Construction method of inverted-Y-shaped upper tower column closed section

A construction method and a technology for closing sections, which are applied in buildings, bridges, bridge parts, etc., can solve problems such as high construction quality requirements, high safety management requirements, and difficult engineering techniques, so as to achieve less surface defects, ensure engineering quality, and improve engineering quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

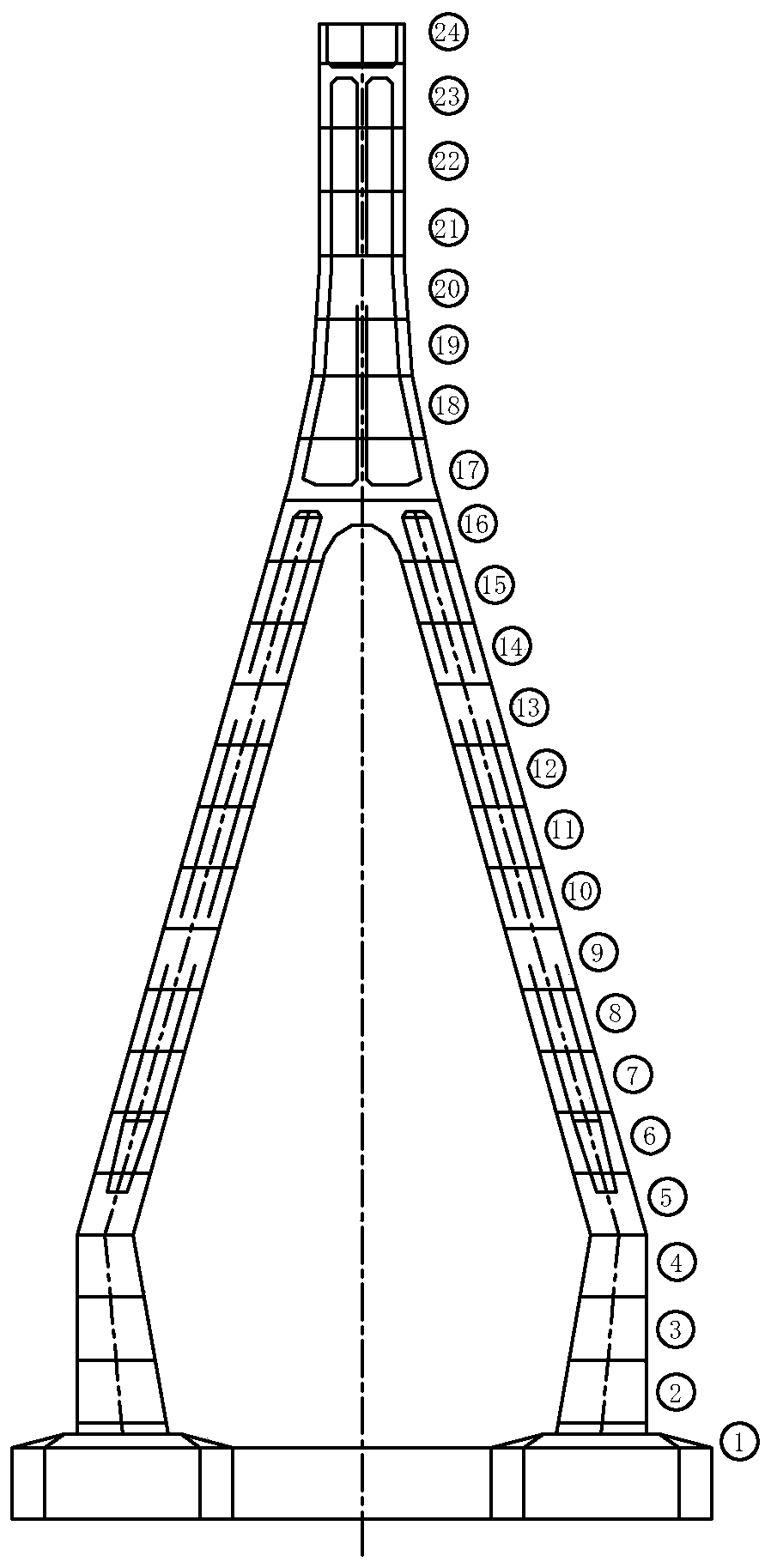

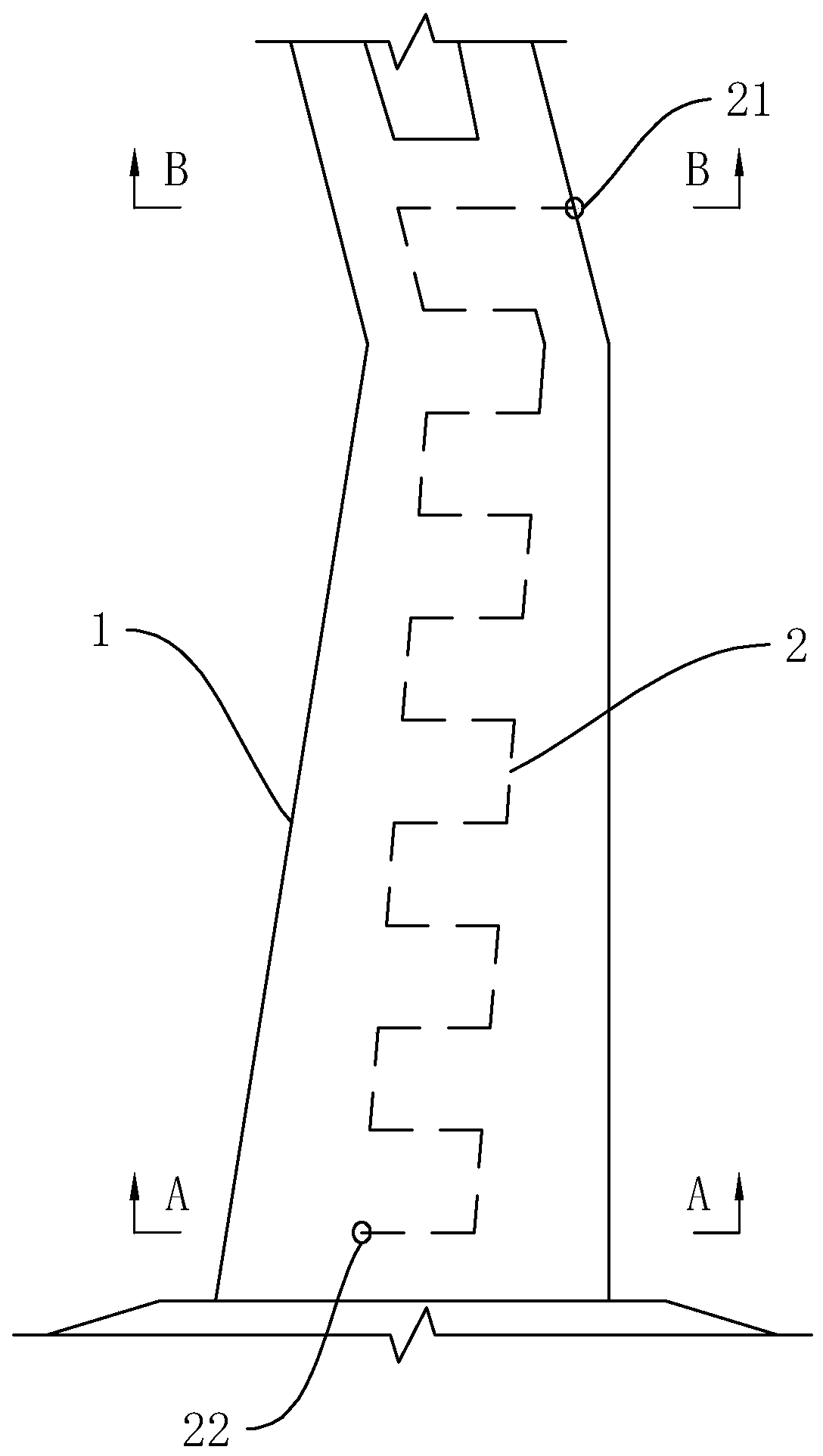

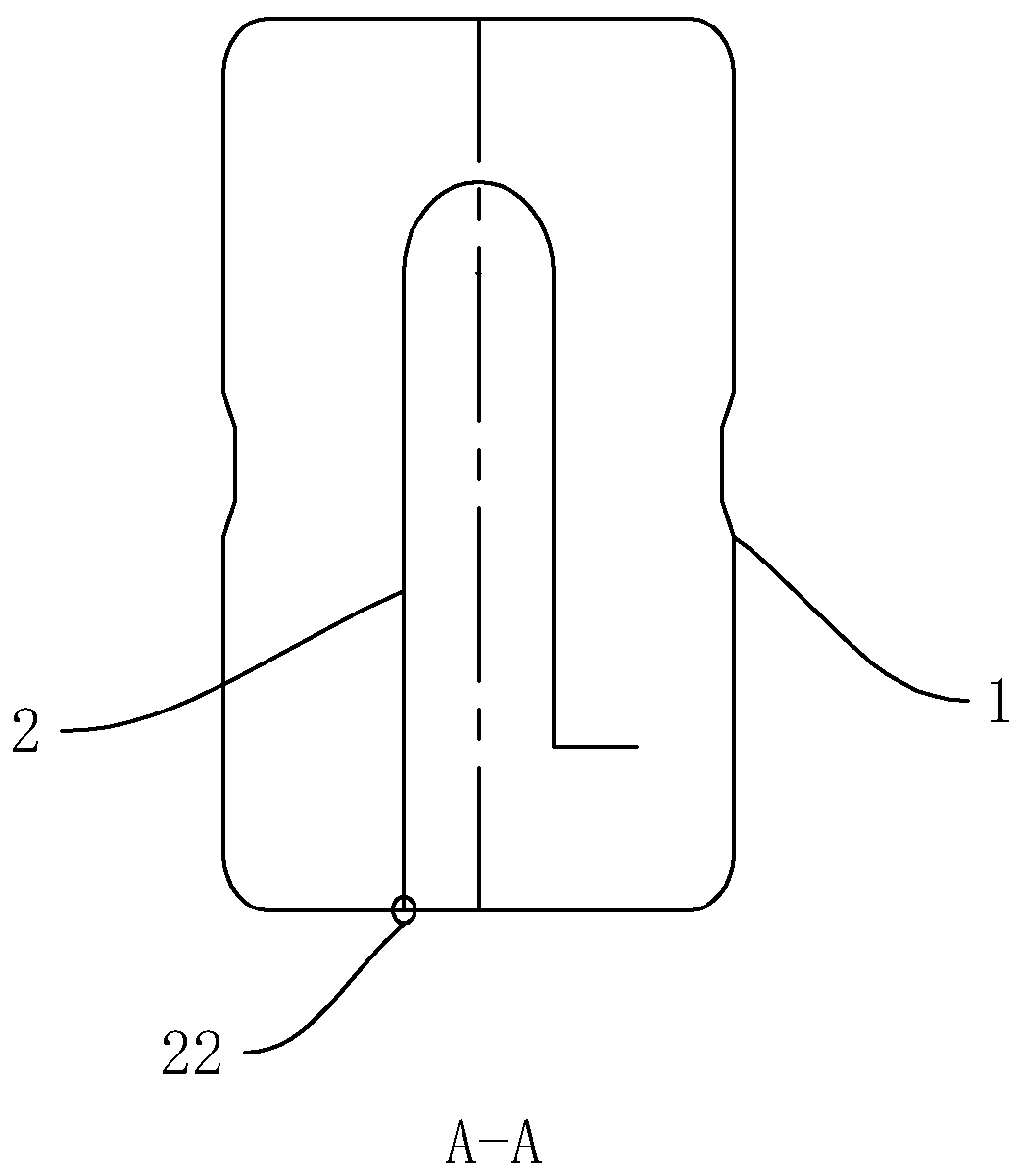

[0078] as attached figure 1 As shown, an inverted Y-shaped bridge tower, the bridge tower is a reinforced concrete structure, and it adopts a special-shaped inverted Y-shaped bridge tower. The bridge tower includes two lower tower columns 1, two lower beams, two middle tower columns, an upper beam and an upper tower column from bottom to top.

[0079] The total height of the bridge tower is 99.074m, the tower height above the bridge deck is 85.062m, the height-span ratio is 0.532, the height of the tower below the bridge deck is 14.012m, and the center distance between the left and right tower columns at the bottom of the tower is 37.0m.

