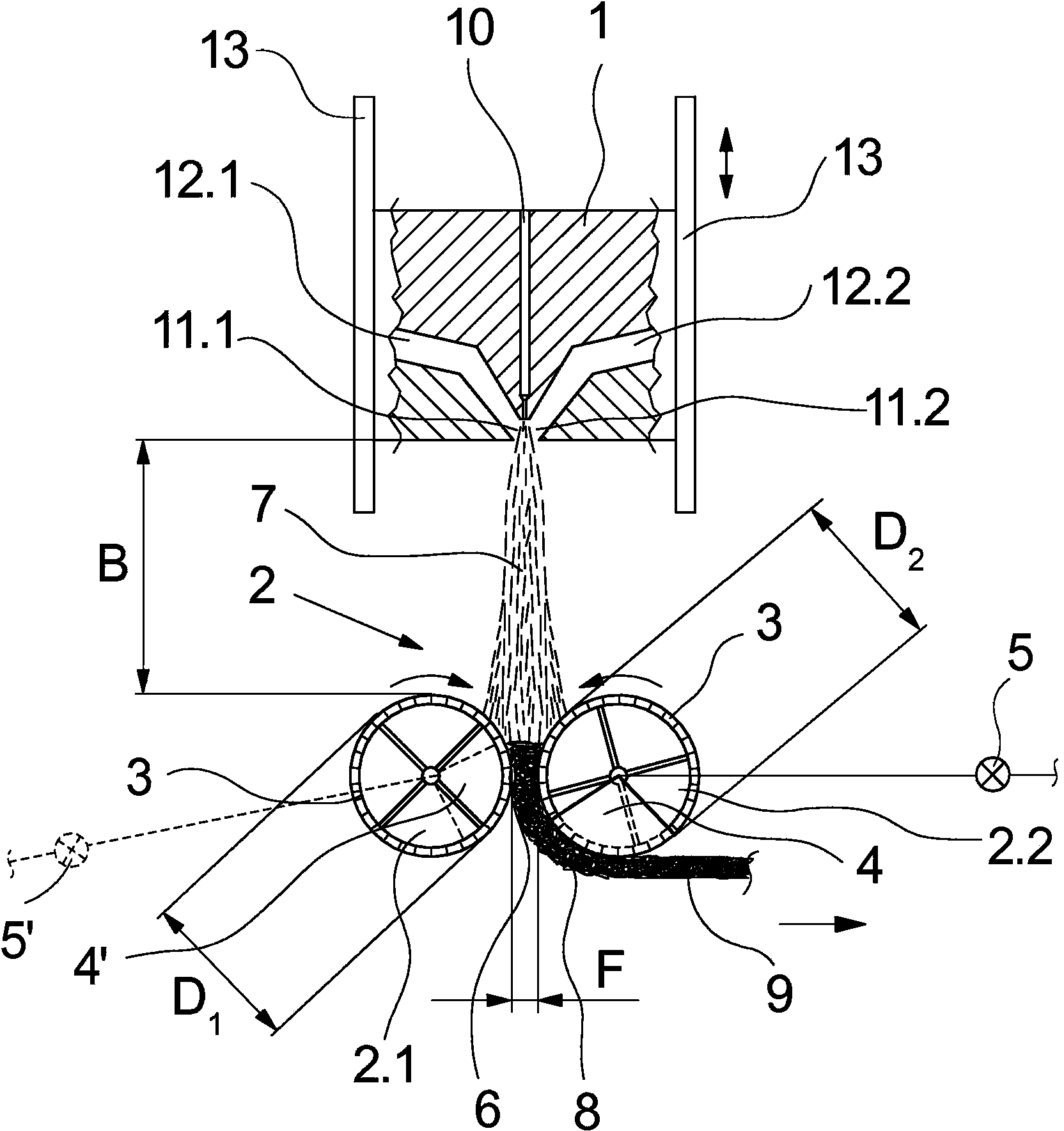

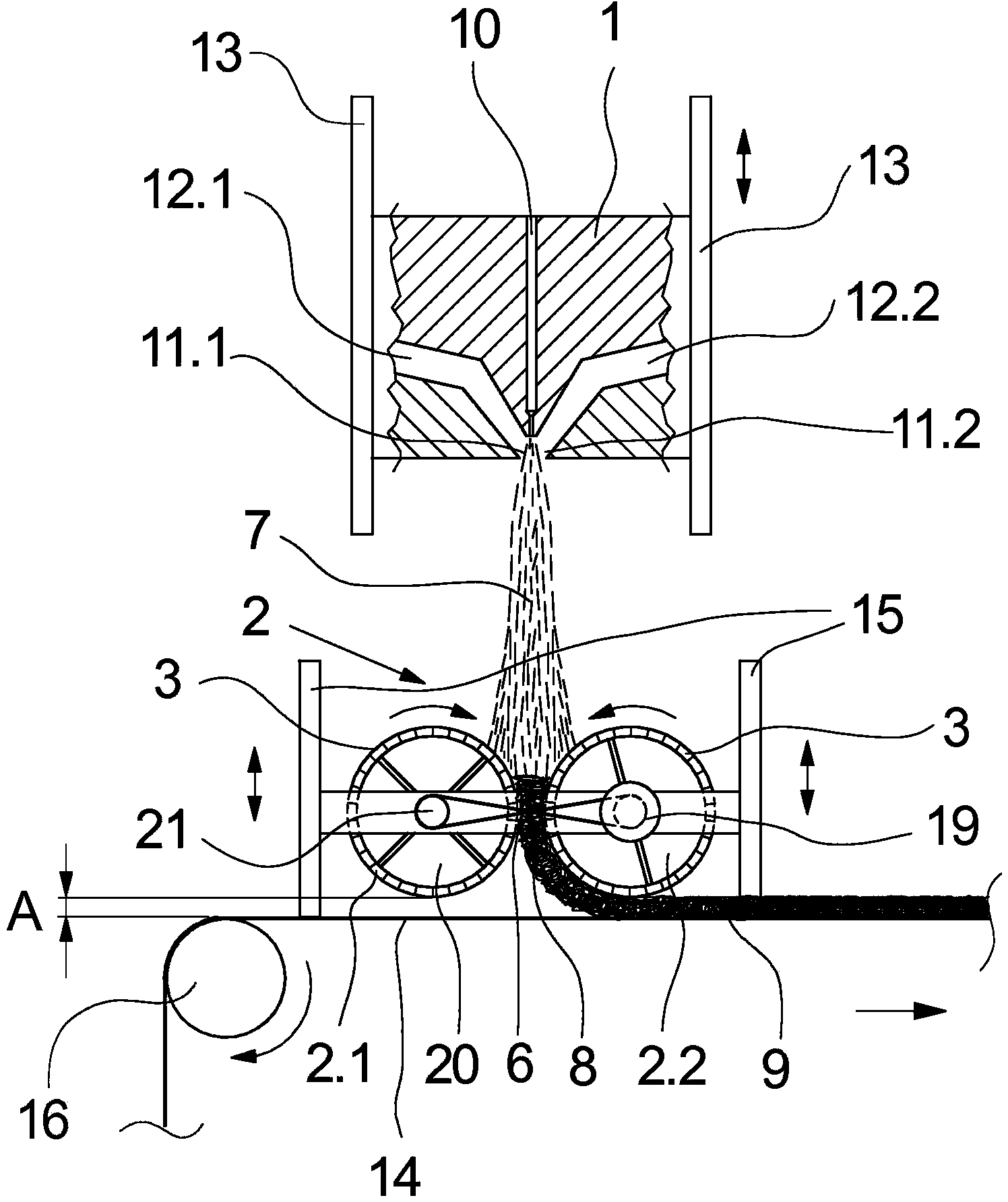

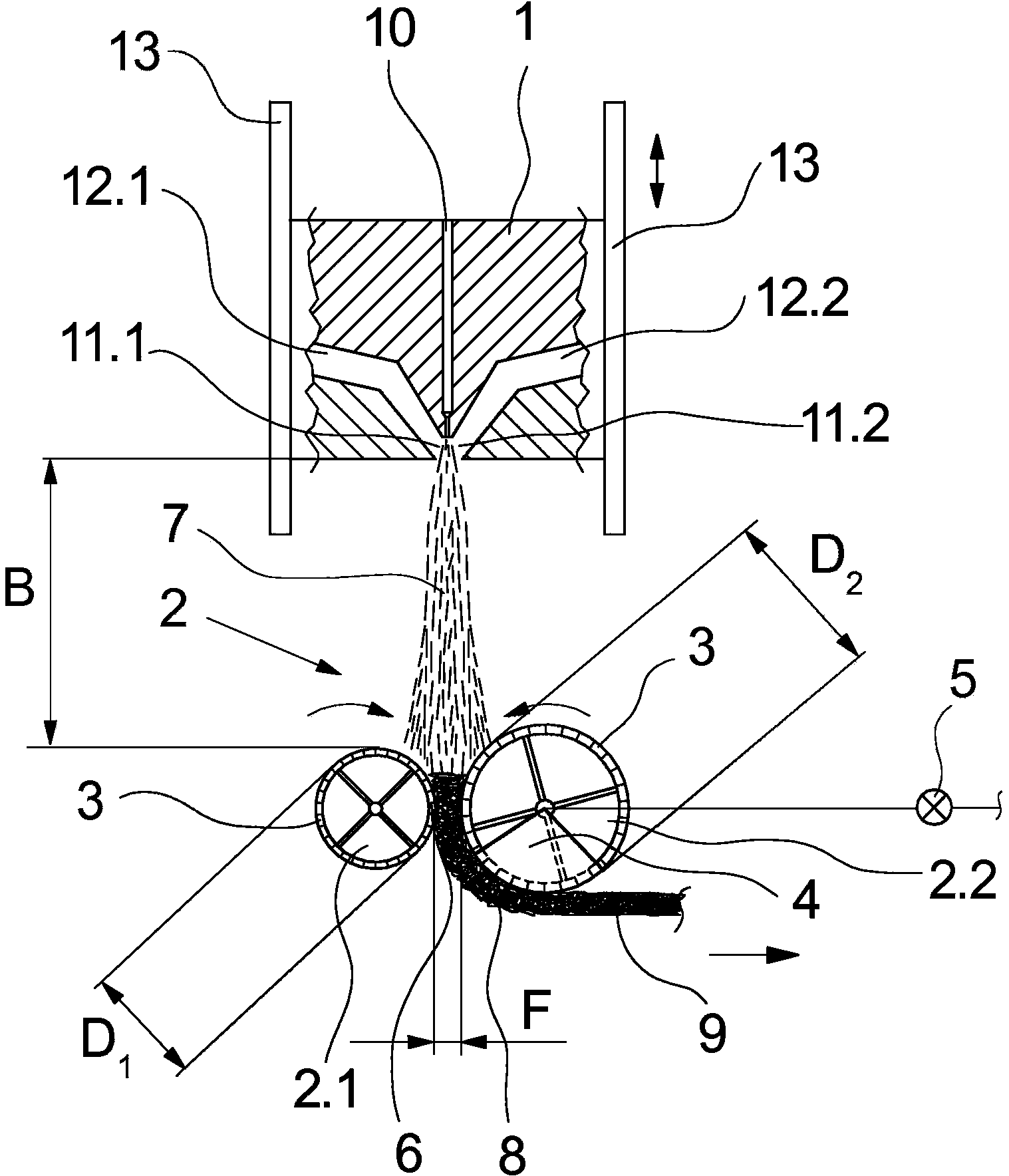

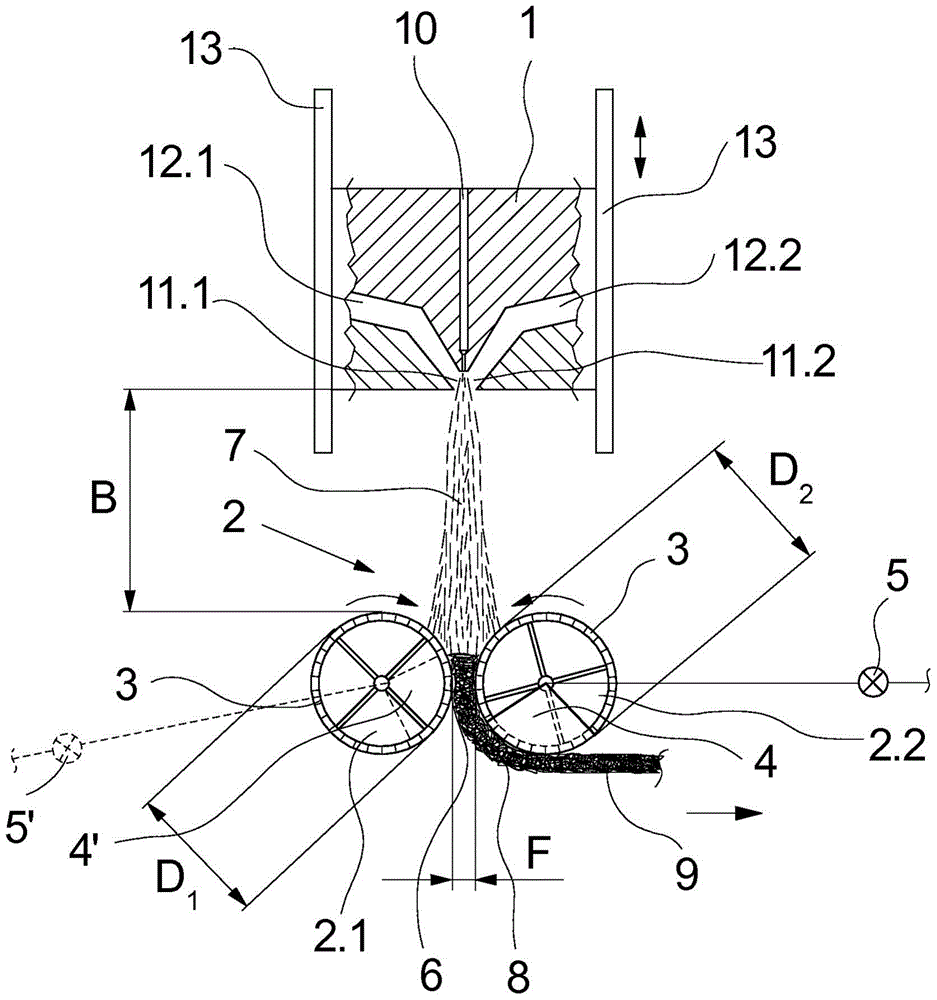

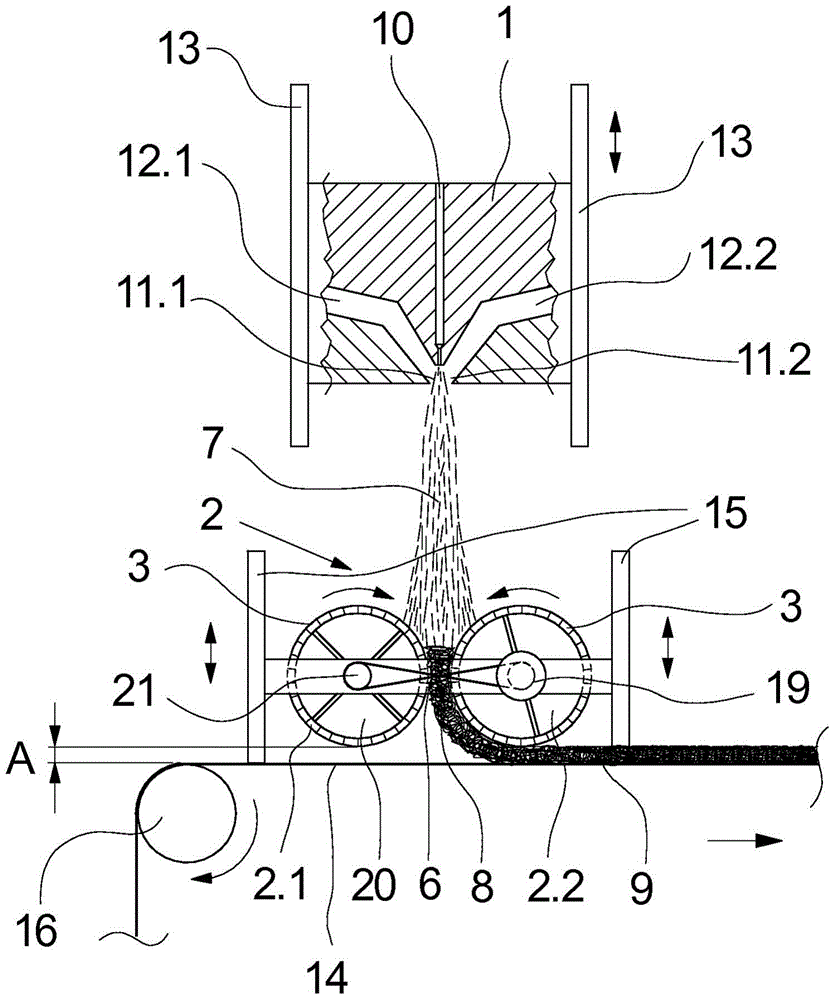

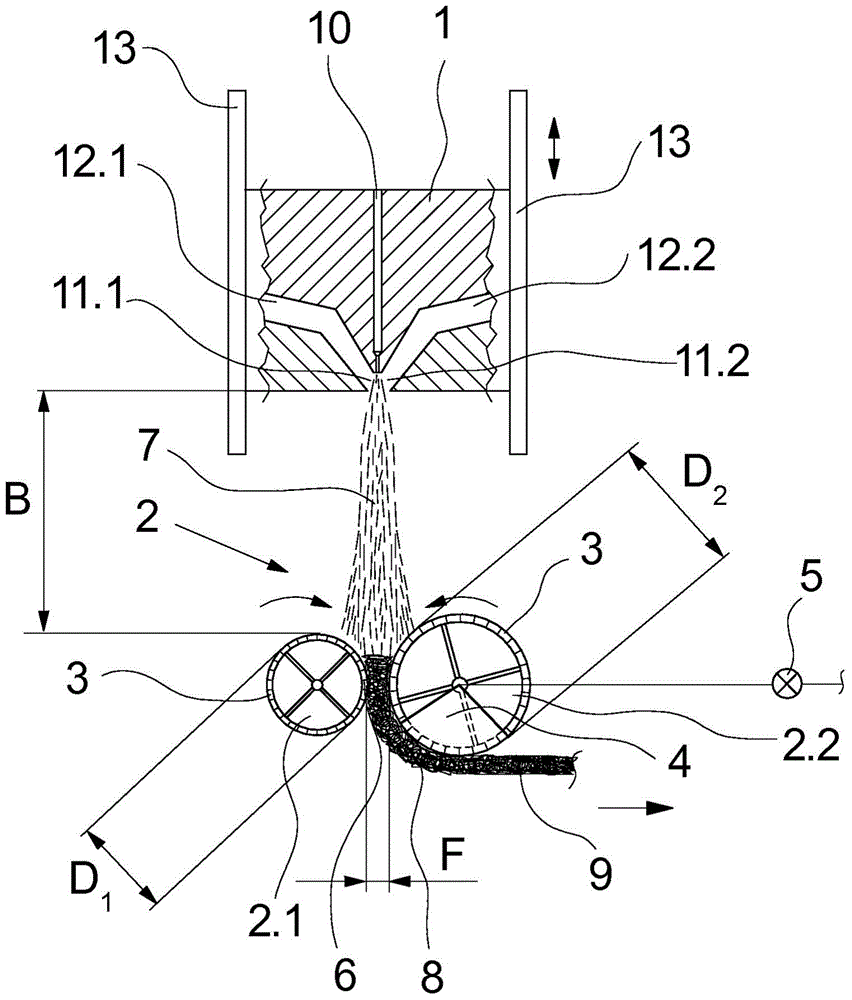

Method and device for melt-blowing, forming and plaiting finite fibres to produce a fibrous nonwoven

ActiveCN104246045AIncrease peripheral speedBlowing path shortened or extendedMelt spinning methodsNon-woven fabricsEngineeringMelt blowing

Owner:OERLIKON TEXTILE GMBH & CO KG

Method and apparatus for meltblowing, forming and laying up finite fibers into fibrous nonwovens

ActiveCN104246045BBlowing path shortened or extendedFavorable vertical orientationMelt spinning methodsNon-woven fabricsPolymer scienceMelt blowing

The present invention relates to a method and apparatus for meltblowing, forming and laying up finite fibers into fibrous nonwovens. In this case, the fiber flow generated by the melt blowing nozzle and the hot gas flow is blown into the forming gap of the forming element, wherein the fibers are combined within the forming gap to form a fiber composite. In order to influence the filling and shaping of the fibers inside the forming gap directly below the meltblowing nozzle, according to the invention the fibers are guided freely essentially vertically on an adjustable blowing path from the meltblowing nozzle to the forming gap, wherein The adjustment range of the blowing path is 100mm to 2000mm. This advantageously enables not only very fine fibers but also coarse fibers to be formed into a loose fiber composite.

