Gas turbine interstage sealing ring structure

A technology of interstage seals and gas turbines, which is applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of unit performance degradation, circumferential speed difference, air flow temperature rise, etc., to improve unit efficiency, reduce speed difference, The effect of dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

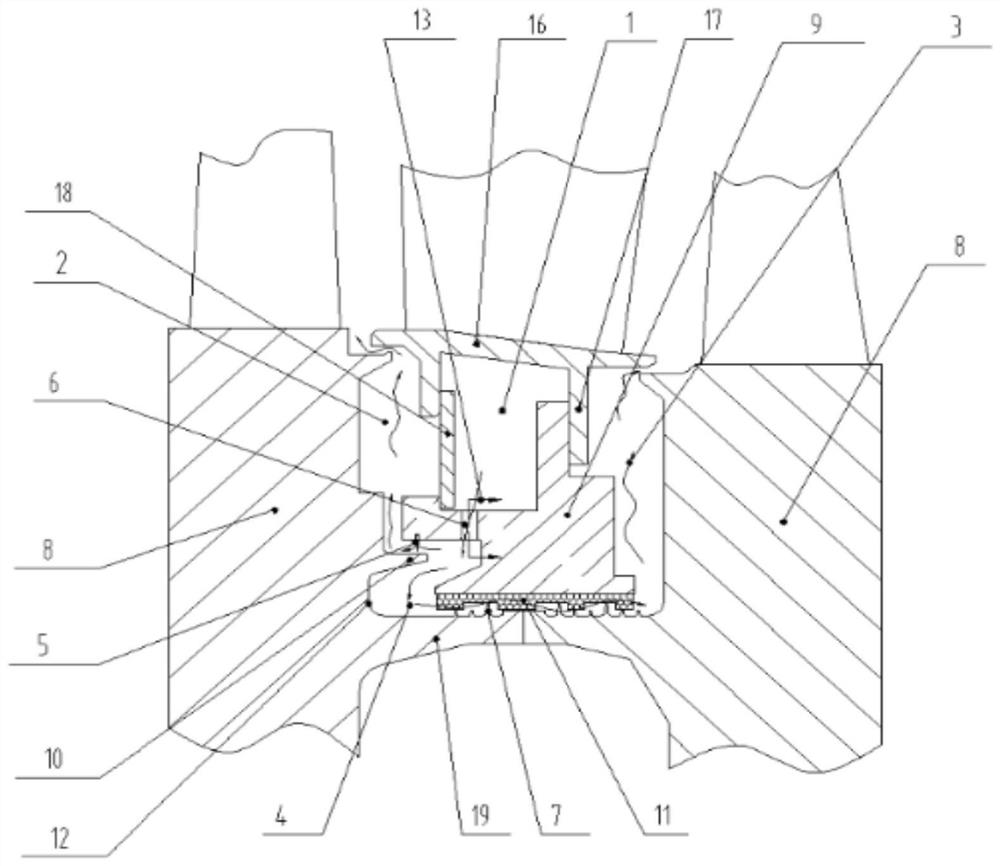

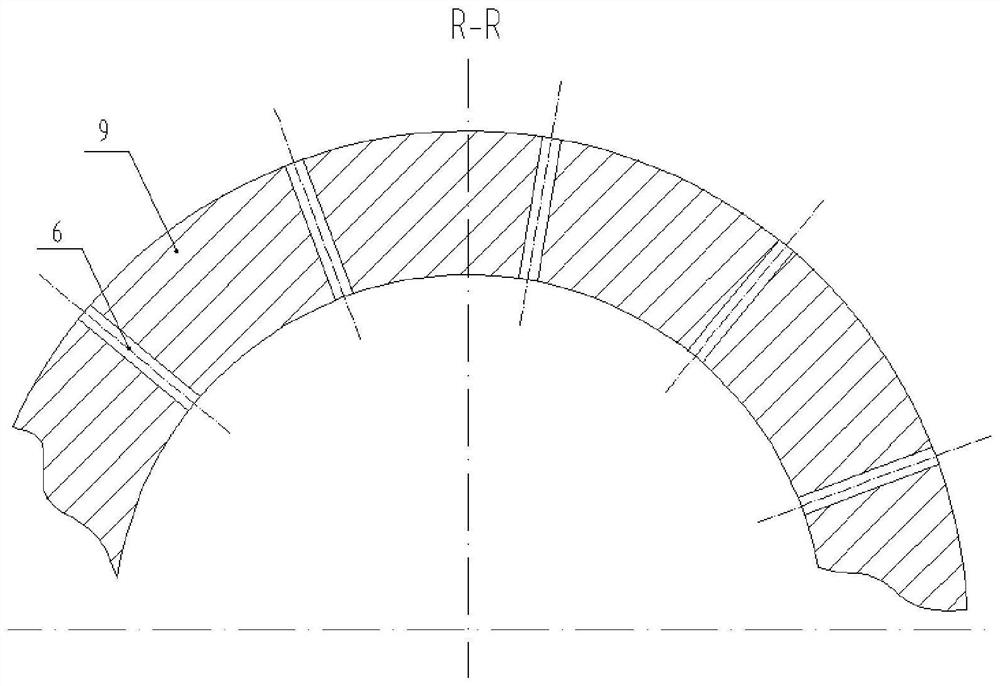

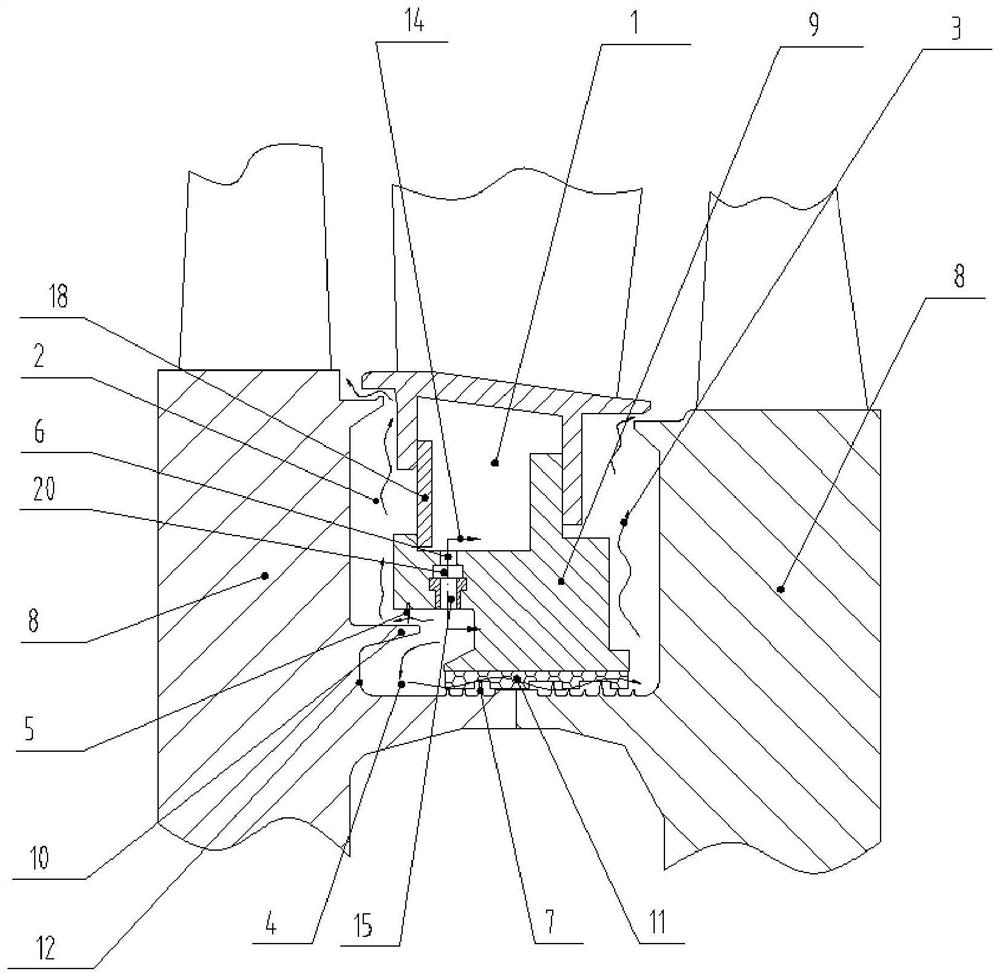

[0042] The present invention provides a gas turbine interstage seal ring structure, including an interstage seal ring 9:

[0043] The inner wall of the radial air supply hole 6 of the interstage seal ring 9 has a tangential angle structure, and the tangential angle β is greater than 0° and less than or equal to 60°, so that the airflow has a pre-rotation after passing through the radial air supply hole 6 . The larger the tangential angle, the more pre-rotation of the airflow, the greater the circumferential velocity of the resulting airflow, the smaller the relative velocity between the airflow and the rotor, and the smaller the temperature rise of the airflow due to frictional resistance. The amount of air-conditioning is also small.

[0044] The radial air supply hole 6 of the interstage seal ring 9 can also be provided with a detachable part 15 with a tangential angle on the inner wall to realize pre-rotation after the air flow passes through the radial air supply hole 6. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com