Phase-change concrete quasi-rectangular pipe gallery structure and construction method thereof

A kind of rectangular and concrete technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of large number of ventilation mechanical equipment, low space utilization rate of pipe gallery, high investment cost, etc., to reduce the number of ventilation mechanical equipment , Shorten the construction period, improve the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

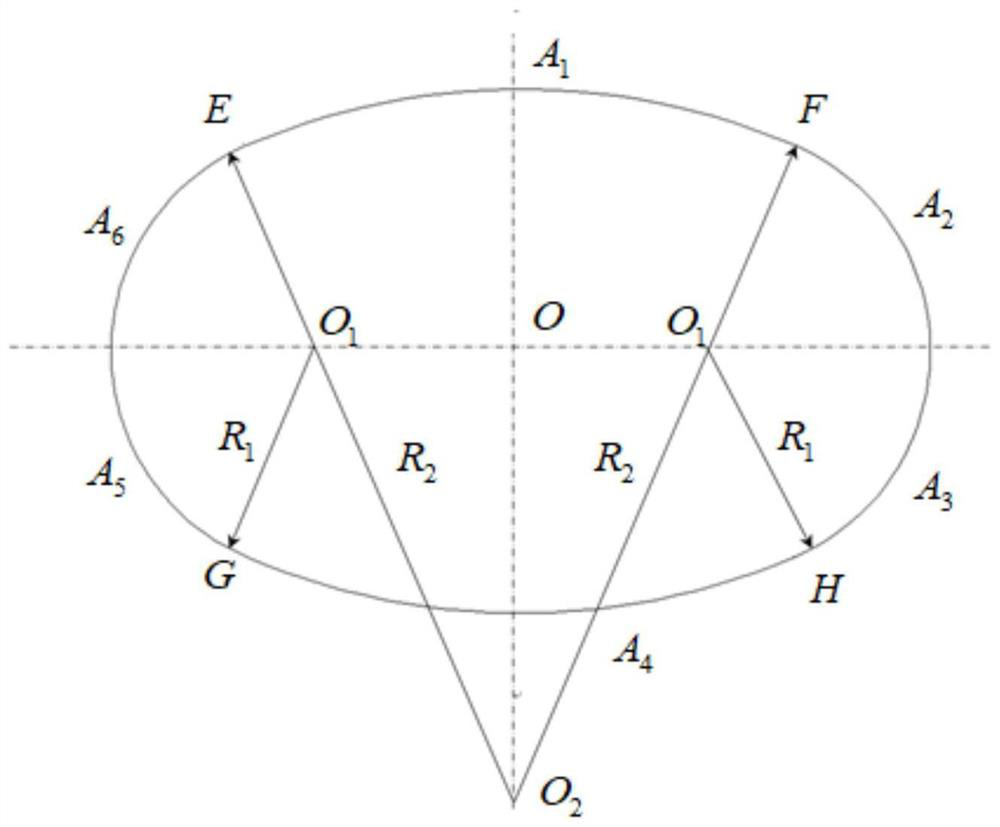

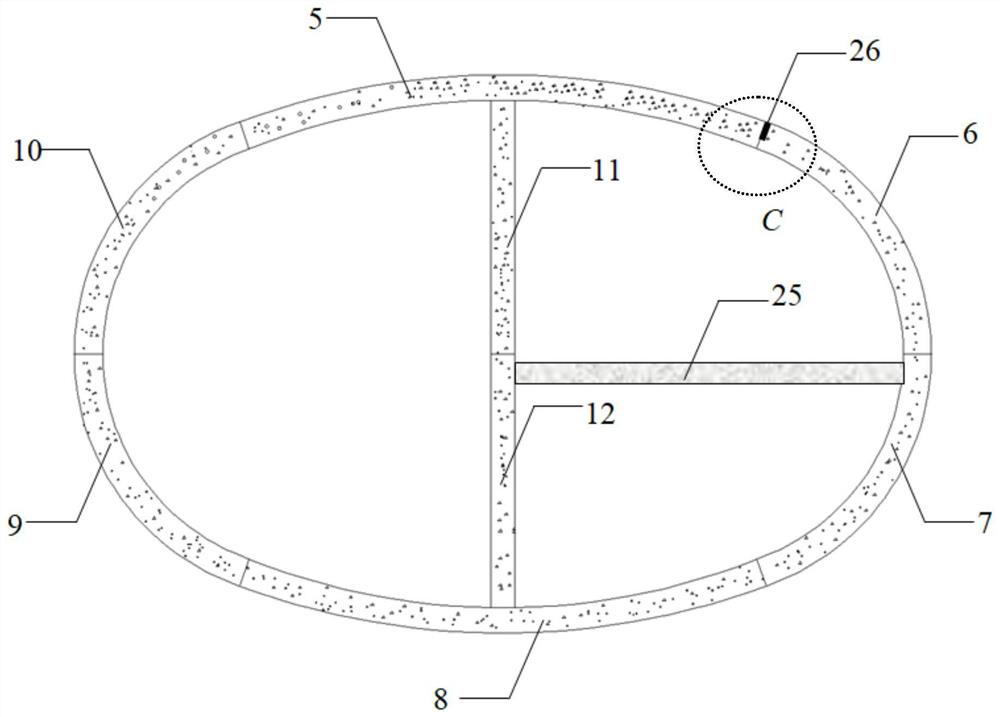

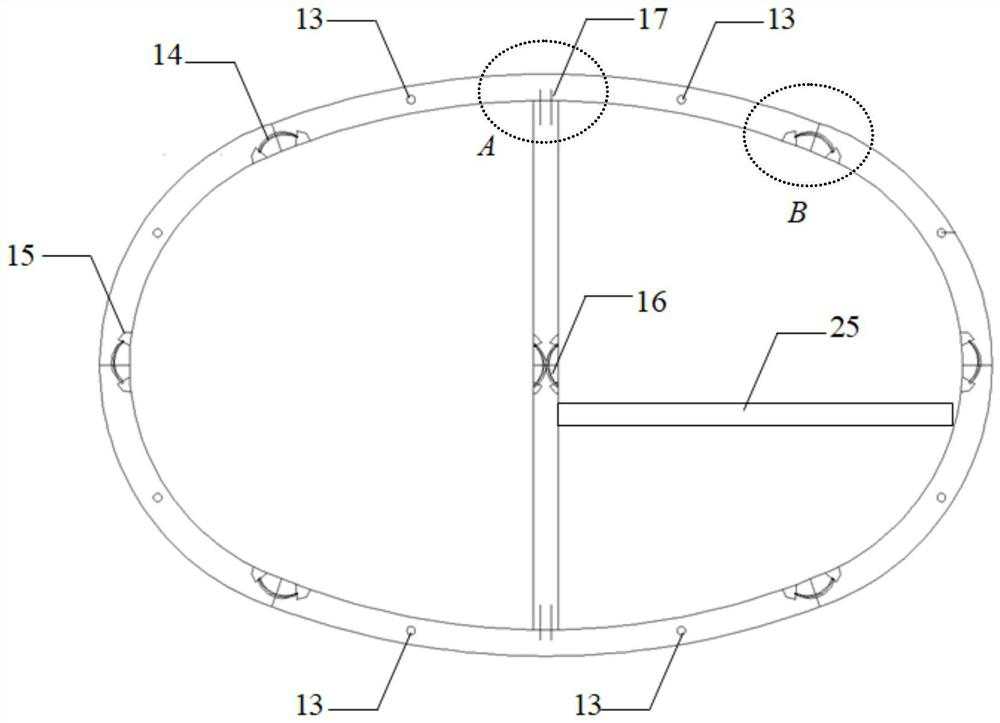

[0042] Such as Figure 1-Figure 4 As shown, the phase-change concrete-like rectangular pipe gallery structure includes several rectangular-like segment rings connected in sequence along the longitudinal direction (that is, the first pipe gallery section structure 1, the second section pipe gallery section structure 2, the third section Pipe gallery section structure 3, fourth section pipe gallery section structure 4), upper half partition wall 11, lower half partition wall 12, cast-in-place transverse partition 25, connecting bolts (ie longitudinal connecting bolt 13, hand hole 15, partition wall Connecting bolts 16) and seam waterproof structure. figure 1 It is a diagram of the segment block method of a rectangular pipe gallery structure. In this block method, the entire segment ring structure is composed of six segment segment blocks A1, A2, A3, A4, A5, and A6, and respectively It is defined as the segment A1 of the arc segment of the vault at the vault position, the segmen...

Embodiment 2

[0069] The assembly construction method of the phase-change concrete-like rectangular pipe gallery structure includes the following steps:

[0070] (1) According to the lithology of different formations, according to the section size of the rectangular comprehensive pipe gallery, the shield method or pipe jacking method is used for excavation, and the segments are assembled.

[0071] (2) The assembly of prefabricated segments by shield tunneling method mainly includes the following steps:

[0072] 1) Producing standard-sized dome arc segment segment 5, upper semi-arc segment segment, lower semi-arc segment segment and arch bottom segment segment 8 in the prefabricated component factory;

[0073] 2) During the advancing process of shield tunneling, each segment is hoisted, and the assembly sequence is segment 8 of the arch bottom arc segment, segment 7 of the right lower half-arc segment, and segment of the left lower half-arc segment 10. Segment 6 of the upper half-arc segmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com