Method for preparing resistant starch by adopting ultrasonic-assisted amylase

A technology of ultrasonic wave and amylase, applied in the field of resistant starch preparation, can solve the problem of less research on the resistant starch of Cigu, and achieve the effects of shortening the reaction time, reducing the usage of enzymes, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

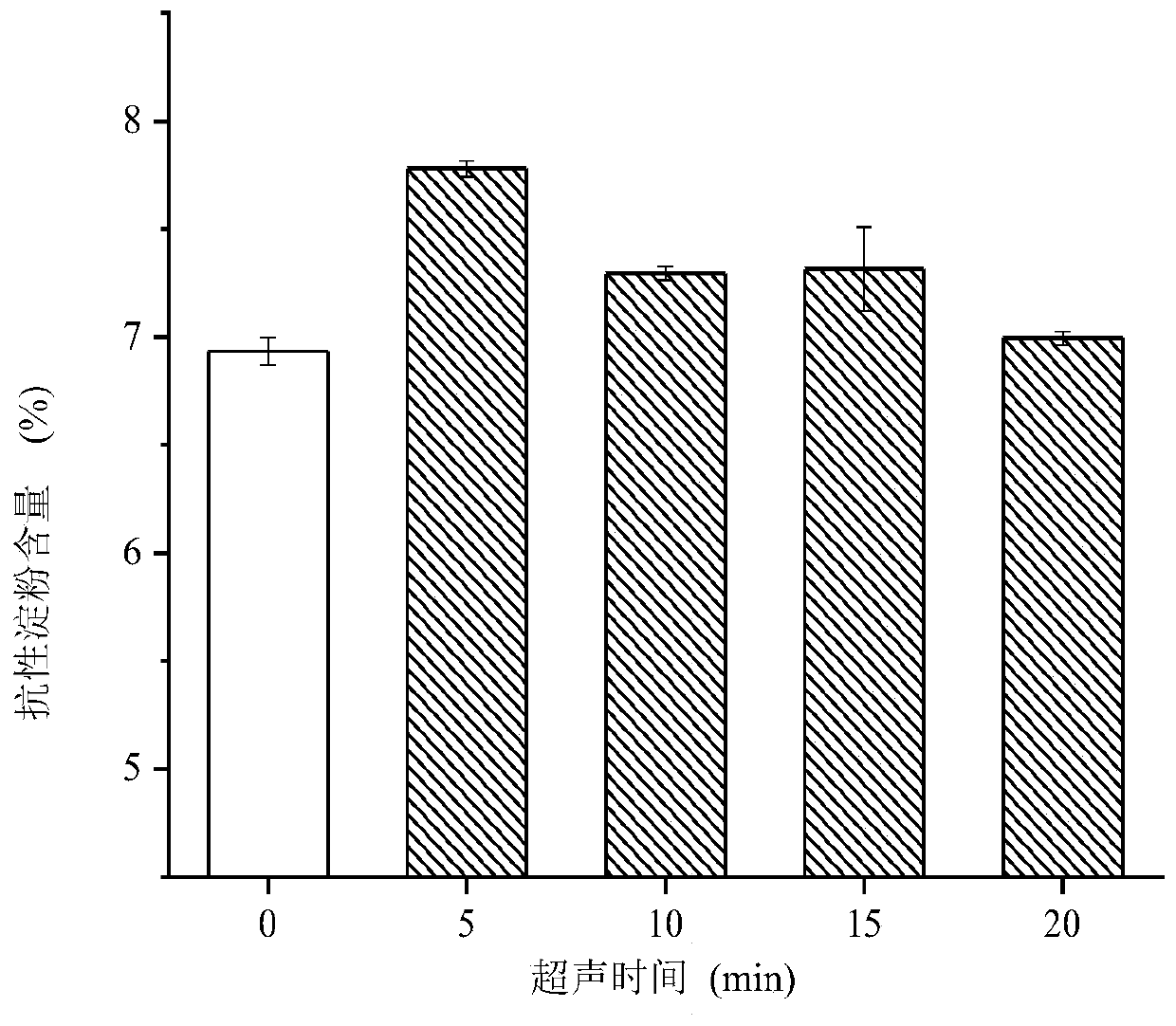

[0030] Embodiment 1-4 (optimization of ultrasonic time in ultrasonic-assisted enzymolysis)

[0031] (1) Cleaning and tidying of Arrowhead

[0032] First select fresh sagittarius and those with large fruit, then clean them, then peel and cut into pieces;

[0033] (2) Ultrasonic extraction of arrowroot starch

[0034] According to the method of water and sagittarius mass ratio of 1:1, put the starch homogenate into different multi-mode ultrasonic conditions for ultrasonic-assisted extraction of sagittarius starch; the ultrasonic-assisted extraction conditions are: three-frequency ultrasonic treatment, and the combination of ultrasonic frequencies is: 28 / 35 / 60kHz; ultrasonic time is 10min; ultrasonic power density is 250W / 100mL. Then use gauze, 100-mesh and 200-mesh sieves to filter repeatedly to obtain starch suspension; let it stand for 24 hours to filter off the supernatant, and obtain the precipitate as coarse starch, add sodium hydroxide solution and stir for 2 hours with ...

