Method for mfg. hydraulic bearing device

A bearing device, hydraulic technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of reduced quality of axial components, deviation of axial components from roundness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

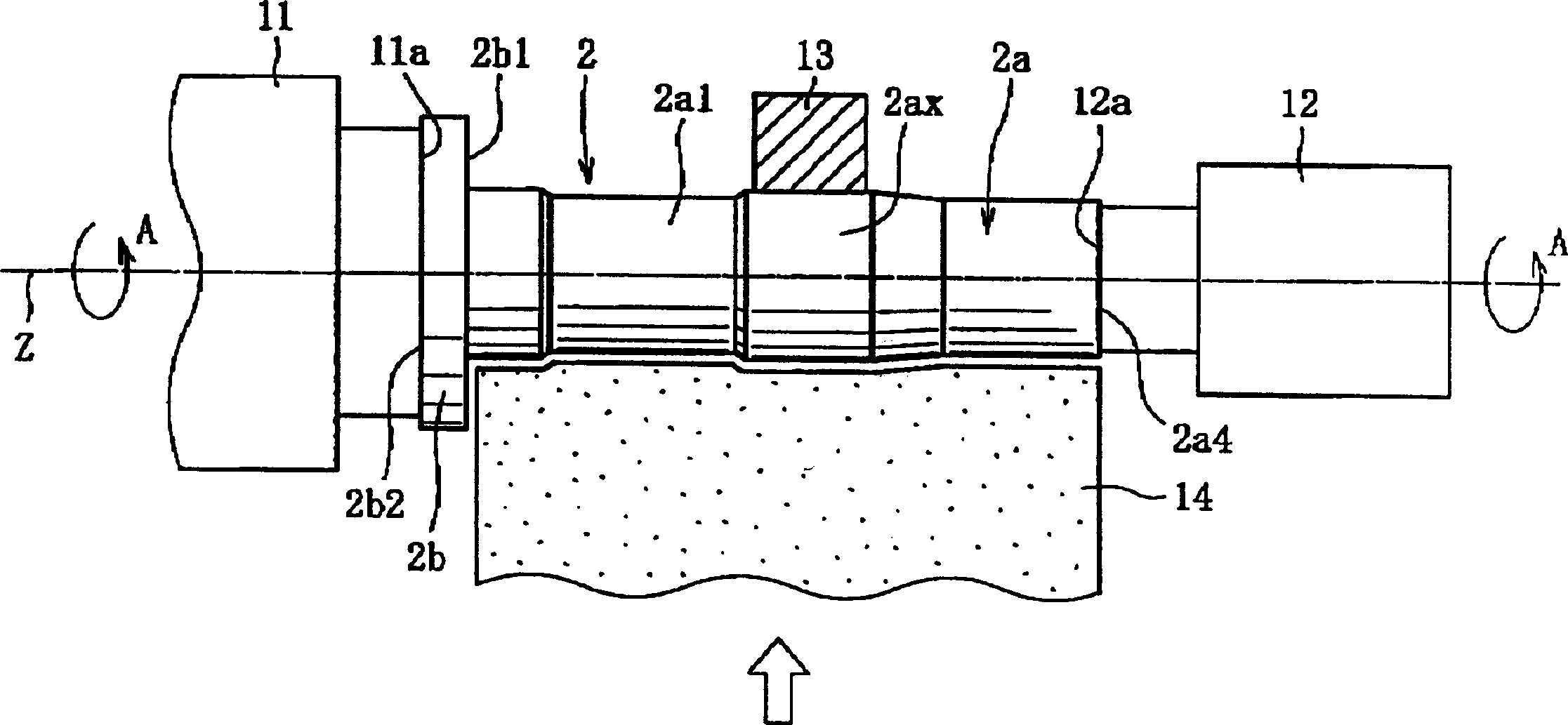

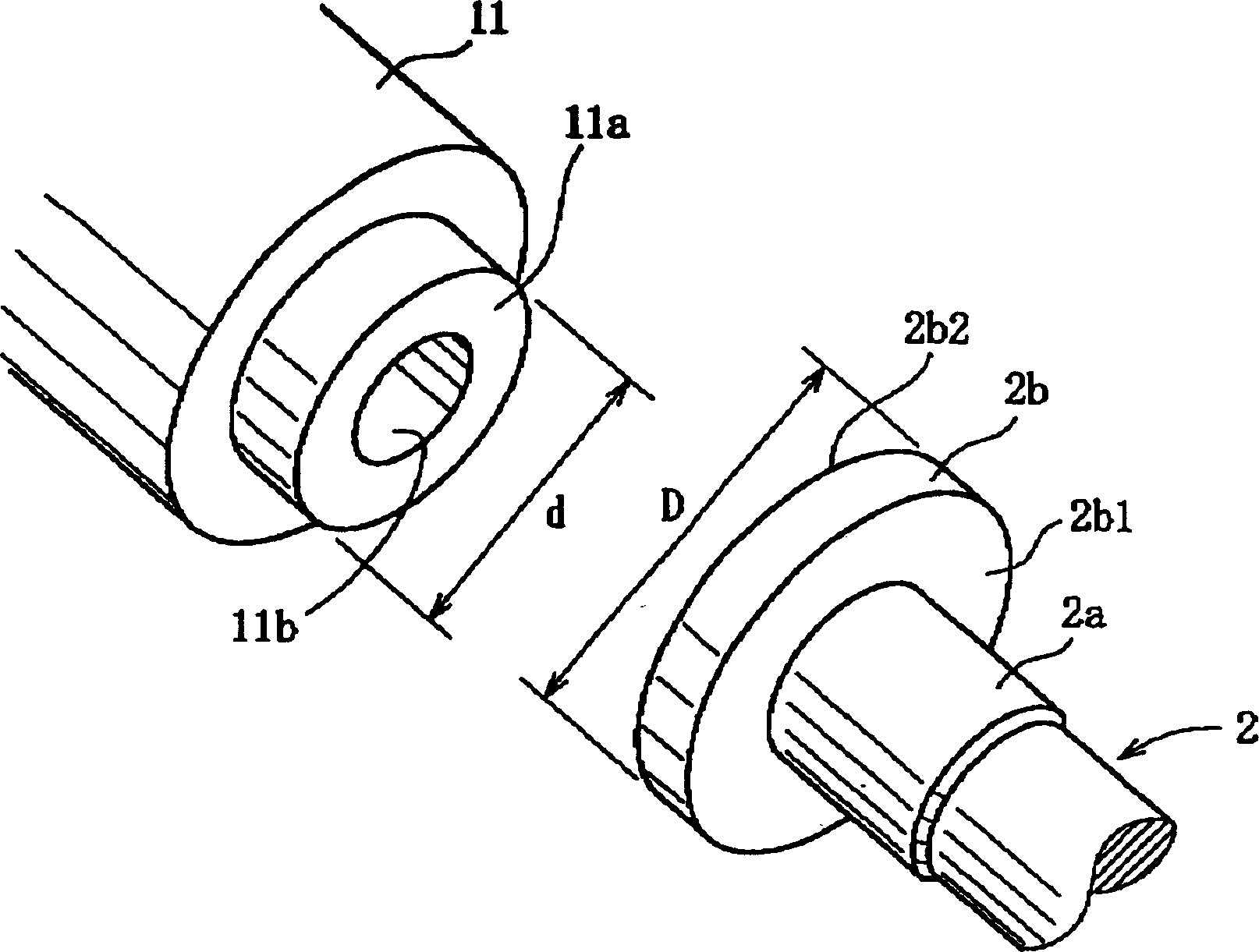

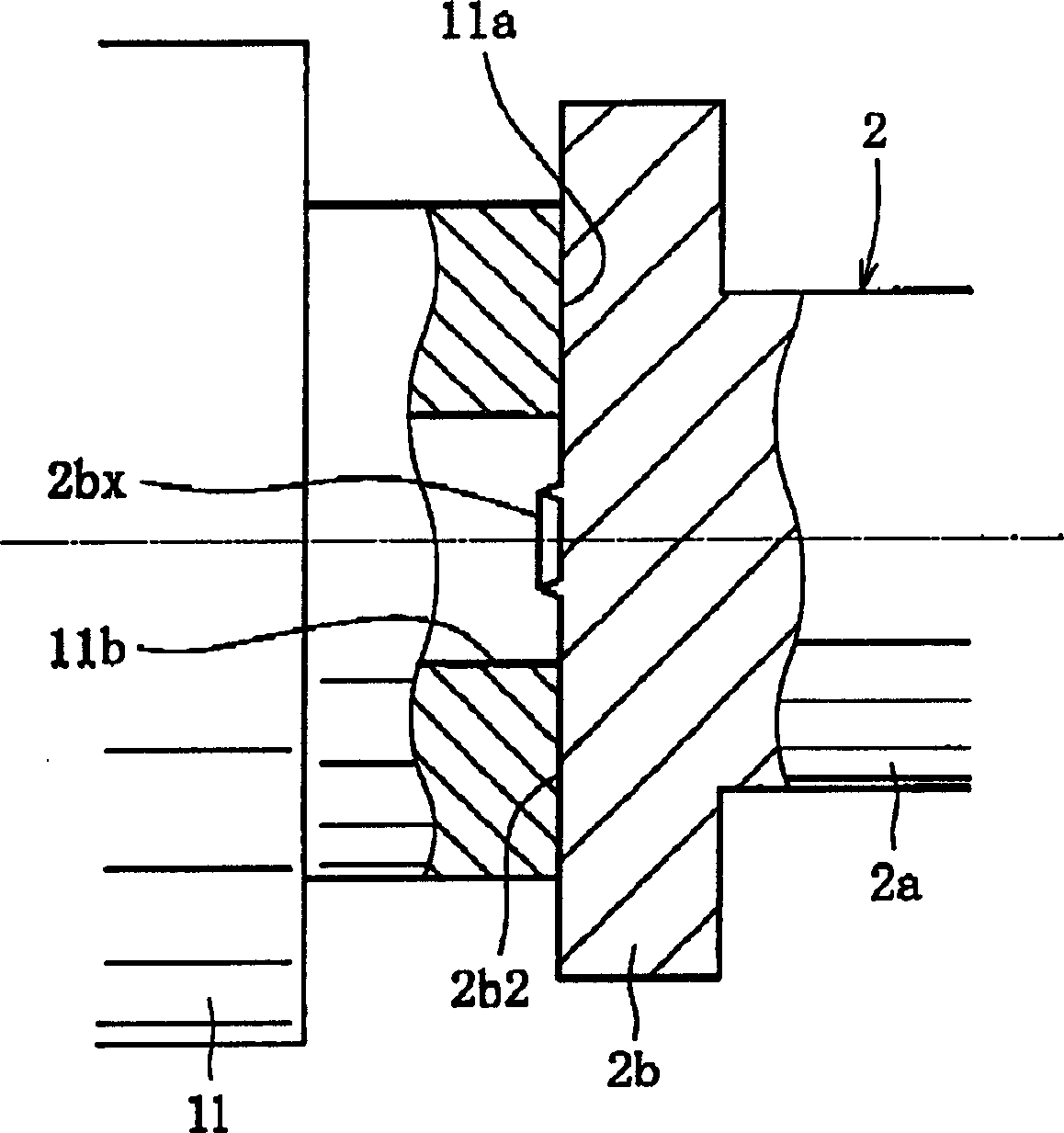

[0033] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. Figure 1-6 is a schematic view showing a state in which a sliding step is performed in the method of manufacturing a hydrodynamic bearing device according to the present invention. Figure 8 is an enlarged sectional front view showing the internal structure of the hydrodynamic bearing device.

[0034] First, for convenience of explanation, the structure of a hydrodynamic bearing device will be described in detail before explaining the state in which the grinding step is performed in the manufacturing method.

[0035] Such as Figure 8 As shown, the hydrodynamic bearing device 1 mainly includes a closed cylindrical shell 7 having an opening 7a at its end, a cylindrical bearing sleeve 8 fixed around the inside of the shell 7, and a cylindrical bearing sleeve 8 mounted on the bearing sleeve 8 The axial member 2 on the inner periphery of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com