Patents

Literature

116results about How to "Evenly good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-path equalization for orthogonal frequency division multiplexing communication system

ActiveUS20030227866A1Evenly goodTransmission control/equalisingAmplitude-modulated carrier systemsViterbi decoderCommunications system

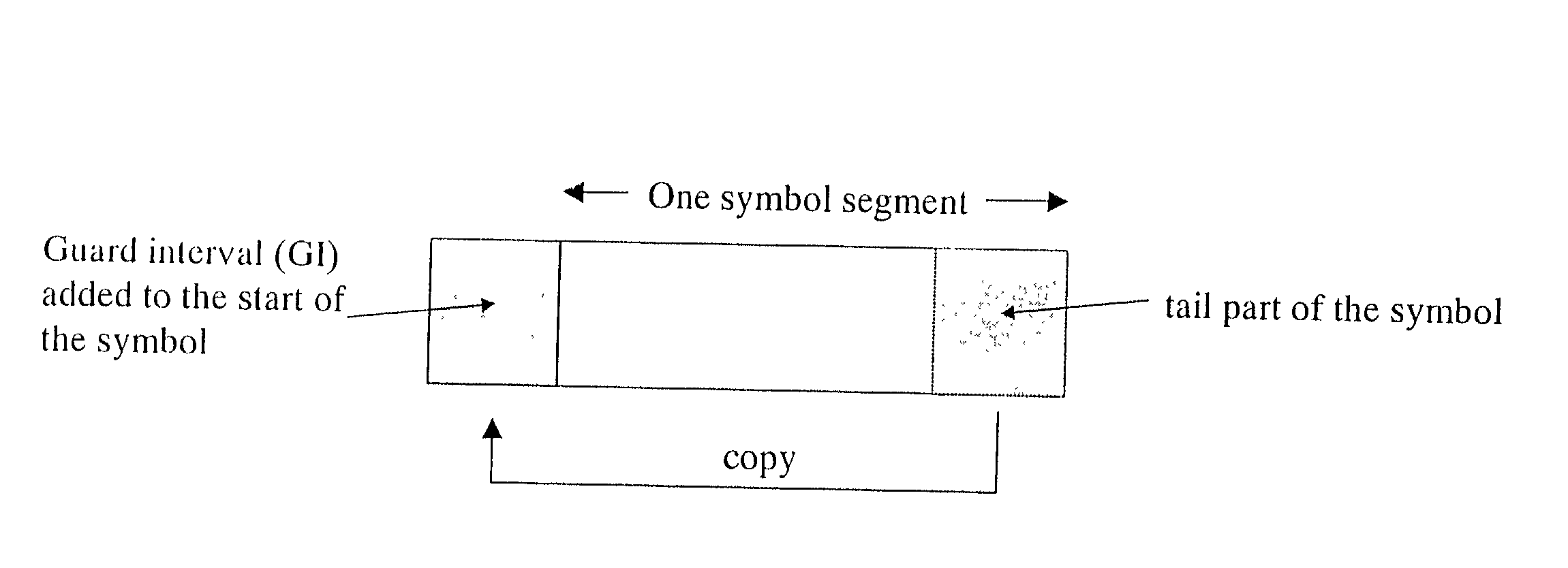

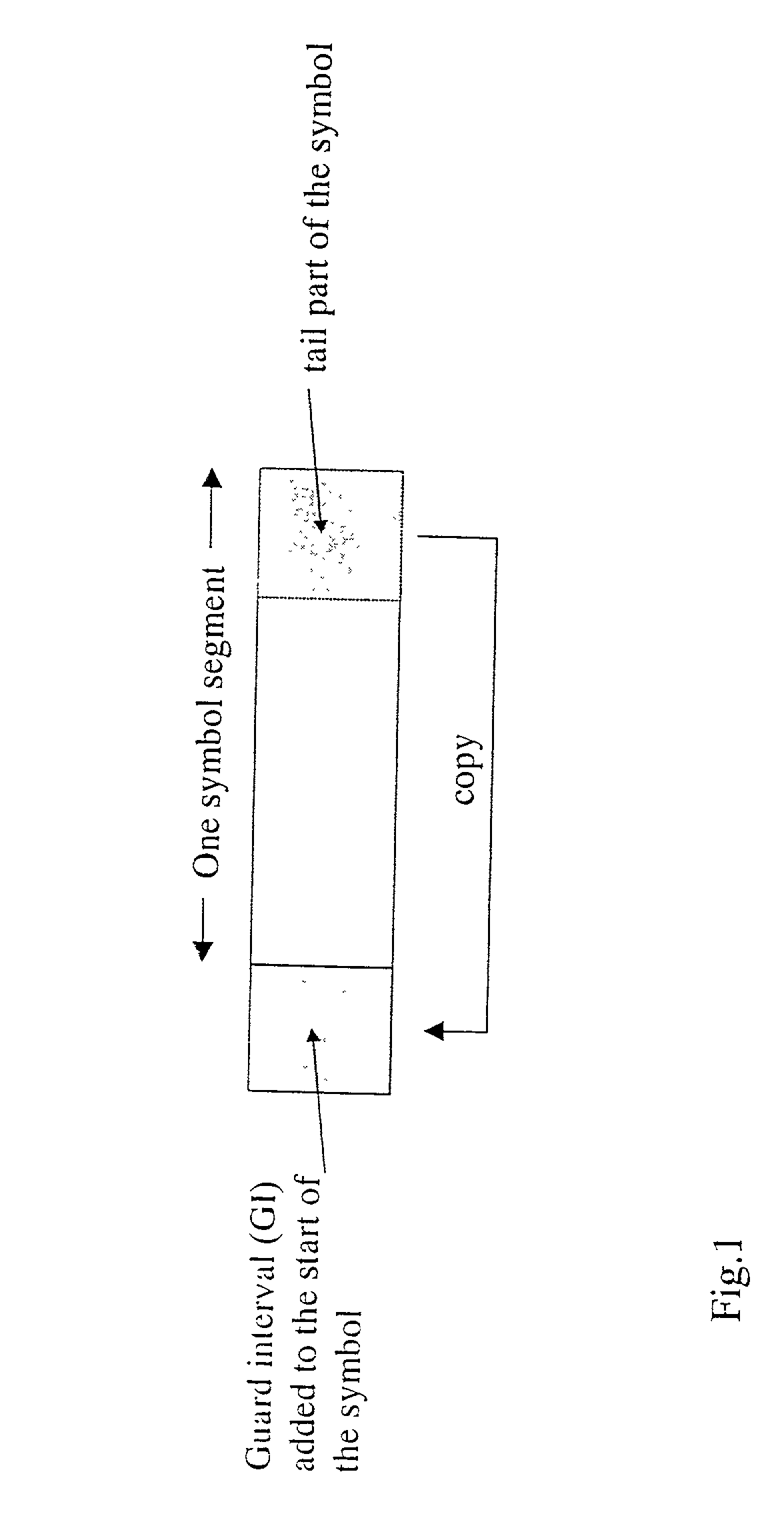

A multi-path equalization system for orthogonal frequency division multiplexing communication (OFDM) system includes a first estimator for estimating the channel characteristic using pilot signal. A divider is coupled to the estimator for dividing each sub-carrier with the channel characteristic to get the equalization to the data signal. A de-mapper uses the phase and amplitude correction of the channel estimate to recover the data signals. An improved channel estimation is provided by a repeat channel estimation feedback loop that includes the de-mapper a multiplier, an inverse fast Fourier transform (IFFT), a low pass filter and a fast Fourier transform (FFT). The improved channel estimation is obtained by multiplying at the multiplier the conjugate of the de-mapped data to the input sub-carriers and applying inverse FFT, low pass filtering and FFT to get the new channel estimate. Each sub-carrier is divided with new channel characteristic to get new equalization to the data signal. The channel estimation is repeated until there is convergence. The output is provided after the de-mapper. In the case of channel decoding to improve performance a Viterbi decoder and convolutional encoder is coupled in loop between the de-mapper and the multiplier.

Owner:TEXAS INSTR INC

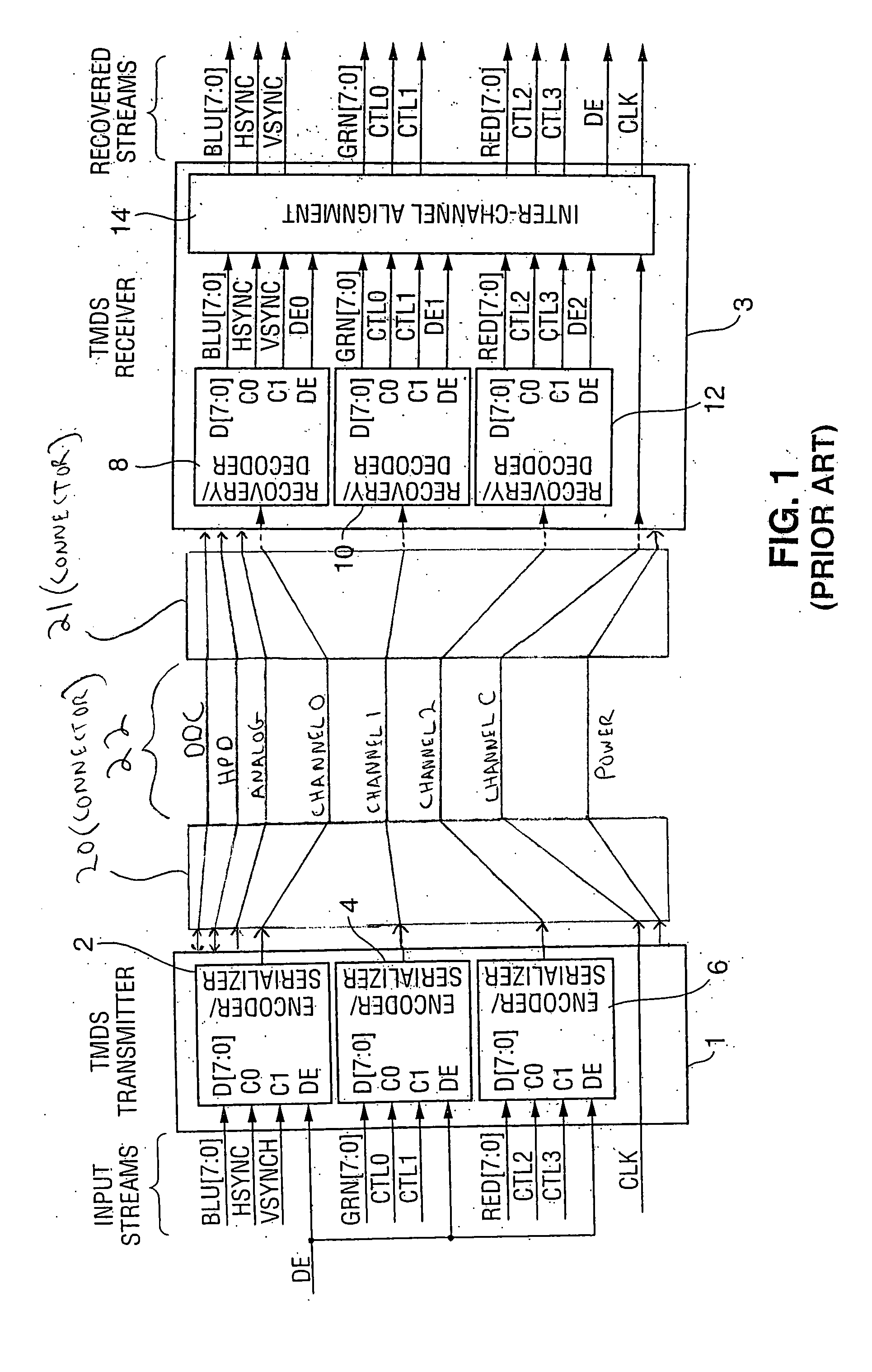

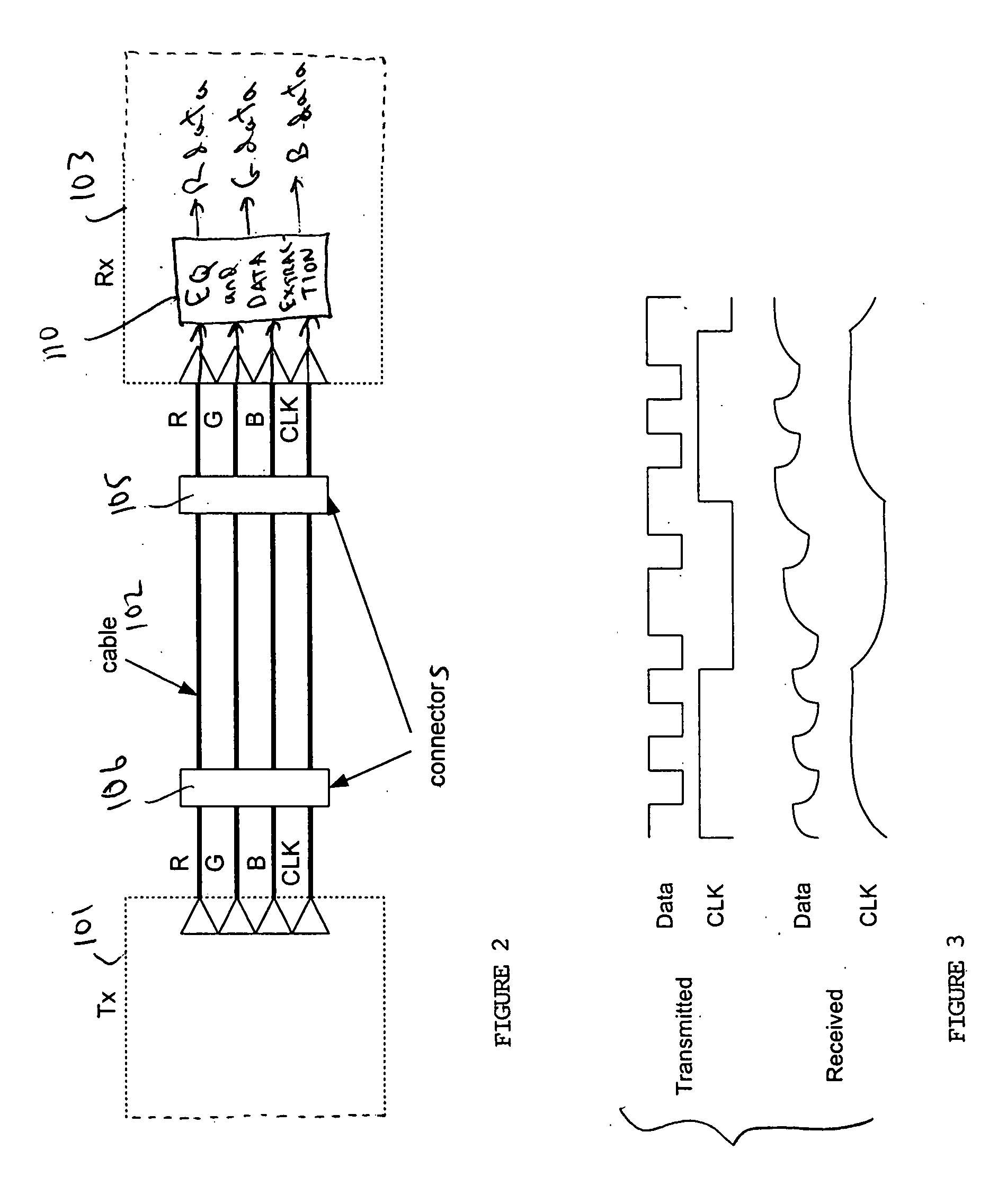

Method and circuit for adaptive equalization of multiple signals in response to a control signal generated from one of the equalized signals

ActiveUS20050195894A1Simple and robustOptimizationMultiple-port networksError preventionControl signalData signal

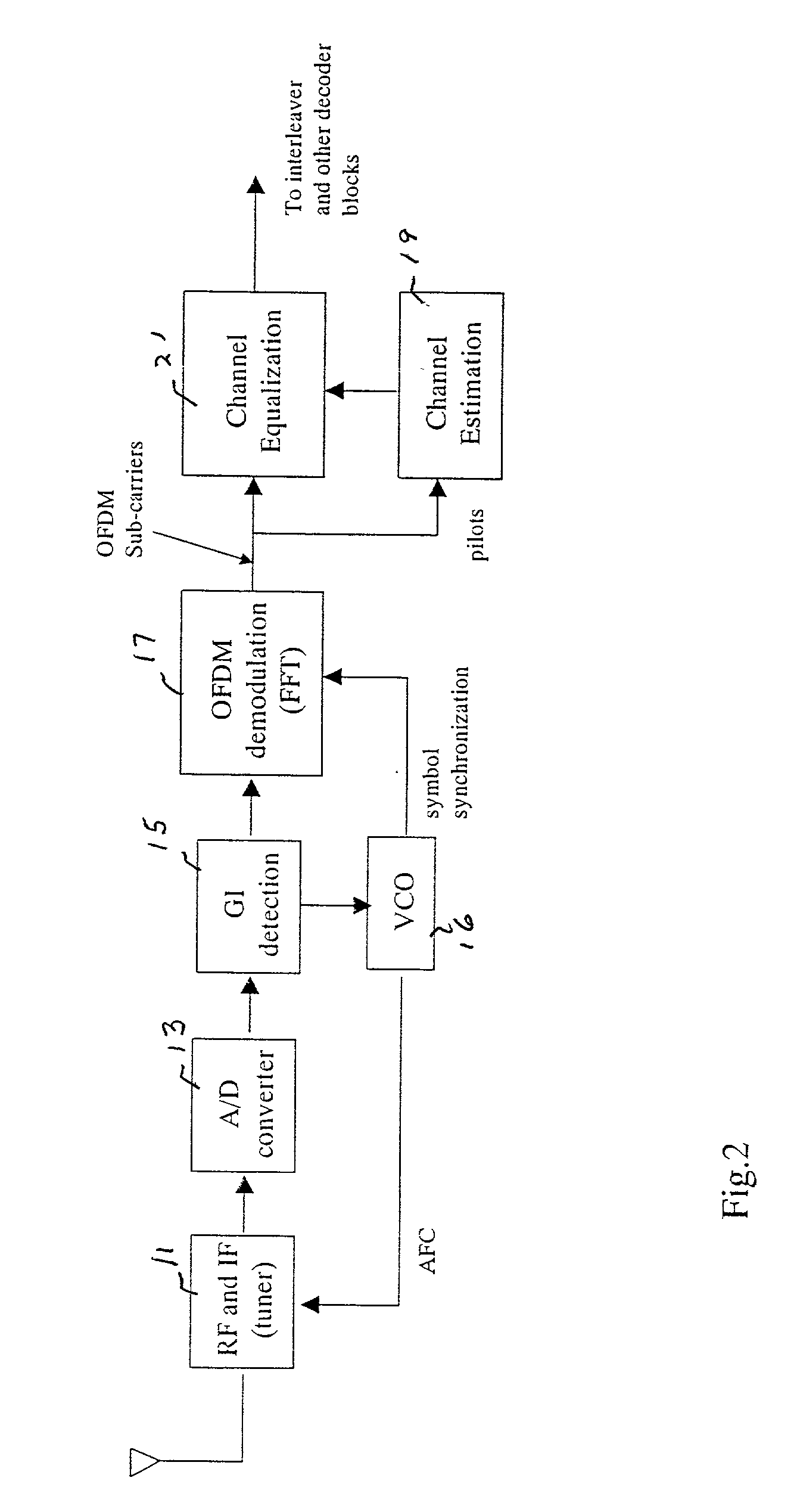

In preferred embodiments, an adaptive equalization circuit including at least two equalization filters (each for equalizing a signal transmitted over a multi-channel serial link) and control circuitry for generating an equalization control signal for use by all the filters. The control circuitry generates the control signal in response to an equalized signal produced by one of the filters, and asserts the control signal to all the filters. Preferably, one filter generates an equalized fixed pattern signal in response to a fixed pattern signal (e.g., a clock signal), each other filter equalizes a data signal, and the control circuitry generates the control signal in response to the equalized fixed pattern signal. In other embodiments, the invention is an adaptive equalization circuit including an equalization filter and circuitry for generating a control signal for the filter in response to a signal indicative of a predetermined fixed pattern, a receiver including an adaptive equalization circuit, a system including such a receiver, and a method for adaptive equalization of signals received over a multi-channel serial link.

Owner:LATTICE SEMICON CORP

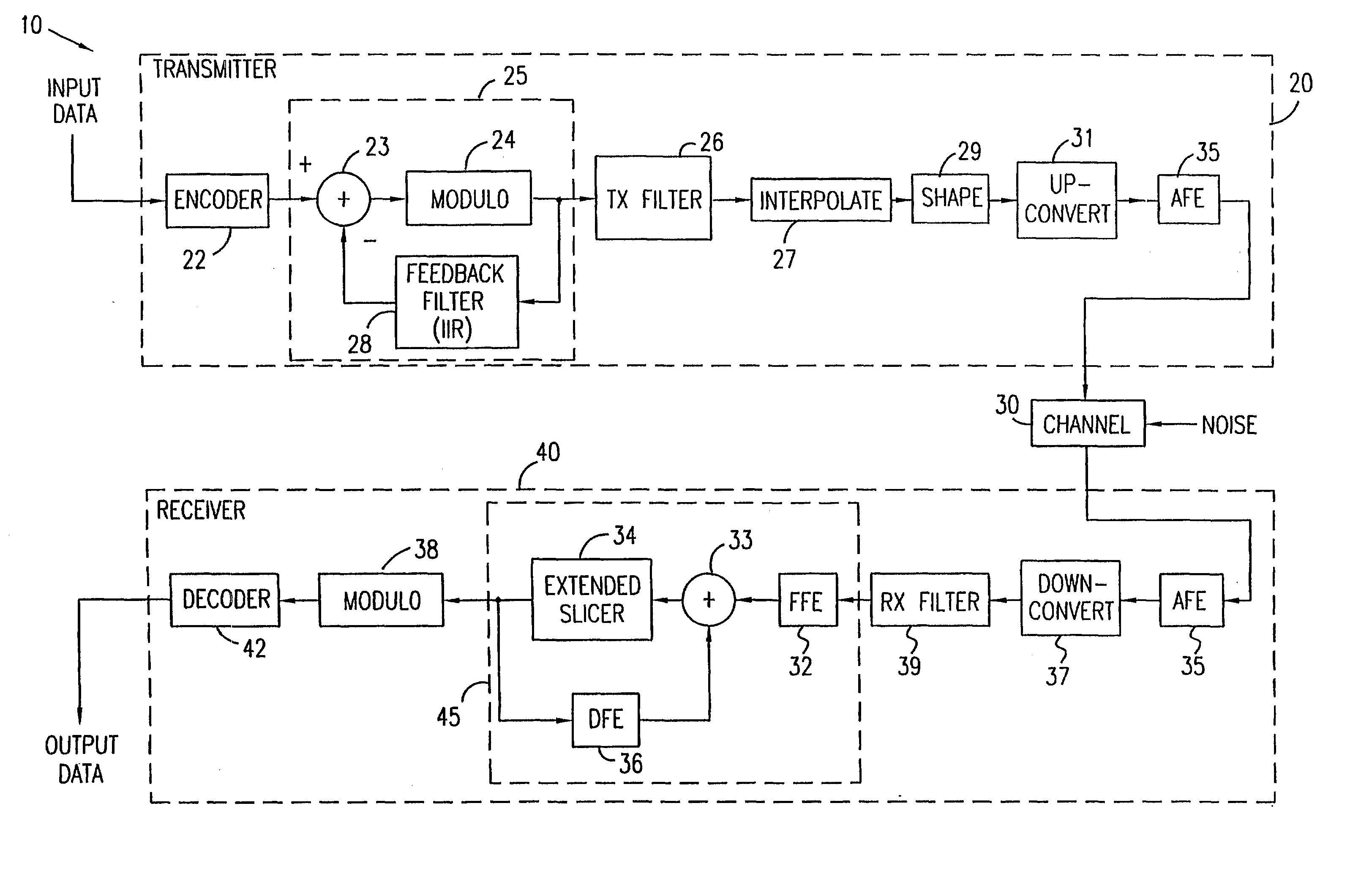

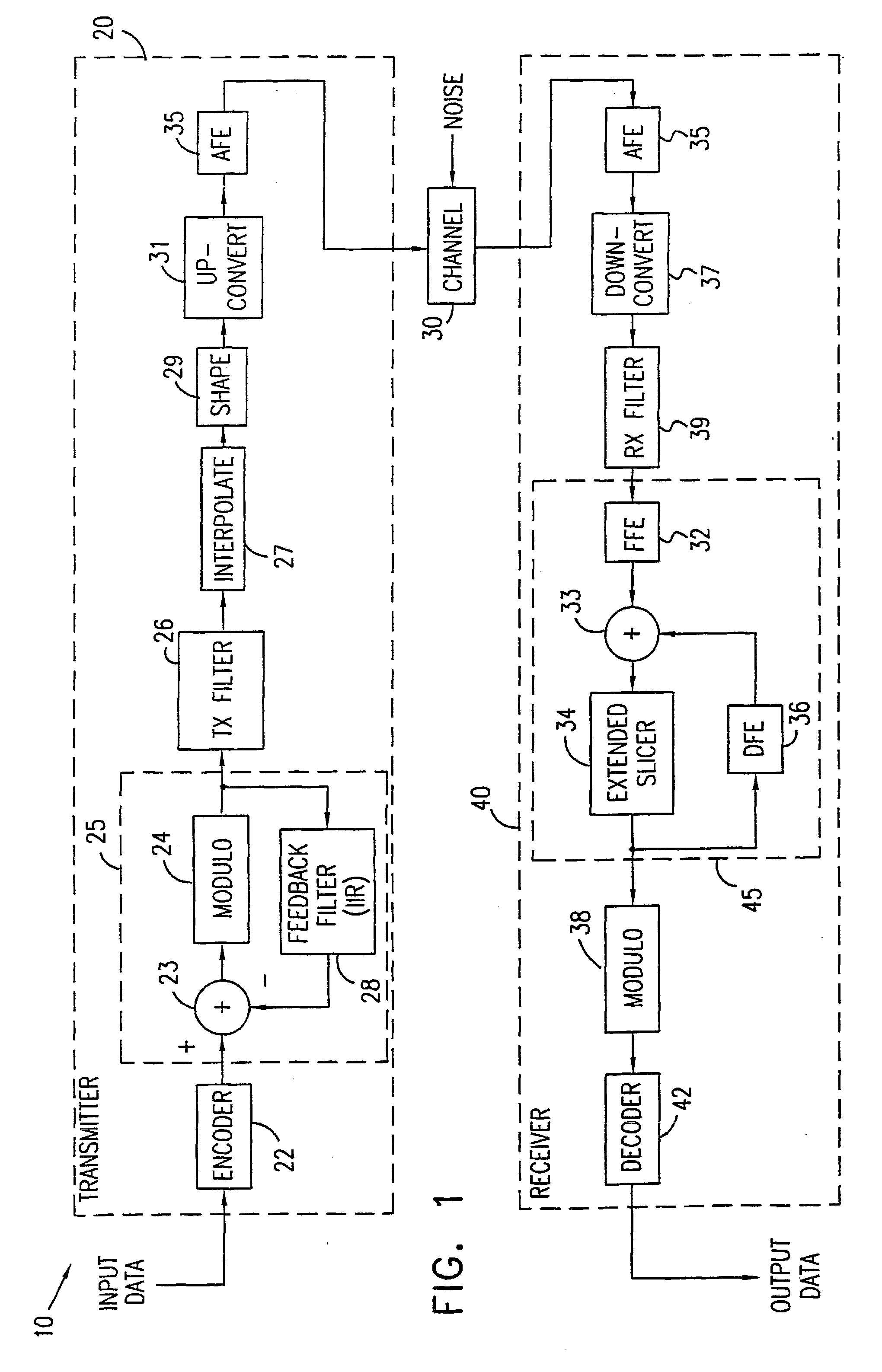

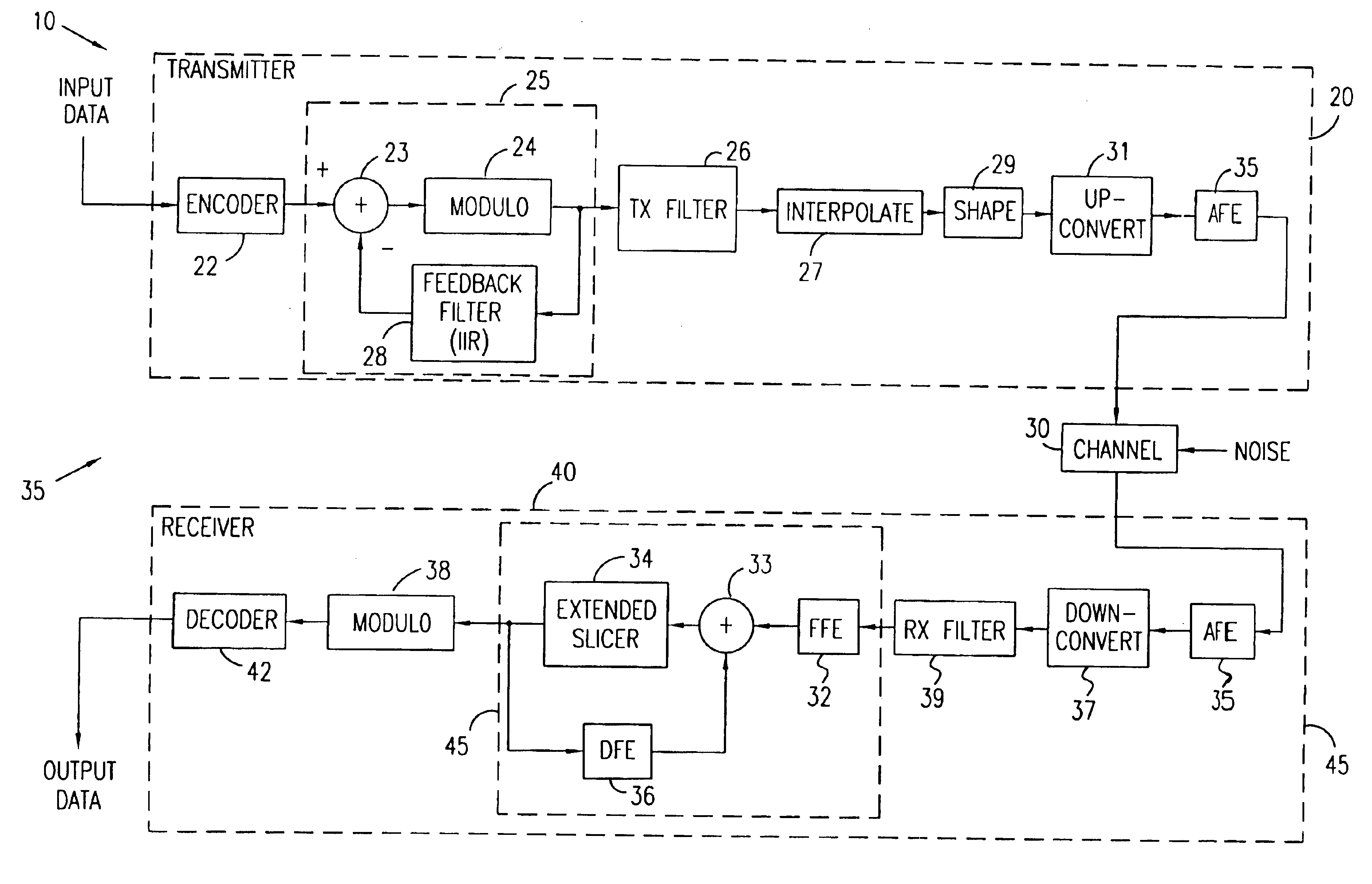

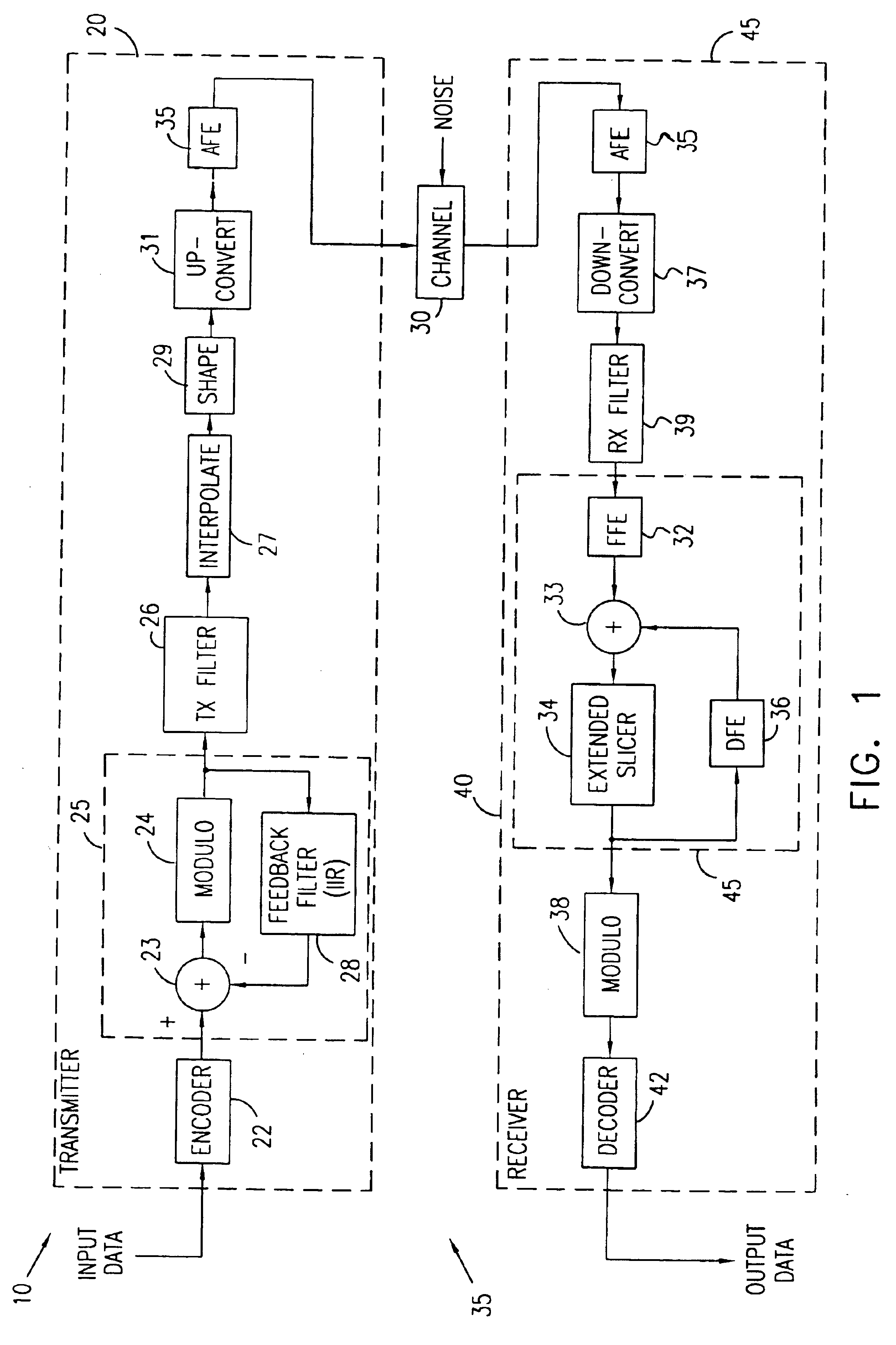

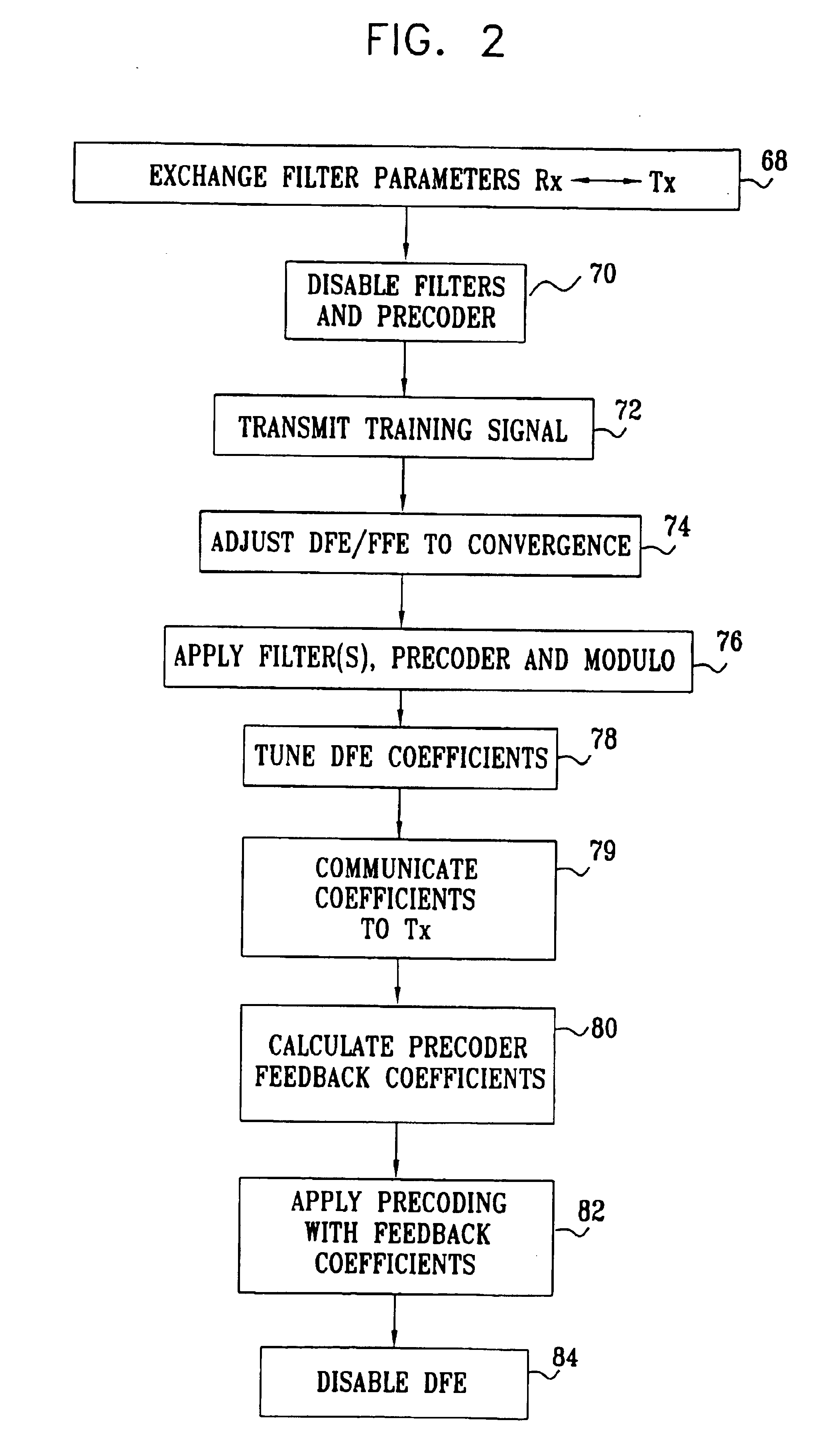

Data transceiver with filtering and precoding

InactiveUS7200180B2Low implementation costEfficiently signaledError preventionLine-faulsts/interference reductionPrecodingDigital data

A method for conveying digital data from a transmitter (20) to a receiver (40) includes specifying a spectral filtering profile to be applied in conveying the data. A sequence of input symbols is generated (22) at the transmitter, corresponding to the data to be conveyed. The input symbols are precoded at the transmitter using Tomlinson-Harashima precoding (25) responsive to the specified profile, so as to generate a corresponding sequence of precoded symbols. The precoded symbols are filtered (26) in accordance with the specified profile. The precoded and filtered symbols are decoded at the receiver so as to recover the data therefrom.