Embodiment 5-9

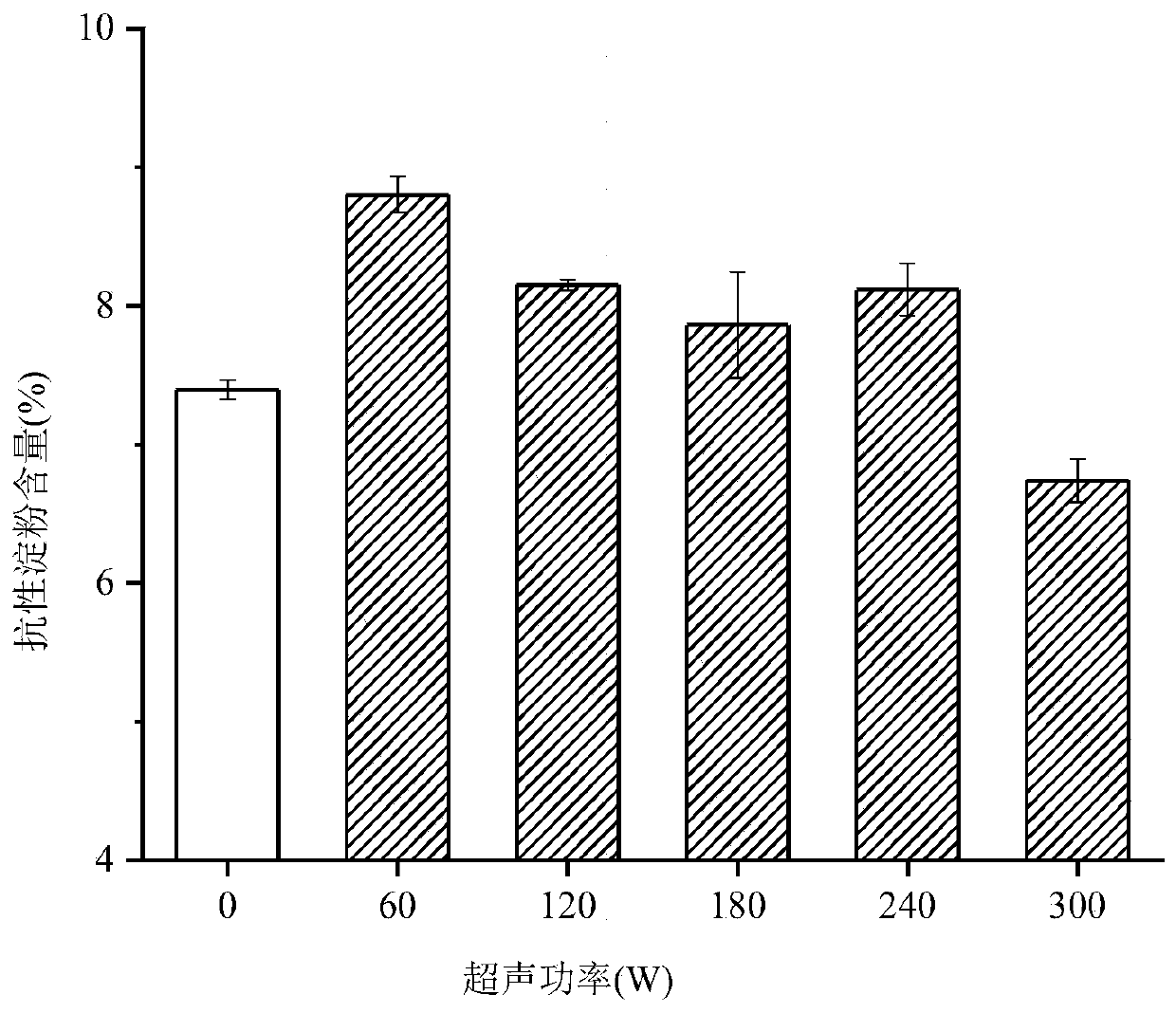

[0037] Embodiment 5-9 (optimization of ultrasonic power in ultrasonic-assisted enzymolysis)

[0038] (1) Cleaning and tidying of Arrowhead

[0039] First select fresh sagittarius and those with large fruit, then clean them, then peel and cut into pieces;

[0040] (2) Ultrasonic extraction of arrowroot starch

[0041] According to the method of water and sagittarius mass ratio of 1:1, put the starch homogenate into different multi-mode ultrasonic conditions for ultrasonic-assisted extraction of sagittarius starch; the ultrasonic-assisted extraction conditions are: three-frequency ultrasonic treatment, and the combination of ultrasonic frequencies is: 28 / 35 / 60kHz; ultrasonic time is 10min; ultrasonic power density is 250W / 100mL. Then use gauze, 100-mesh and 200-mesh sieves to filter repeatedly to obtain starch suspension; let it stand for 24 hours to filter off the supernatant, and obtain the precipitate as coarse starch, add sodium hydroxide solution and stir for 2 hours with...

