Device for stretching web formed of thermoplastic synthetic resin

A synthetic resin and thermoplastic technology, applied in the field of sheet material devices, can solve difficult and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the apparatus for stretching a sheet formed of a thermoplastic synthetic resin of the present invention will be specifically described with reference to the drawings.

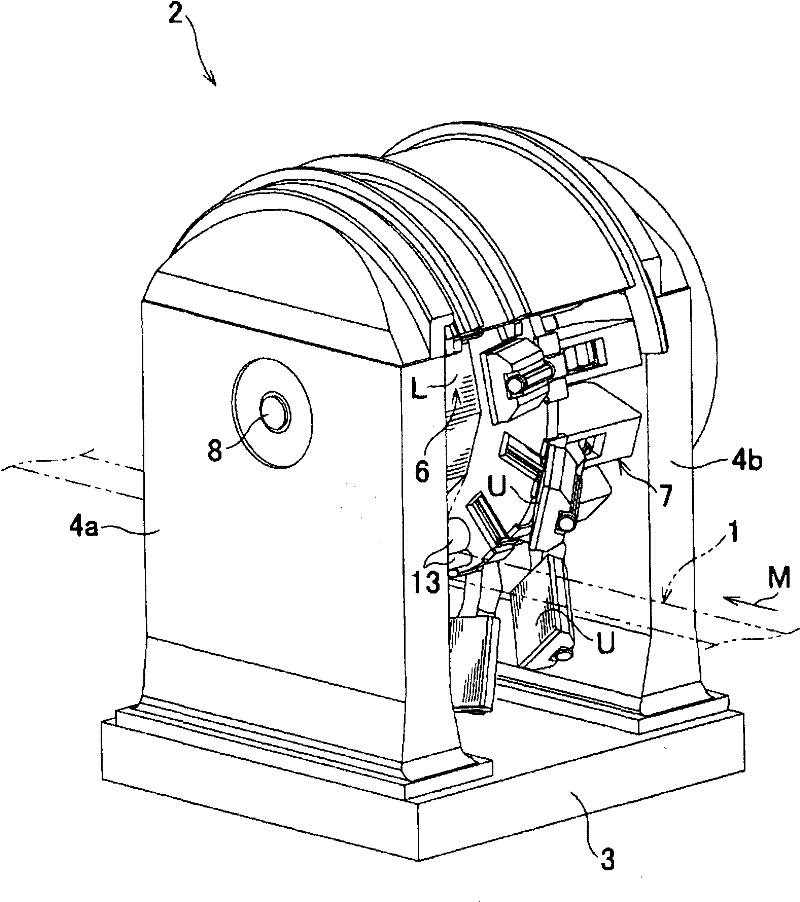

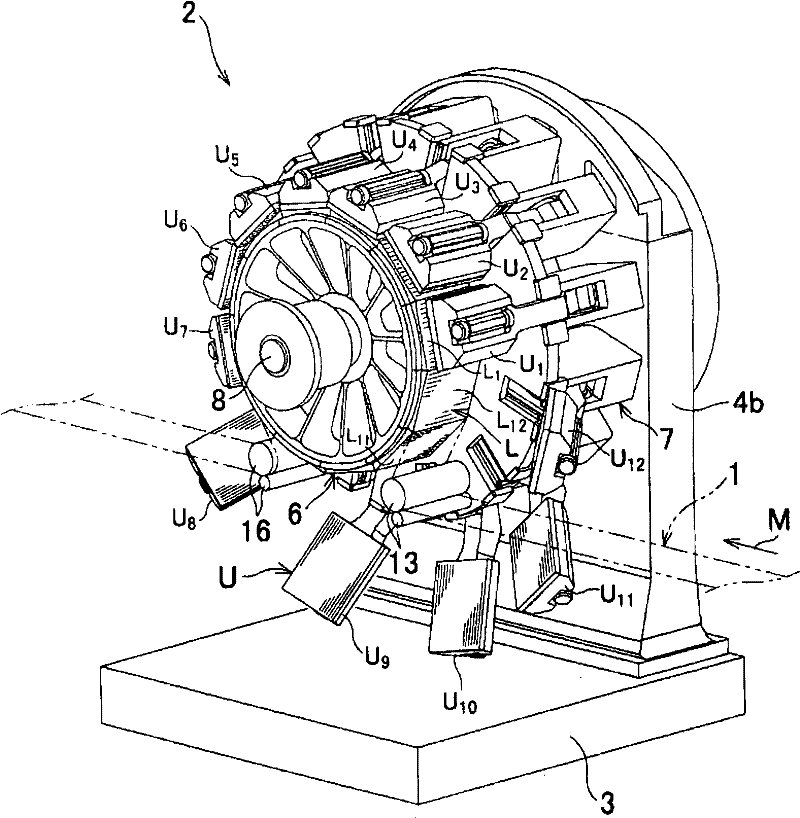

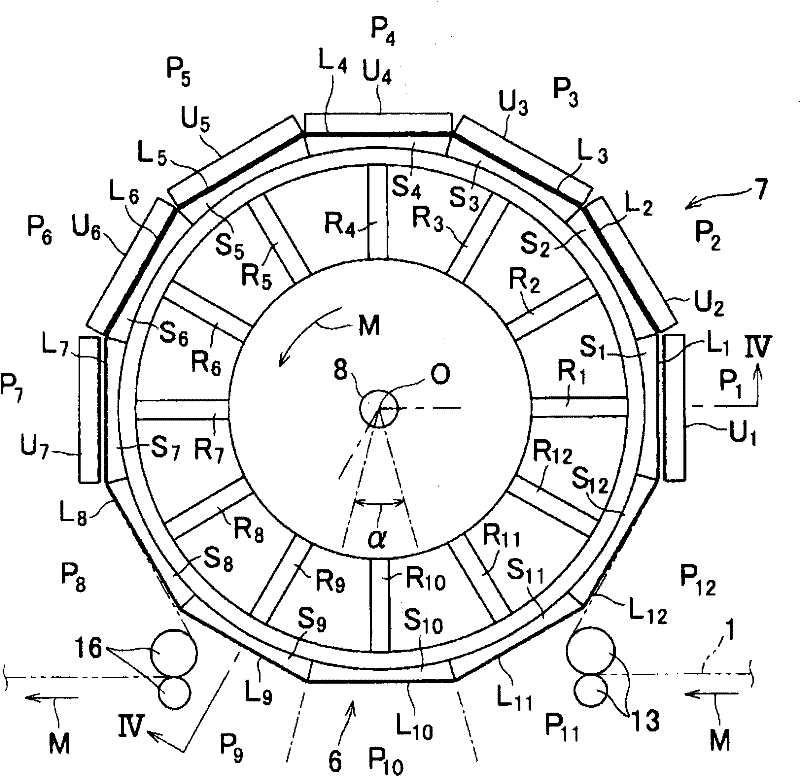

[0030] figure 1 , 2 It is an overall perspective view and a partial perspective view of the device 2 for stretching the fiber sheet 1 shown by the imaginary line. The device 2 has a horizontal base 3 and a pair of support bodies 4a, 4b that stand vertically from the base 3. The roller 6 and the plate assembly 7 are supported by the two support bodies 4a, 4b via a shaft 8. figure 2 It shows a state where one side 4a of the support body is separated from the base 3. The arrow M indicates the machine direction of the device 2. The roller 6 and the plate assembly 7 are used to extend the fiber sheet 1 around the shaft 8 supported by the two support bodies 4a, 4b or to the same machine direction M together with the shaft 8. The rotating body rotates at a circumferential speed. The peripheral surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com