Owner:COMCAST CABLE COMM LLC

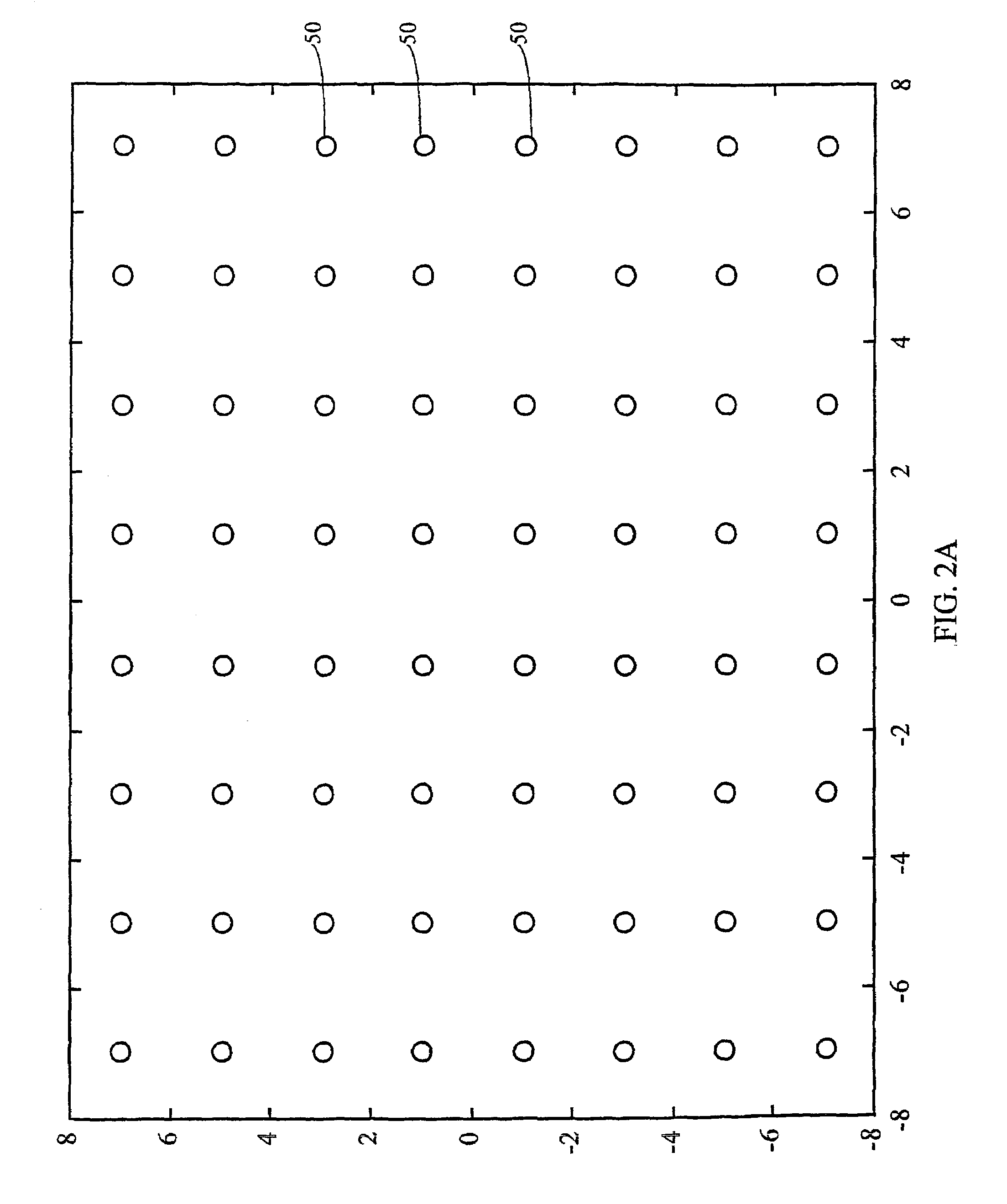

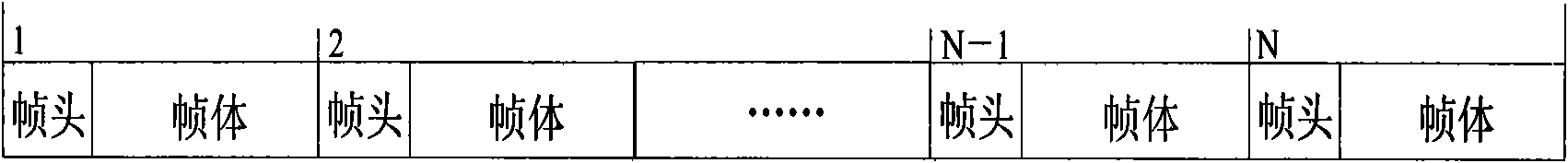

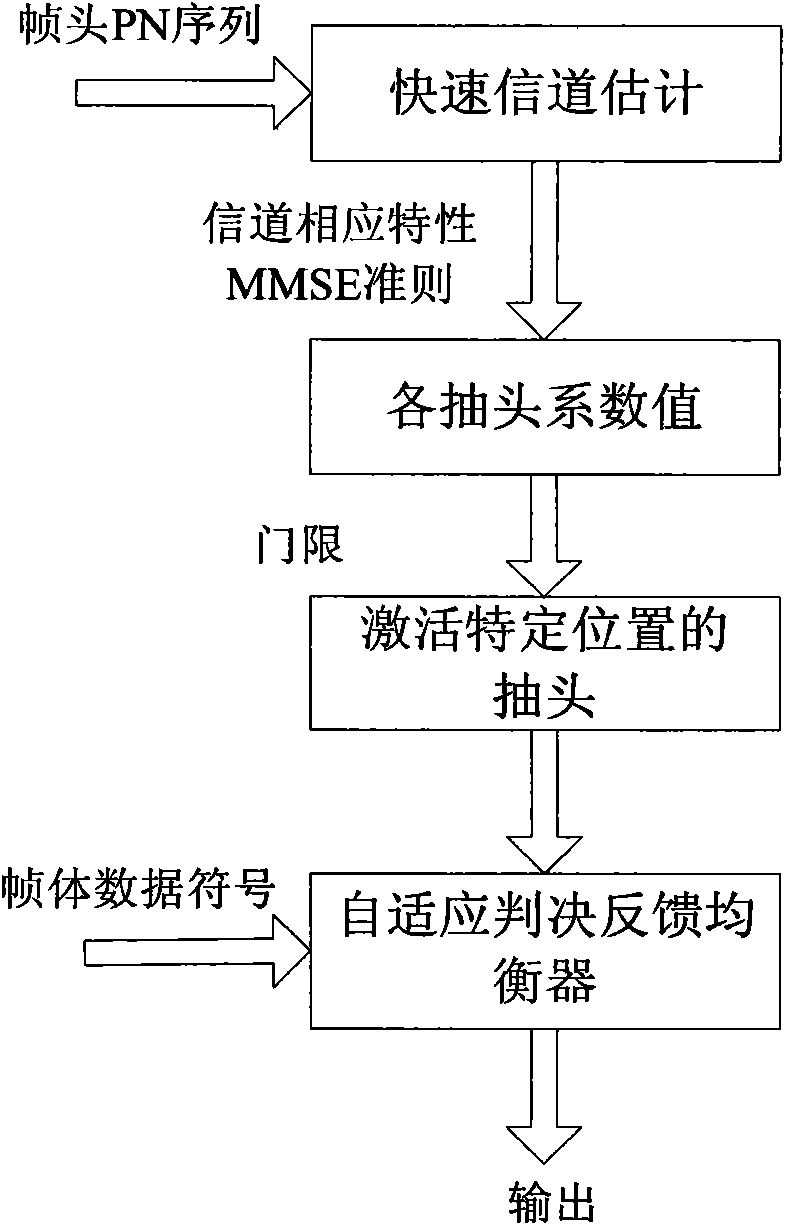

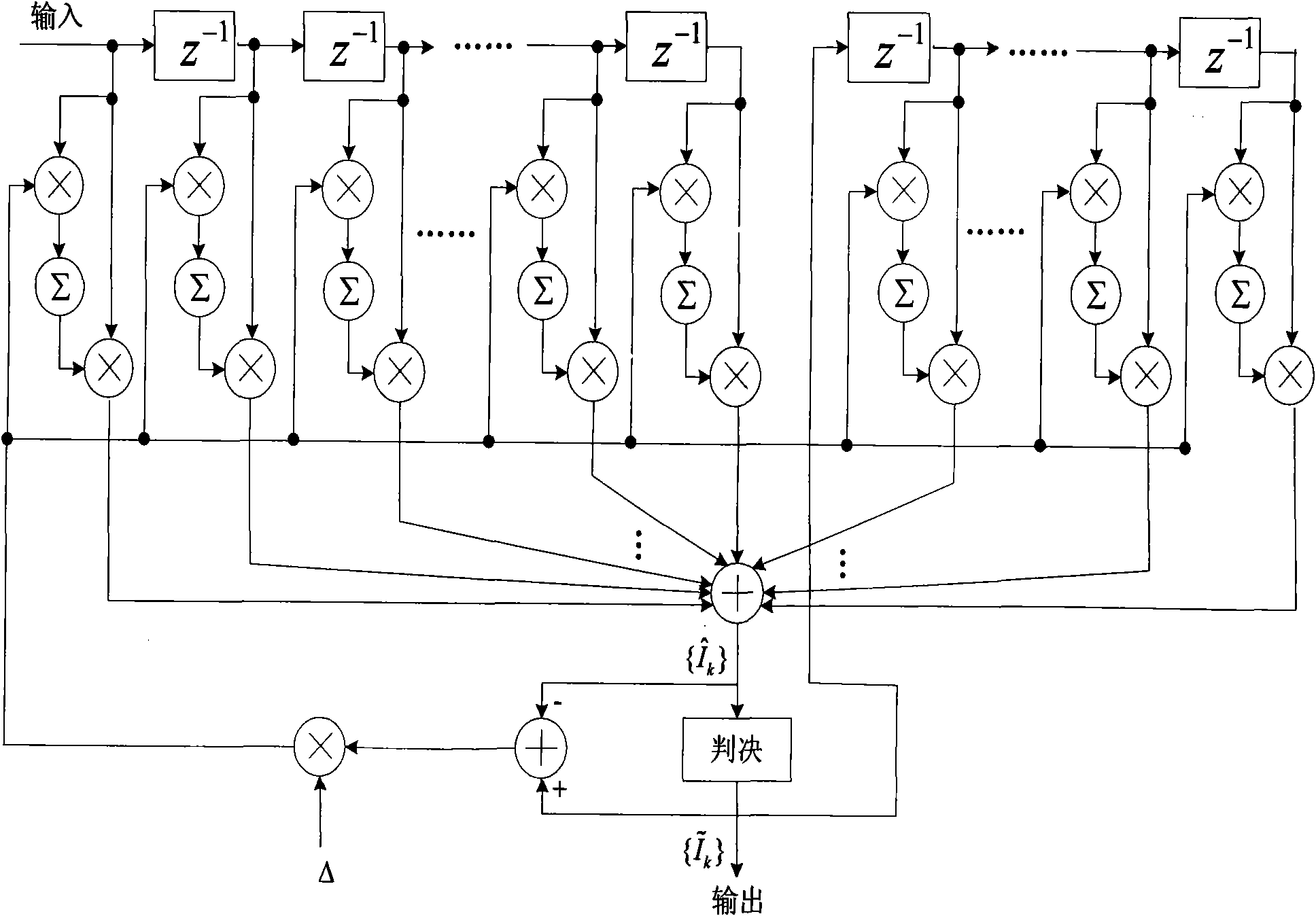

Indirect self-adaptive balancing method of shallow-sea underwater acoustic communication system

InactiveCN101567863ASimple structureGood estimateTransmitter/receiver shaping networksCommunications systemShallow sea

The invention discloses an indirect self-adaptive equalization method of a shallow-sea underwater acoustic communication system to eliminate transmission intersymbol interference brought by a shallow-sea underwater acoustic channel with the time-varying and multi-diameter characteristics. The method comprises the following steps: designing a signal frame structure suitable for transmission in the shallow-sea underwater acoustic channel at a sending terminal; utilizing a frame head PN sequence to carry out rapid channel estimation and the initialization of equalizer tap coefficients at a receiving terminal; selecting a corresponding threshold according to the practical transmission environment to realize the decentralization of equalizer taps; and adopting an LMS algorithm with a variable step size to further reduce errors so as to better equalize frame body data. The invention enables an equalizer in the shallow-sea underwater acoustic communication system to have rapid convergence and lower hardware complexity, has good equalization effect on a sending signal after high-level modulation and can be effectively applied to the shallow-sea high-speed digital communication system.

Owner:魏昕

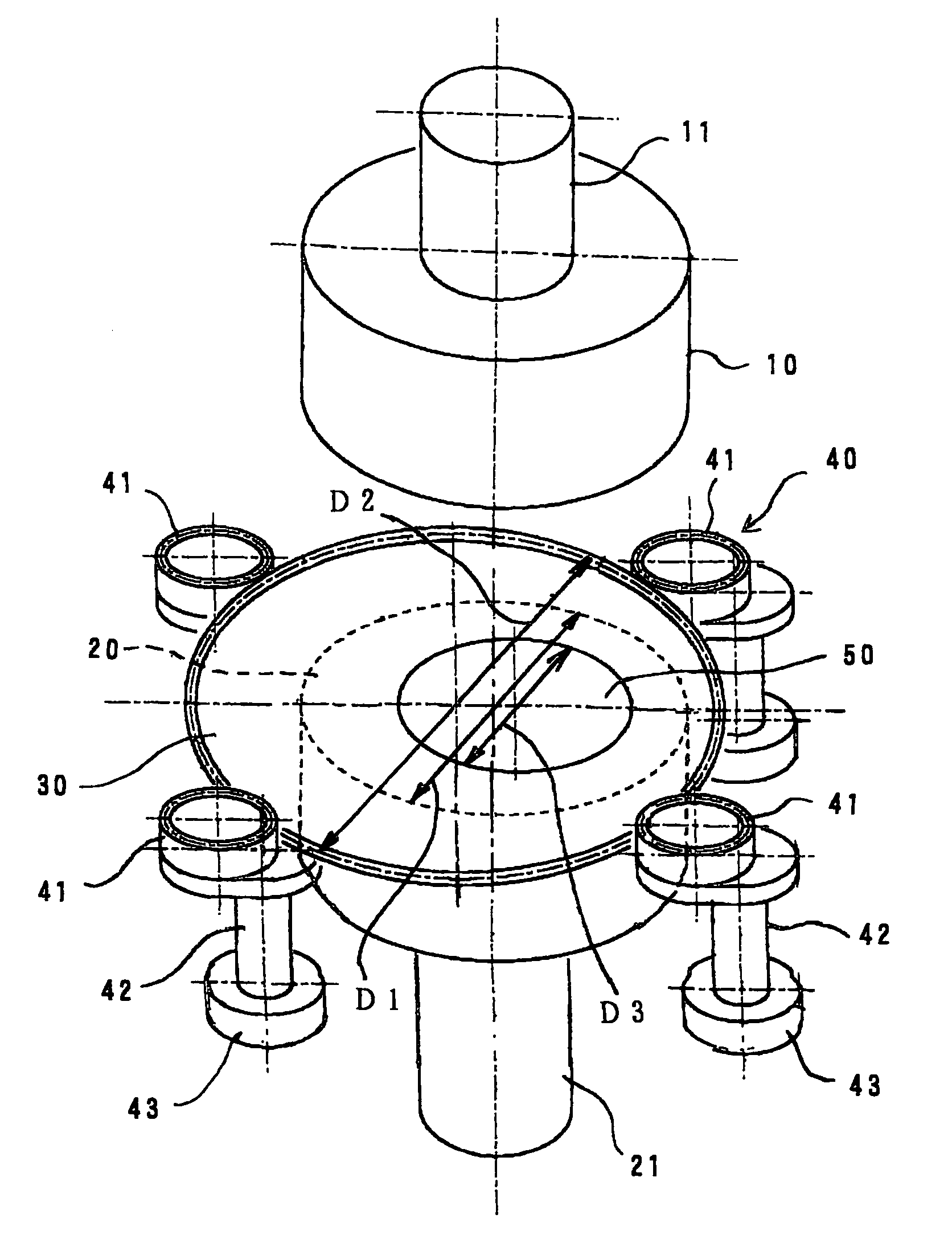

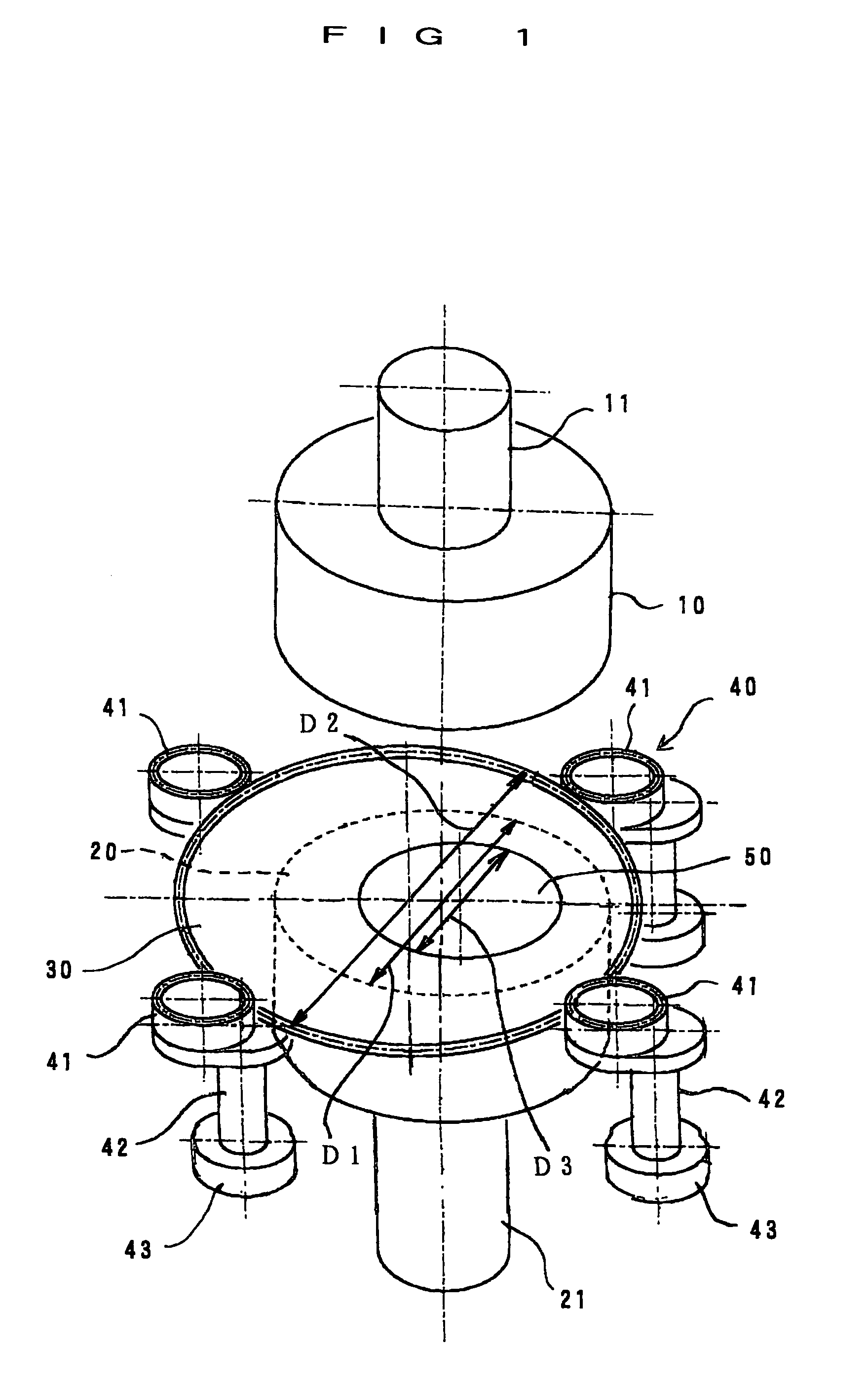

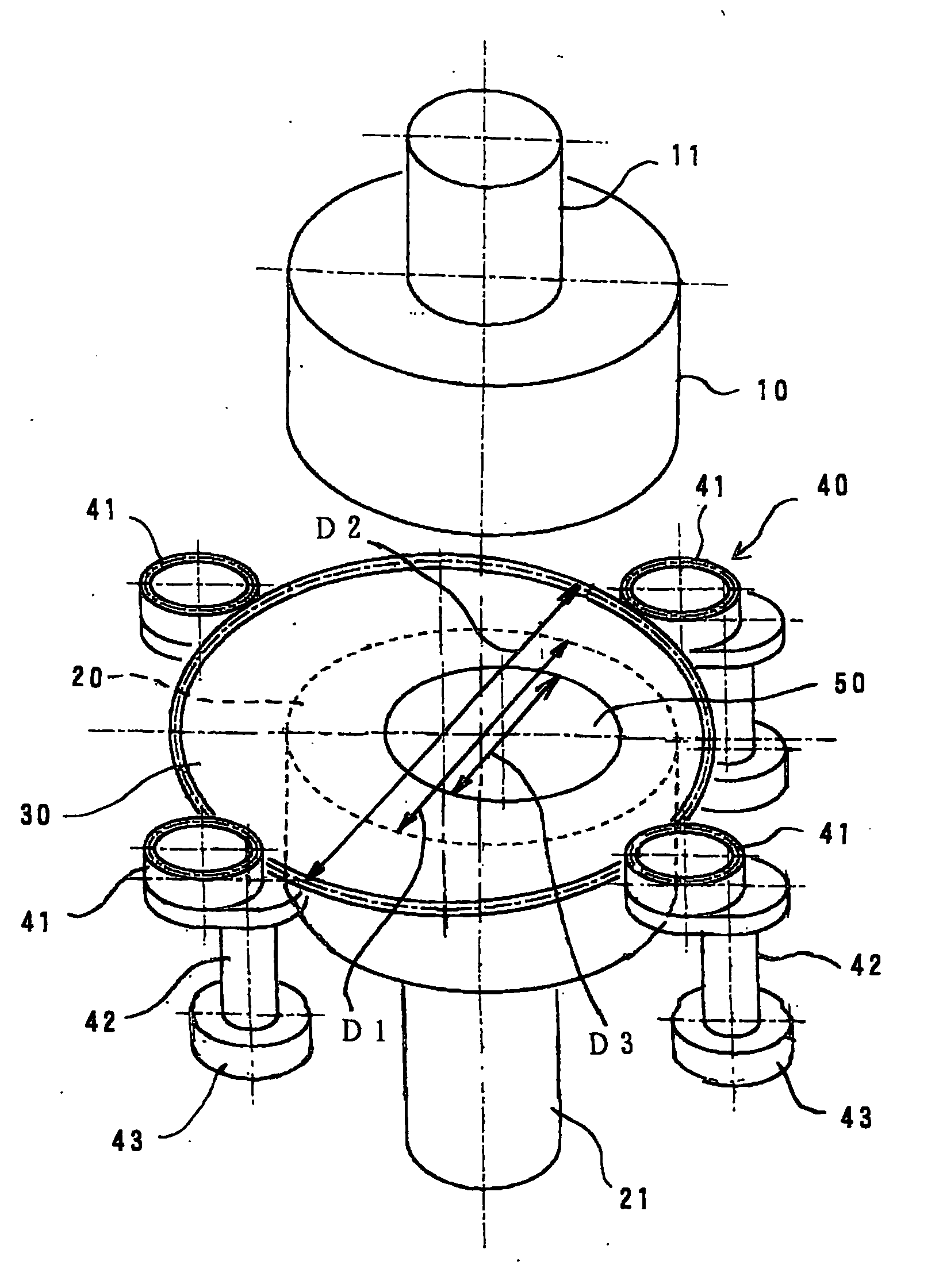

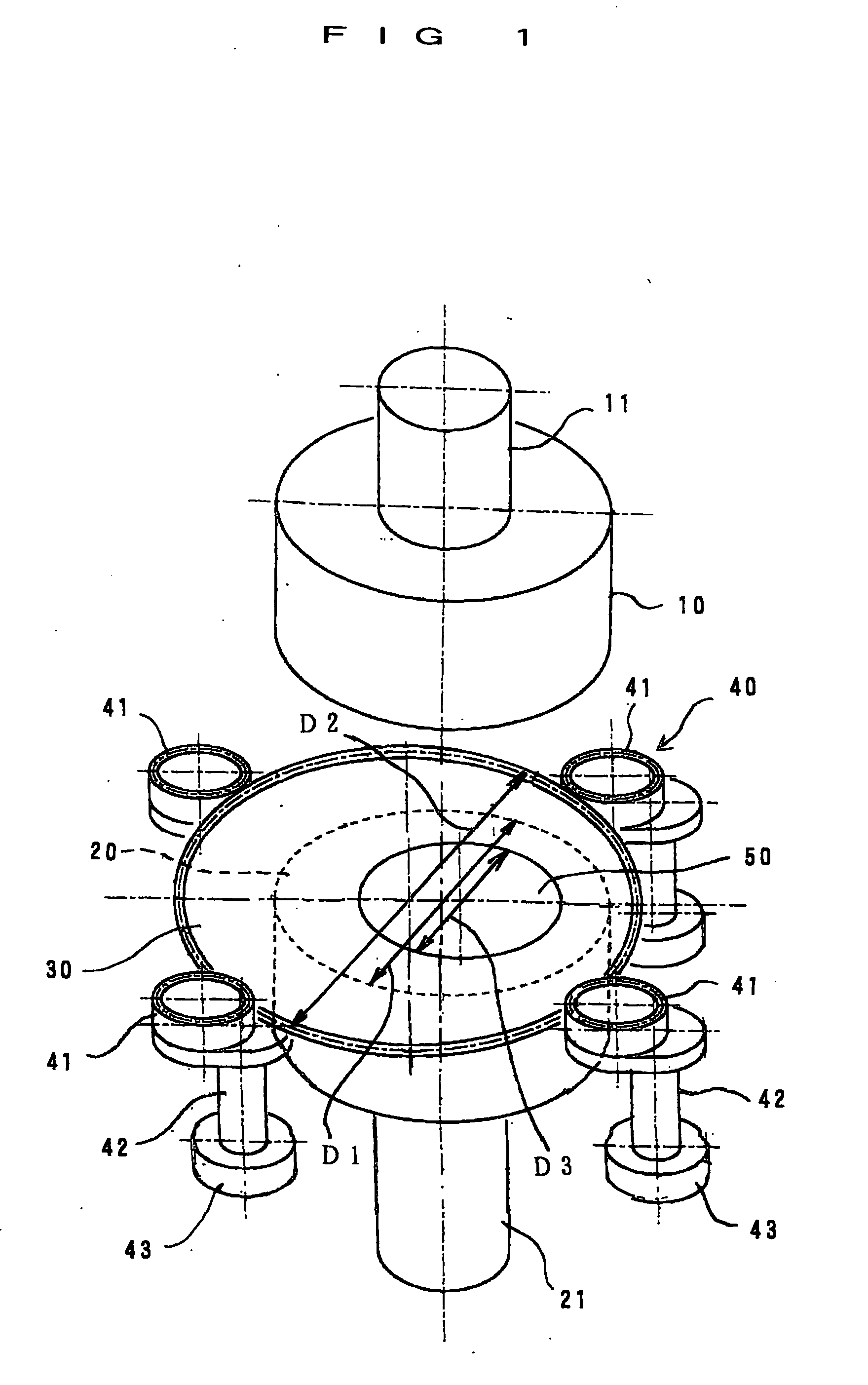

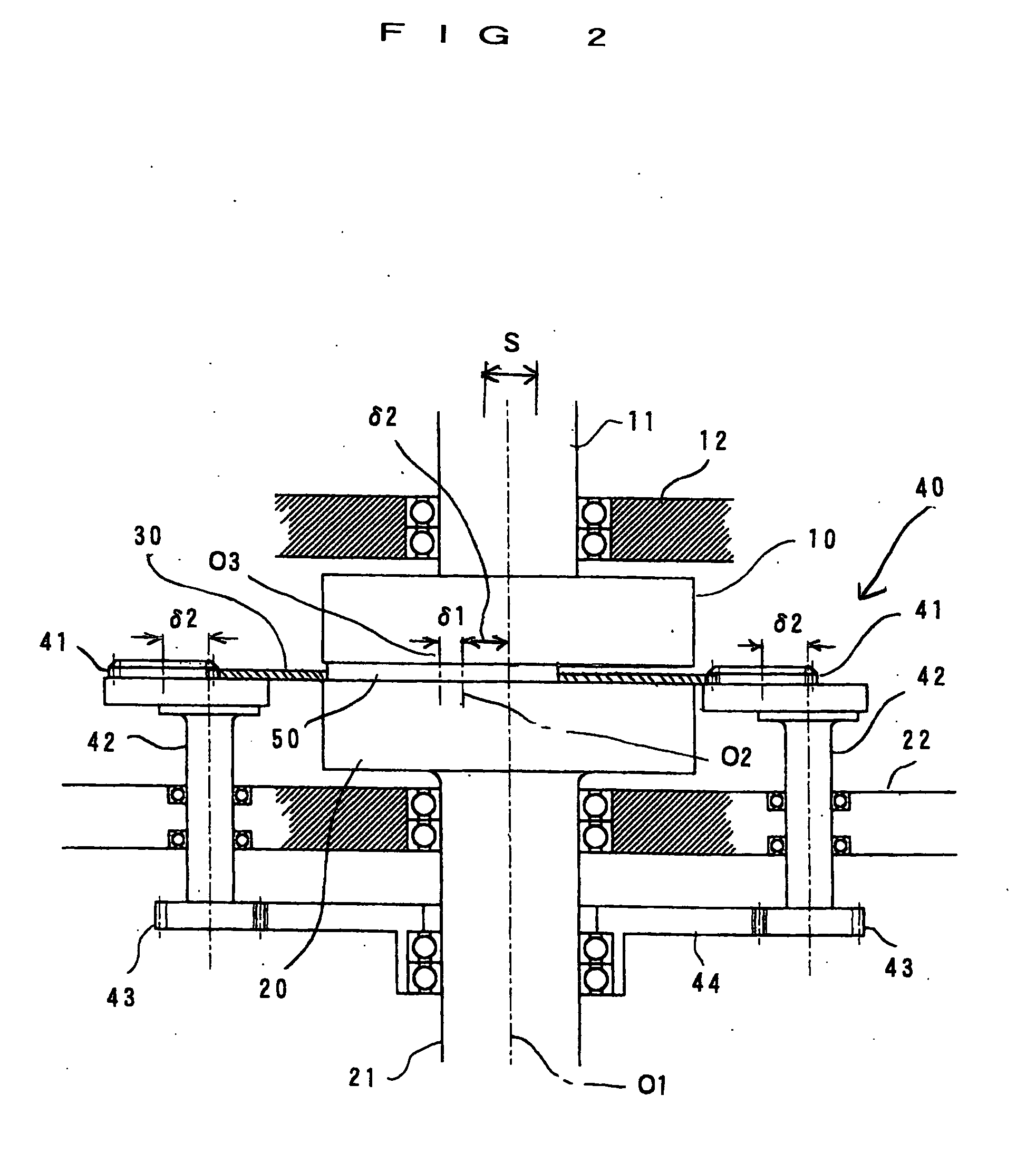

Double-side polishing method and apparatus

ActiveUS7029380B2Improve flatnessEasy constructionEdge grinding machinesRevolution surface grinding machinesReciprocating motionEngineering

In order to improve a flatness of a work in single wafer type double-side polishing in which one wafer is polished with one carrier, a carrier larger in diameter than upper and lower surface plates that rotate is inserted between the surface plates, and a wafer smaller in diameter than the surface plates is held with the carrier. The carrier is rotated by plural eccentric gears that mesh with external gear teeth formed on the outer peripheral surface of the carrier at plural positions along a circumferential direction thereof and revolve around positions spaced from the centers as centers in synchronism with each other or one another at the plural positions of meshing. The carrier rotates about its center and moves circularly around the center of the surface plates spaced from the center thereof. The upper surface plate is reciprocated in a direction perpendicular to the central axis when required. Geometrical motion loci of points on the wafer are complex and peripheral speeds alter to large extents to thereby enhance equalization of peripheral speeds of points on the wafer to a higher level to thereby improve a flatness.