Owner:OERLIKON TEXTILE GMBH & CO KG

An air intake ventilation structure for aircraft auxiliary power system

ActiveCN107416214BIncrease peripheral speedEliminate backflowPower plant cooling arrangmentsPower installationsInlet channelClassical mechanics

The invention discloses an air inlet ventilation structure used for an aircraft auxiliary power system. The structure comprises an aircraft auxiliary power system cabin (1) and an air inlet channel (2) which is formed in the aircraft auxiliary power system cabin. An auxiliary power system body (3) is arranged in the aircraft auxiliary power system cabin and communicates with the air inlet channel. A closed type annular guide channel (5) is formed in the inner wall of the aircraft auxiliary power system cabin. A cat ear air inlet (4) is formed in the aircraft auxiliary power system cabin and communicates with the guide channel. Diversion spray nozzles (6) are arranged in the positions, perpendicular to the aircraft auxiliary power system cabin, of the guide channel, are located at the side, close to the auxiliary power system body, of the guide channel, and communicate with the guide channel. According to the air inlet ventilation structure provided by the invention, a single cooling air inlet is changed into a plurality of cooling air inlets based on a prior air inlet ventilation structure, and flowing and heat exchanging in the auxiliary power cabin are optimized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Sealing device, centrifugal compressor and gas turbine

PendingCN111878448AIncrease peripheral speedIncrease centrifugal forcePump componentsPumpsEngineeringCentrifugal compressor

The invention discloses a sealing device, a centrifugal compressor and a gas turbine. The sealing device comprises an impeller hub, a diffuser body and a sealing part, the sealing part is located between the impeller hub and the diffuser body, the sealing part is arranged on the impeller hub, and the sealing part is located in front of sealing comb teeth in the leakage flow direction of a workingmedium, wherein the sealing part can rotate along with rotation of the impeller hub, so that the kinetic energy of the working medium flowing through the sealing part is reduced. According to the sealing device, when the sealing part rotates along with rotation of the impeller hub, the sealing part does positive work on the working medium in the circumferential direction and the centripetal direction of the impeller hub, and kinetic energy of the working medium flowing through the sealing part is reduced, so that the total pressure between the impeller hub and the diffuser body is greatly reduced, the pressure difference between the front portion and the rear portion of the sealing comb teeth is greatly reduced, the sealing effect is improved, the efficiency loss of the centrifugal compressor is reduced, and the efficiency of the centrifugal compressor is improved.

Owner:新奥能源动力科技(上海)有限公司

A sulfur tail gas supergravity desulfurization device

ActiveCN106744705BAchieve partial oxidationImplement spin-inGas treatmentDispersed particle separationSulfurLiquid storage tank

The invention relates to a sulfur tail gas super-gravity desulfurization device and process thereof. The sulfur tail gas super-gravity desulfurization device comprises an alkali liquid storage tank and a super-gravity machine; the device utilizes alkali liquid to desulfurize sulfur tail gas, and a unique super-gravity machine structure is provided; in the structure, a hollow rotary shaft with a fluid channel is formed in a shell in a manner of penetrating through the middle axis of the shell, and a sleeve with a gas channel function sleeves the hollow rotary shaft; meanwhile, a rotary channel, which is communicated with a filling region and is provided with a spiral channel, is also formed on the basis; fluid passes through the hollow rotary shaft and then self rotation of the fluid is realized through the rotary channel, and then the fluid enters the filling region; the liquid is crushed and torn into small liquid drops under the action of a centrifugal force of liquid and is in sufficient contact with liquid reverse-flow small bubbles, and a phase interface, which is rapidly updated, is provided; crushing and tearing mixing of the fluid and gas is further realized by utilizing the self-rotation under a rotary state; the sufficient degree of gas-liquid contact is improved, and furthermore, the better sulfur tail gas desulfurization effect is obtained.