[0080] The bridge tower is divided into 24 sections from bottom to top. The lower column 1 is the 1-4# section, and the height of the lower column 1 is 14.012m. The lower tower column 1 adopts a rectangular solid section, and the section size changes from 4.2m (horizontal) X7.0m (longitudinal) to 7.0m (horizontal) X10.0m (longitudinal). T...

Embodiment 2-7

[0116] Concrete with low heat of hydration was mixed according to the above-mentioned low heat of hydration concrete, and Examples 2-7 were prepared, and the specific parameter ratios are shown in Table 1.

[0117] Table I

[0118]

[0119] Different concrete samples or reinforced concrete samples were prepared from the concrete obtained in Examples 2-7, and performance tests were performed.

[0120] Among them, the peak value of heat of hydration and the detection of the peak time of heat of hydration: the low heat of hydration concrete in this application is mainly used in large-volume concrete pouring, so the sample here is a solid concrete body of 2m*2m*2m. A box with an open top is built from a template, and a fixed frame made of steel bars with a diameter of 1.2cm is placed inside. The fixed frame is equipped with 27 temperature sensors at equal intervals in a space of 2m*2m*2m, and the temperature change is monitored by a computer. The prepared concrete is poured in...

Embodiment 8-11

[0149]A low-heat-of-hydration concrete, based on the low-heat-of-hydration concrete in Example 1, the gravel is mixed with low-hydration concrete before being sprayed with low-temperature water at 0-5°C to cool down, and then drained Keep the temperature of crushed stones at 10°C for mixed use, the amount of crushed stones is 980-1100 parts, and the specific parameters are shown in Table 7.

[0150] Table seven

[0151] Ambient temperature: 23°C, distribution water temperature: 18°C Example 8 Example 9 Example 10 Example 11 Slag cement / kg 80 80 80 80 Ordinary Portland cement / kg 210 210 210 210 Distribution water / kg 160 160 160 160 Sand / kg 730 730 730 730 Gravel / kg 980 985 1000 1100 Fly ash / kg 250 80 80 80 Ammonium sulfate / kg 22 210 210 210 Guar gum / kg 14 160 160 160 Water reducer / kg 4.2 730 730 730

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com