Owner:KASHIWARA KIKAI SEISAKUSHIYO +1

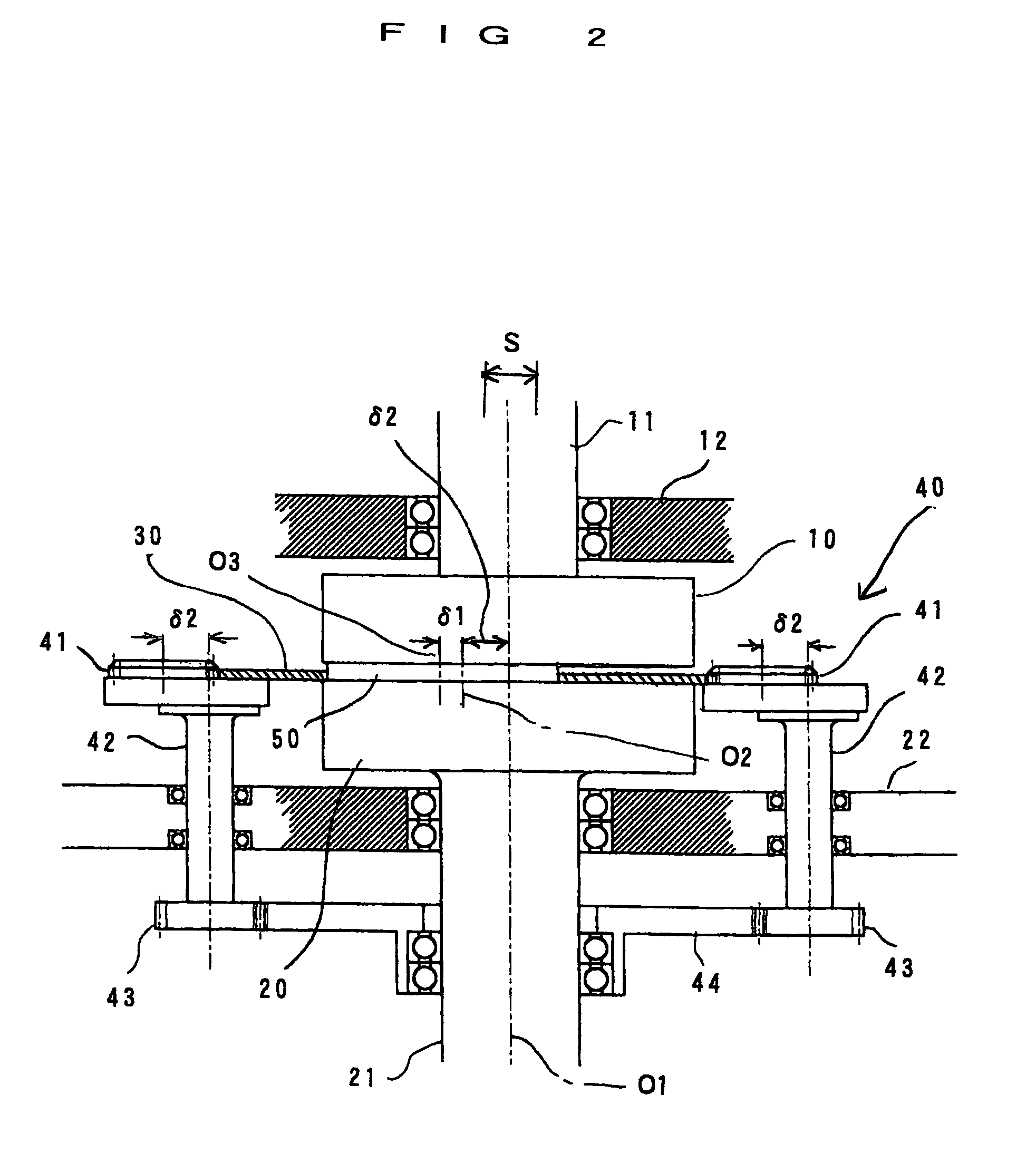

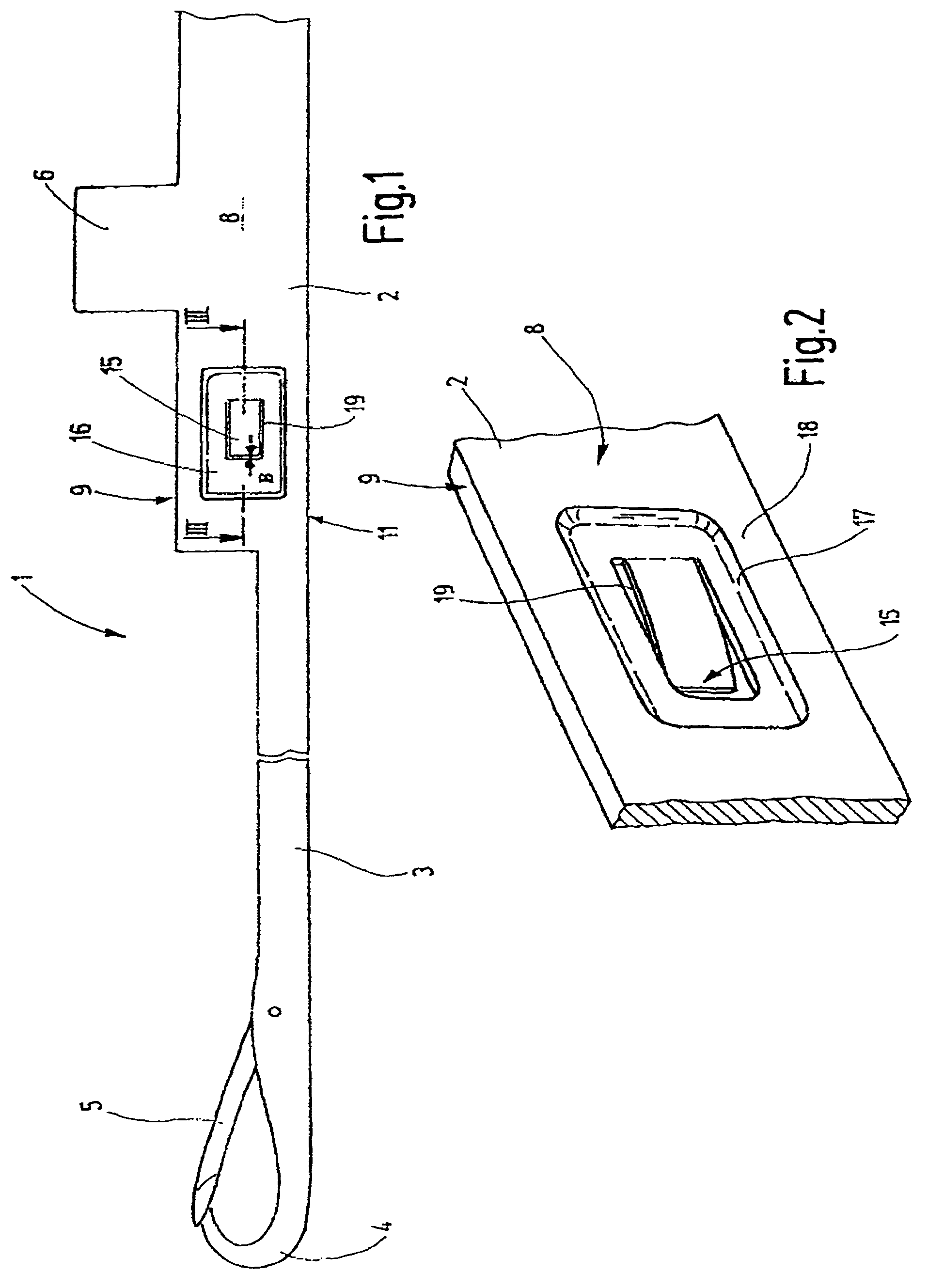

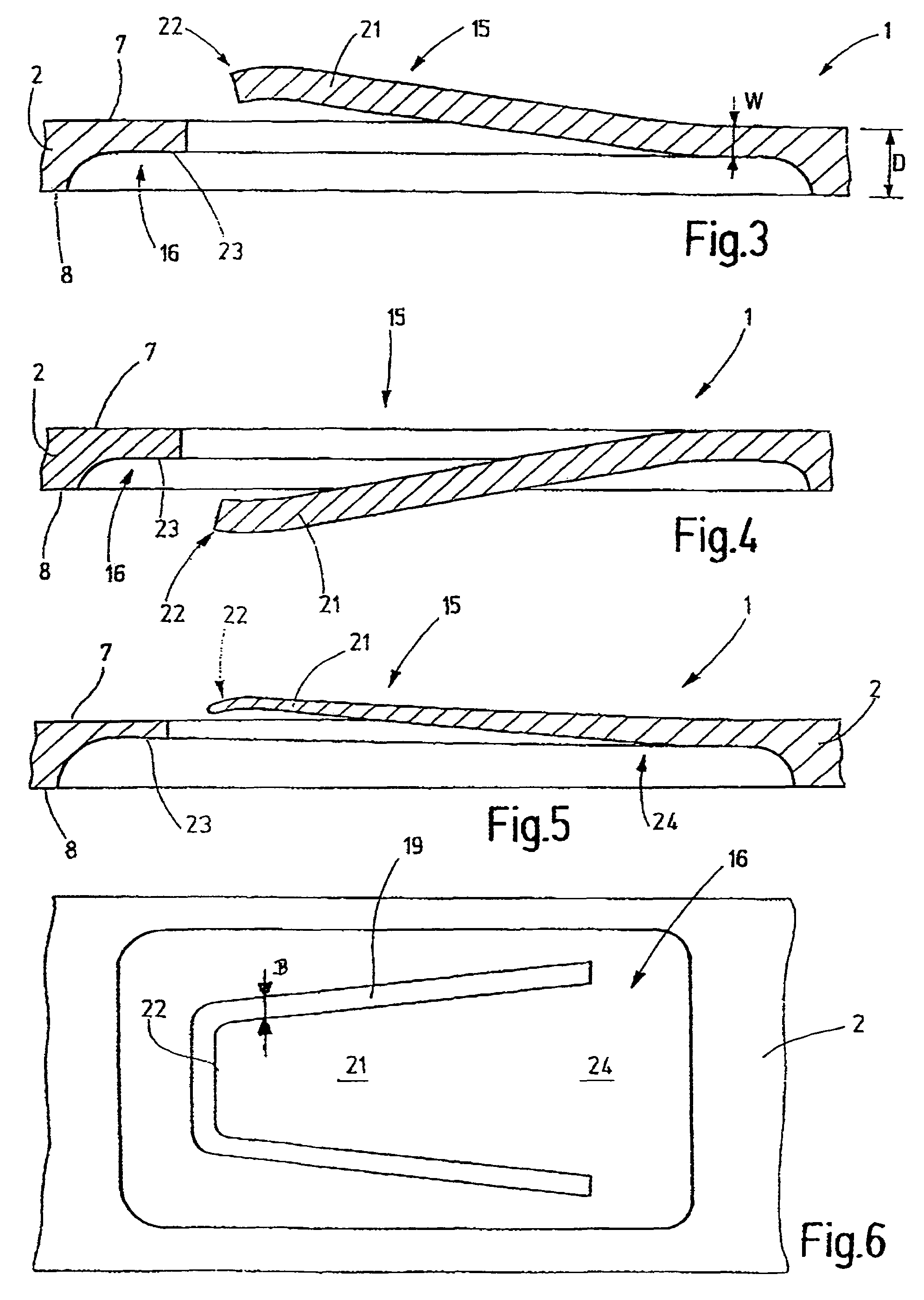

System component having a braking spring

ActiveUS7117694B2Simple and reliable manufactureEvenly goodWater treatment parameter controlSludge treatmentSpring force

A knitting tool (1) is provided with a braking spring (15) formed on the knitting tool as a one-piece member thereof. The braking spring has a thickness (W) which is less than that of the knitting tool (1), whereby the braking spring (15) may yield to a great extent and has a soft spring characteristic. Such a result may be achieved even with short spring lengths, whereby dimensional deviations of the spring have only a slight effect on the spring force. The structure is only slightly prone to soiling. The knitting tool may be manufactured in a simple manner.

Owner:GROZ BECKERT KG

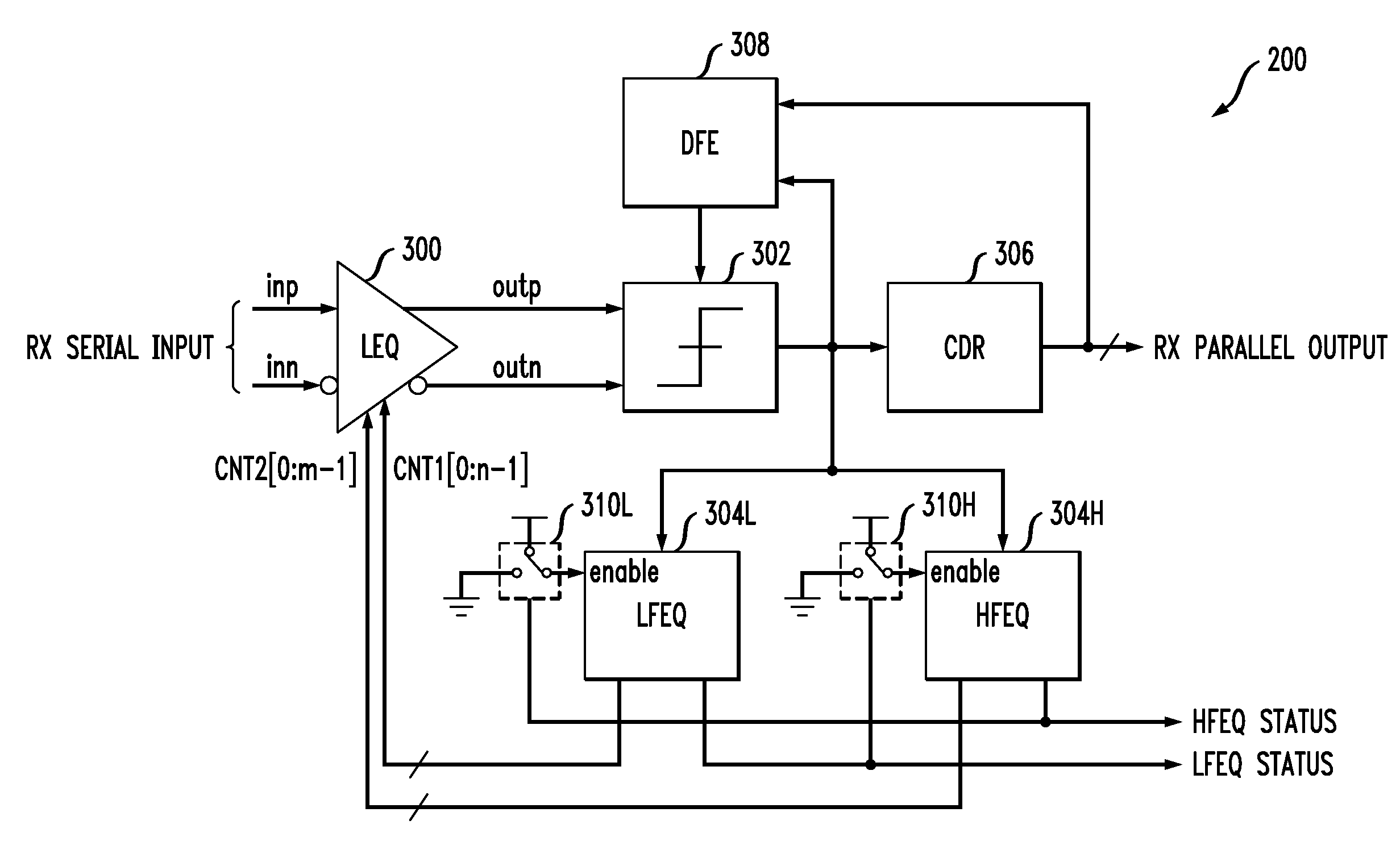

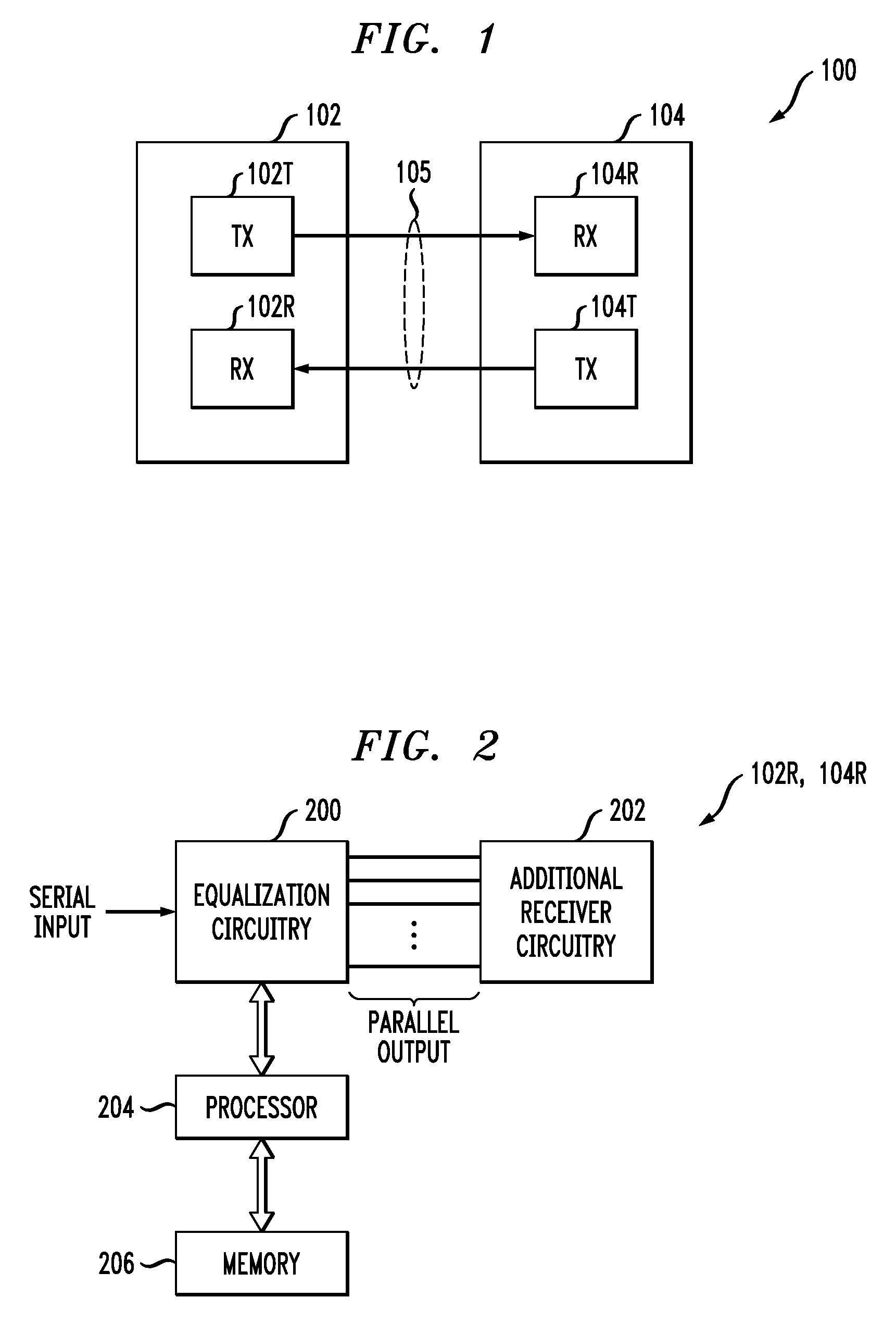

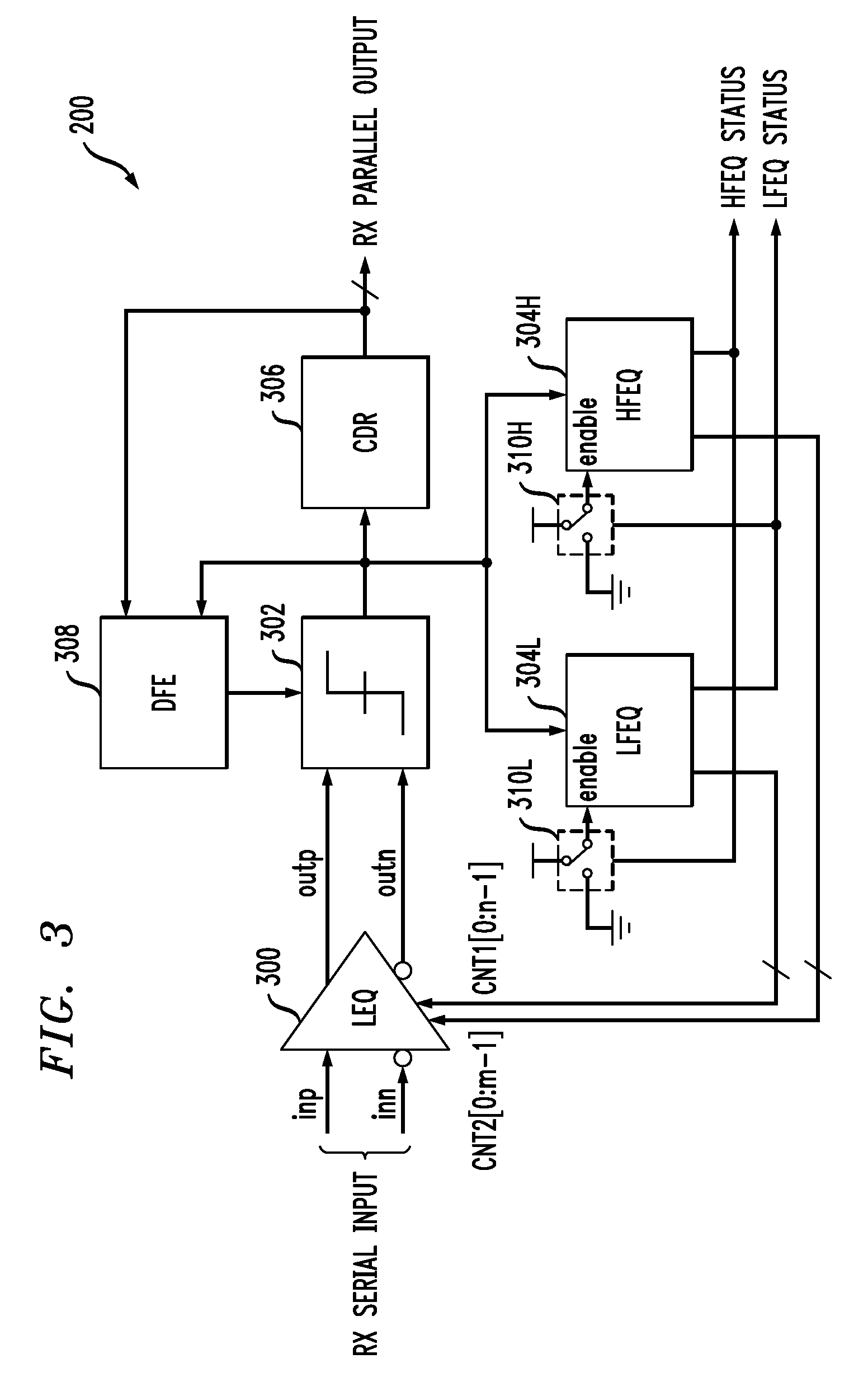

Multi-Band Gain Adaptation for Receiver Equalization Using Approximate Frequency Separation

InactiveUS20100290515A1Improved receiver equalizationLow costMultiple-port networksDelay line applicationsMulti bandData stream

A receiver comprises equalization circuitry implementing at least first and second gain adaptation loops associated with respective first and second frequency bands. The equalization circuitry in one aspect is operative to identify a pattern in a portion of a received serial data stream, and to perform gain adaptation for the receiver utilizing a particular one of the gain adaptation loops responsive to the identified pattern. For example, the gain adaptation may be performed utilizing a low frequency gain adaptation loop if the detected pattern is of a first type generally associated with a low frequency band, and may be performed utilizing a high frequency gain adaptation loop if the detected pattern is of a second type generally associated with a high frequency band. In other aspects, the first and second gain adaptation loops may be activated in a particular serial order or in parallel.

Owner:LSI CORPORATION +1

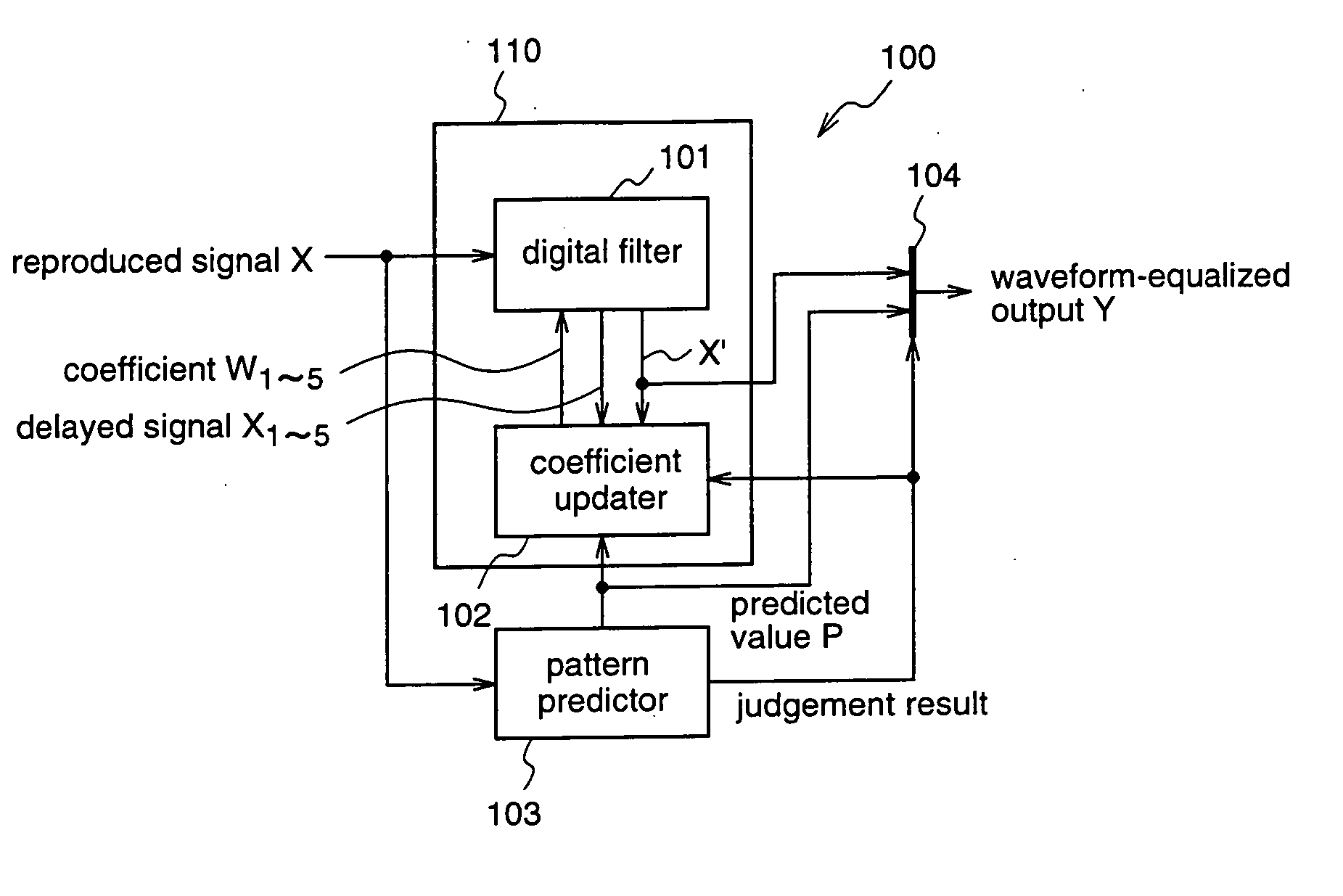

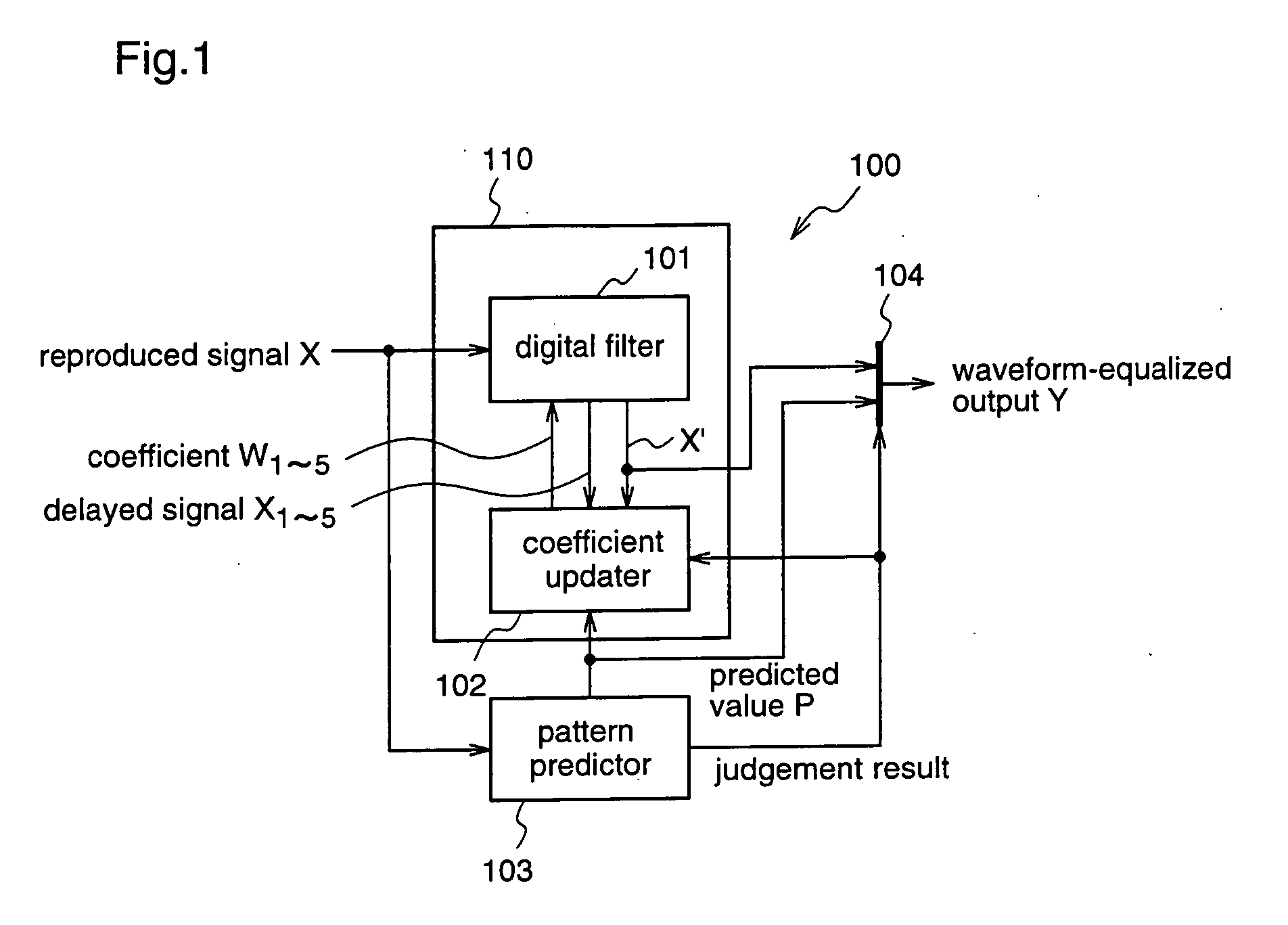

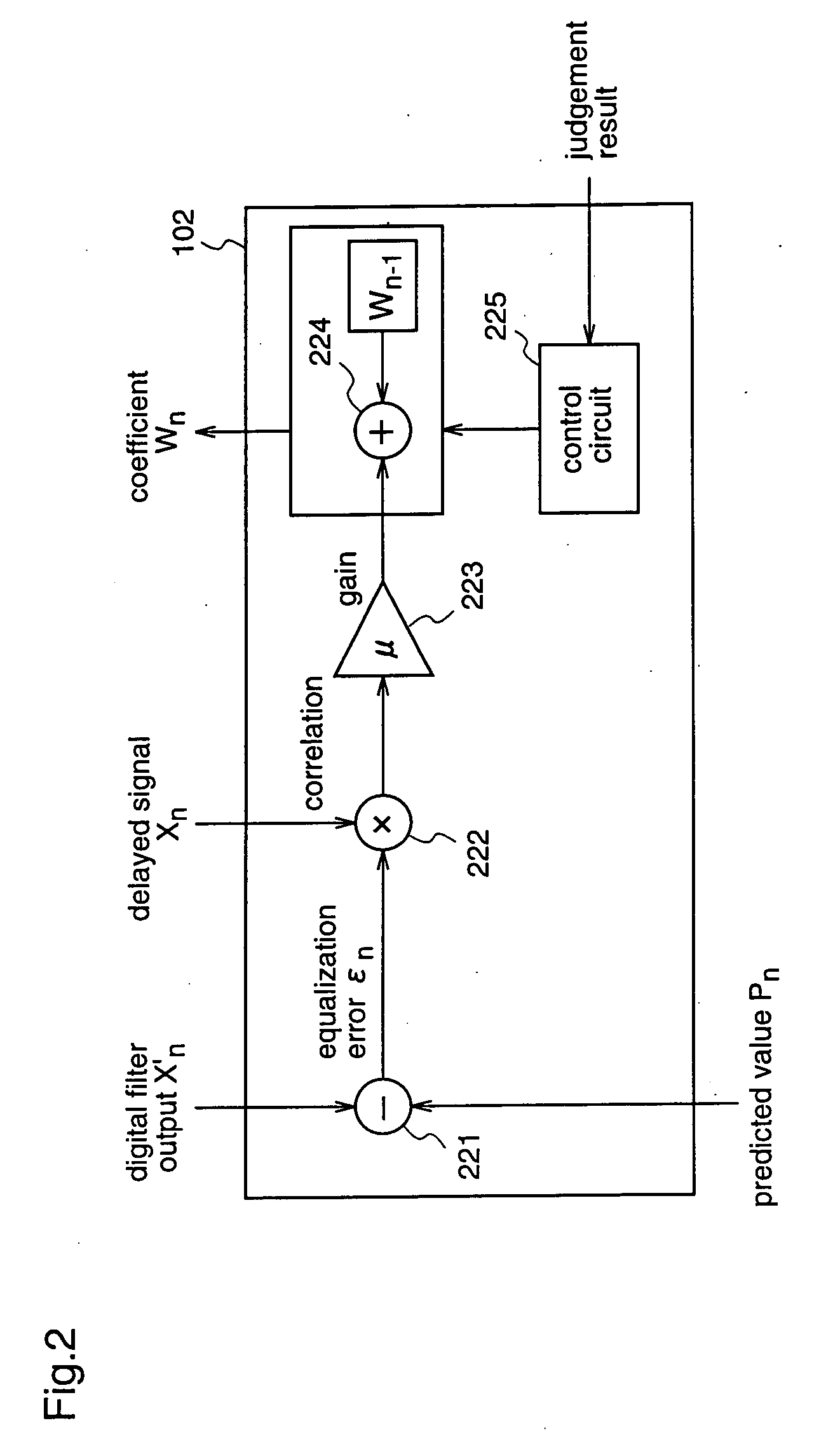

Reproduced signal processor and reproduced signal processing method

InactiveUS20050219985A1Evenly goodTelevision system detailsModification of read/write signalsNonlinear distortionDigital filter

As shown in FIG. 1, in the reproduced signal processing apparatus (100) of the present invention, the pattern predictor (103) predicts a predicted value which is a data sequence of a reproduced signal X and judges whether the predicted value matches a previously set specific pattern or not, and the adaptive equalizer (110) performs adaptive equalization on the reproduced signal X with timely updating the coefficients W of the digital filter according to the judgement result from the pattern predictor (103), and the selection circuit (104) outputs one of the output from the adaptive equalizer (110) and the predicted value as a waveform-equalized output Y on the basis of the judgement result. The reproduced signal processing apparatus (100) so constructed can realize optimal waveform equalization for coping with the non-linear distortion included in the reproduced signal.