Embodiment 10-15

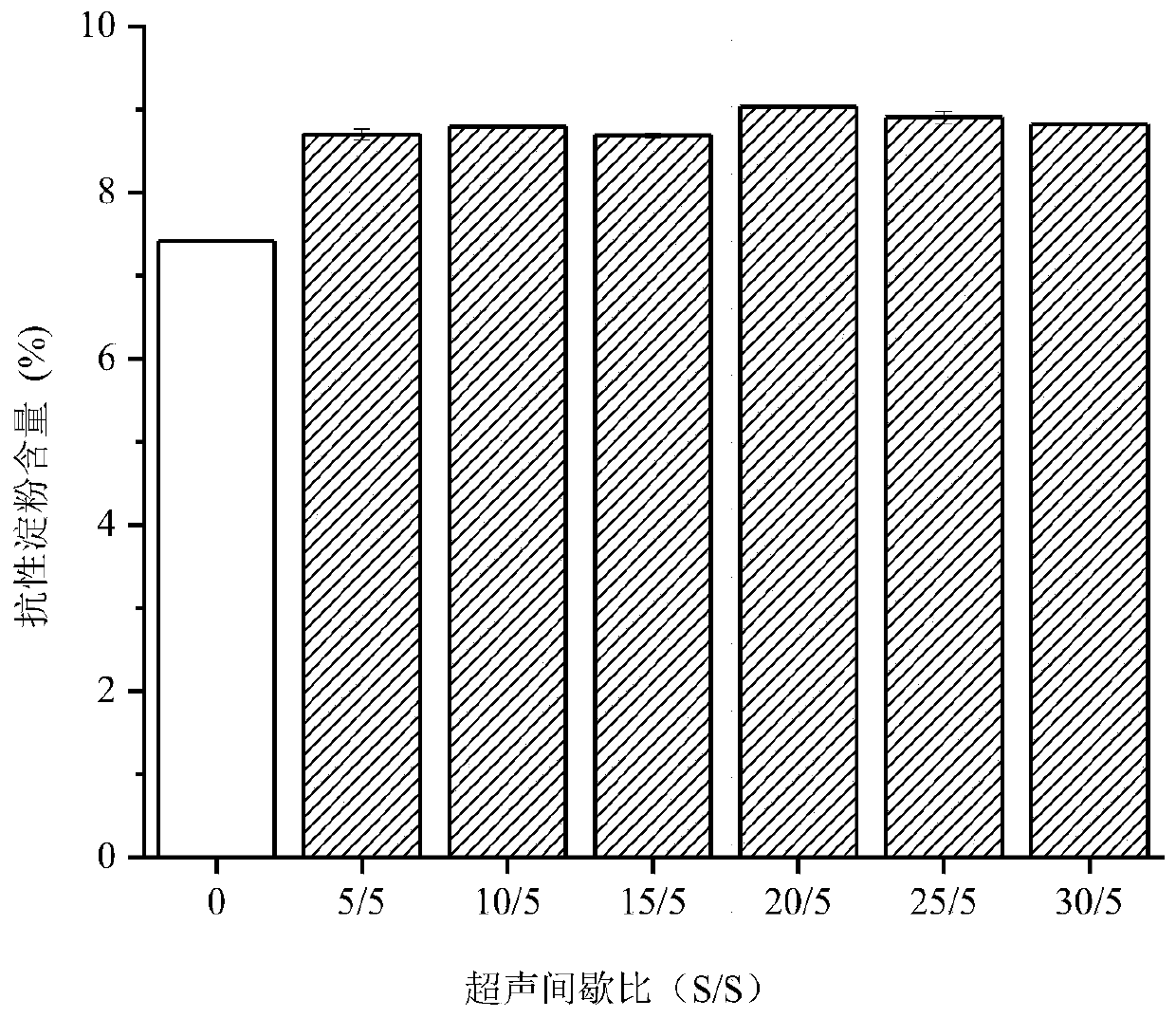

[0045] Embodiment 10-15 (optimization of ultrasonic intermittent ratio in ultrasonic-assisted enzymolysis)

[0046] (1) Cleaning and tidying of Arrowhead

[0047] First select fresh sagittarius and those with large fruit, then clean them, then peel and cut into pieces;

[0048] (2) Ultrasonic extraction of arrowroot starch

[0049] According to the method of water and sagittarius mass ratio of 1:1, put the starch homogenate into different multi-mode ultrasonic conditions for ultrasonic-assisted extraction of sagittarius starch; the ultrasonic-assisted extraction conditions are: three-frequency ultrasonic treatment, and the combination of ultrasonic frequencies is: 28 / 35 / 60kHz; ultrasonic time is 10min; ultrasonic power density is 250W / 100mL. Then use gauze, 100-mesh and 200-mesh sieves to filter repeatedly to obtain starch suspension; let it stand for 24 hours to filter off the supernatant, and obtain the precipitate as coarse starch, add sodium hydroxide solution and stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com