Owner:北京清大华亿科技有限公司 +2

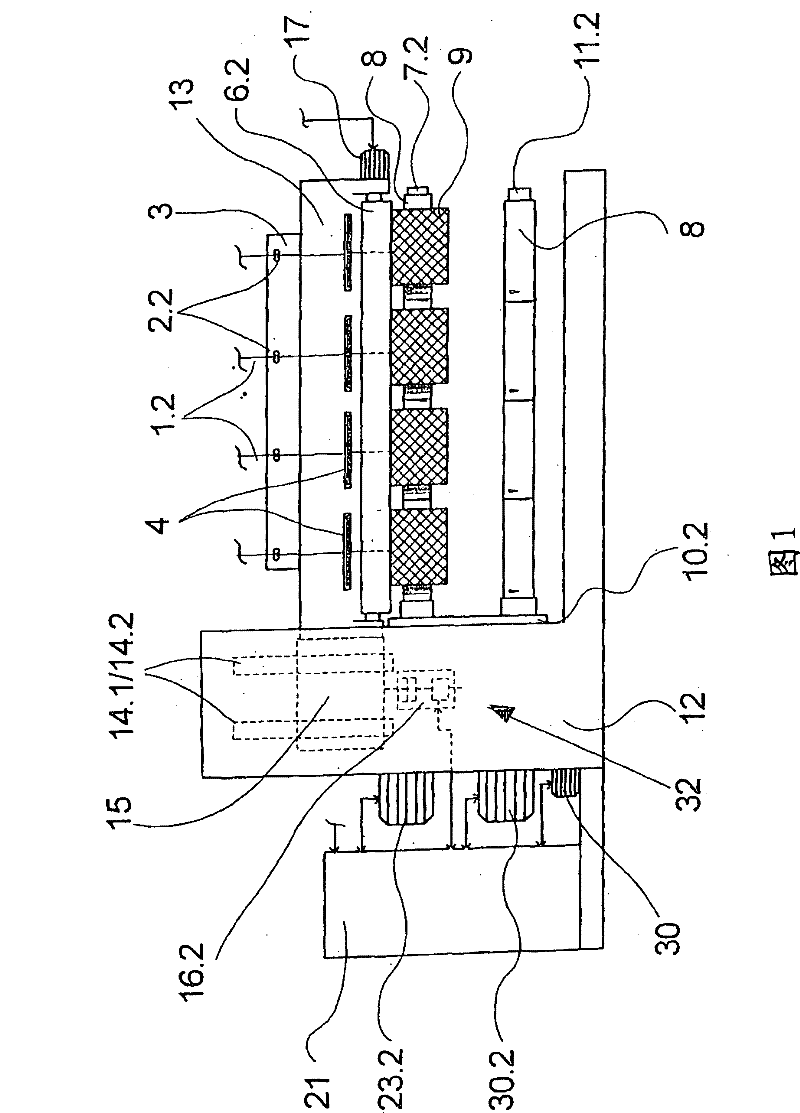

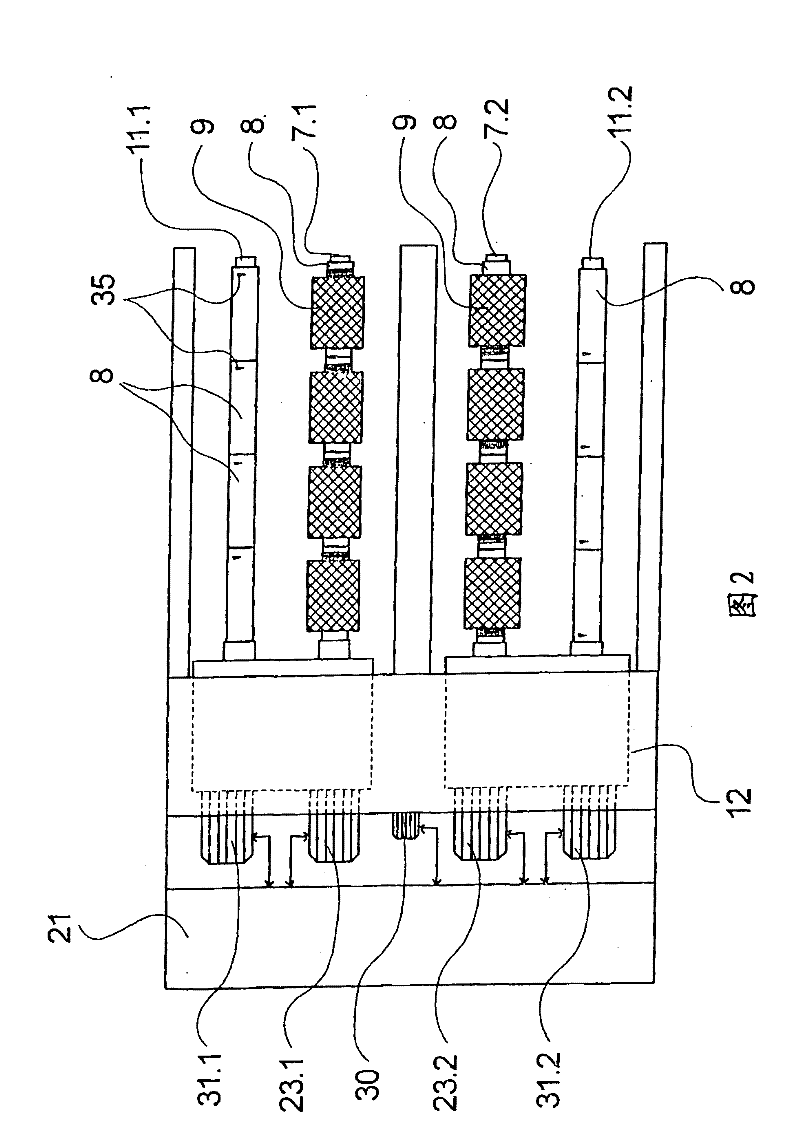

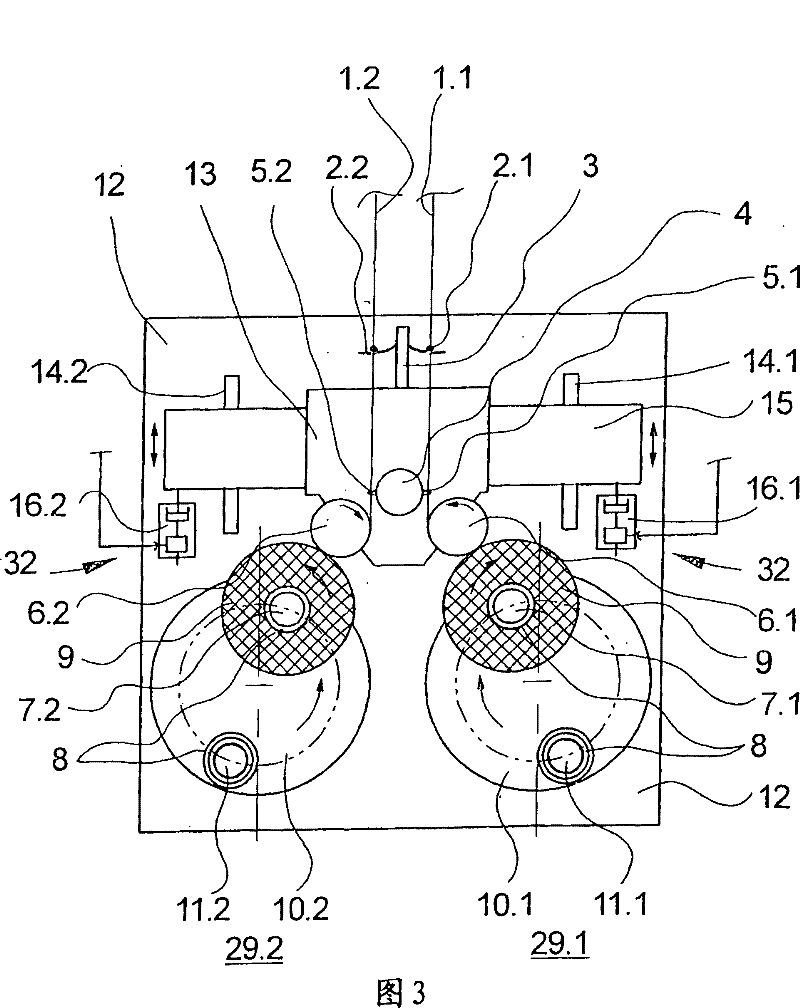

Method and device for continuously winding up several threads

Disclosed are a method and a device for continuously winding up several threads to bobbins. According to the invention, the bobbins are simultaneously retained and wound on two driven bobbin spindles (7.1, 7.2). Each of the bobbin spindles (7.1, 7.2) is disposed on two rotatably mounted bobbin revolvers (10.1, 10.2) which are provided with two additional driven bobbin spindles (11.1, 11.2) for taking over the threads and continuing the winding process. During the winding process, the threads are fed to the bobbins by means of two pressing rollers (6.1, 6.2) which are allocated to the bobbin spindles and rest against the circumference of the bobbins. In order to ensure that all threads are pulled as uniformly as possible off a device that is mounted upstream when changing bobbins on both bobbin spindles (11.1, 11.2), the pressing rollers (6.1, 6.2) are driven at a thread-guiding circumferential speed which is greater than the circumferential speed of the bobbins of both bobbin spindles (11.1, 11.2) when changing the bobbin spindle. To this avail, both pressing rollers (6.1, 6.2) are driven by a joint roller drive unit which is connected to a control device (21) that controls the rotary drive of the bobbin revolvers (10.1, 10.2).

Owner:OERLIKON TEXTILE GMBH & CO KG

Labyrinth seal for optimizing dynamic characteristics of rotor based on inter-tooth anti-rotation plates