Owner:PANASONIC CORP

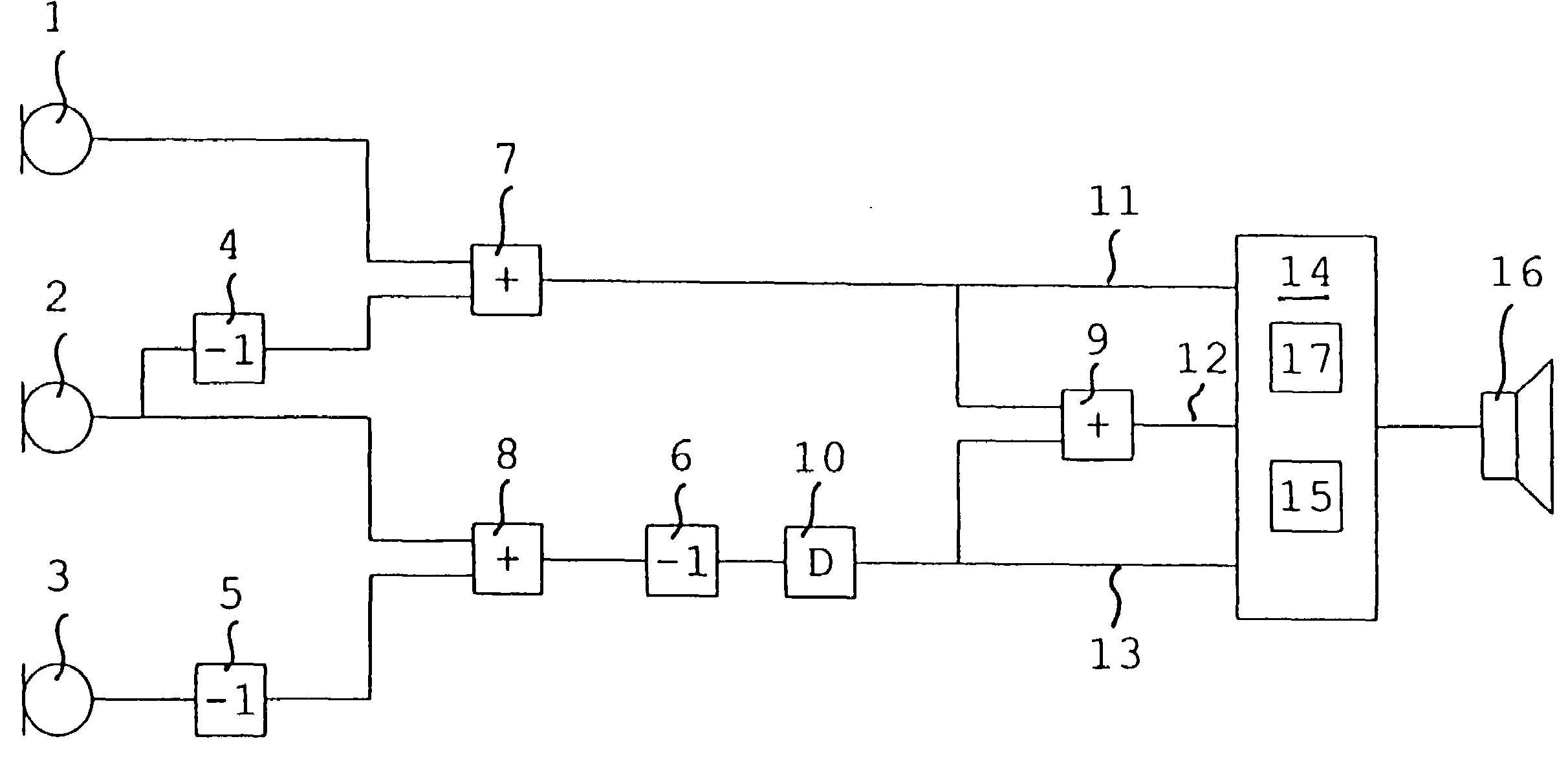

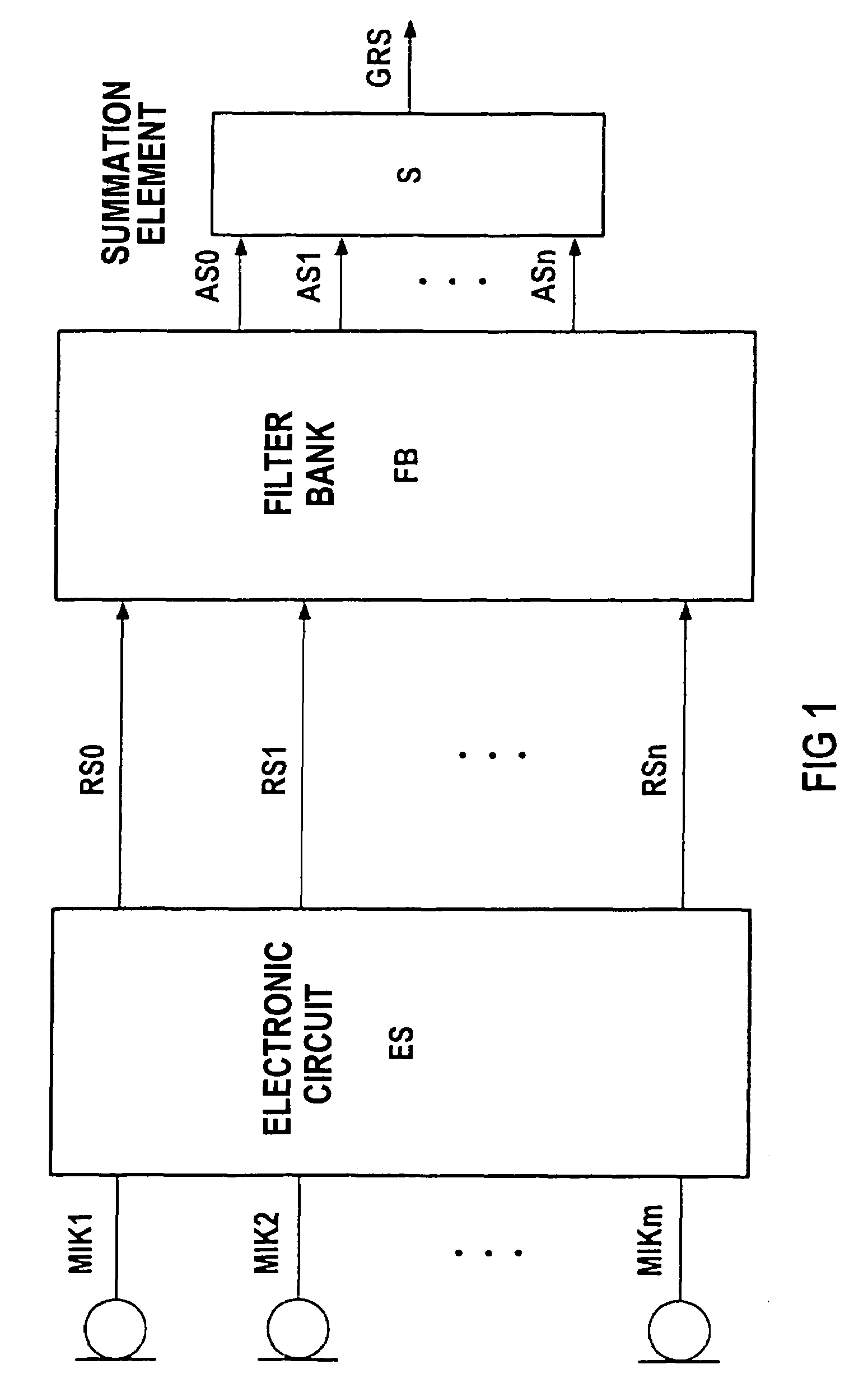

Hearing aid device, comprising a directional microphone system and a method for operating a hearing aid device

InactiveUS7324649B1Improve audibilityPrecise positioningDeaf-aid setsStereophonic arrangmentsMicrophone signalHearing aid

The invention relates to a hearing aid with a signal processing unit (14) and at least two microphones (1, 2, 3) which can be coupled together to form directional microphone systems of a different order, where microphone signals (11, 12, 13) emitted by directional microphone systems of a different order can be coupled together in a weighting dependent on the frequency of the microphone signals. The invention further relates to a method for operating a hearing aid of this type.

Owner:SIVANTOS PTE LTD

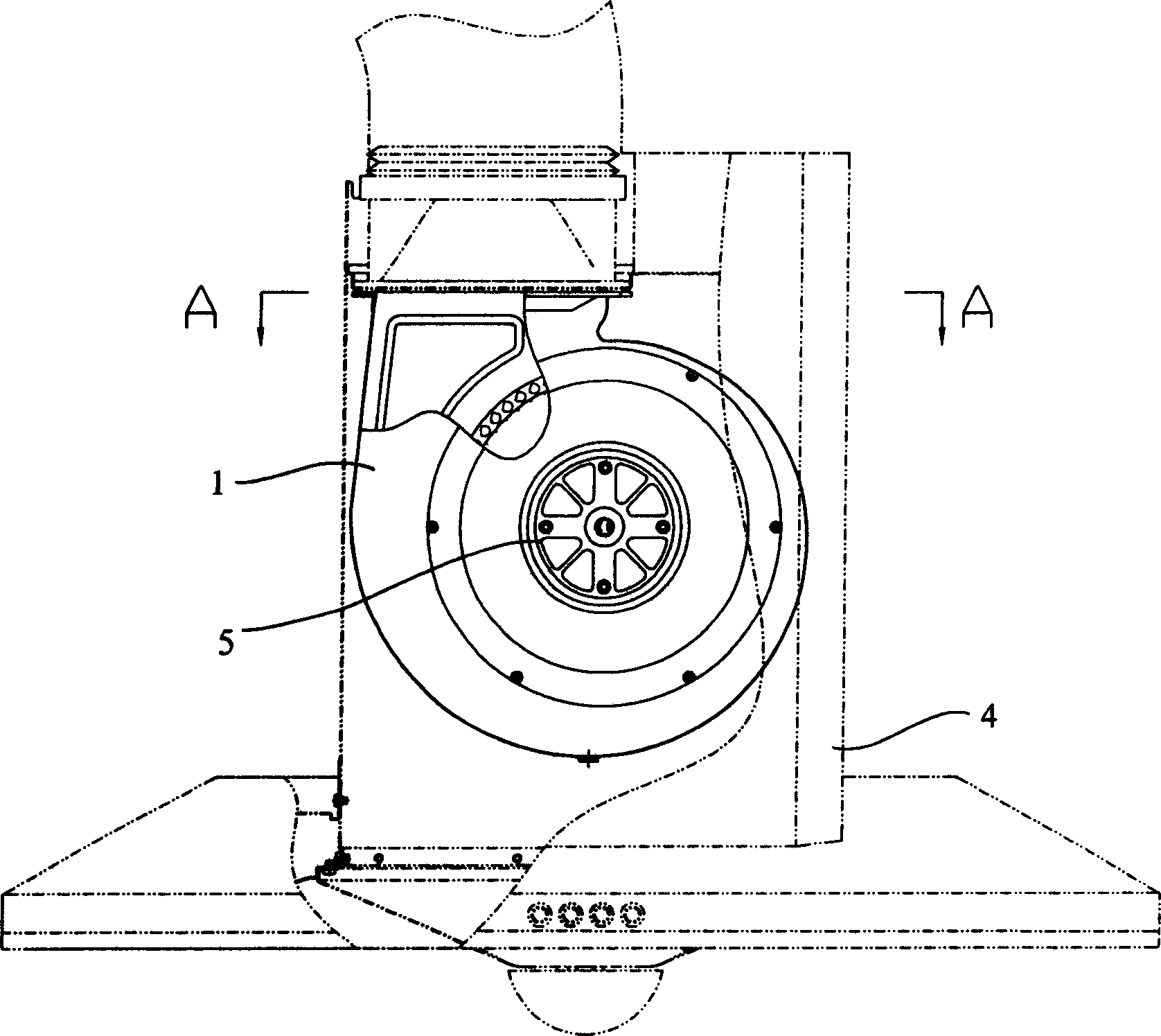

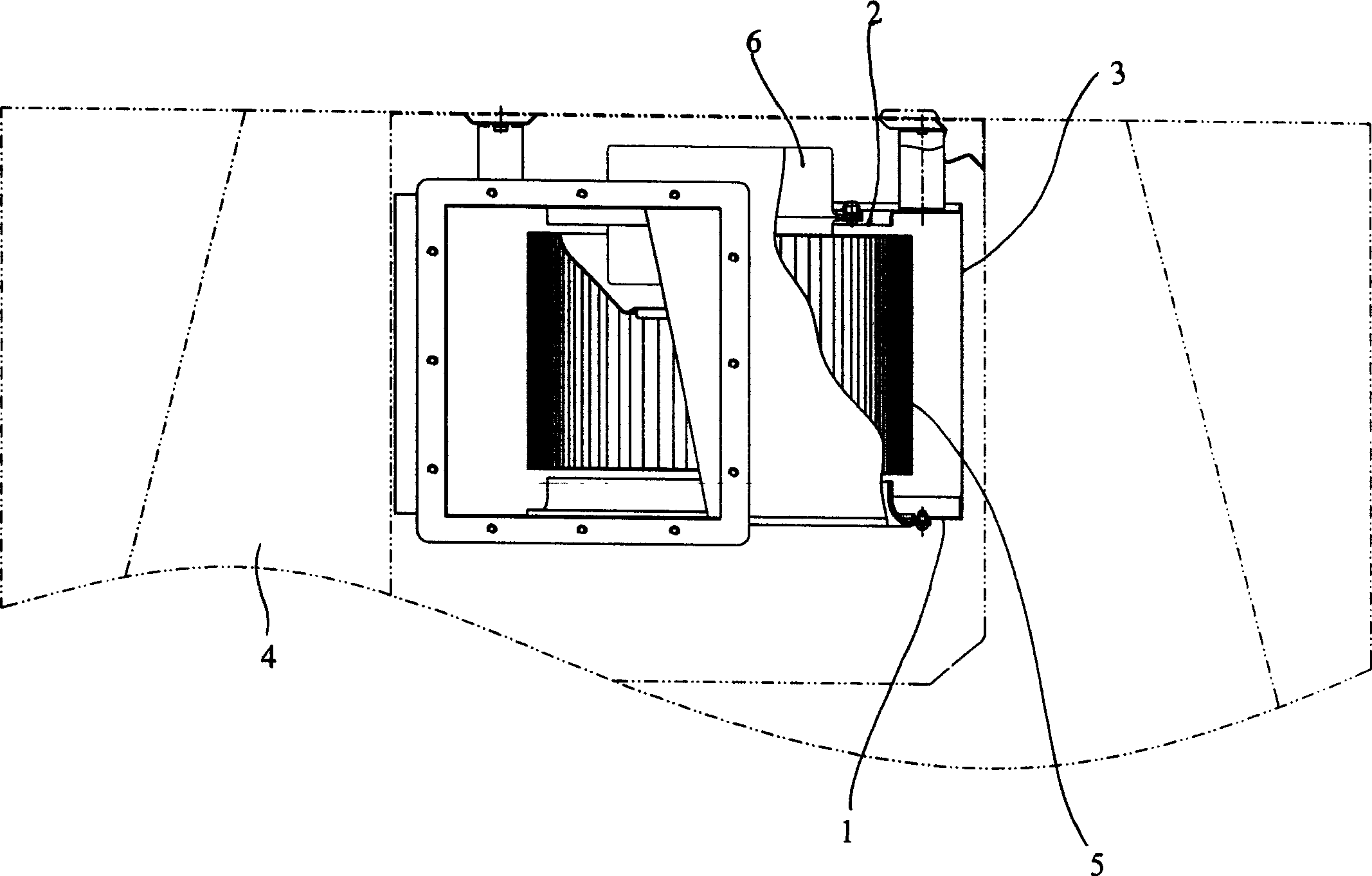

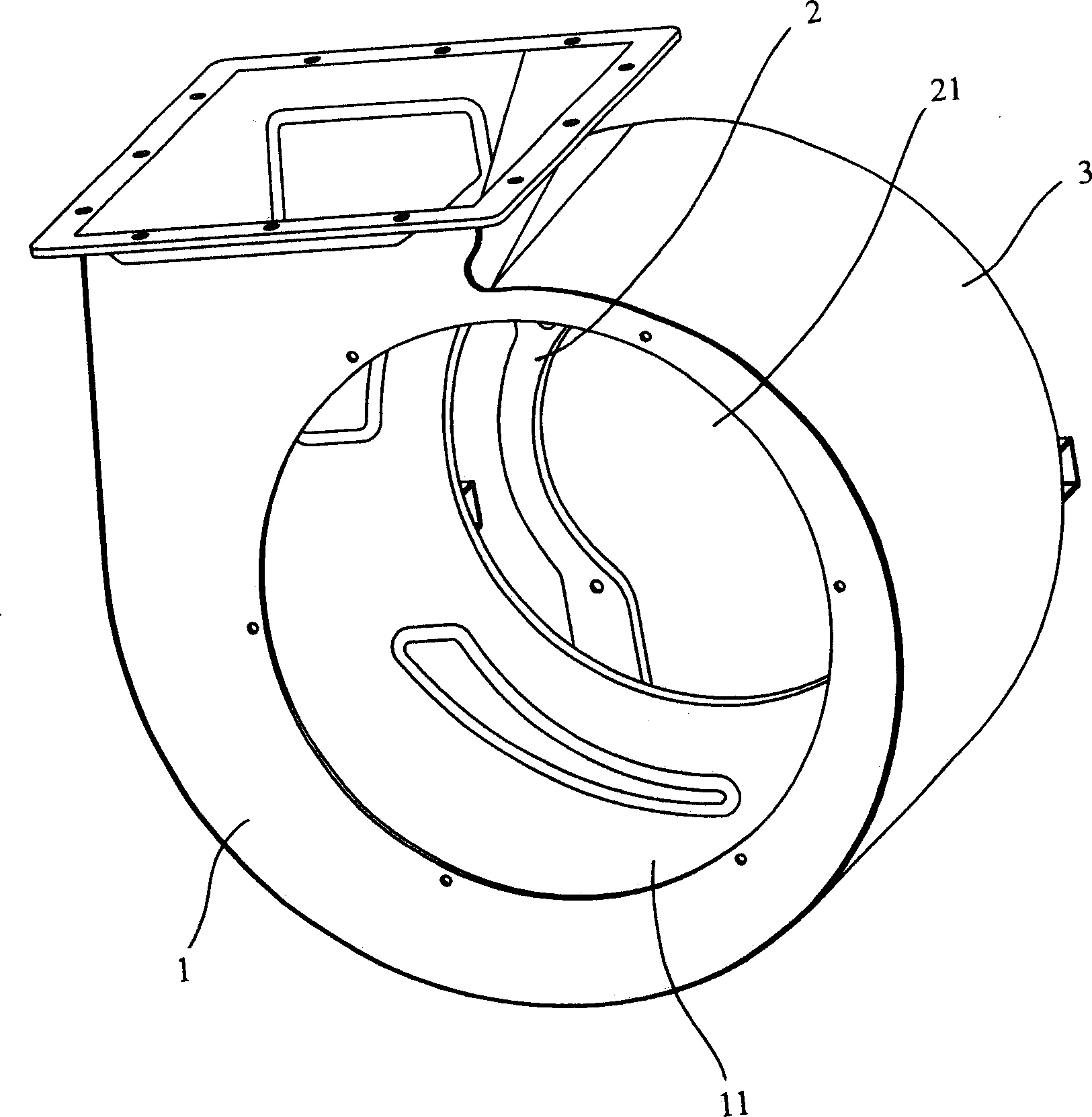

Fan volute structure with air inlets on double sides for European-style smoke exhaust ventilator

ActiveCN1844758AAvoid separationTotal noise reductionDomestic stoves or rangesLighting and heating apparatusAgricultural engineeringFront cover

The invention discloses a wind engine volute of Europe-type kitchen ventilator, which can adsorb wind via two surfaces. Wherein, the front and back cover plates (1, 2) are both mounted with wind inlets (11, 21); the edge of front cover plate (1) is formed by a straight line (AB), several arcs (BC, CD, DE, EF, FG, GH) and straight lines (HJ, JA); the edge of back cover plate (2) is formed by a straight line (A'B'), several arcs (B'C, C'D', D'E', E'F', F'G, G'H'), and a straight line (H'A'); the ratio between the radius of edge (FG) at the volute tongue of front cover plate (1) and the edge radius of edge (G'H') at the volute tongue of back cover plate (2) is 7.3-18.5. Compared to present technique, the invention can generate a new noise source at the volute tongue, which is reverse to other noise, to be eliminated some.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

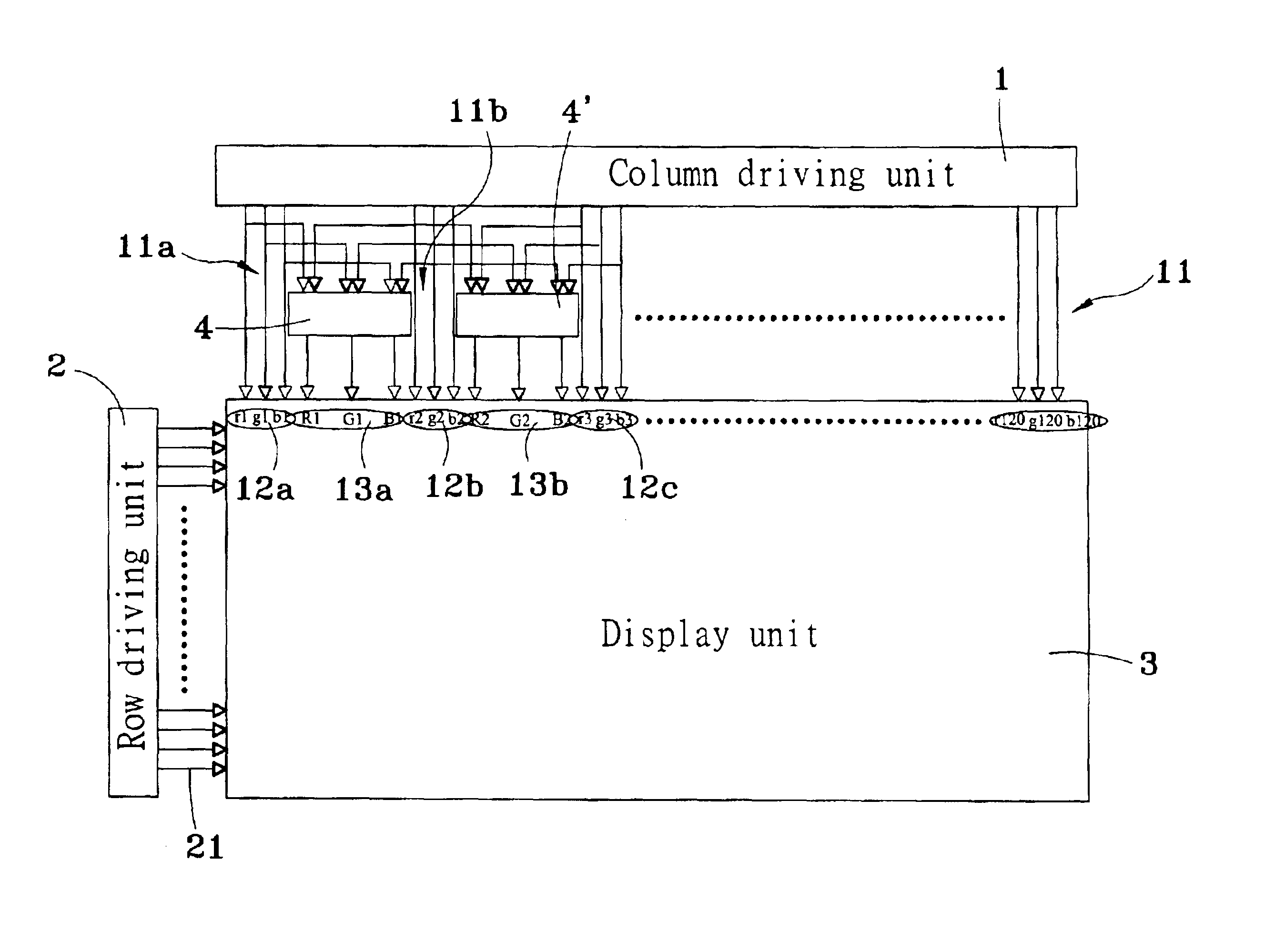

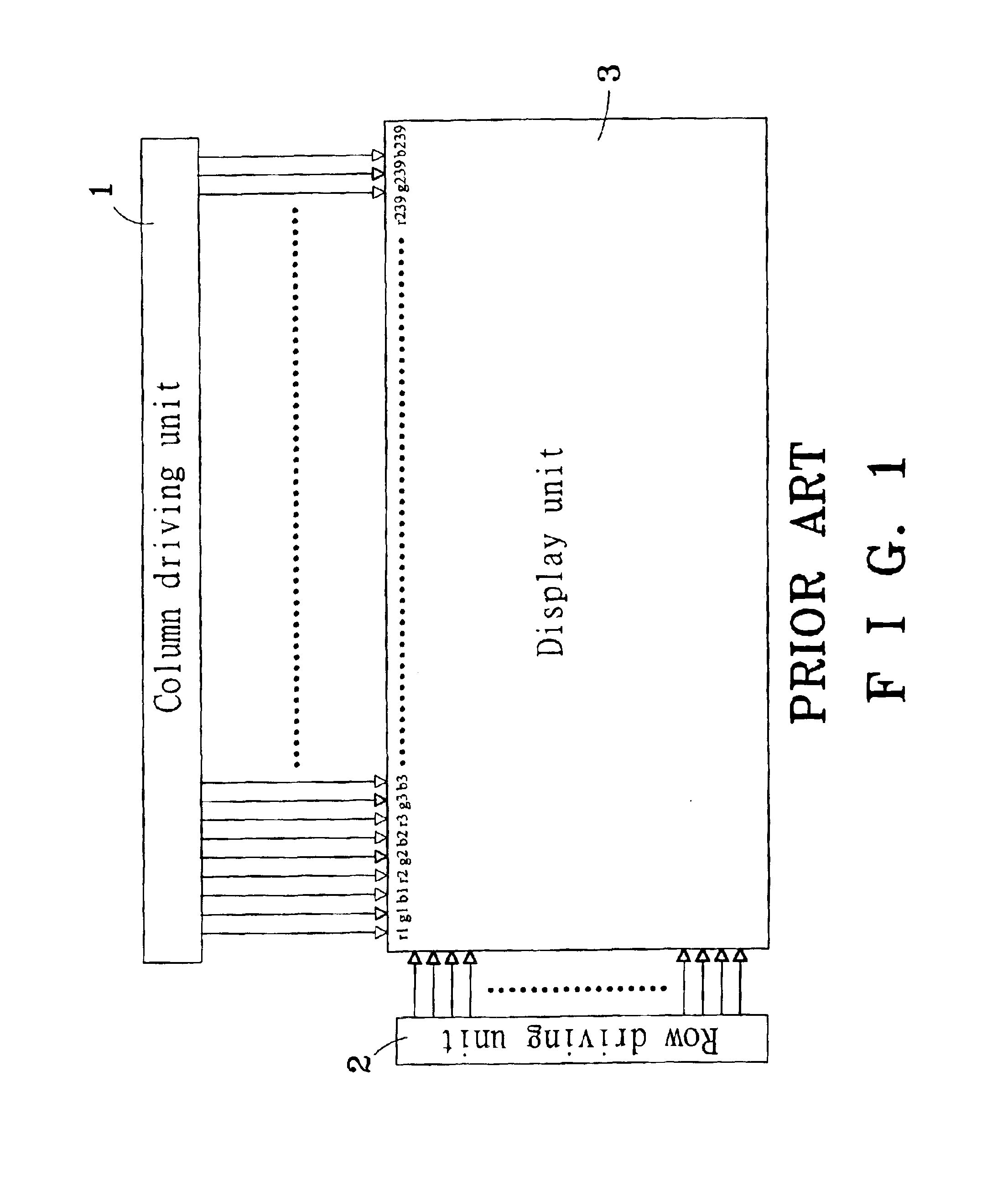

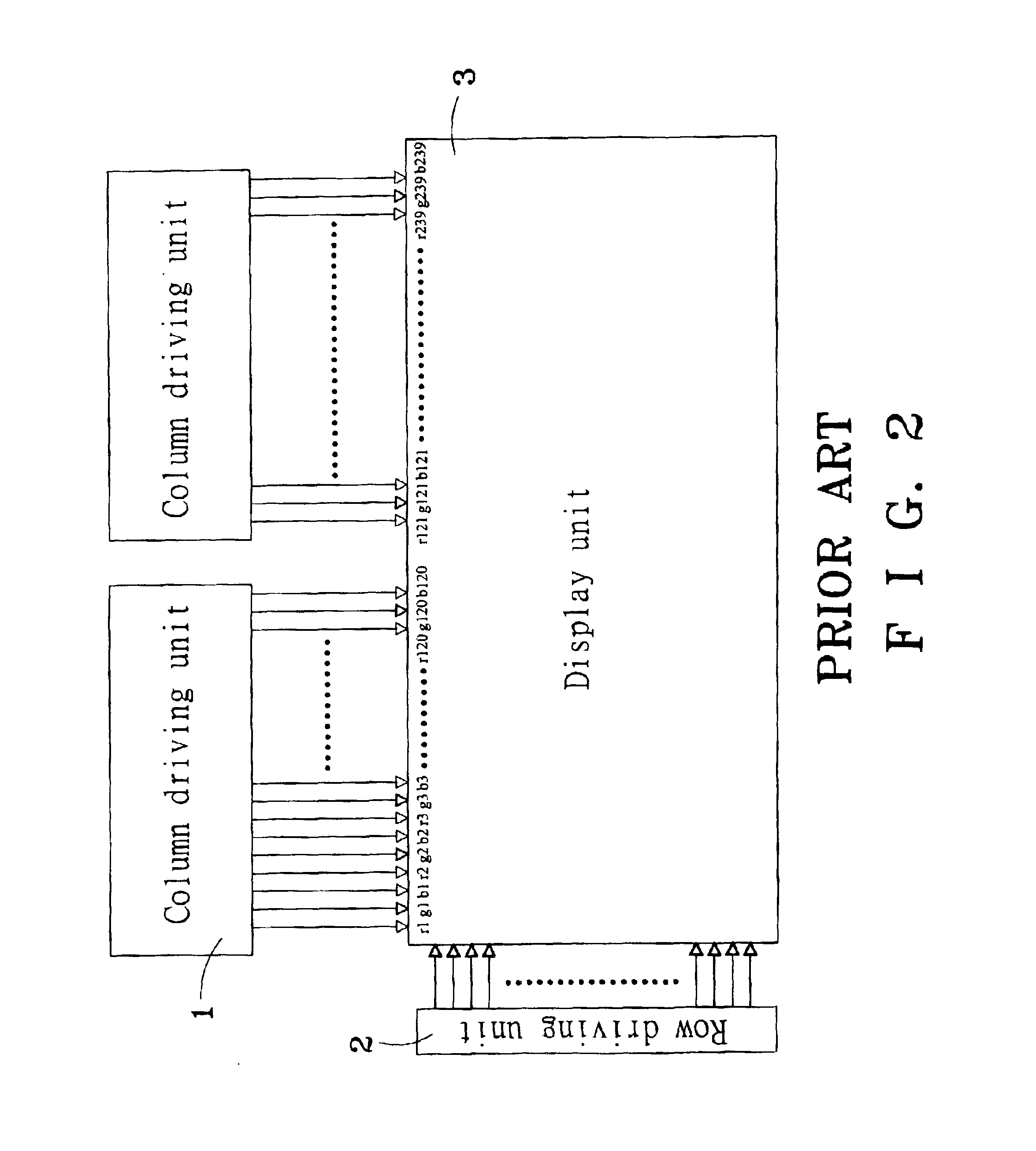

Method and apparatus for improving resolution of display unit

ActiveUS6927754B2Increase display resolutionImprove image smoothnessCathode-ray tube indicatorsInput/output processes for data processingImage resolutionDisplay resolution

A method and apparatus for enhancing the resolution of a display unit by adding any one of the two-channels of the three primitive color (r1, g1, b1, r2, g2, and b2) signals output from the column driving unit and dividing the sum by 2, and generating a new channel between the two channels. Such channel outputs a new three primitive color (R1, G1, B1) signal. These three primitive colors are also located between the two pixels of the primitive image data matrix to improve the display resolution and image smoothness and to enhance the display quality by less channel of the column driving unit.

Owner:WINTEK CORP

Data transceiver with filtering and precoding

InactiveUS6879639B1Evenly goodRadio frequency interferenceError preventionSecret communicationDigital dataPrecoding

A method for conveying digital data from a transmitter to a receiver includes specifying a spectral filtering profile to be applied in conveying the data. A sequence of input symbols is generated at the transmitter, corresponding to the data to be conveyed. The input symbols are precoded at the transmitter using Tomlinson-Harashima preceding responsive to the specified profile, so as to generate a corresponding sequence of precoded symbols. The precoded symbols are filtered in accordance with the specified profile. The precoded and filtered symbols are decoded at the receiver so as to recover the data therefrom.

Owner:COMCAST CABLE COMM LLC

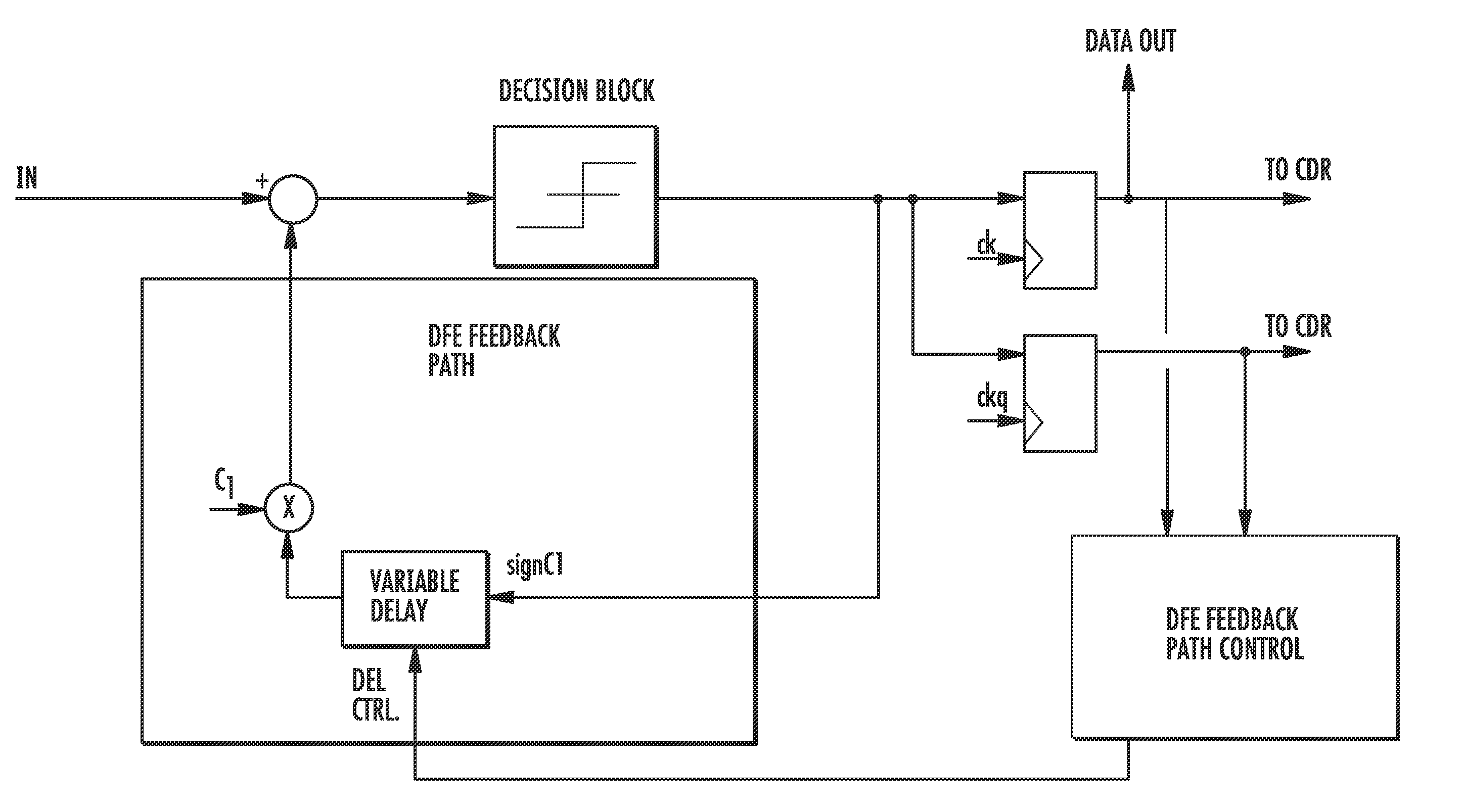

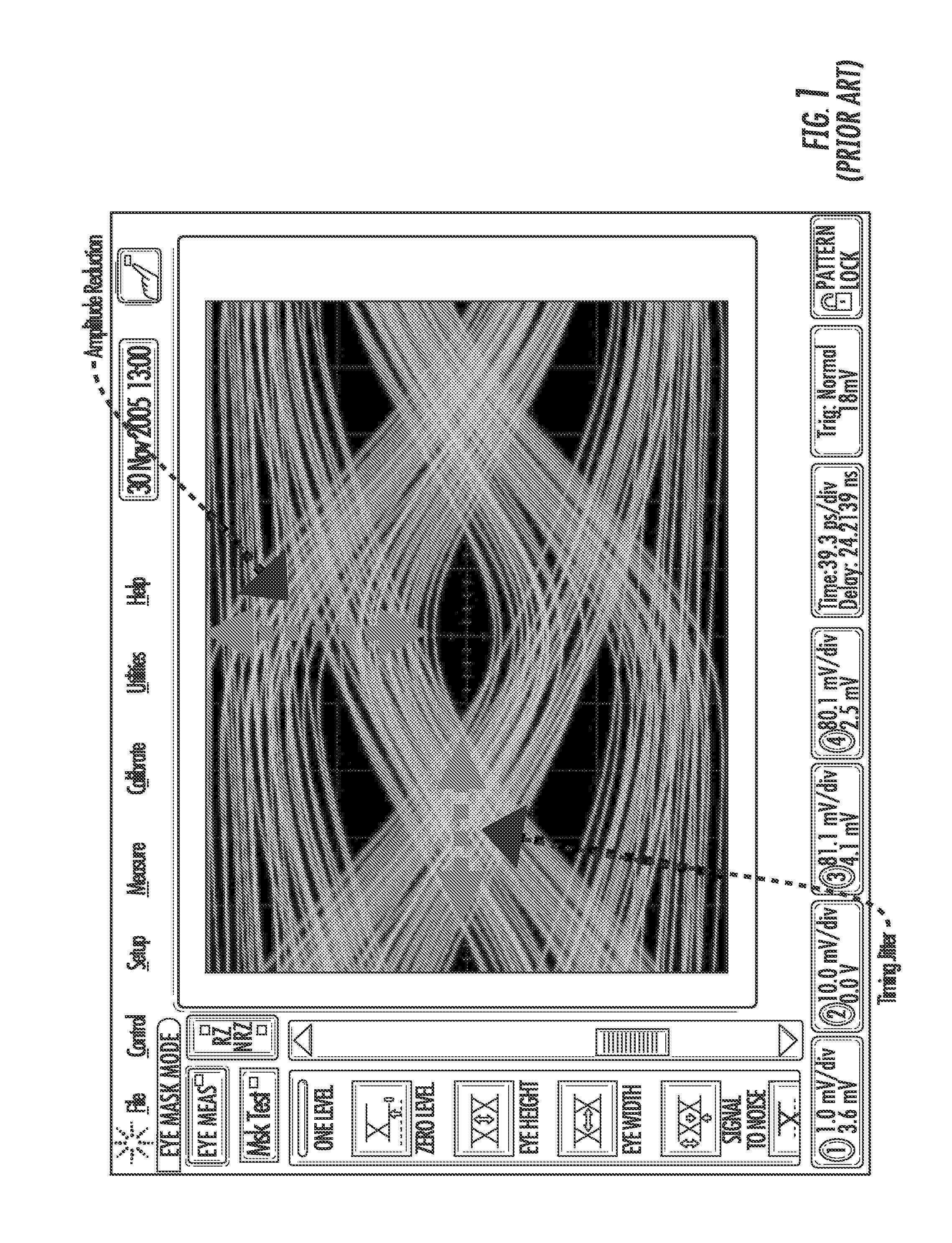

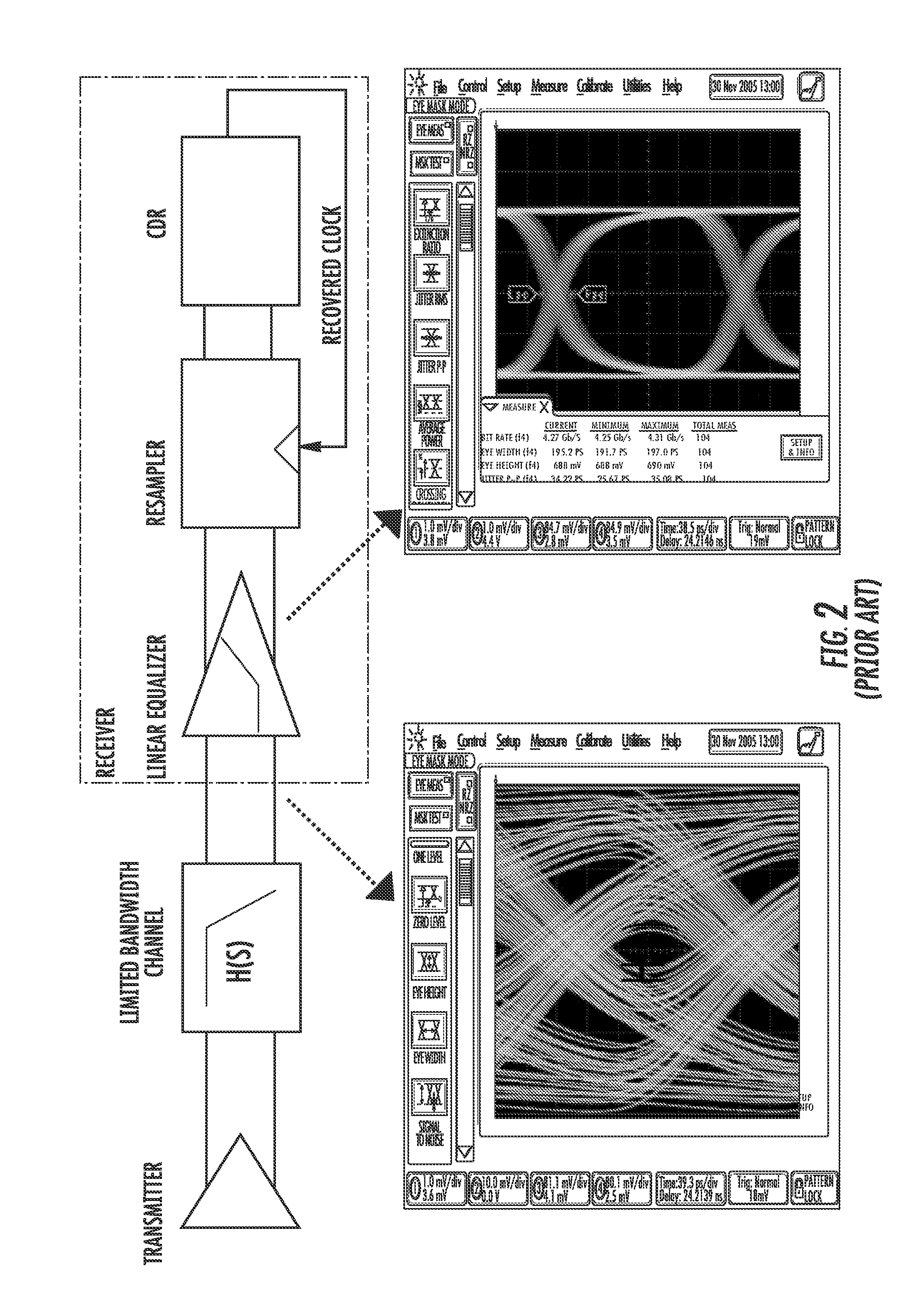

Enhancement of transition region equalization in a decision feedback equalizer

ActiveUS20100104000A1Reduce imbalanceEvenly goodMultiple-port networksDelay line applicationsSampling instantEngineering

