Radial flow type rotating mechanical impeller

A rotary machine, radial flow technology, applied in mechanical equipment, non-variable-capacity pumps, engine components, etc., can solve the problem of high power loss, and achieve the effect of reducing the axial force on the back, enhancing acceleration, and balancing the axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

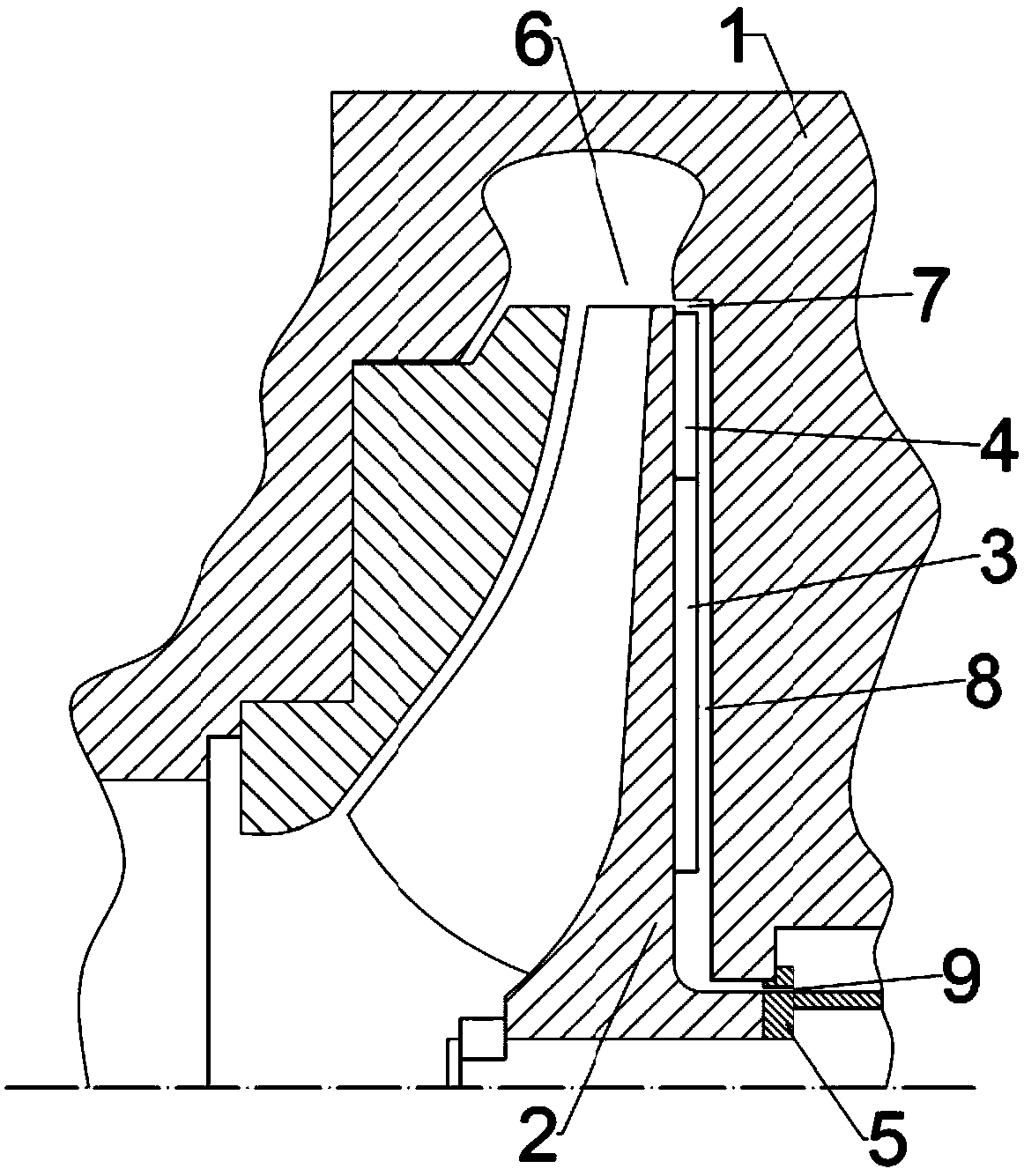

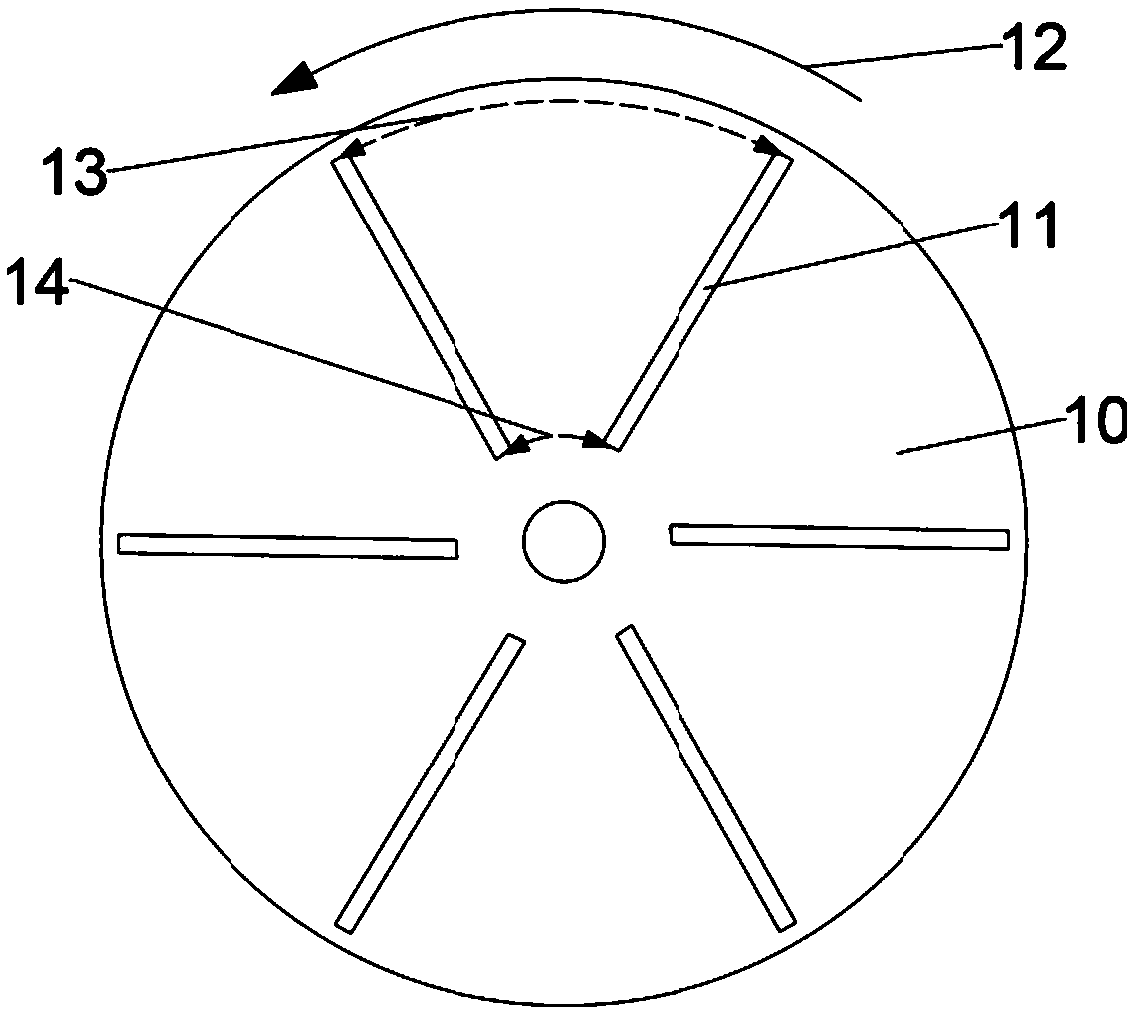

