Method and device for continuously winding up several threads

A technology of wire, equipment, applied in the field of equipment for implementing the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

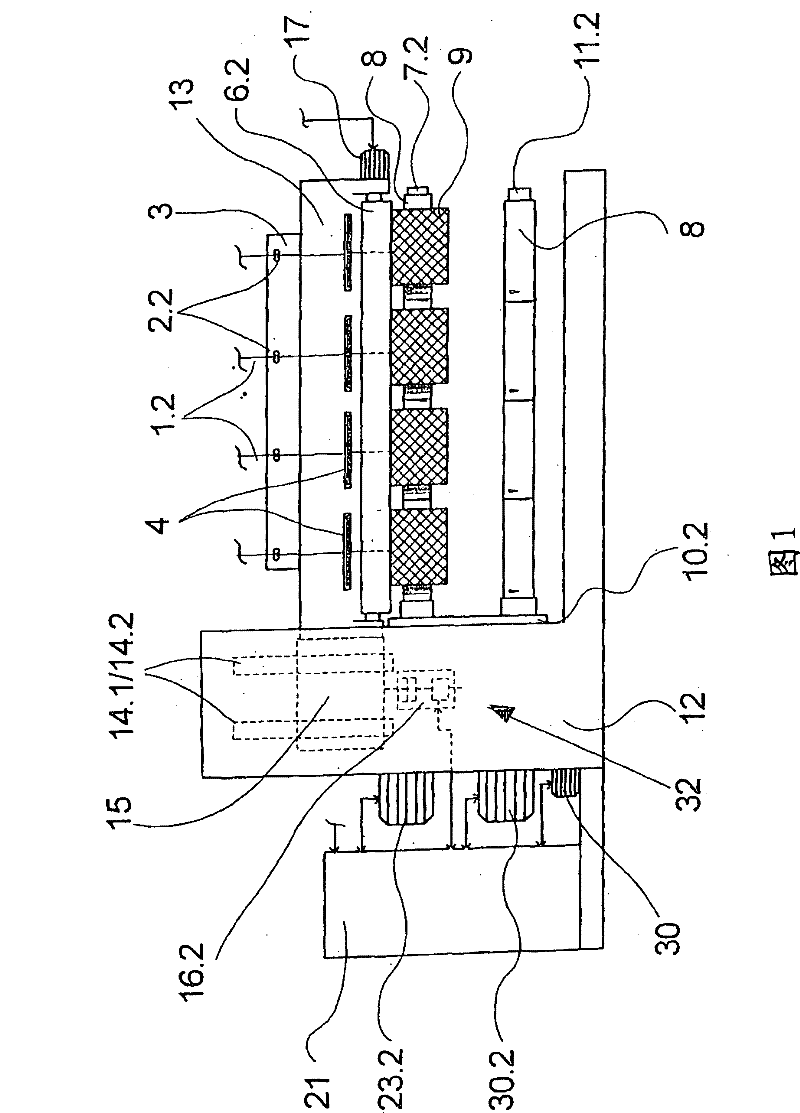

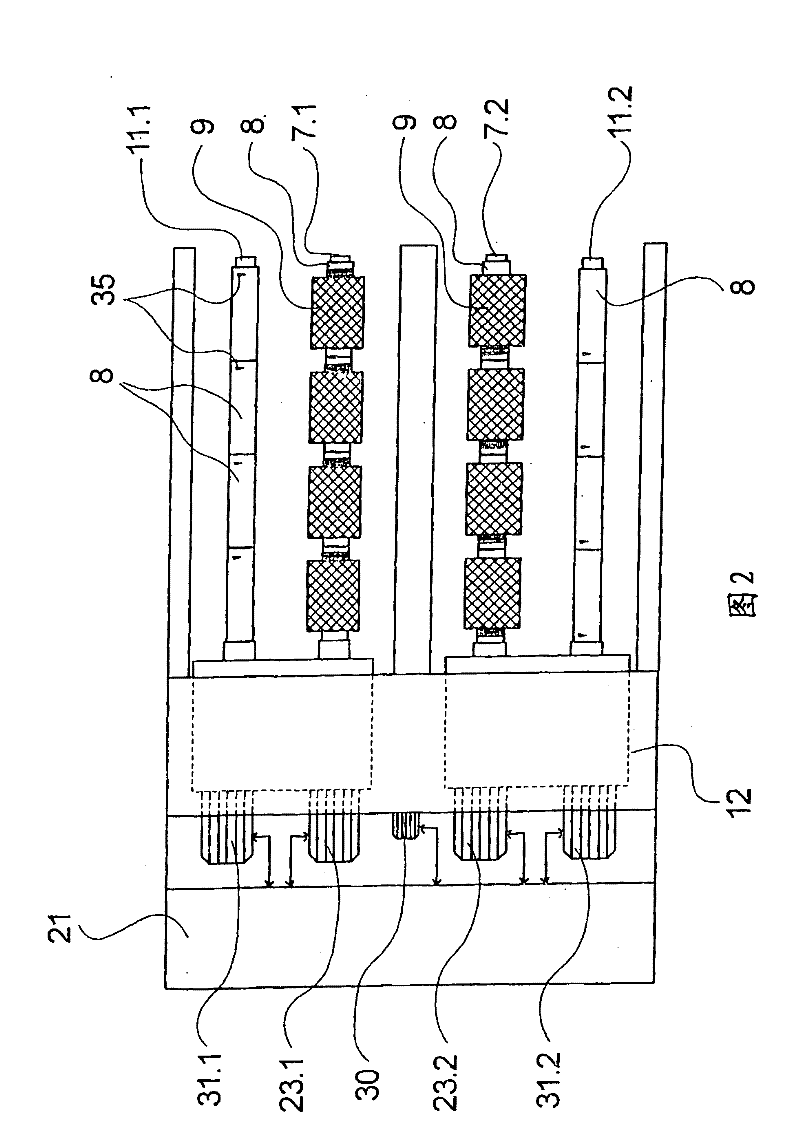

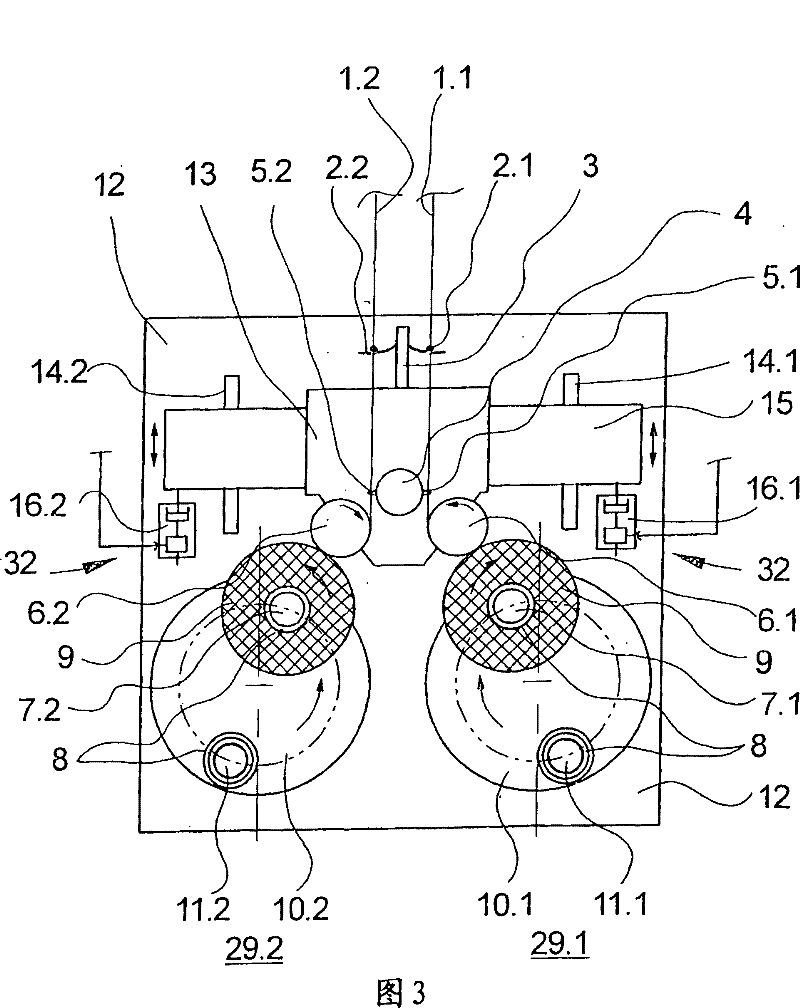

[0025] Figures 1 to 4 A first embodiment of the winding device of the invention is shown in several views in . in figure 1 shows a side view of an embodiment, figure 2 is a plan view of each bobbin spindle of the embodiment and image 3 and 4 It is the front view of the embodiment in different working states. The following description applies to all drawings so far as long as no one is concerned.

[0026] The embodiment of the winding device according to the invention has two winding stations 29.1 and 29.2 which are arranged side by side in a frame. In this case the winding stations 29.1 and 29.2 are arranged mirror-symmetrically to a central plane of symmetry. Thus, the right-hand winding station 29.1 comprises a winding turret 10.1 mounted rotatably in the machine frame 12. An overhanging first bobbin spindle 7.1 and an overhanging second bobbin spindle 11.1 offset by 180° are supported on the winding turret 10.1. In the operating state shown, the first bobbin spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com