A decision feedback equalizer includes an input path for receiving a bitstream with inter-symbol interference, and a feedback signal path is coupled to the input path for correcting a sampled value of an incoming bit of the bitstream based on inter-symbol interference of a preceding bit. The feedback signal path includes a controllable delay circuit for receiving the preceding bit. A feedback path controller is coupled to the controllable delay circuit to regulate a delay introduced to the preceding bit. The delay is a function of an accumulated value of data of early-late events of a sampling instant of the bitstream for different data pulse patterns.

Owner:STMICROELECTRONICS SRL

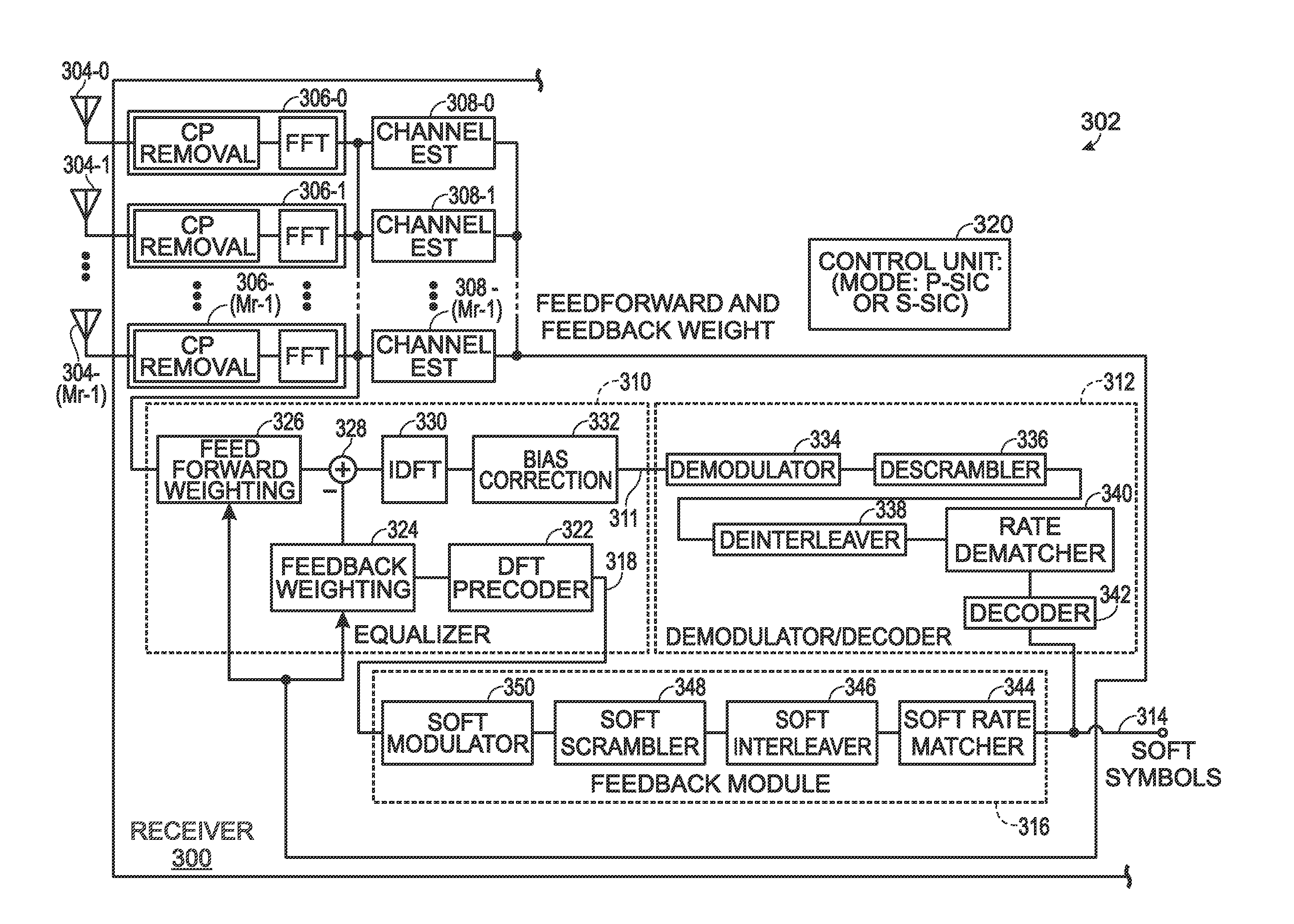

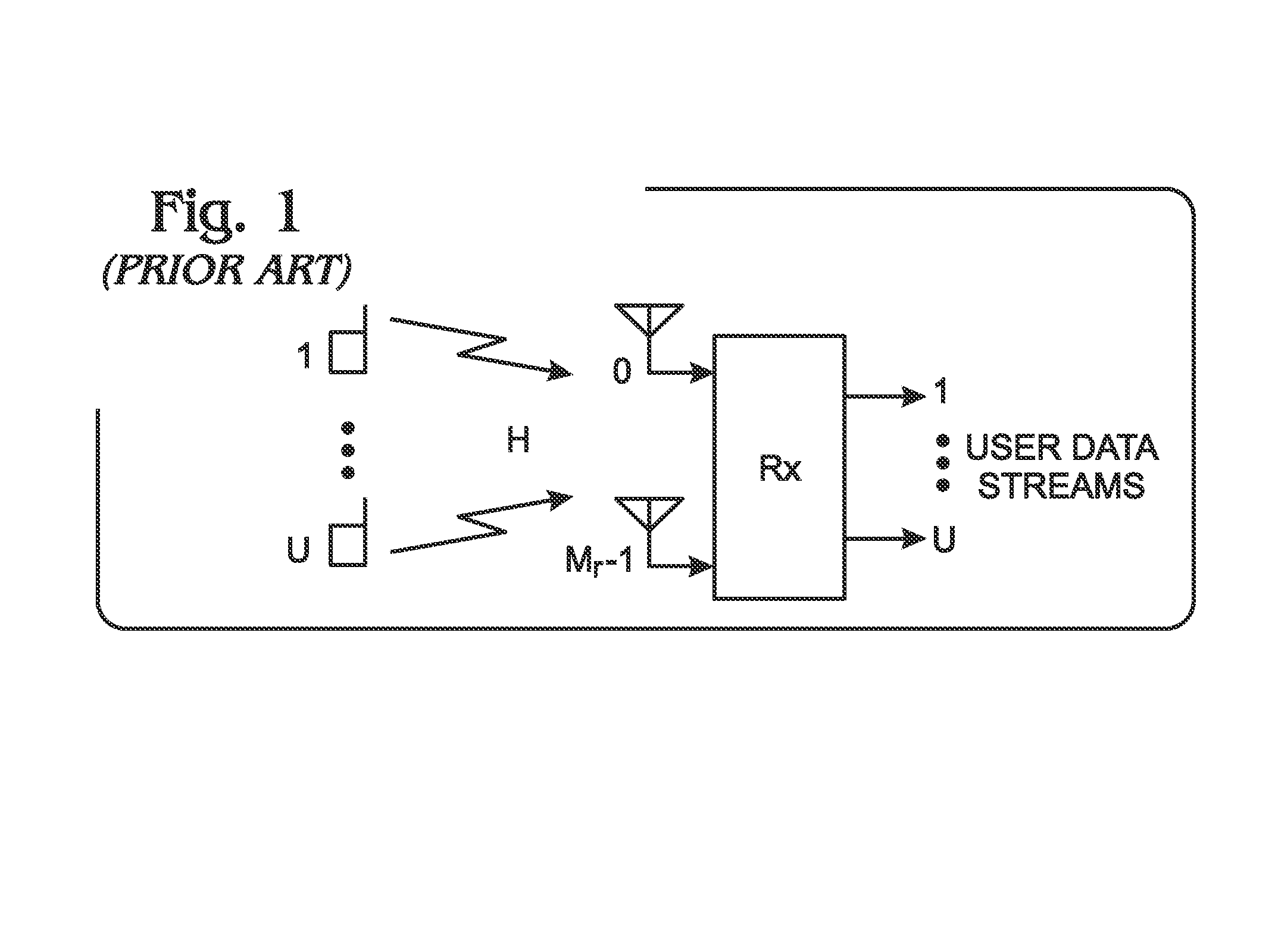

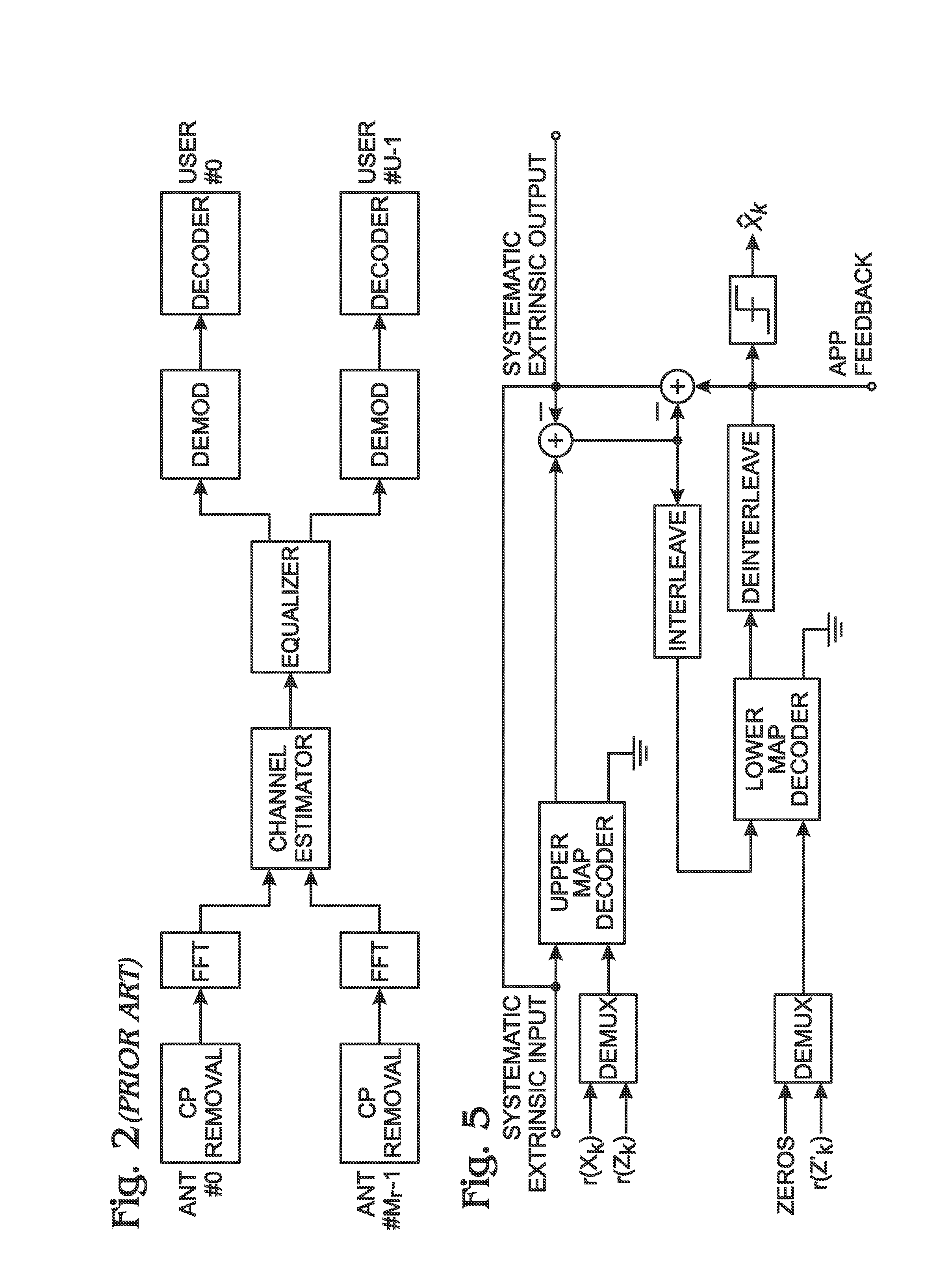

Uplink single carrier frequency division multiple access multiple-input multiple-output soft interference cancellation receiver

ActiveUS8665693B1Reduce complexityQuality improvementSpatial transmit diversityLine-faulsts/interference reductionFourier transform on finite groupsCarrier signal

A system and method are provided for Soft Interference Cancellation (SIC) in receiving Single Carrier Frequency Division Multiple Access (SC-FDMA) Multiple-Input Multiple Output (MIMO) signals. A receiver with Mr antennas accepts multicarrier signals transmitted simultaneously, with N overlapping carrier frequencies. The receiver removes a cyclic prefix (CP), and fast Fourier transforms (FFT) the multicarrier signal from each antenna, supplying Mr number of N-tone signals y. Using either parallel SIC (P-SIC) or successive SIC (S-SIC), interference is canceled in each of the Mr signals, and soft symbols are supplied for each of U layers. Interference is canceled using the P-SIC process by parallel processing the U layers in an i-th iteration, in response to feedback from an (i−1)th iteration. Alternatively, interference is canceled using the S-SIC process by sequentially processing the U layers in an i-th iteration, in the order of u0,u1, . . . , uU−1, using feedback generated from previously processed layers.

Owner:MACOM CONNECTIVITY SOLUTIONS LLC

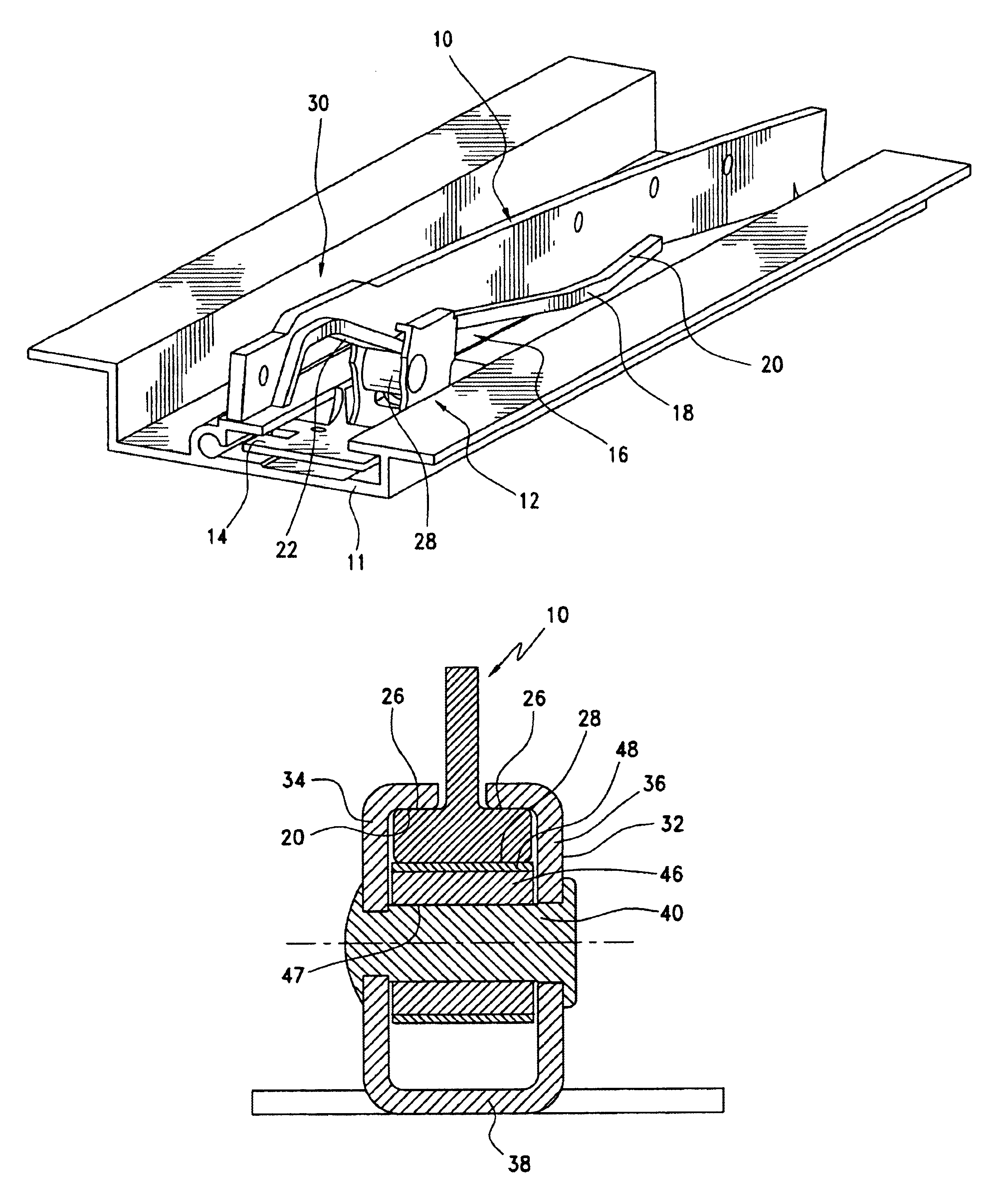

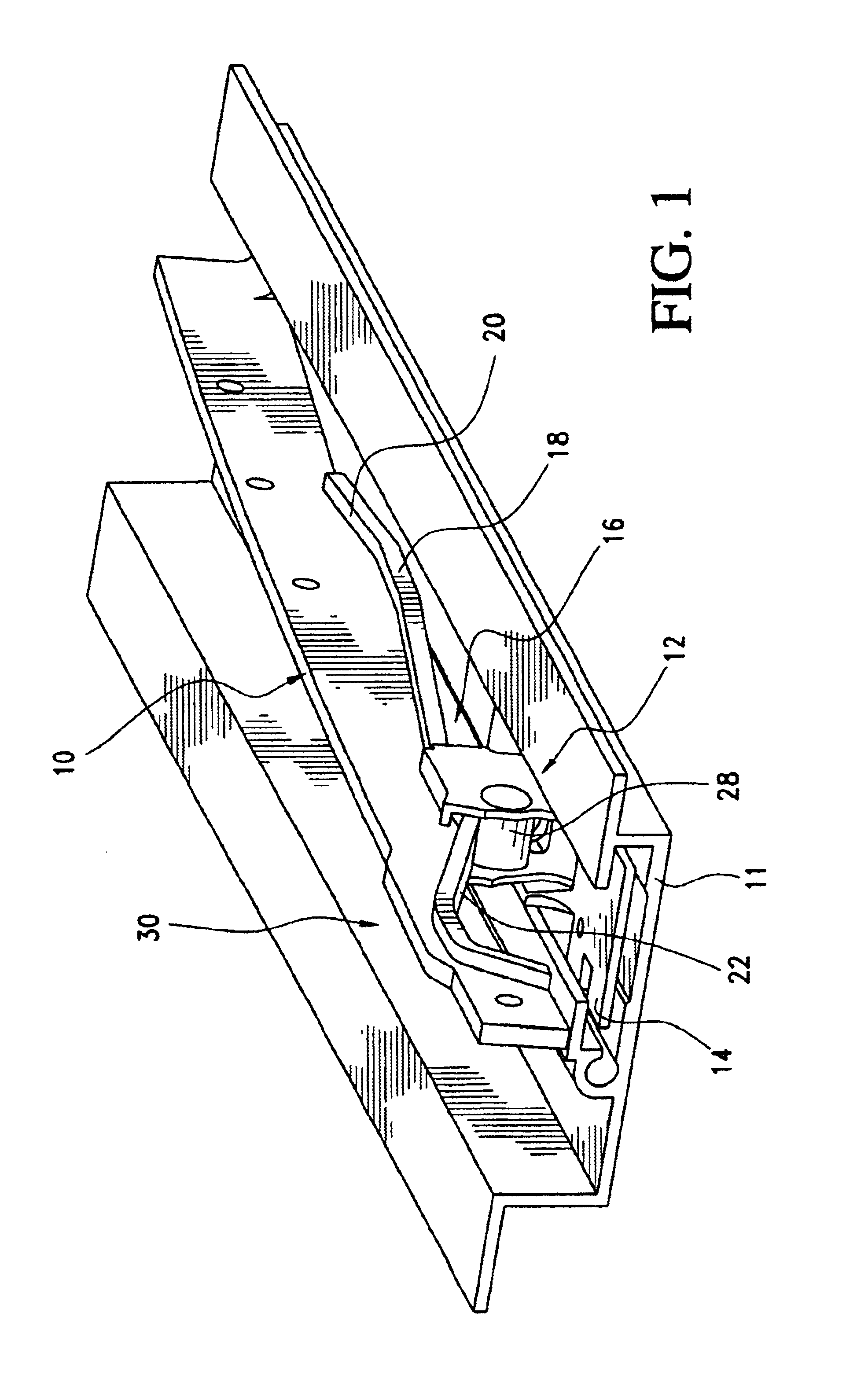

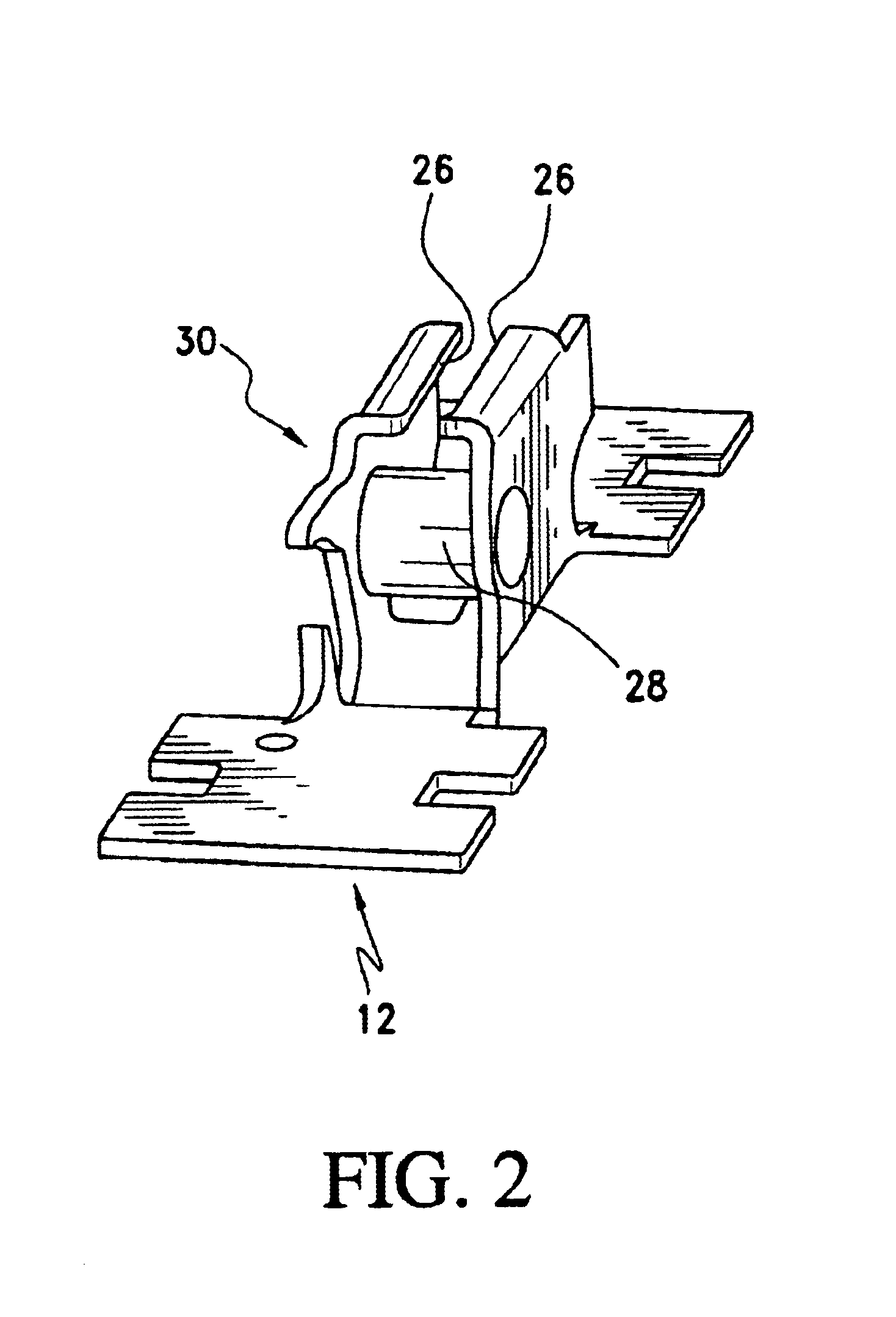

Guide arrangement for a roof element on an opening vehicle roof

InactiveUS6890025B2Evenly goodAvoid stiffnessEngine sealsSuperstructure subunitsEngineeringMechanical engineering

Owner:WEBASTO VEHICLE SYST INT

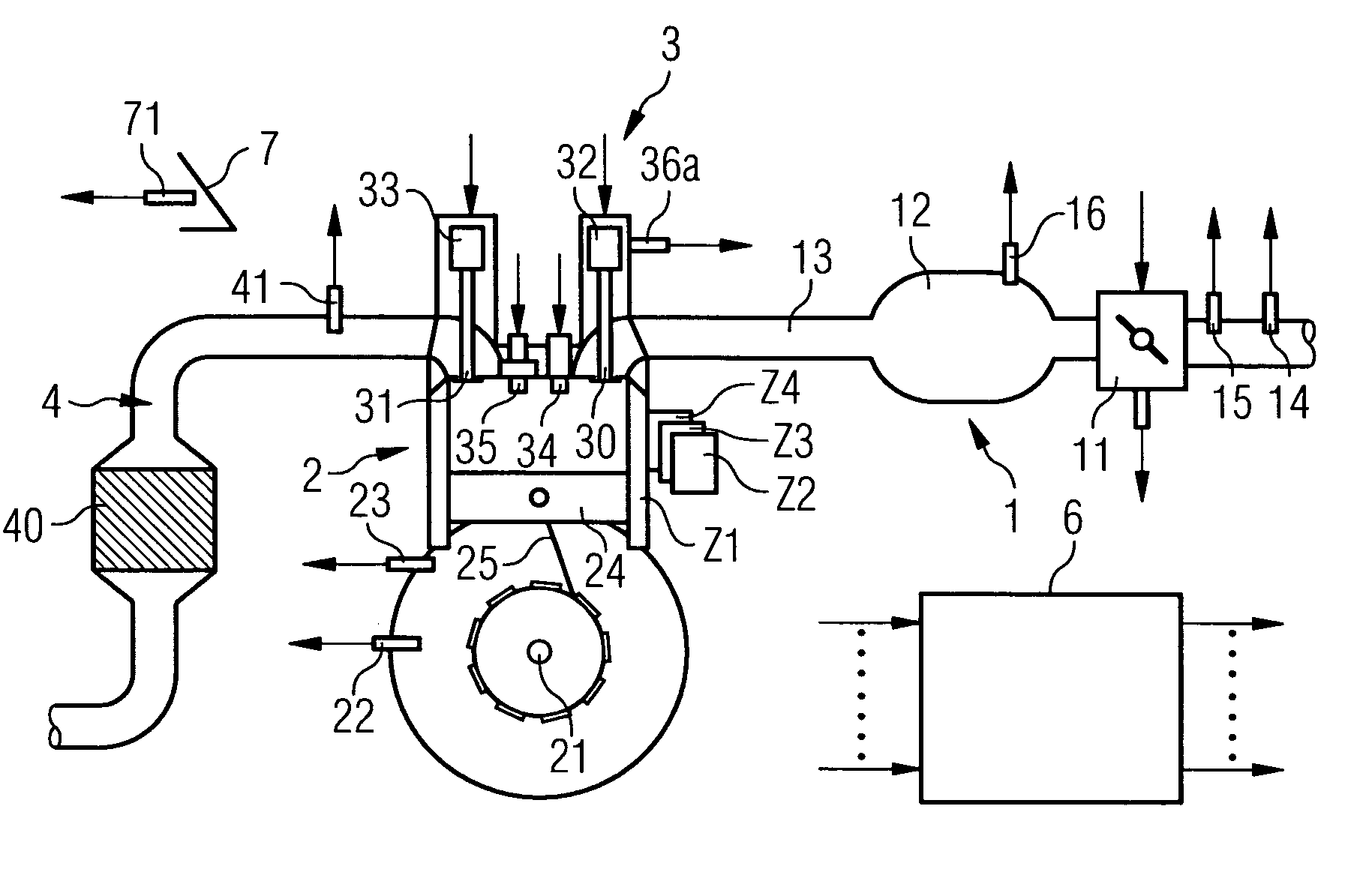

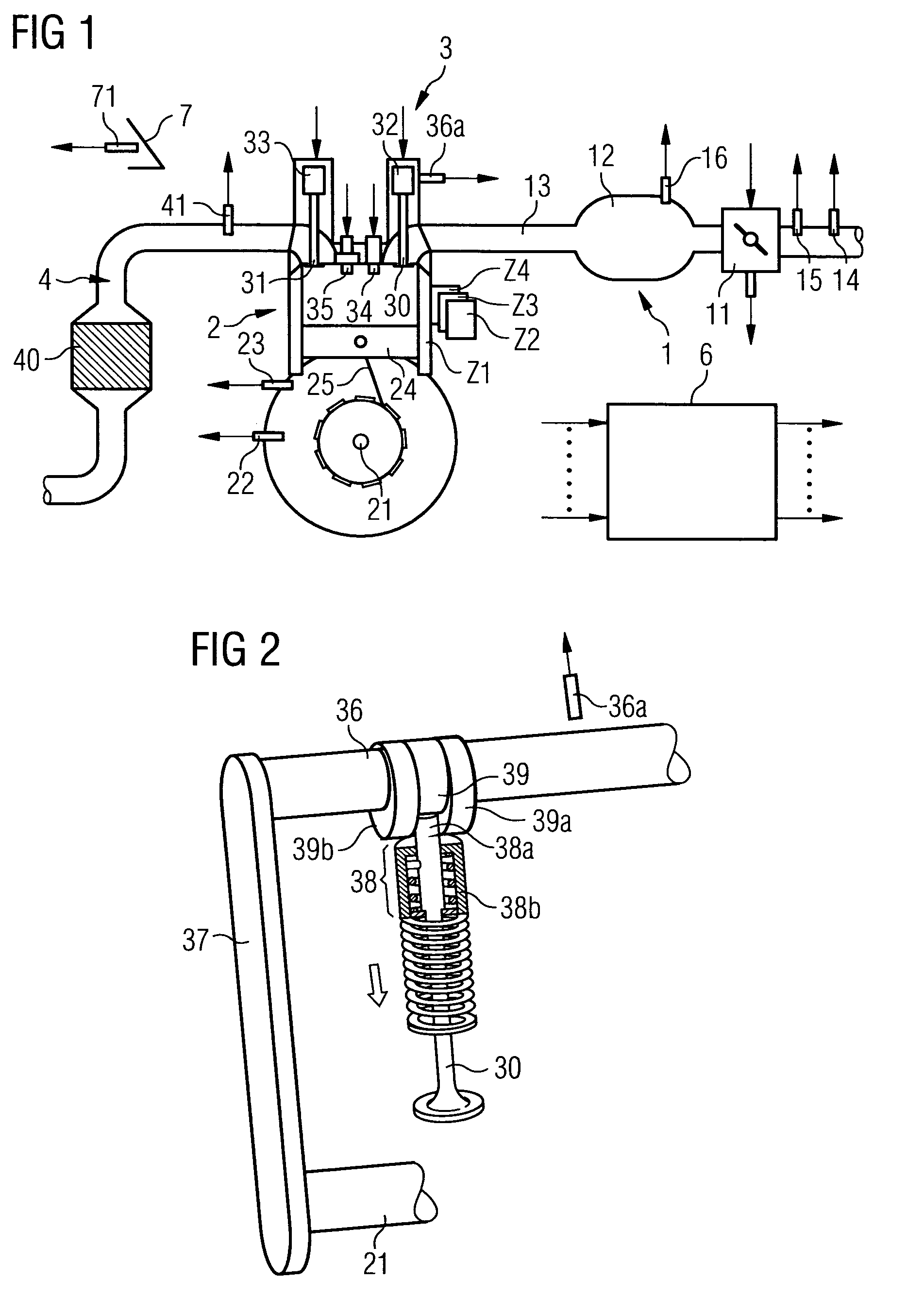

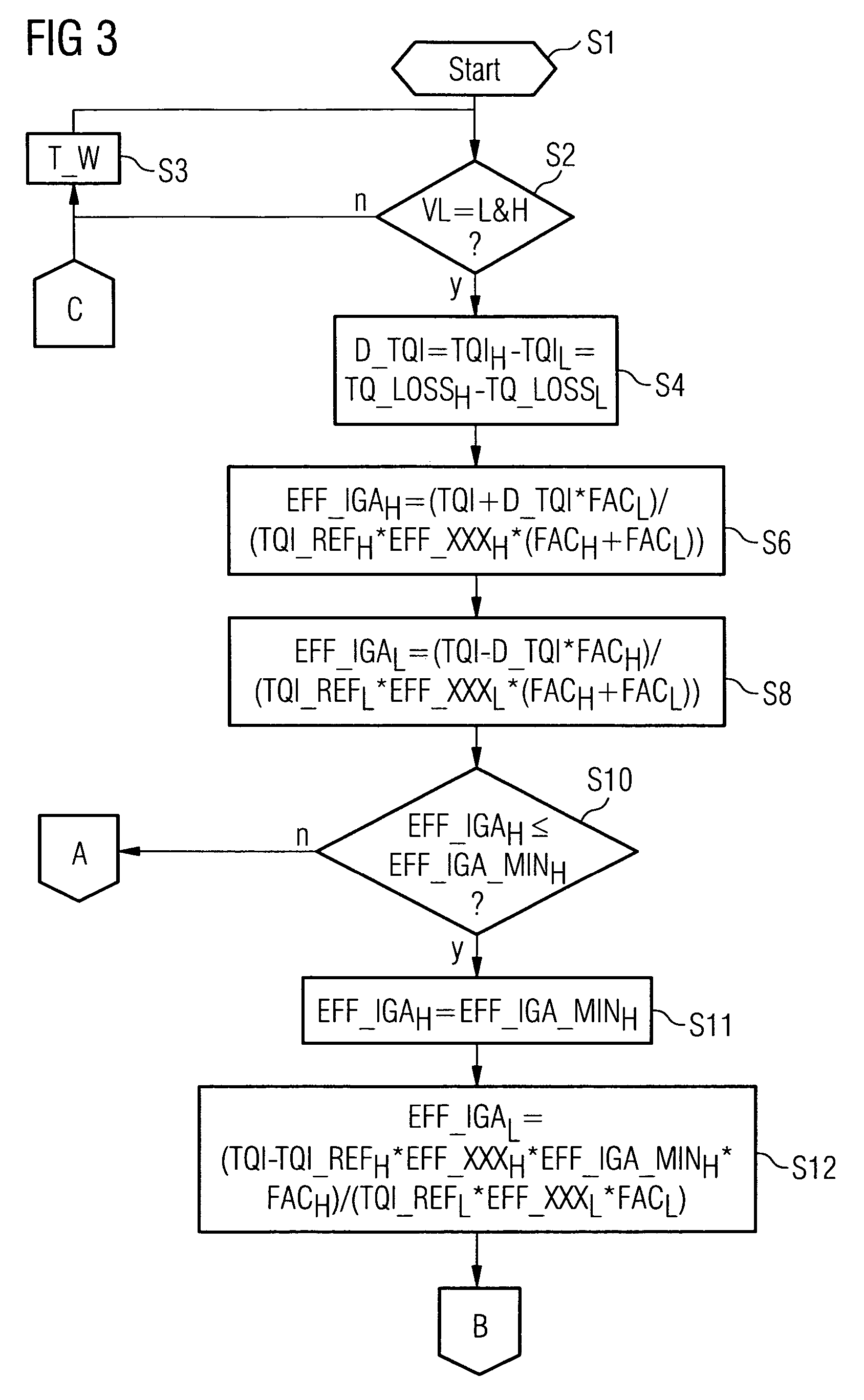

Method and device for controlling an internal combustion engine

ActiveUS7377260B2Reduce irregularitiesEvenly goodAnalogue computers for vehiclesElectrical controlGas cylinderExternal combustion engine

An internal combustion engine has a plurality of cylinders having combustion chambers and each being associated with a spark plug designed for igniting a mixture of air and fuel in the combustion chamber, and at least two adjusting devices for adjusting the air supply to the combustion chambers of the different cylinders. To control the internal combustion engine, an individual ignition angle is detected for each group of cylinders to which the same air mass per working cycle is respectively supplied and during the respective working cycles of which the same loss torque is decisive. The decisive loss torque is the one associated with the cylinder that is in its intake cycle during the respective working cycle of the respective cylinder of the respective group. The individual ignition angle for each group is detected as a function of the decisive loss torque for the respective group.