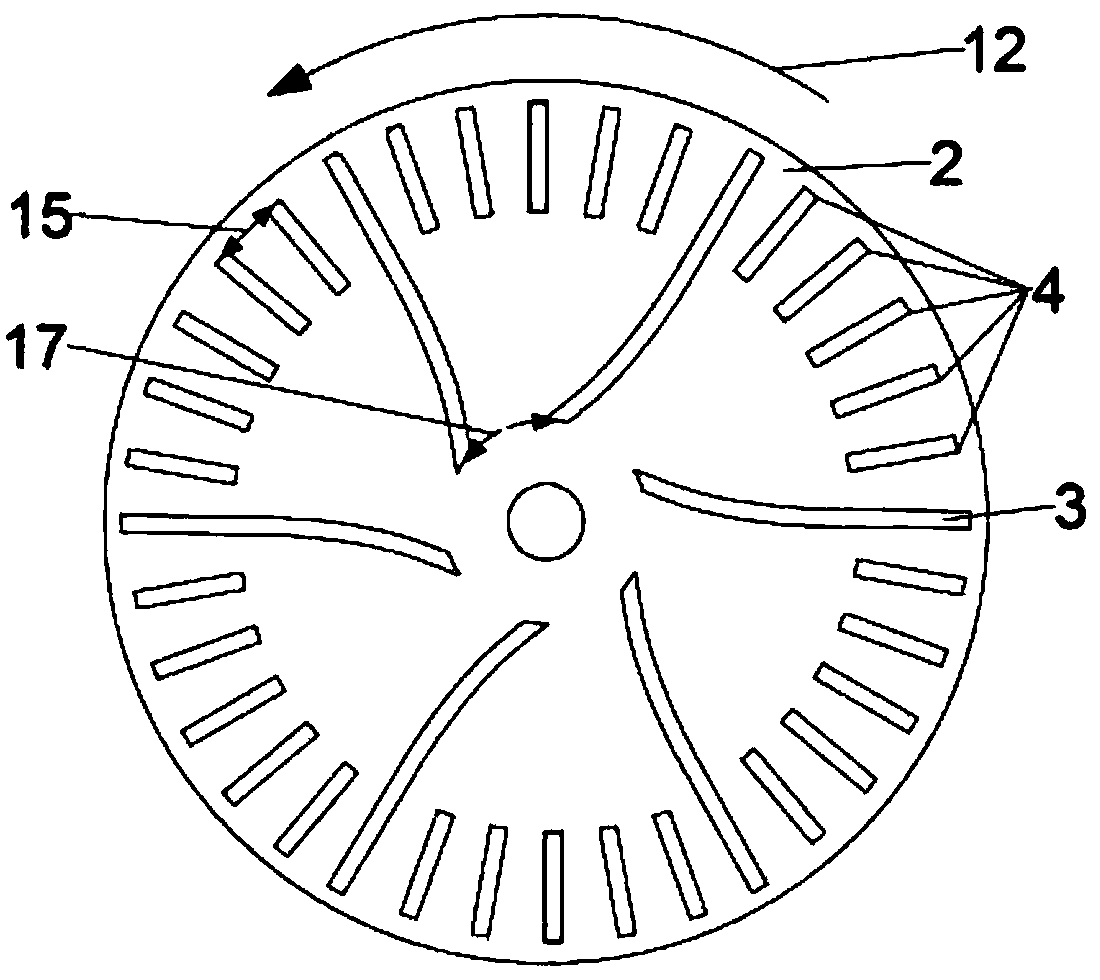

[0020] The invention provides a radial-flow type rotary mechanical impeller, which can realize. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as image 3 As shown, the radial-flow rotary mechanical impeller provided by the present invention includes the impeller main body, including main blades 3 and edge blades 4 . There are a plurality of main blades 3, which are evenly distributed on the back of the impeller body along the circumferential direction of the impeller body, and the main blades 3 are protrudingly arranged. There are a plurality of edge blades 4, which are evenly arranged between the inlet sections of adjacent main blades 3 along the circumferential direction, and the edge blades 4 protrude. There is a small axial gap between the main blade 3 and the edge blade 4 and the fixed wall surface on the back side of the impeller.

[0022] In the present invention, main bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com