Labyrinth seal for optimizing dynamic characteristics of rotor based on inter-tooth anti-rotation plates

A technology of dynamic characteristics and labyrinth sealing, which is applied in the direction of engine sealing, fluid flow, engine components, etc., and can solve problems such as rotor instability, reduced rotor stability, and insufficient rotor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

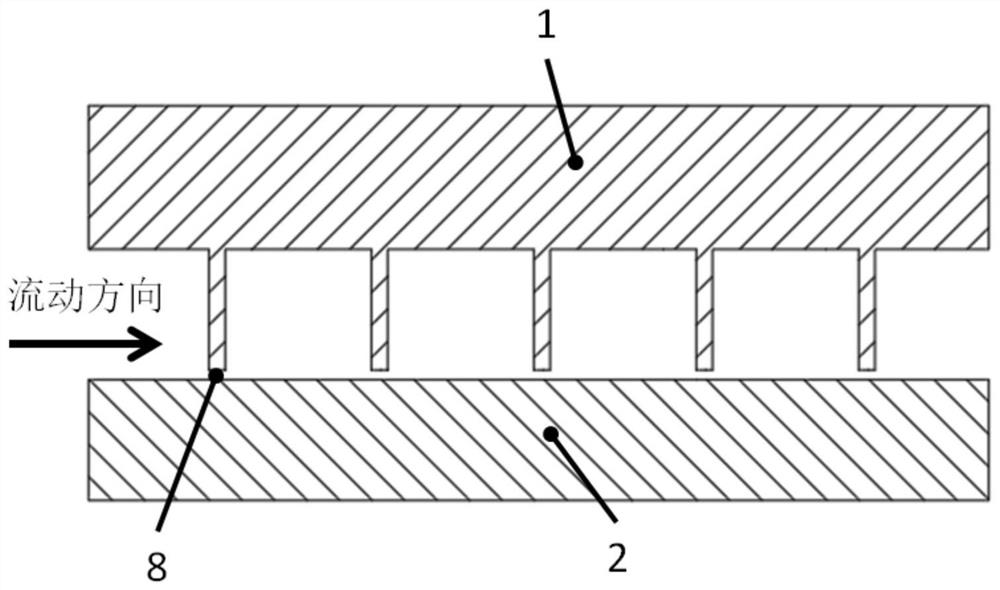

[0028] like figure 1 As shown, a typical straight-through labyrinth seal includes a sealed stator 1 and a sealed rotor 2. The sealing teeth are arranged on the wall of the sealed stator 1. Along the flow direction, there may be multiple sealing teeth, and there is a sealing gap between the sealed rotor 2 and the wall. One 8, the distance of sealing gap one 8 is D 1 .

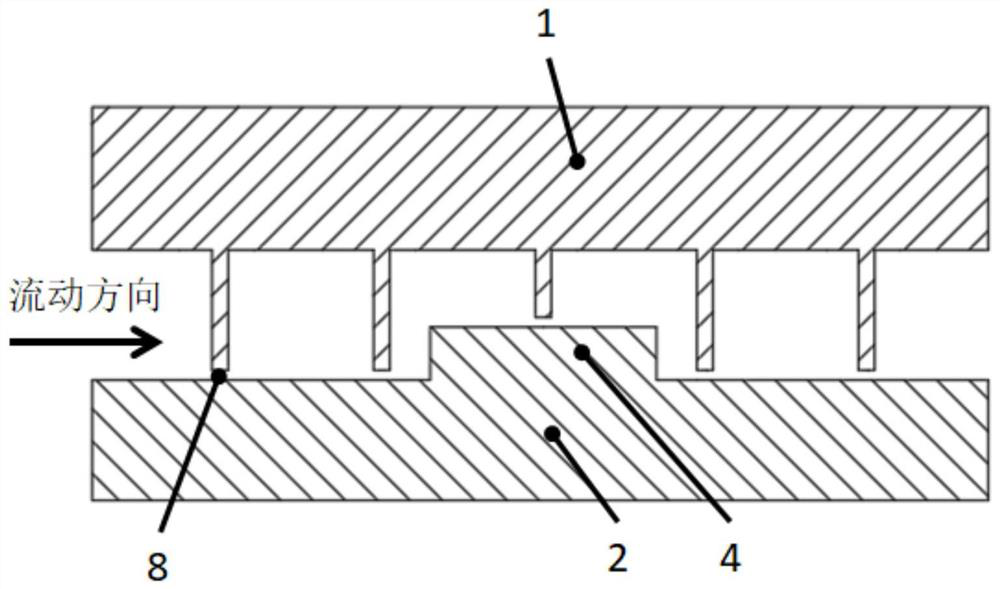

[0029] like figure 2 As shown, a typical labyrinth seal with high and low teeth is based on the straight-through labyrinth seal, and one or more rotor bosses 4 are arranged on the wall of the sealed rotor 2 along the circumferential direction. When the rotor boss 4 is set, all the sealing teeth The length of the seal should be kept consistent with the length of other seal teeth, maintaining a seal gap of 8.

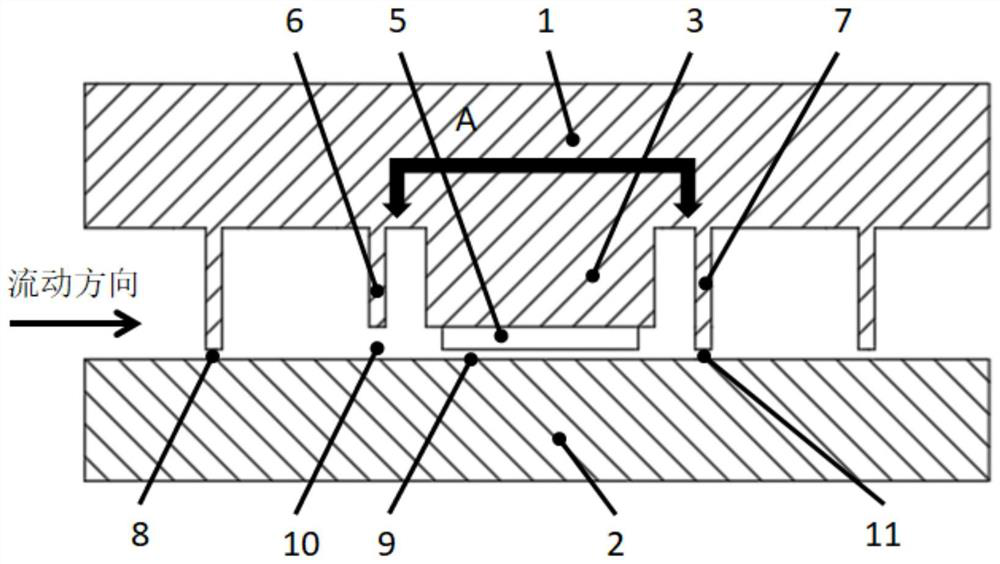

[0030] like image 3 , Figure 4 and Figure 5 , the invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com