Owner:VITESCO TECH GERMANY GMBH

Coal asphalt/SBS (Styrene Butadiene Styrene)/waste colloid powder composite modified asphalt and preparation method thereof

ActiveCN103044938AExcellent performanceConducive to stability and balanceBuilding insulationsColloid millPolymer chemistry

The invention relates to a coal asphalt / SBS (Styrene Butadiene Styrene) / waste colloid powder composite modified asphalt and a preparation method thereof. The technical scheme of the invention is that: the preparation method comprises the following steps of: firstly, putting 58-80wt% of petroleum asphalt and 4-20wt% of coal asphalt in a reaction tank, subsequently heating to 160-180 DEG C, adding 1-4wt% of SBS and using a colloid mill to cut for 0.4-0.6 hour; adding 10-36wt% of waste colloid powder into a product after cutting, stirring for 0.4-0.6 hour under a condition at a bottom temperature of 180-200 DEG C and a speed of 150-300r / min (revolutions per minute), then using the colloid mill to cut for 0.4-0.6 hour again; and feeding the product after cutting for the second time into a development tank, swelling for 1-3 hours under a condition at a temperature of 170-180 DEG C and a speed of 150-300r / min, adding 0.5-1.0wt% of high-boron calcium borate and 0.2-0.3wt% of stabilizing agent, developing for 1-2 hours and preparing the coal asphalt / SBS / waste colloid powder composite modified asphalt. The coal asphalt / SBS / waste colloid powder composite modified asphalt prepared by the invention has the characteristics of low cost, no fracture at a low temperature, no softening at a high temperature, good elasticity, strong adhesive force, long service life and stable storage.

Owner:WUHAN UNIV OF SCI & TECH +1

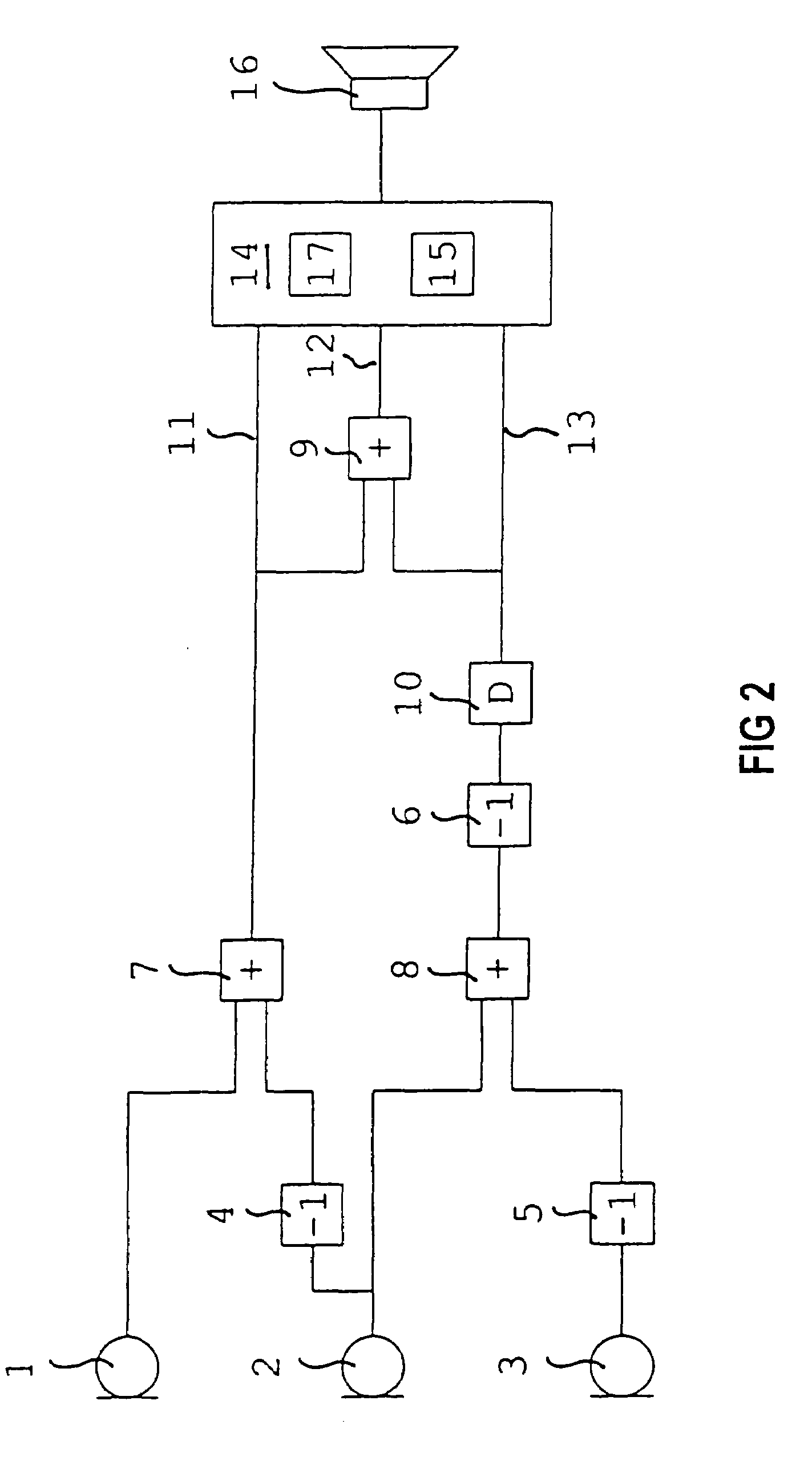

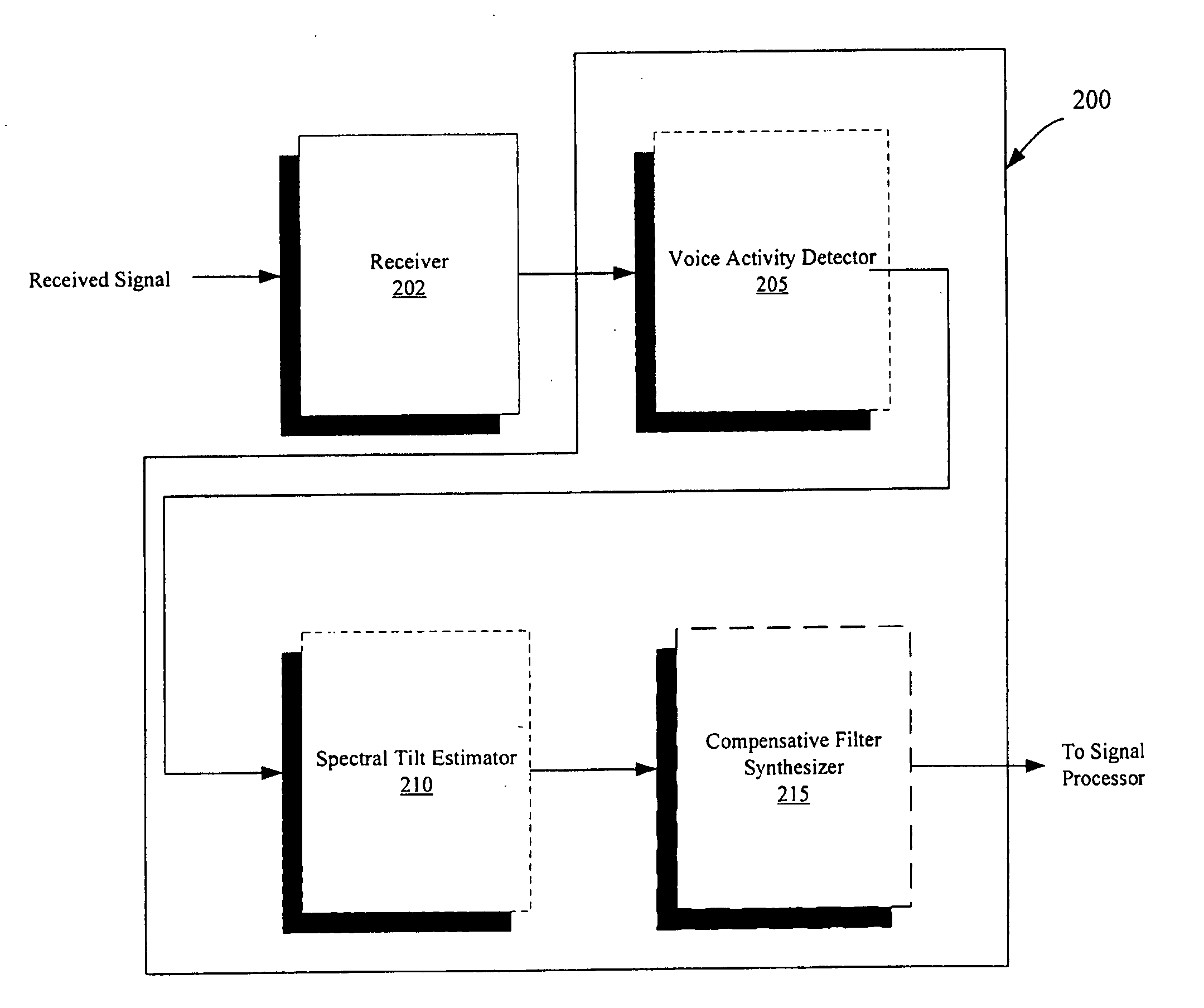

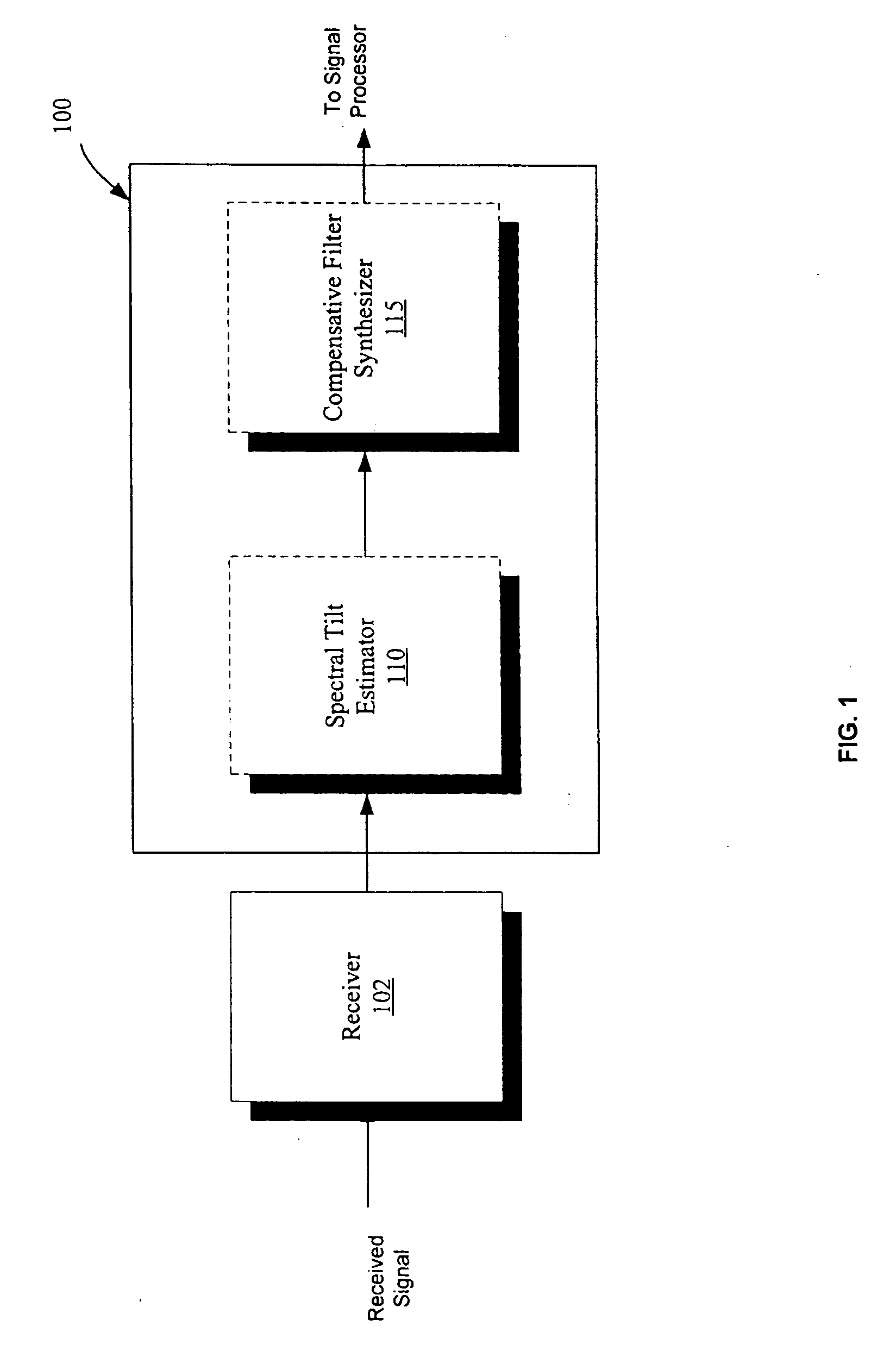

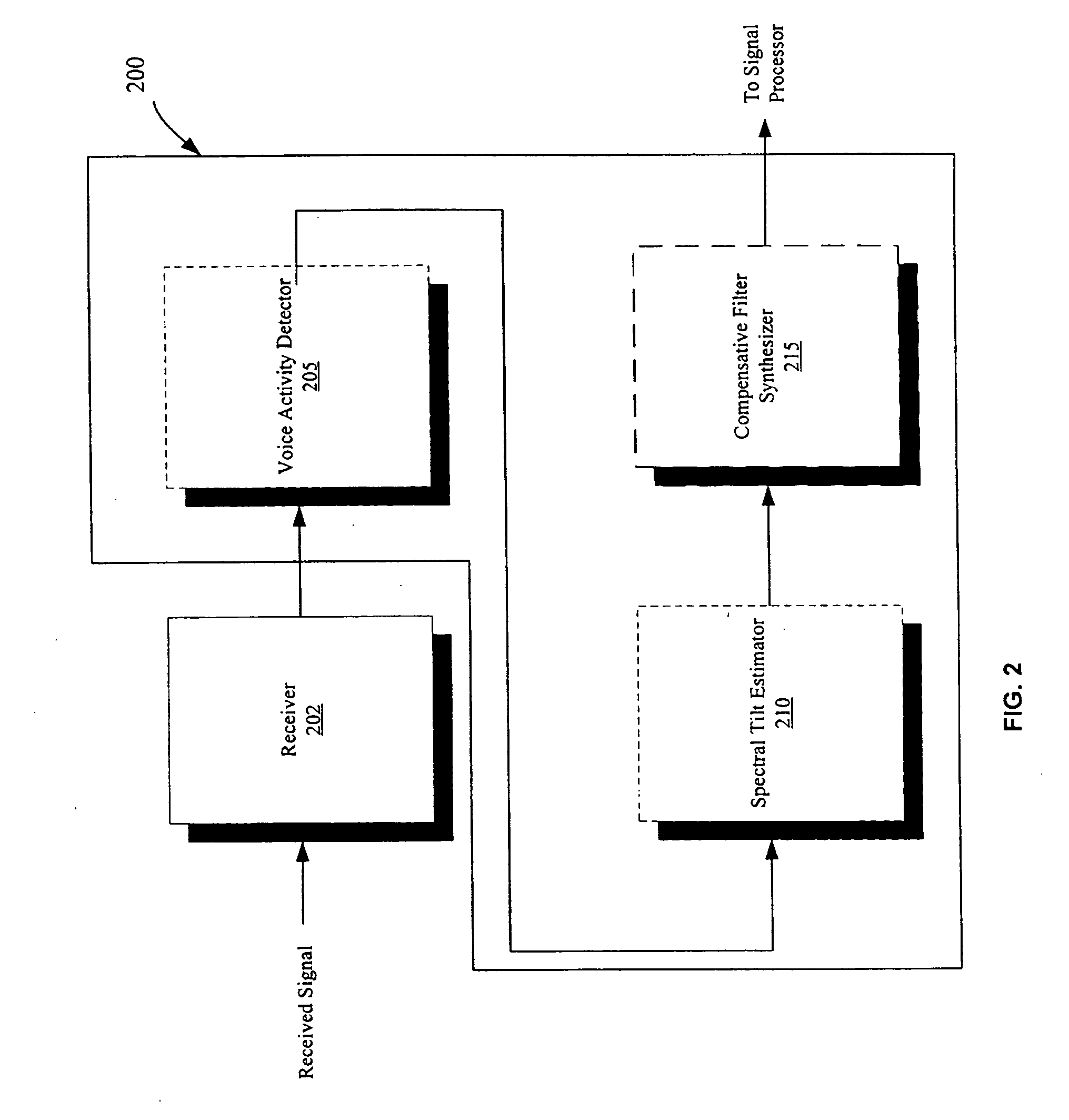

System and method of signal pre-conditioning with adaptive spectral tilt compensation for audio equalization

InactiveUS20060089836A1Increase decibel (dB) headroom of audio signalEvenly goodSpeech analysisFrequency spectrumPre-condition

Systems and methods for pre-conditioning a received audio signal prior to audio equalization of the audio signal are provided. The system (100) includes a spectral tilt estimator (110) for estimating a spectral tilt of the received audio signal, and a compensative filter synthesizer (115) for synthesizing a compensative filter based upon the spectral tilt estimated by the spectral tilt estimator. The filter comprises at least one compensative filter coefficient for mitigating the spectral tilt of the received audio signal prior to audio equalization of the audio signal.

Owner:MOTOROLA INC

Double-side polishing method and apparatus

ActiveUS20050159089A1Improve flatnessEasy constructionEdge grinding machinesRevolution surface grinding machinesReciprocating motionEngineering

In order to improve a flatness of a work in single wafer type double-side polishing in which one wafer is polished with one carrier, a carrier larger in diameter than upper and lower surface plates that rotate is inserted between the surface plates, and a wafer smaller in diameter than the surface plates is held with the carrier. The carrier is rotated by plural eccentric gears that mesh with external gear teeth formed on the outer peripheral surface of the carrier at plural positions along a circumferential direction thereof and revolve around positions spaced from the centers as centers in synchronism with each other or one another at the plural positions of meshing. The carrier rotates about its center and moves circularly around the center of the surface plates spaced from the center thereof. The upper surface plate is reciprocated in a direction perpendicular to the central axis when required. Geometrical motion loci of points on the wafer are complex and peripheral speeds alter to large extents to thereby enhance equalization of peripheral speeds of points on the wafer to a higher level to thereby improve a flatness.

Owner:KASHIWARA KIKAI SEISAKUSHIYO +1

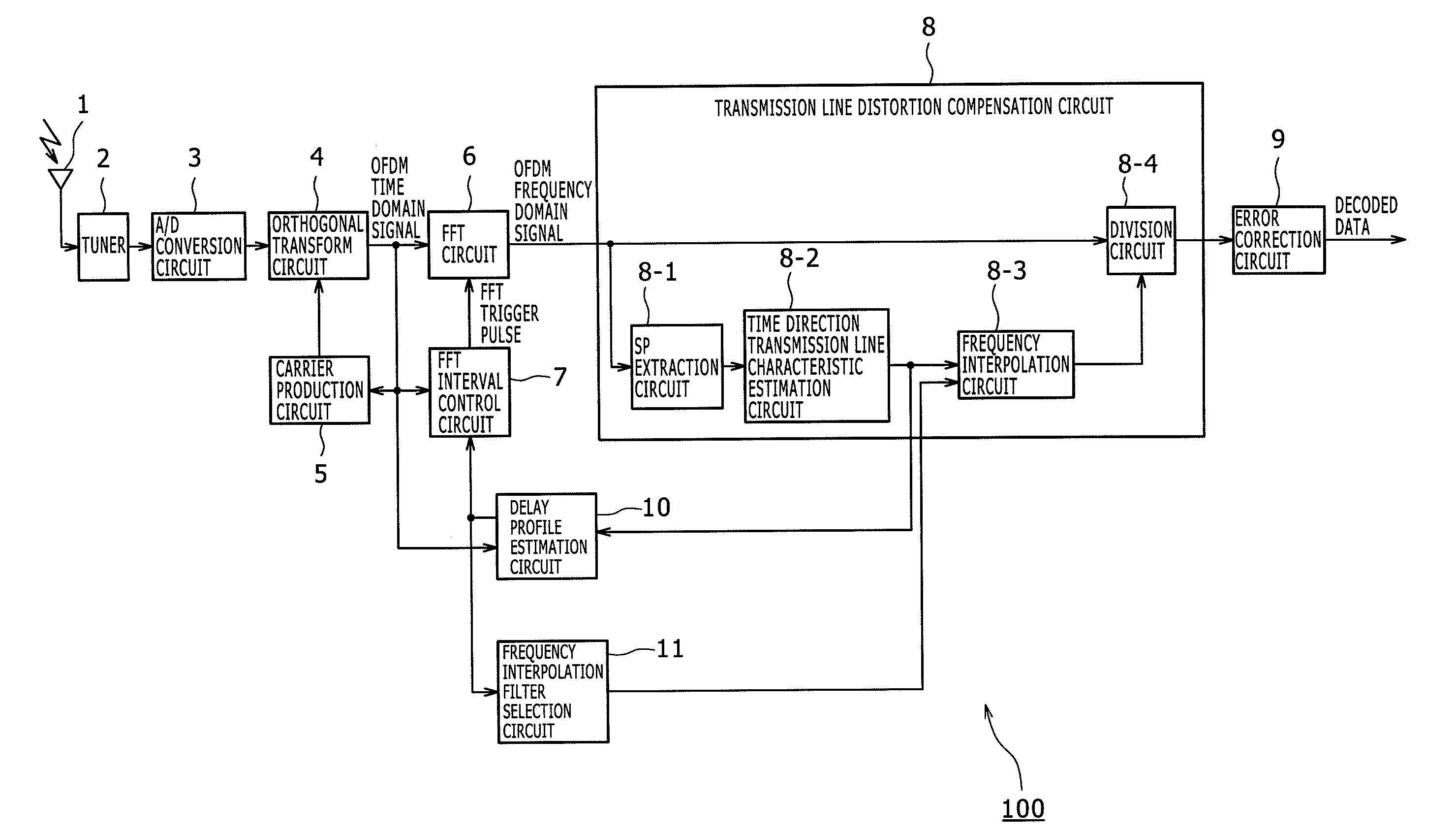

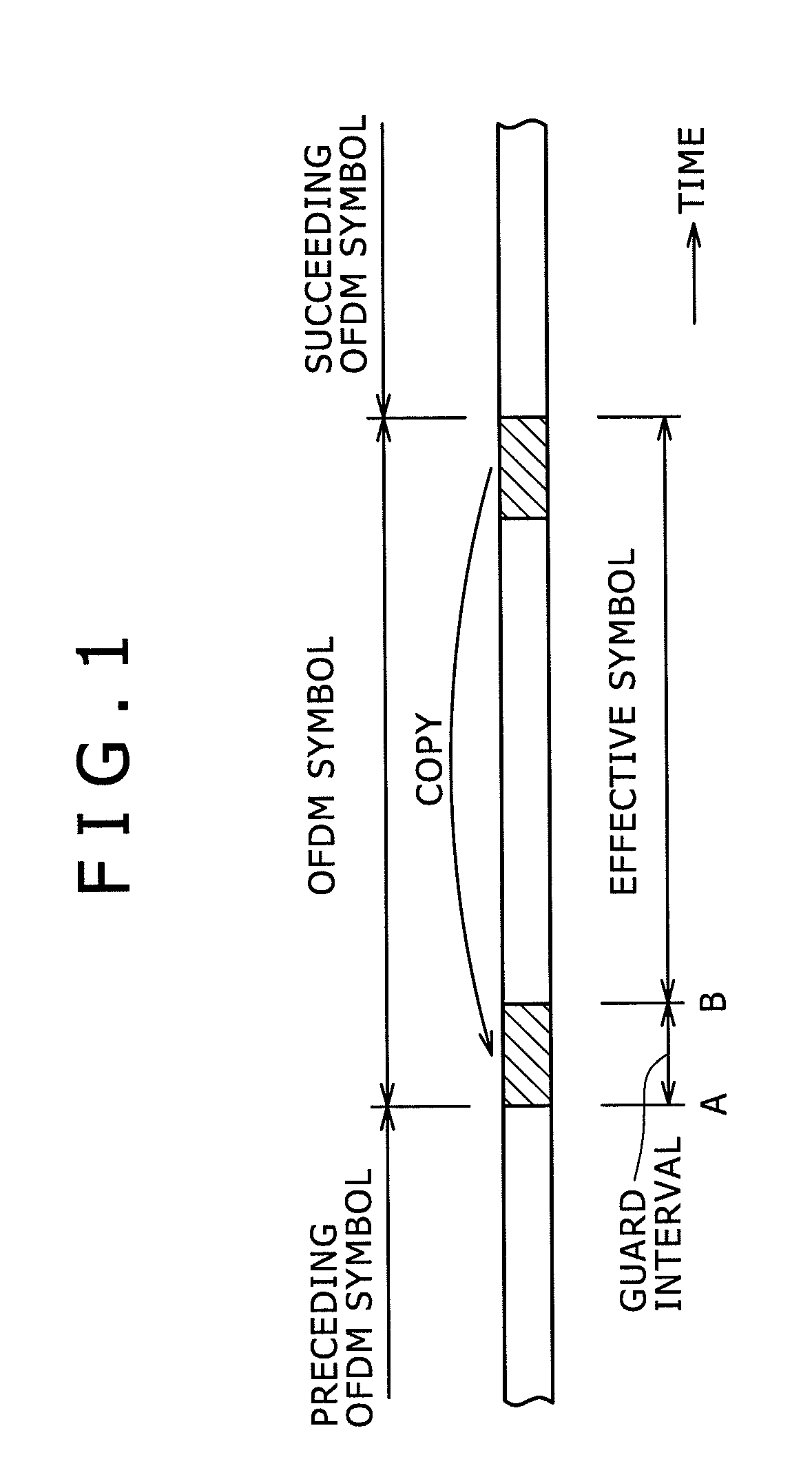

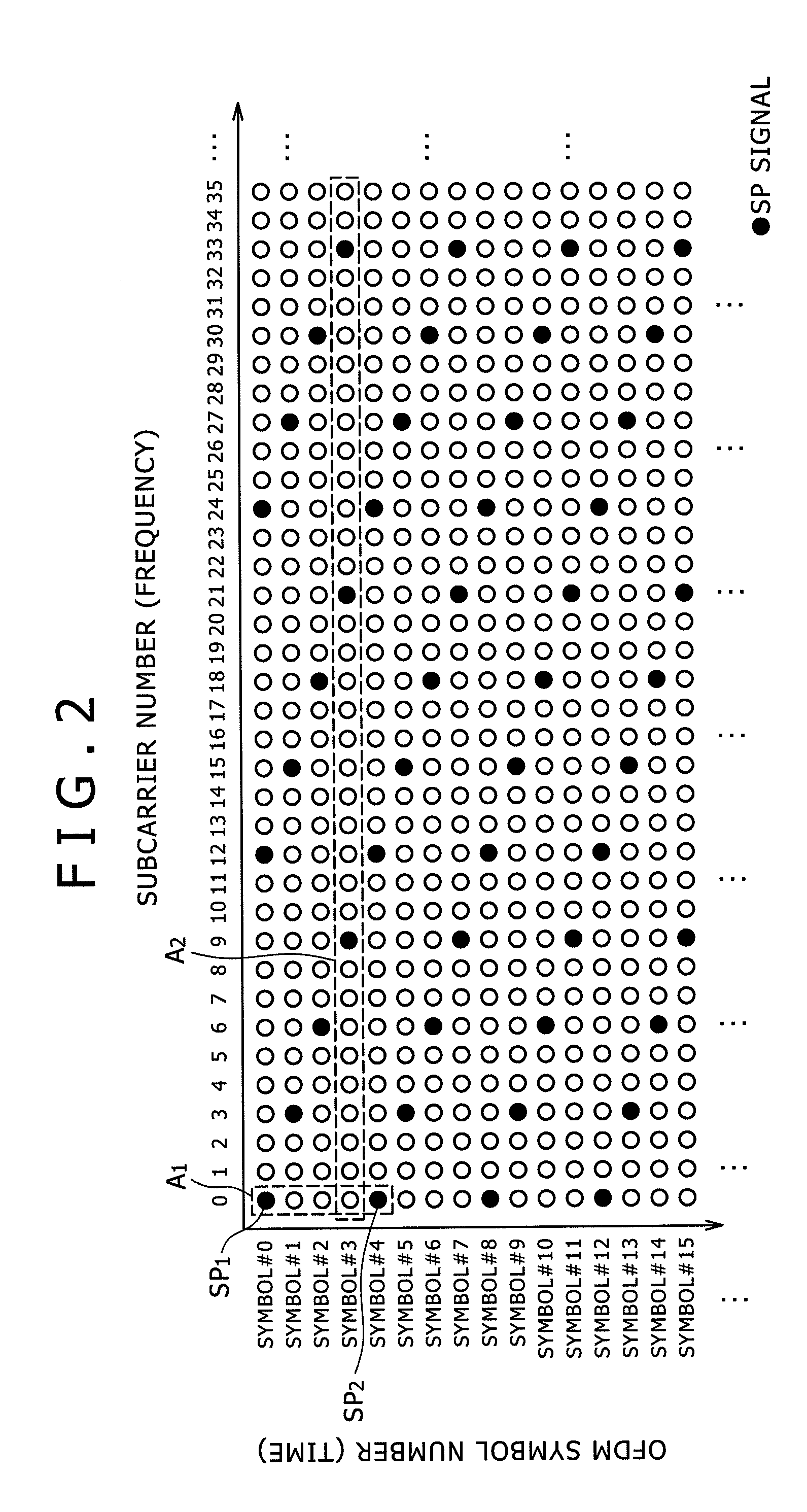

Reception apparatus, reception method and program

InactiveUS20090221254A1Deterioration of performance can be preventedInhibit deteriorationPilot signal allocationTransmission noise suppressionEngineeringTransmission line

A reception apparatus including an extraction section; a transmission line characteristic estimation section; an interpolation section; a compensation section; a detection section; and a selection section.