ActiveCN113606344AIncrease peripheral speedImprove stabilityEngine sealsFluid dynamicsJet flowStructural engineering

The invention discloses a labyrinth seal for optimizing the dynamic characteristics of a rotor based on inter-tooth anti-rotation plates. The labyrinth seal comprises a sealing stator and a sealing rotor, and a plurality of groups of anti-rotation plate structures are arranged on the wall surface of the sealing stator and located between sealing teeth. Each group of anti-rotation plate structures are evenly distributed in a circumferential direction and deflect in a reverse rotation direction on the meridian plane, so that an airflow can flow to the downstream in the reverse rotation direction through flow guiding of the anti-rotation plate structures. Meanwhile, sealing gaps of upstream sealing teeth and / or downstream sealing teeth adjacent to the anti-rotation plate structures can be changed, so that a radial height of an inter-tooth jet flow is increased. A circumferential rotational flow generated by inlet pre-rotation and rotor rotation in the seal has a great promotion effect on tangential airflow exciting force generated by cross stiffness in a same direction as rotation, and rotor instability can be caused. The labyrinth seal disclosed by the invention can achieve the purposes of weakening the circumferential rotational flow in a sealing cavity, weakening the cross stiffness and enhancing the sealing stability and can well meet the dynamic characteristic requirement of the labyrinth seal rotor so as to improve the turbine operation stability.