Owner:SONY CORP

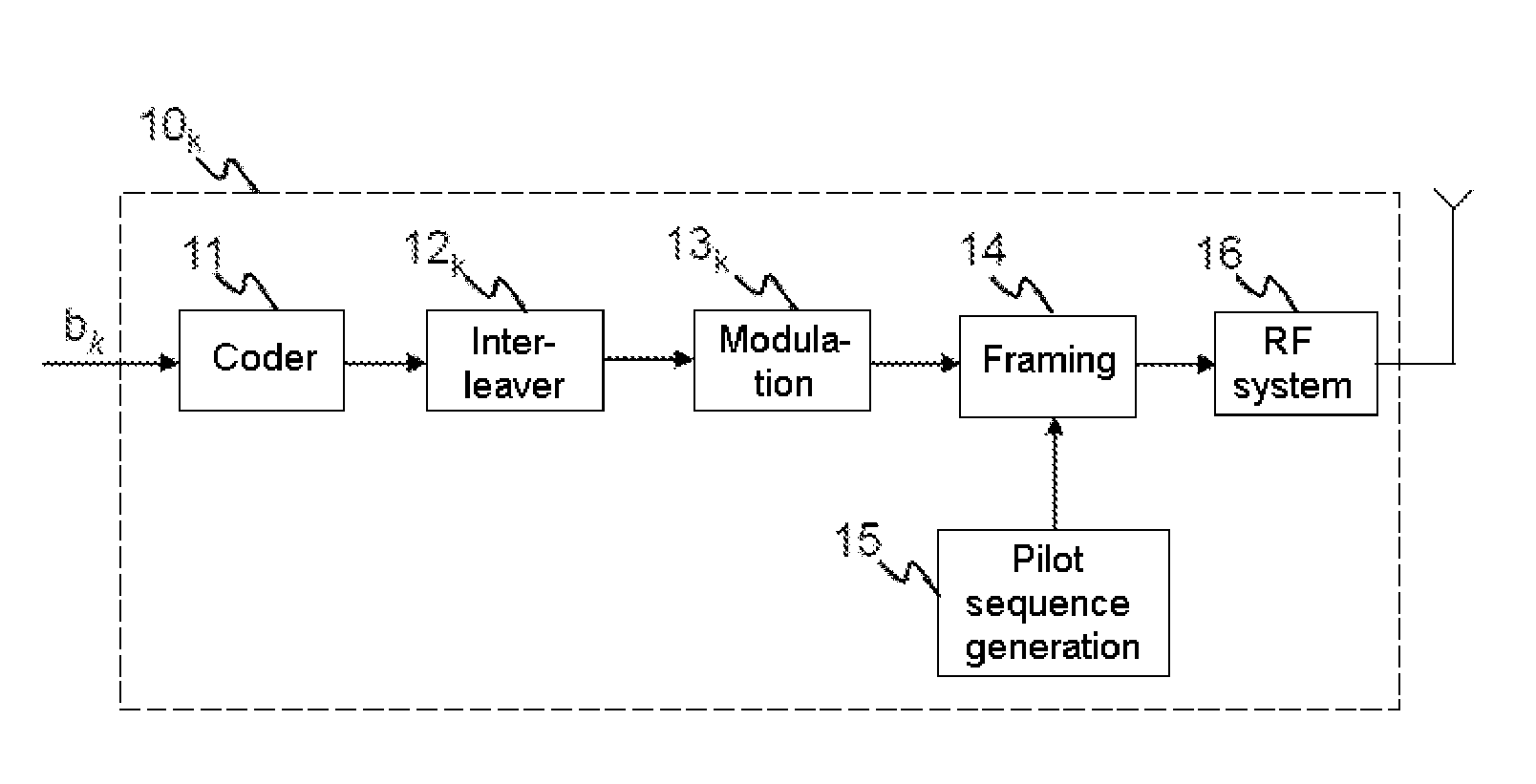

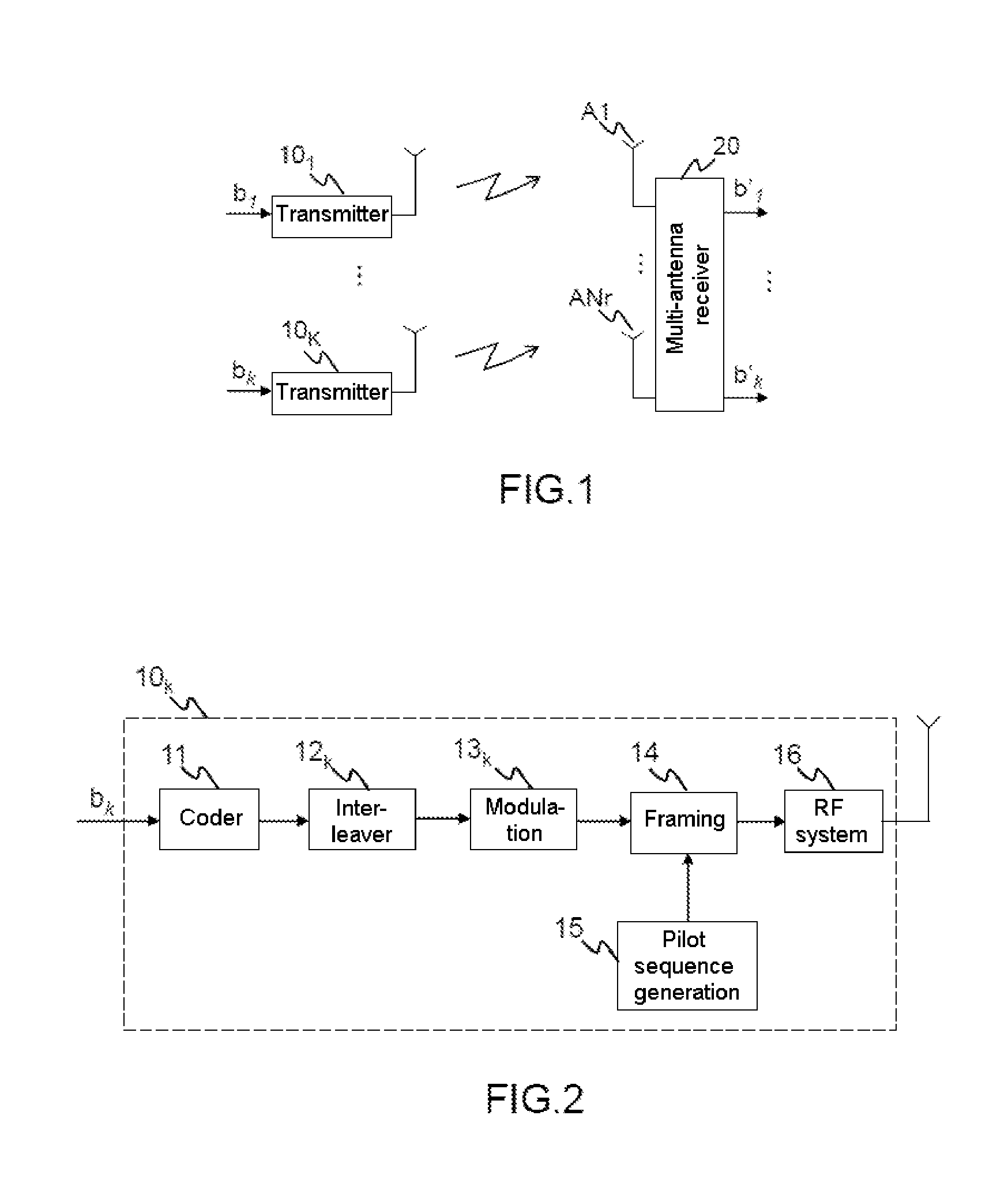

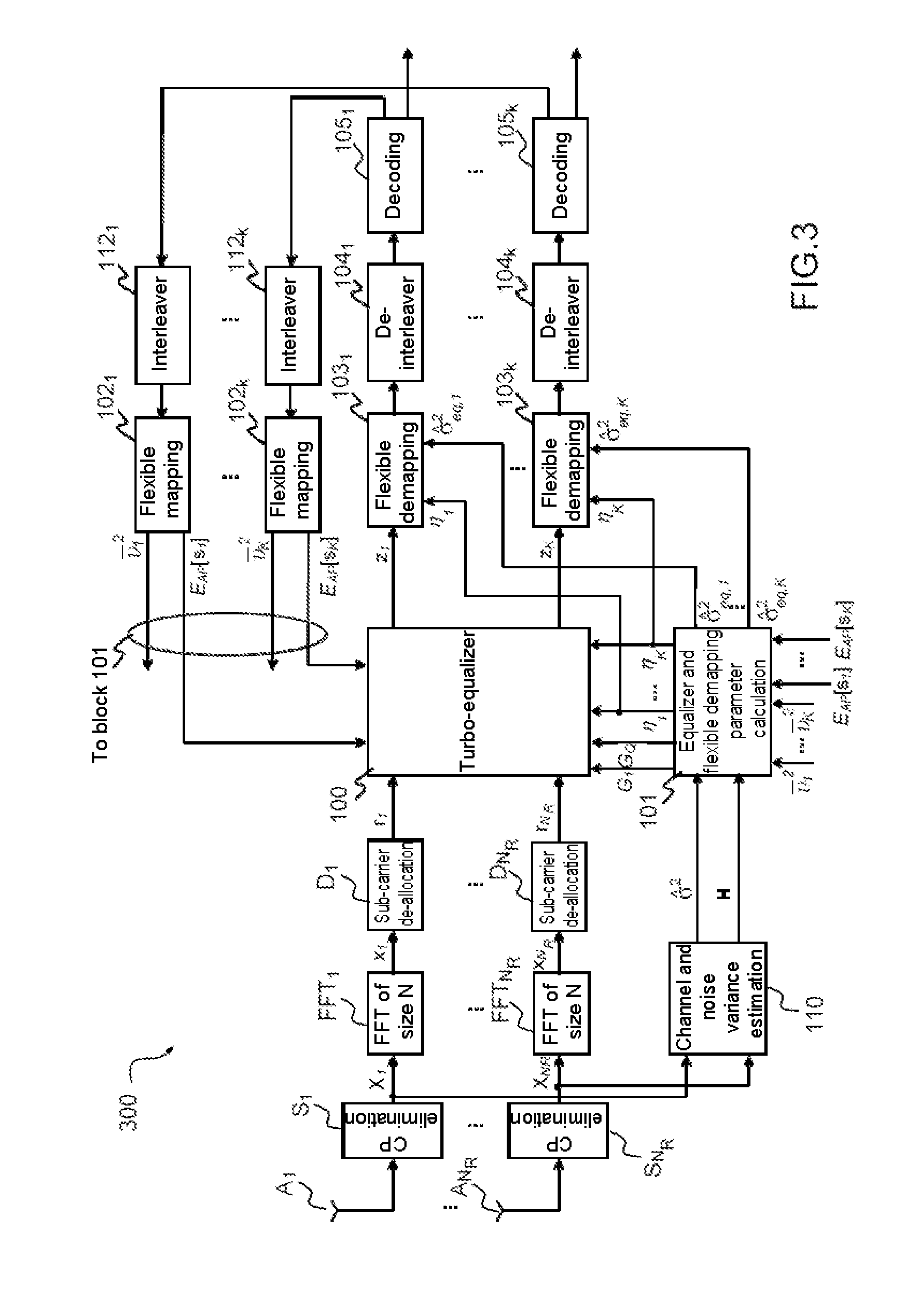

Method of widely linear turbo-equalization in a multi-user context and for a multi-channel multi-antenna receiver

InactiveUS20150341190A1Eliminate distractionsImprove equalization filterMultiple-port networksDelay line applicationsEngineeringEqualization

A method of equalizing a signal received by a plurality of antenna elements, the received signal being produced by the transmission of signals by a plurality of transmitters, includes: a step of converting the received signal into the frequency domain; a step of subtracting from the signal an estimate of the intersymbol interference and the interference between users so as to obtain a complex corrective signal; a step of conjoint widely linear filtering of the complex corrective signal and the conjugate complex corrective signal to obtain an equalized signal; a step of converting the equalized corrective signal into the time domain; a step of calculating coefficients of the at least one equalizer filter from the covariance matrix and the pseudo-covariance matrix of the received signal.

Owner:THALES SA

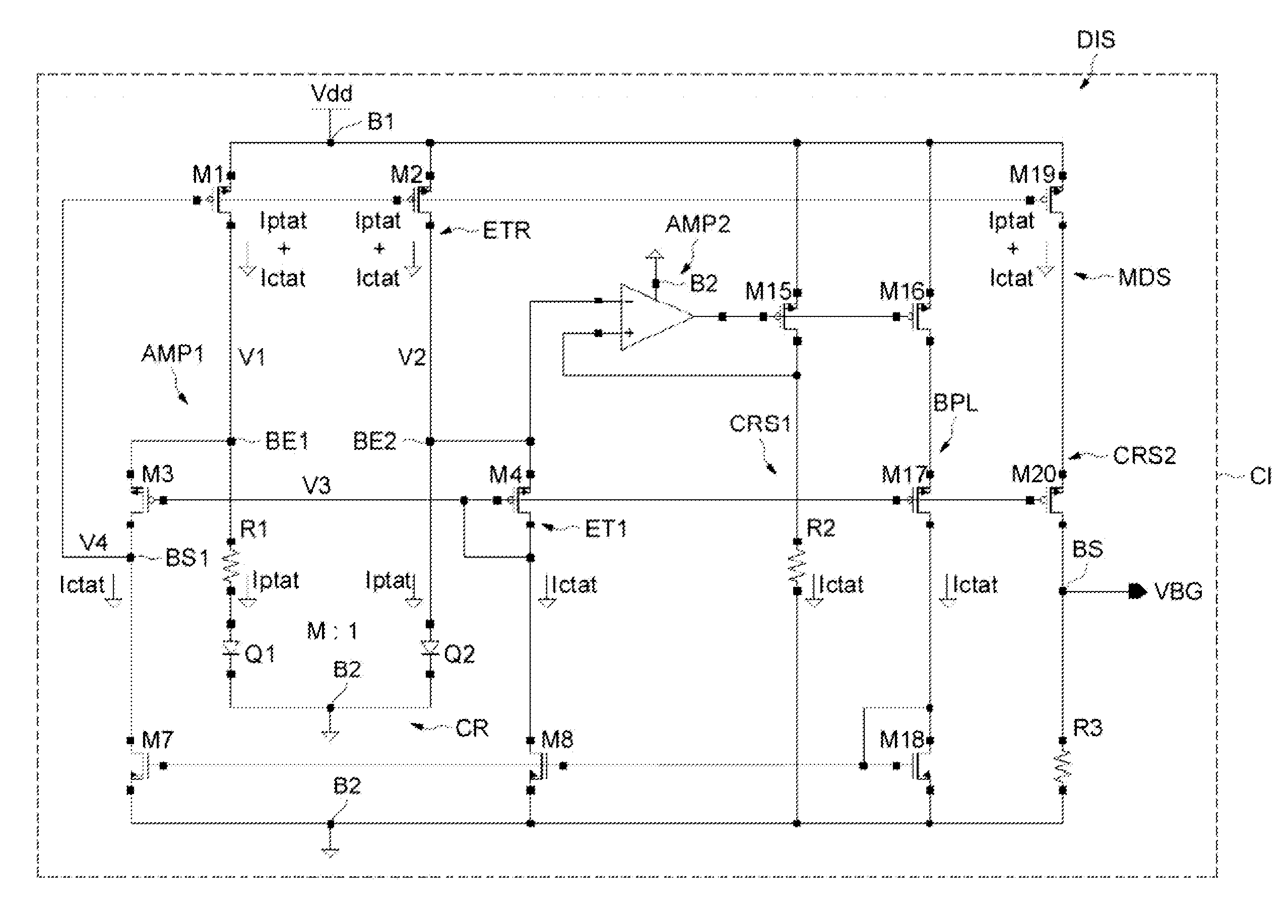

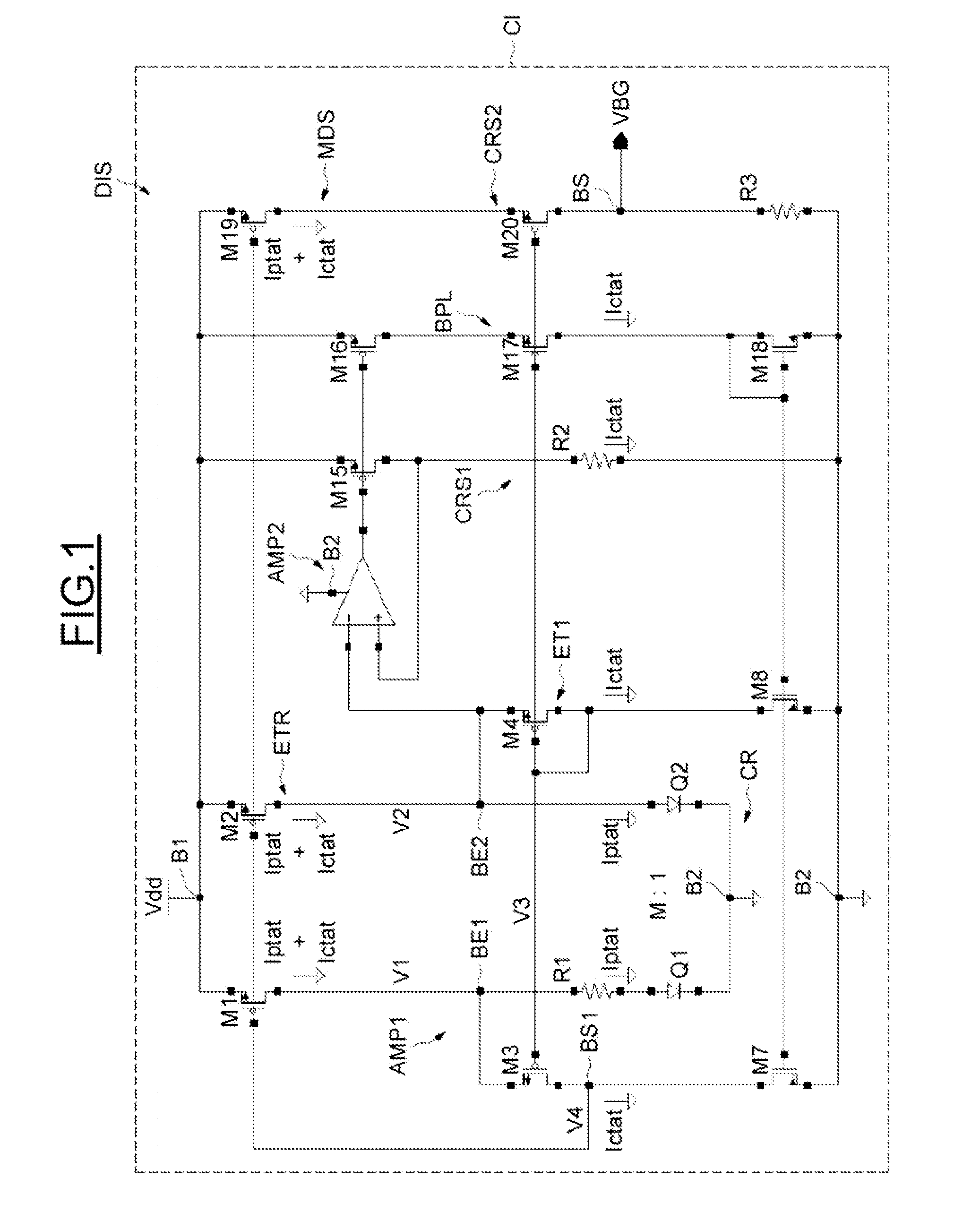

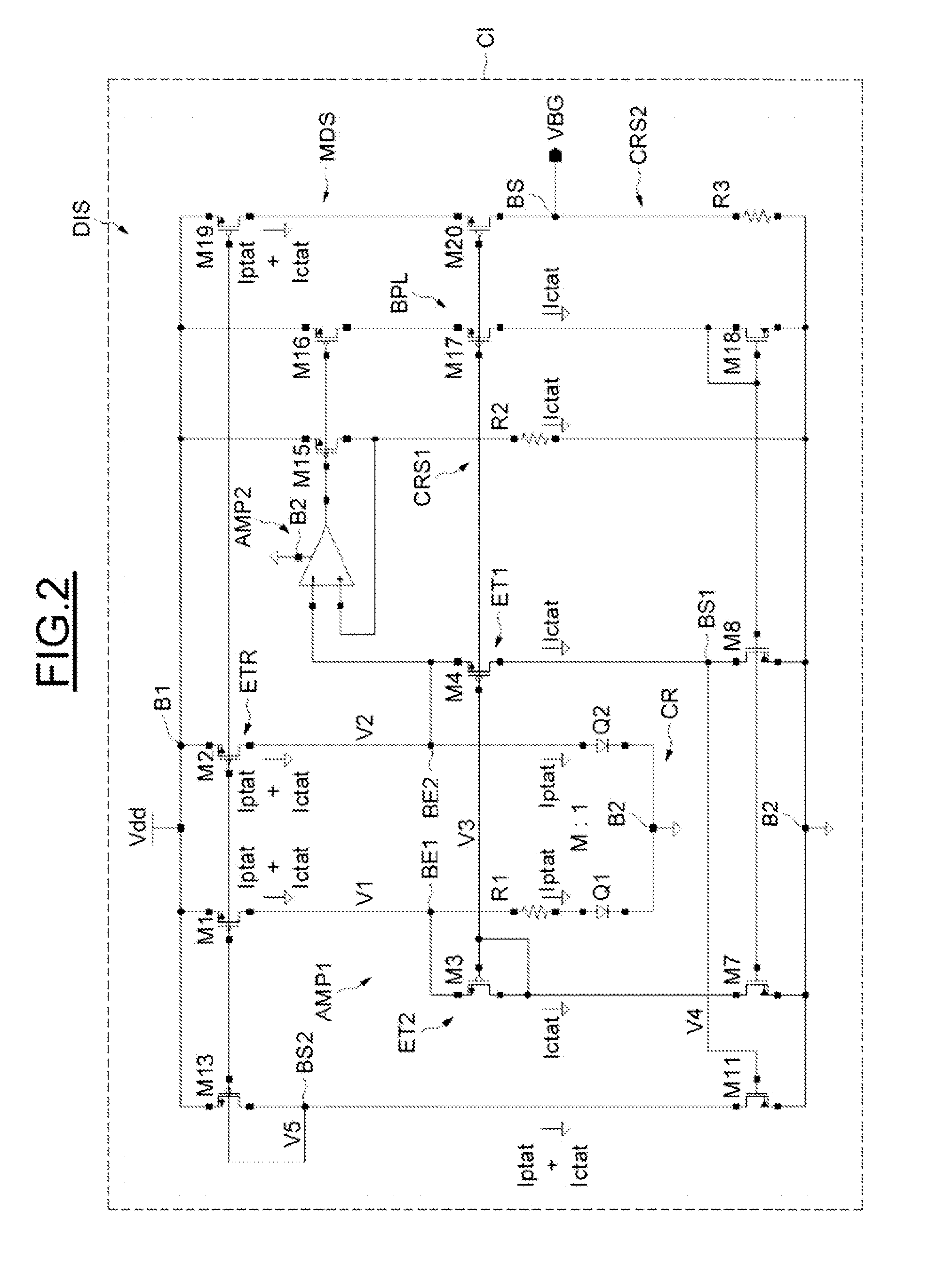

Device for Generating an Adjustable Bandgap Reference Voltage with Large Power Supply Rejection Rate

ActiveUS20120293149A1Lower input impedanceImprove the PSRR parameter.Electric variable regulationMagnetic coreVoltage reference

An adjustable bandgap reference voltage comprises means for generating current proportional to absolute temperature comprising first means connected to terminals of a core and designed to equalize voltages across the terminals, means for generating a current inversely proportional to absolute temperature connected to the core, and an output module designed to generate the reference voltage; the first processing means comprise a first amplifier possessing a stage, biased by the current inversely proportional to absolute temperature, arranged according to a folded setup and comprising first PMOS transistors arranged according to a common-gate setup, and a stage whose input is connected to the amplifier output and whose output is connected to the first stage input and to a terminal of the core, the second generating means comprise a follower amplifier setup connected to a terminal of the core and separated from the first amplifier, the output module is connected to the feedback stage.

Owner:STMICROELECTRONICS SRL

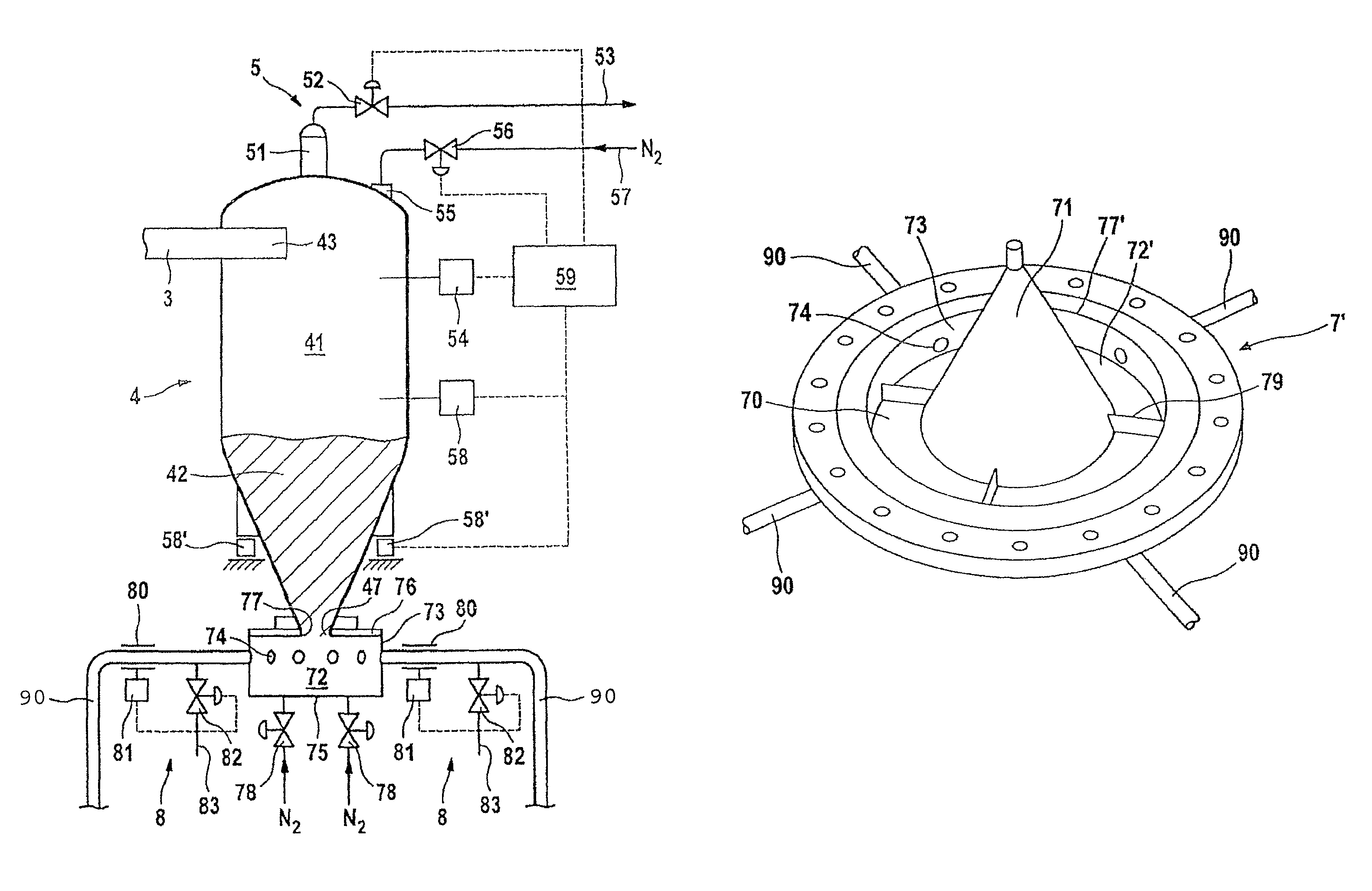

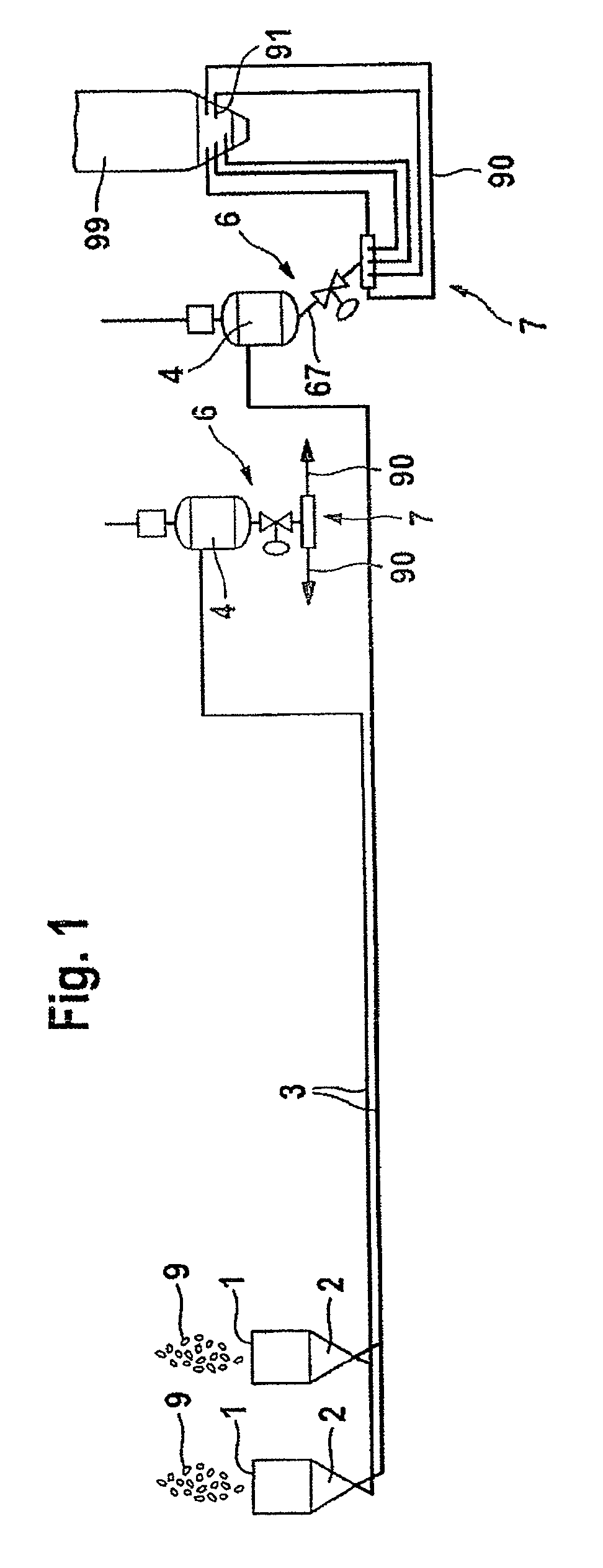

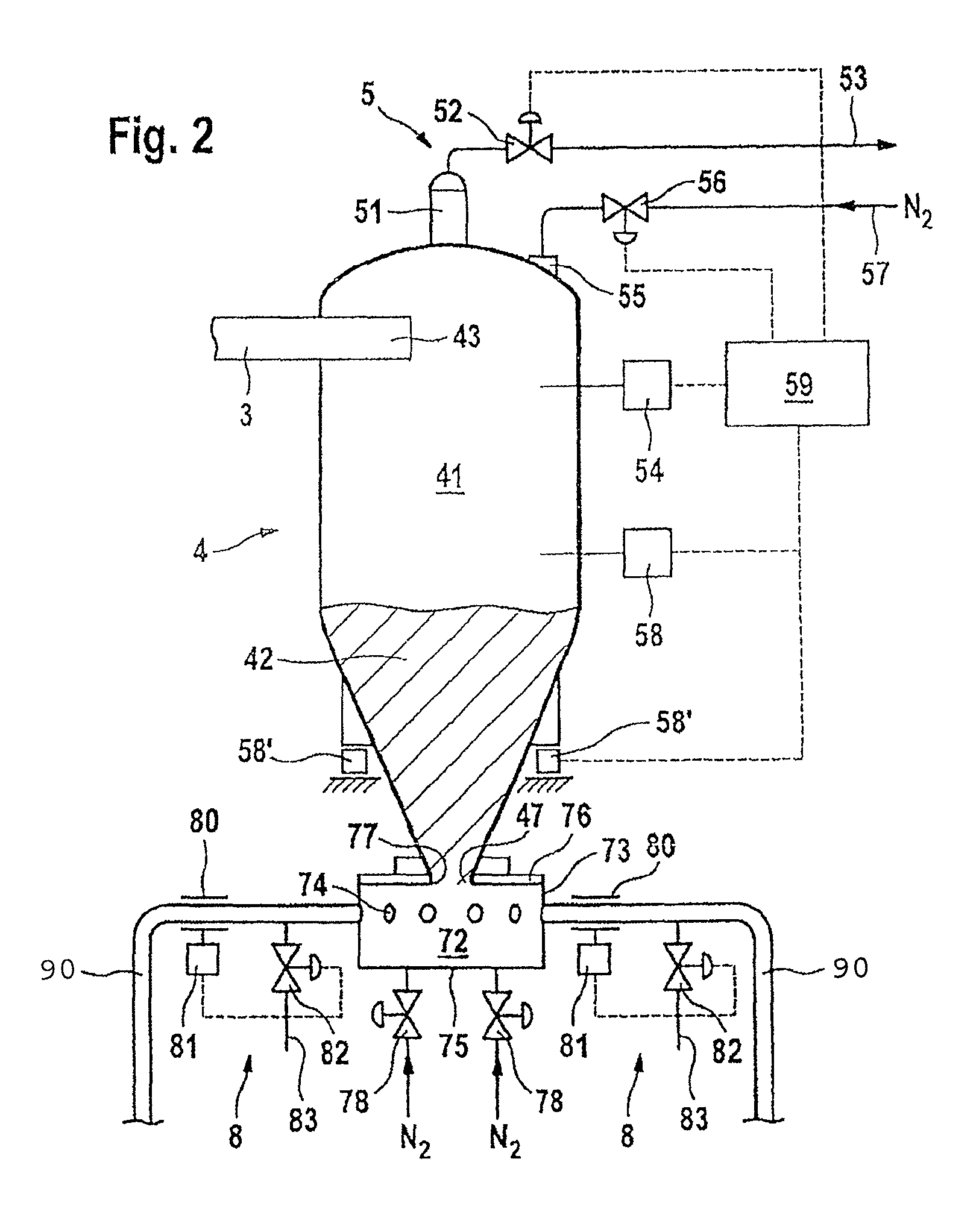

Solids distributor for injection plants, blast furnaces and the like

ActiveUS8348556B2Buildup of pressureEvenly goodBlast furnace detailsTravelling cranesEngineeringDistributor

A solids distributor for injection plants includes a collecting chamber having a plurality of lance lines leading away from the chamber. The chamber has a supply connection for a solid to be distributed and is surrounded by a common wall in which a plurality of ports is formed. The lance lines are connected to the ports, and an annular gap is formed in front of the ports and along the common wall. A pressure vessel is arranged geodetically above the collecting chamber, the lower part of the pressure vessel being designed as a bunker, having an outlet providing a direct and continuous junction to the supply connection and an upper part designed as a gas space. The collecting chamber may include a central displacement body which forms the annular gap with the common wall and which may be an upwardly tapering cone which projects out of the collecting chamber.

Owner:CLAUDIUS PETERS PROJECTS

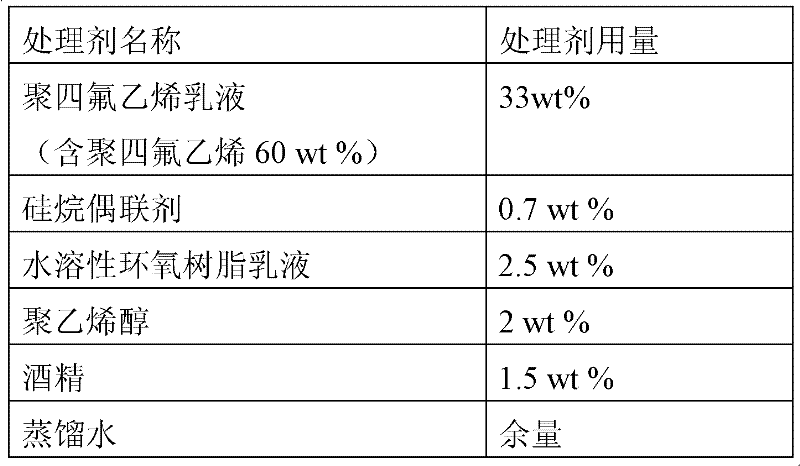

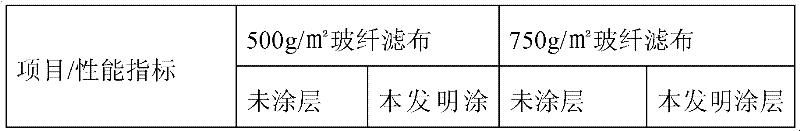

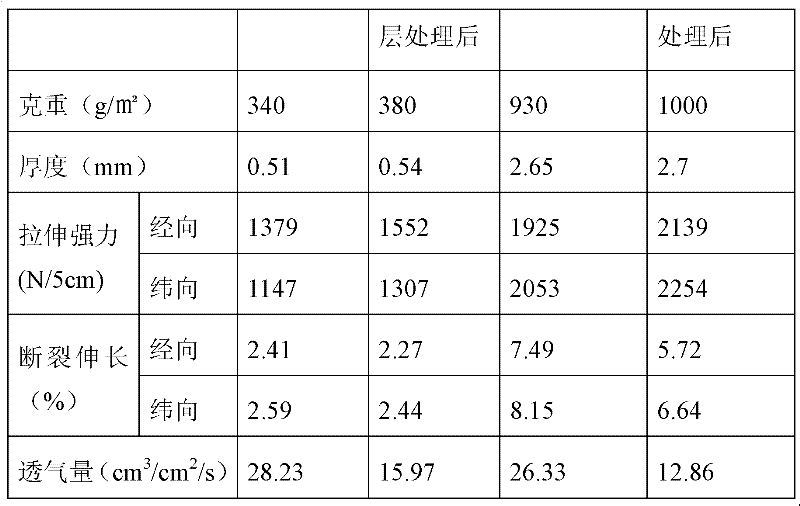

Manufacturing method for high-accuracy coating filter material

InactiveCN102512877AGood acid and alkali resistanceImprove water resistanceSynthetic resin layered productsGlass/slag layered productsFiberLoss strength

The invention provides a manufacturing method for a high-accuracy coating filter material, which has the advantages of good binding effect between the filter material and PTFE (Polytetrafluoroethylene) and capability of improving the performance of the filter material. The method comprises the following steps of: (1) thermal cleaning treatment, performing the thermal cleaning treatment on the filter material and removing various auxiliary agents on the surface of the filter material through high temperature; (2) dipping treatment, performing PTFE dipping treatment on the filter material which is subjected to the thermal cleaning treatment; (3) sequentially performing baking, drying and thermal forming treatment on the filter material which is subjected to the dipping treatment; (4) performing coating treatment on the filter material which is subjected to thermal forming; and (5) sequentially performing volatile treatment, baking treatment, sintering treatment and thermal forming treatment on the filter material which is subjected to the coating treatment. In the manufacturing method for the high-accuracy coating filter material, the thermal cleaning treatment is performed before the filter material is subjected to the dipping treatment, so that a wire drawing impregnating agent remained on the surfaces of fibers can be effectively removed, meanwhile, no loss strength of a textile is guaranteed; and the acid and alkali resistance, water resistance, oxidation resistance, wear resistance and folding resistance of the filter material are effectively improved, and the service life of the filter material is prolonged.