Owner:XI AN JIAOTONG UNIV

Device for stretching web formed of thermoplastic synthetic resin

InactiveCN101490328BIncrease peripheral speedWell formedNon-woven fabricsStretchingSynthetic resinMechanical engineering

The invention provides a device for stretching a web formed of thermoplastic synthetic resin ove r its entire width. The device (2) for stretching a web (1) formed of thermo plastic synthetic resin comprises a plurality of first stretching members (L) arranged in the peripheral direction on the peripheral surface of a drum (6) rotating in a machine direction (M). A rotation element (7) rotating in t he same direction of and in synchronization with the drum (6) is provided on the rotation shaft (8) of the drum (6). A plurality of second stretching me mbers (U) respectively corresponding to thefirst stretching members (L) are provided on the rotation element (7). Portions, facing in the radial direct ion of the drum (6), of respectively corresponding first stretching member (L) and second stretching member (U) are formed by protrusions (31, 41) and r ecesses (32, 42) extending in parallel to the shaft (8) and alternately arra nged in the peripheral direction of the drum (6) to form a complementary sha pe meshing detachably in the radial direction of the drum (6). At least one of the first stretching member (L) and the second stretching member (U) is f ormed to be movable in the radial direction of the drum (6).

Owner:UNI CHARM CORP

Integrated Blade Hydraulic-Magnetic Transmission Wellbore Cleaning Tool

ActiveCN104653130BIncrease peripheral speedImprove cleaning efficiencyFlushingCouplingMagnetic poles

The invention relates to an integrated blade hydraulic-magnetic transmission wellbore cleaning tool, which is composed of a flow tube shell, a rotating magnetic core, an upper gage body, and a rotating blade. , the outer wall of the flow tube shell is provided with a lower gage body and a limit ring, and the upper gage body is installed on one side of the limit ring; the rotating magnetic core is integrally formed by the drum and the shaft, and the transition section between the drum and the shaft has a drilling Liquid hole, fixed hydraulic conversion device outside the rotating shaft, permanent magnets are evenly distributed on the outer wall of the rotating drum, and the magnetic poles of two adjacent permanent magnets are opposite in direction; the rotating magnetic core is installed in the flow tube shell, and the rotating blade is set outside the flow tube shell There is a bearing raceway on the outer wall of the flow tube shell, which corresponds to the bearing raceway of the rotating blade. Rolling bodies are installed in the bearing raceway, and there are sealing grooves on the outer wall of the flow tube shell; the rotating blade is integrated, and the inner wall of the cylinder is uniformly distributed. The magnetic poles of two adjacent permanent magnets are opposite in direction; the outer wall of the rotating blade is also equipped with an oil storage sealing compensation system. The invention adopts hydraulic-magnetic coupling transmission and is not limited by whether the drill pipe rotates, and can greatly improve the wellbore cleaning efficiency.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for mfg. hydraulic bearing device

InactiveCN1451890AIncrease peripheral speedPrevent centrifugal rotationLathesRevolution surface grinding machinesGrindstoneContact method

Methods for making hydrodynamic bearing devices are provided. The method can effectively increase the peripheral speed when grinding the axial element which is the structural element of the hydrodynamic bearing device, and can prevent centrifugal rotation to improve grinding efficiency and work efficiency, and improve product quality at the same time. An axial member serving as a structural member of a hydrodynamic bearing device is supported at both ends in surface contact using a pair of plate members while rotating the axial member about its axis. The peripheral surface of the axial portion of the axial member is ground on a grinding stone while supporting the peripheral surface of the axial portion with a supporting member. Furthermore, the plate member which is in surface contact with the flange portion of the axial member is formed with at least one turned-out portion in a predetermined area of the center of rotation of the contact surface thereof. In addition, the contact portion of the plate member with the flange portion is elastically supported by an elastic member.

Owner:NTN CORP

Circumferential acceleration type material issuing chamber for horizontal screw centrifugal machine

The invention discloses a circumferential acceleration type material issuing chamber for a horizontal screw centrifugal machine. The circumferential acceleration type material issuing chamber for the horizontal screw centrifugal machine is characterized in that a material issuing chamber body is fixedly arranged in a hollow shaft of a spiral conveyor and rotates along with a spiral conveying shaft; the material issuing chamber comprises a first conical cavity, first-stage blades, a second conical cavity and second-stage blades, wherein the small end face of the first conical cavity is of a convex circular structure, the convex circle of the small end face of the first conical cavity faces an outlet of the feeding pipe, the first-stage blades are uniformly welded on the conical surface of the first conical cavity in the circumferential direction, inlet edges of the first-stage blades are flush with the outlet plane of the feeding pipe, and outlet edges of the first-stage blades are flush with the large end face of the first conical cavity; the large end face of the second conical cavity faces the large end face of the first conical cavity, the feeding pipe penetrates through the center of the small end face of the second conical cavity, the second-stage blades are uniformly welded between the large end face of the first conical cavity and the large end face of the second conical cavity in the circumferential direction, and the first conical cavity, the first-stage blades, the second conical cavity, the second-stage blades coincide with the axis of the feeding pipe. According to the circumferential acceleration type material issuing chamber, the separation efficiency of the horizontal screw centrifuge is improved.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com