Owner:辽宁鸿顺环保新材料有限公司

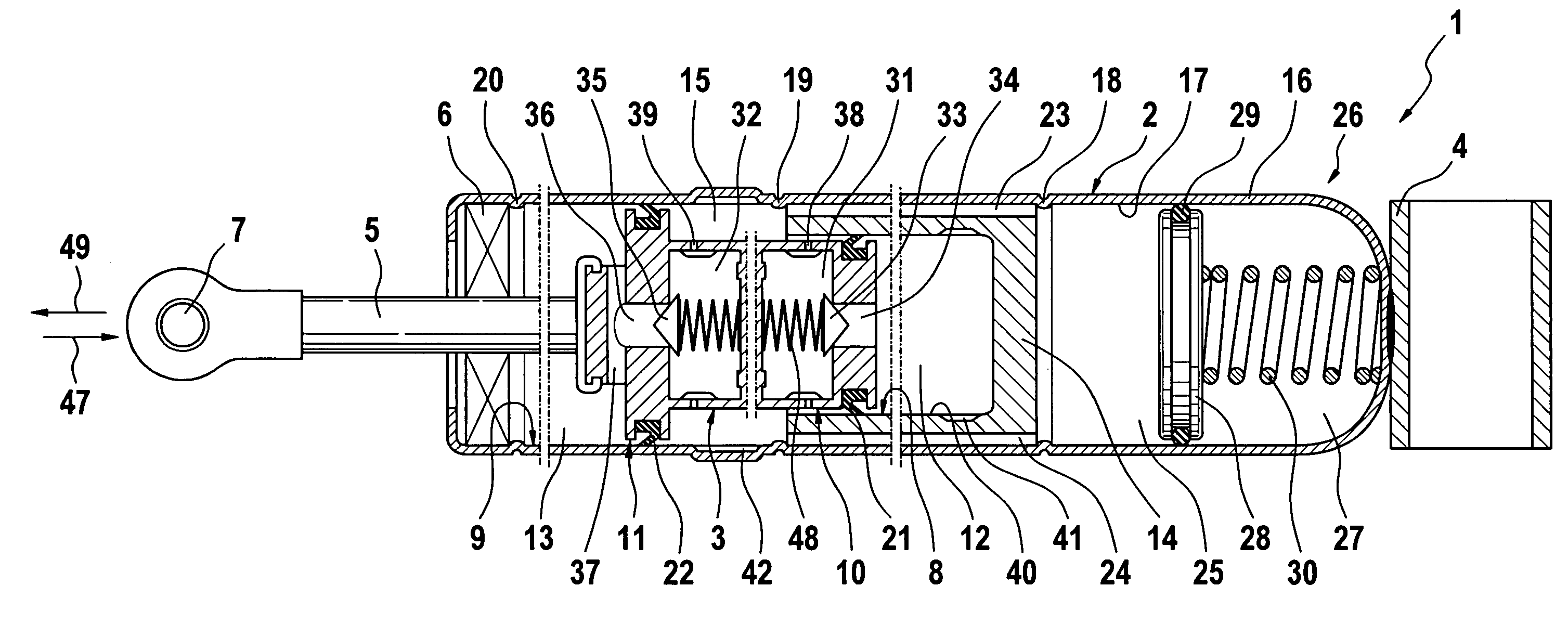

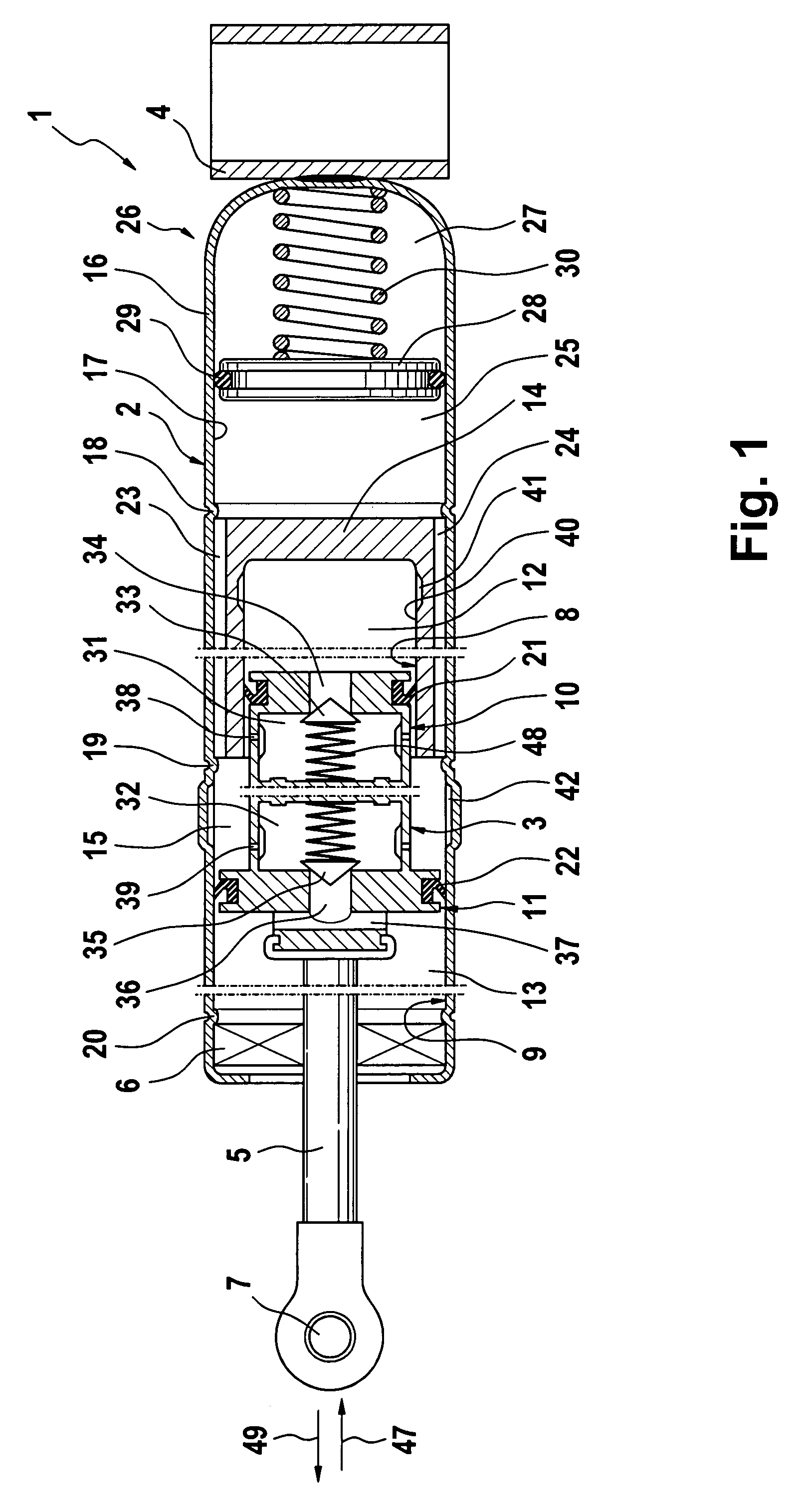

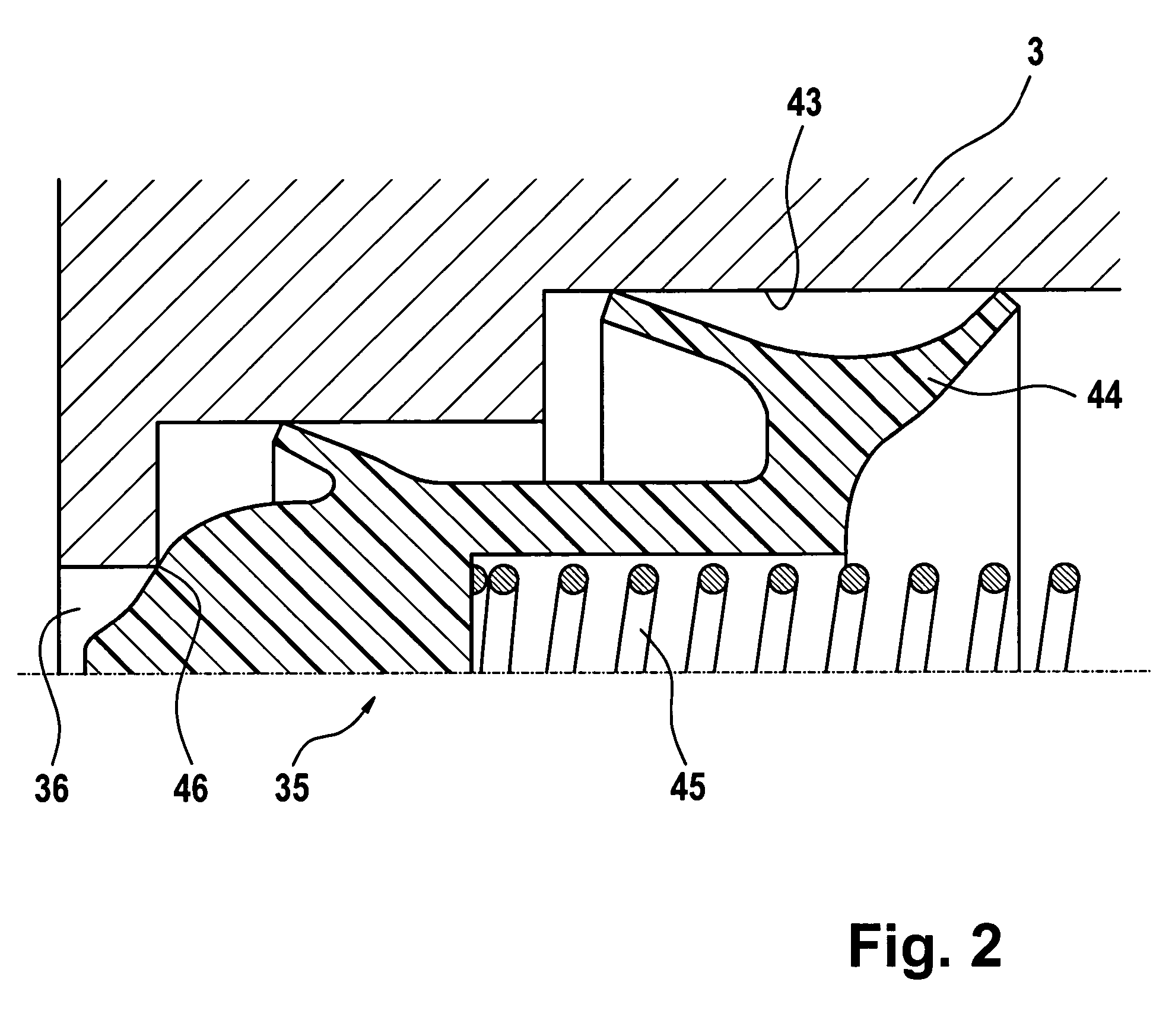

Continuously lockable adjustment device

InactiveUS7237471B2Easy constructionReduce weightSpringsServomotor componentsWorking fluidPiston rod

Owner:STABILUS

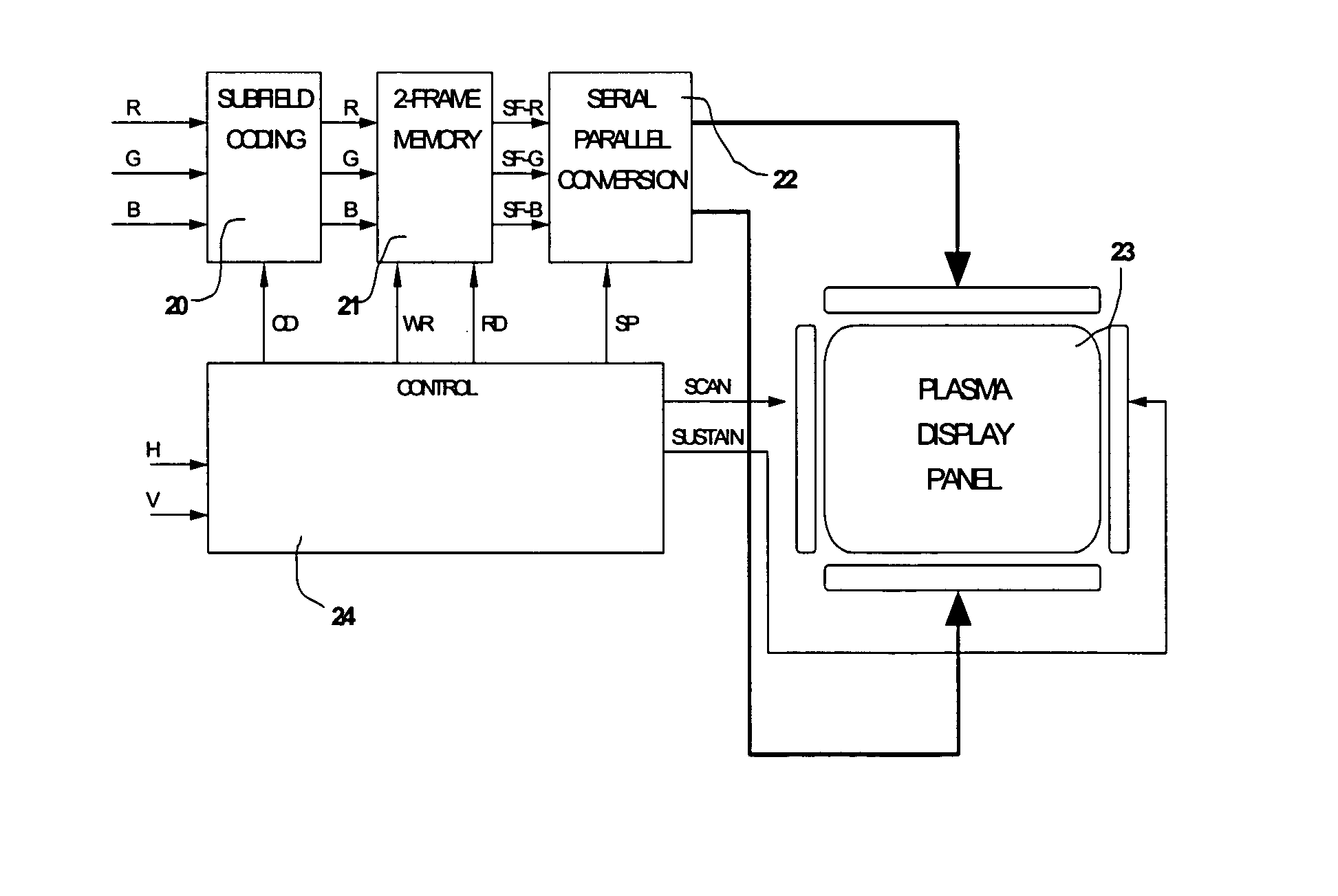

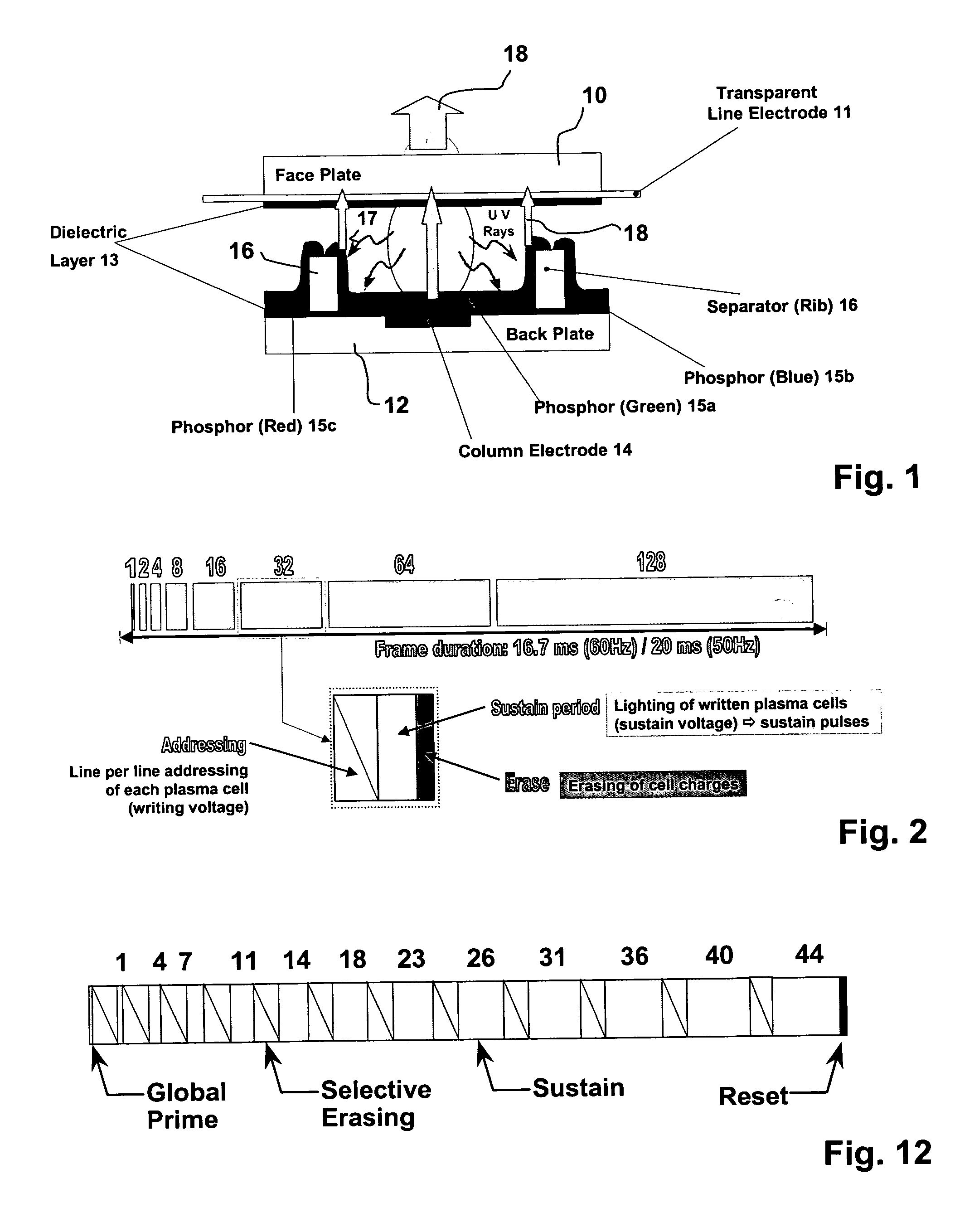

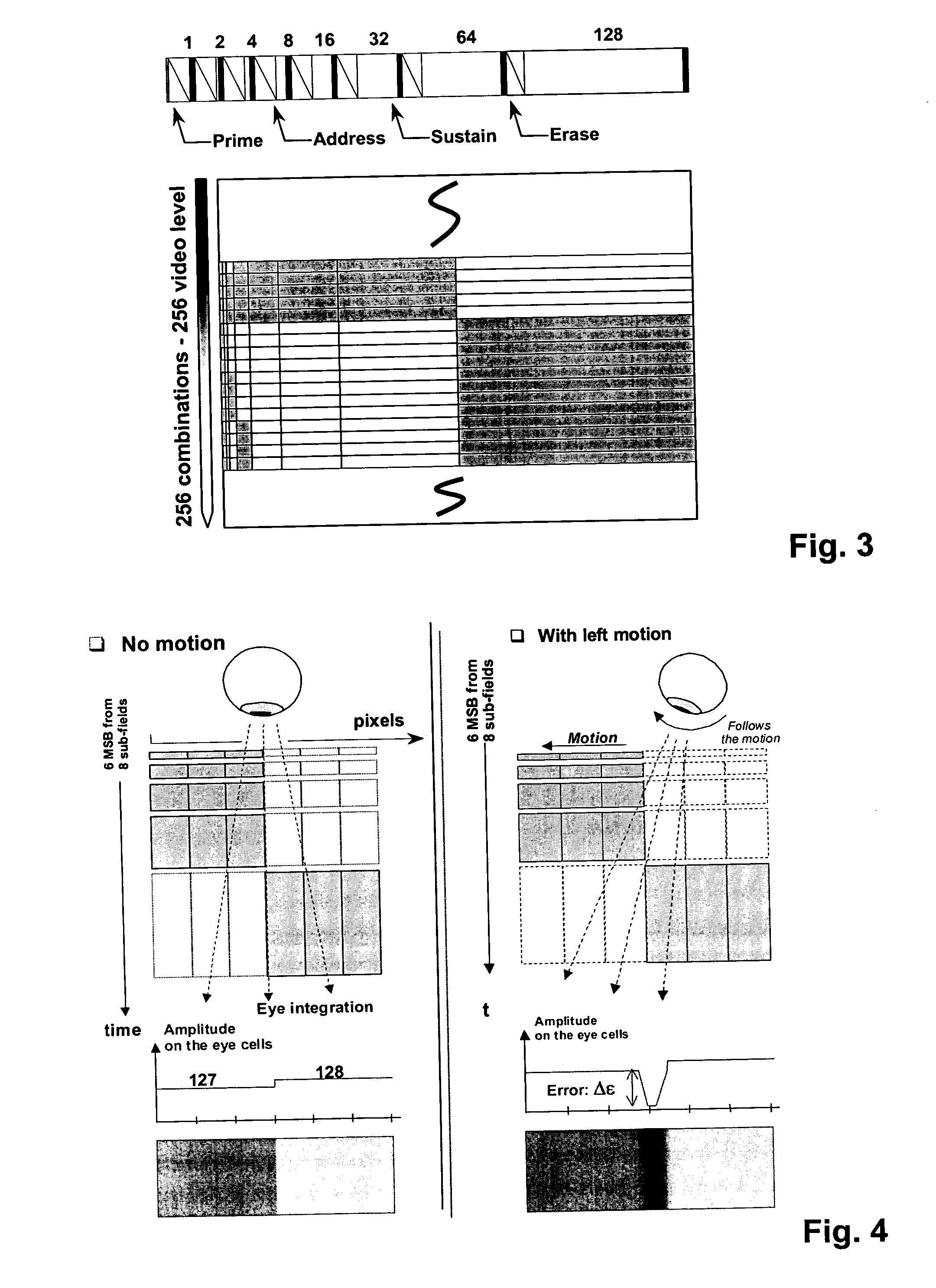

Method and apparatus for controlling a display device

InactiveUS20040032533A1Evenly goodIncrease the areaTelevision system detailsTelevision system scanning detailsDisplay deviceSmall pulse

The invention deals with the large area flicker effect reduction in display devices like plasma display panels, in which the light output is controlled by small pulses over a whole frame period and the amount of small pulses determine the brightness of the light output. The invention proposes an adaptation of the known principle of sub-field grouping for large area flicker reduction for the specific sub-field coding process called incremental sub-field coding, in which only those sub-field code words are taken for display driving having the characteristic that there is never a sub-field inactivated between two activated sub-fields or never a sub-field is activated between two inactivated sub-fields. For this specific sub-field coding it is proposed to make the sub-field grouping in a simple manner, where all the odd sub-fields are grouped together in one group (G1) and all the even sub-fields are grouped together in a second group (G2). Despite the fact that some luminance differences are present in the groups it has been proved, that this sub-field grouping leads to a very efficient large area flicker reduction because of its complementary behaviour to the required dithering technique.

Owner:THOMSON LICENSING SA

Preparation method of foamed aluminum alloy

The invention provides a preparation method of foamed aluminum alloy. The preparation method of the foamed aluminum alloy comprises the following steps: (1) melting aluminum and insulating to the temperature of 800-850 DEG C, adding a tackifier Ca which accounts for 1%-4% of the total mass of aluminum melt into the aluminum melt, stirring and mixing evenly, and reacting for 5-15 minutes to enable the viscosity of the melt to be stable; (2) cooling the aluminum melt of which the viscosity is increased in the step (1) to the temperature of 650-750 DEG C, adding titanium hydride which accounts for 0.2-2.1% of the total mass of the aluminum melt and is coated in a double-layered manner in the aluminum melt, stirring for 2-12 minutes at high speed, foaming the stirred melt at constant temperature, and cooling with water and solidifying after foaming is finished. A titanium hydride coating method comprises the following steps: carrying out chemical iron plating treatment on titanium hydride at first; and then grinding and mixing the titanium hydride coated with iron and aluminum oxide to obtain the final product. The foamed aluminum alloy prepared by the preparation method is uniform in pore diameter distribution, the average pore size of foamed aluminum is 1.2-1.5 mm, and the porosity is 75-80%.

Owner:郑州峰泰纳米材料有限公司

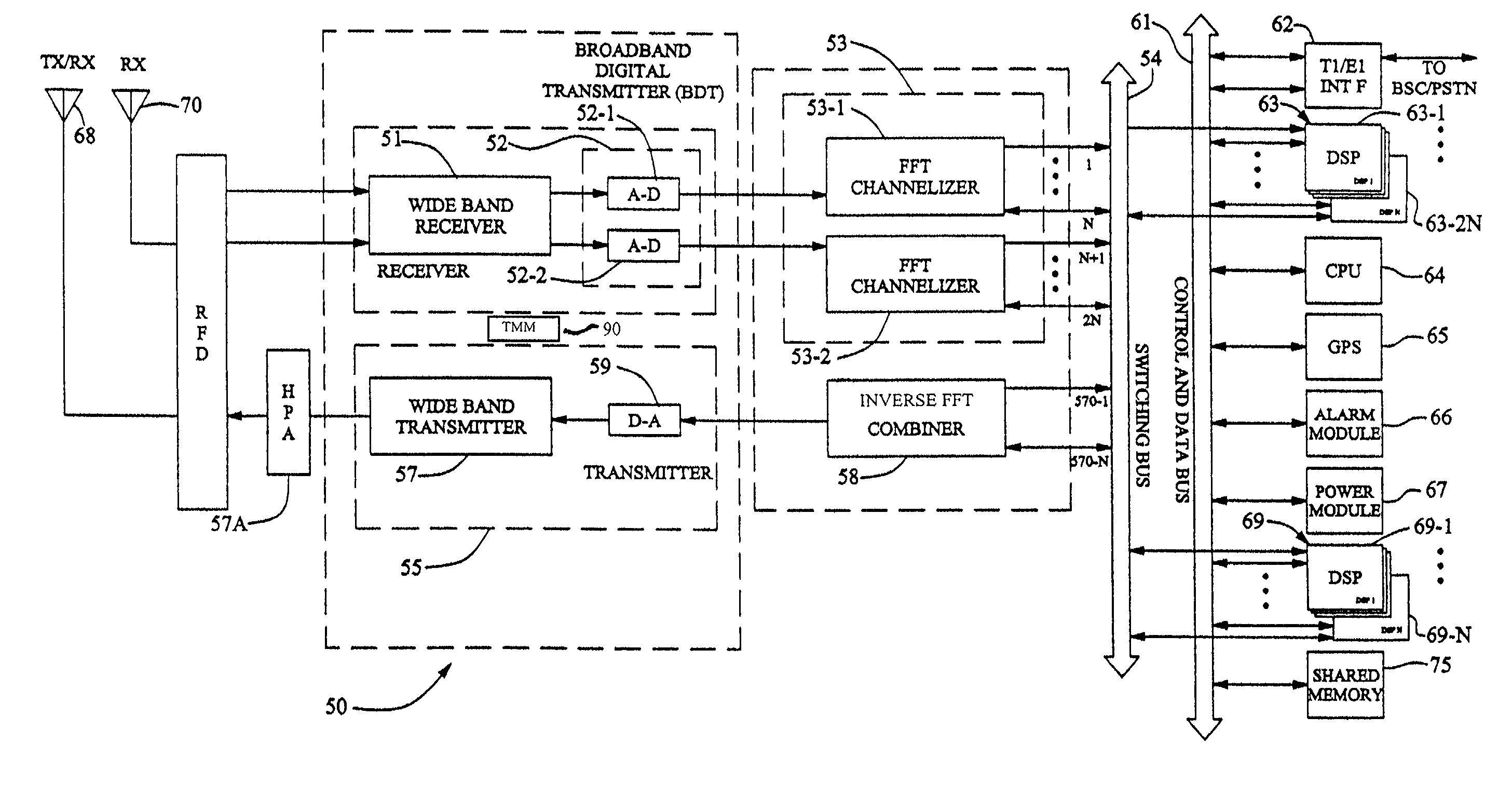

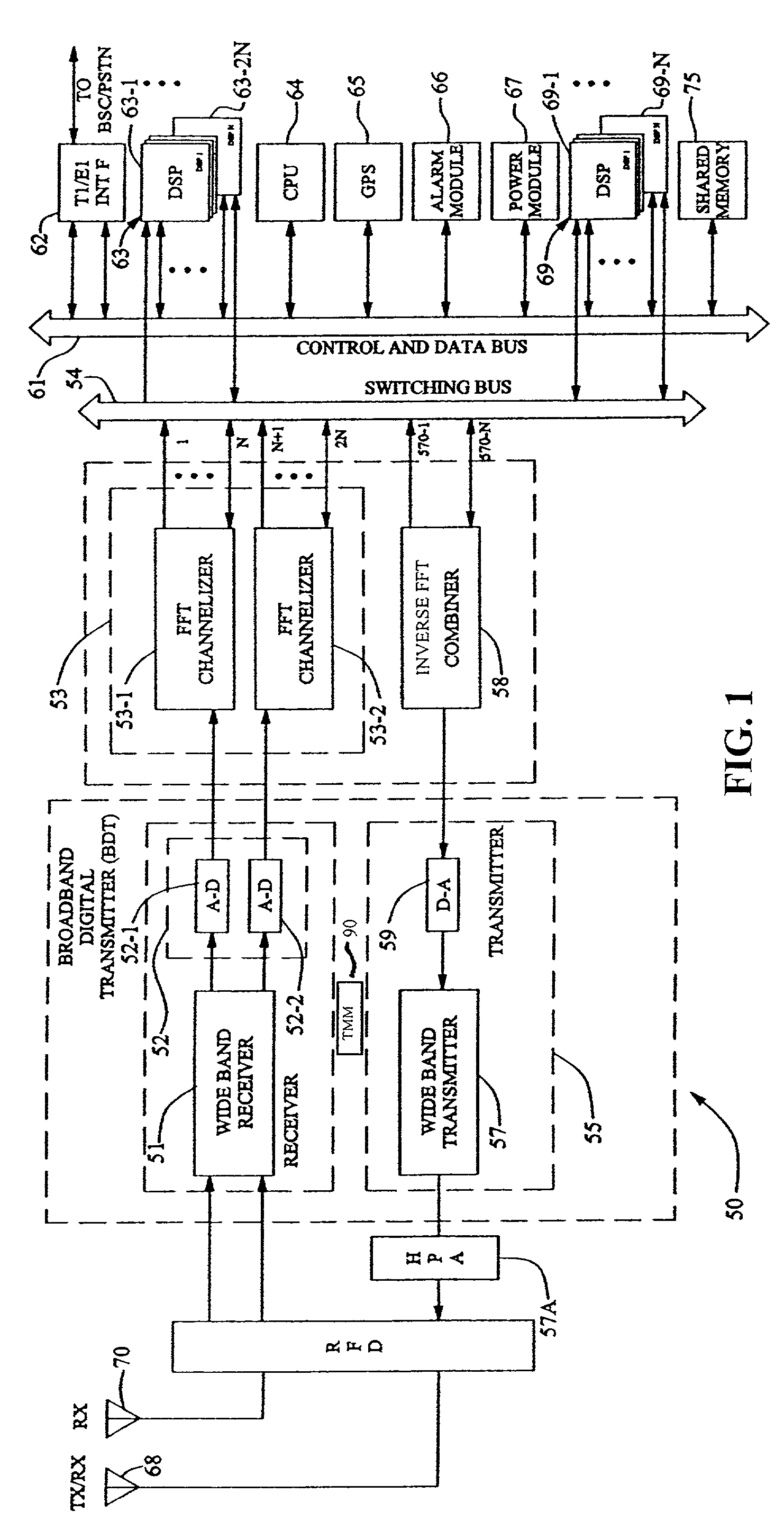

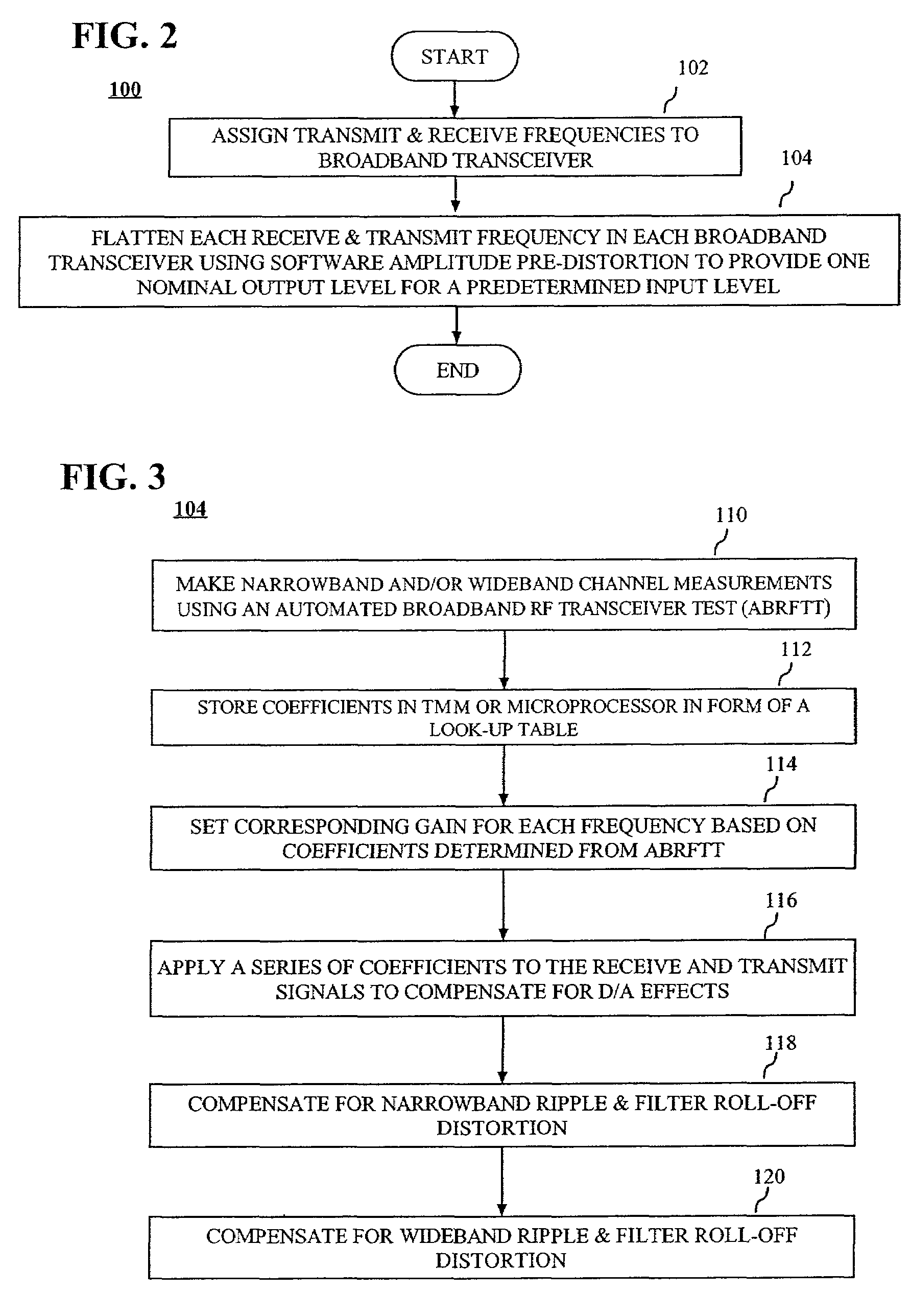

Method and apparatus for equalization in transmit and receive levels in a broadband transceiver system

A method (100) for amplitude equalization in transmit and receive levels in a base station wideband transceiver (50) includes the step of assigning (102) a plurality of transmit and receive carrier frequencies to the base station wideband transceiver and the step of flattening (104) the power in the plurality of transmit and receive carrier frequencies in the plurality of base wideband transceivers using software amplitude pre-distortion.

Owner:RATEZE REMOTE MGMT LLC

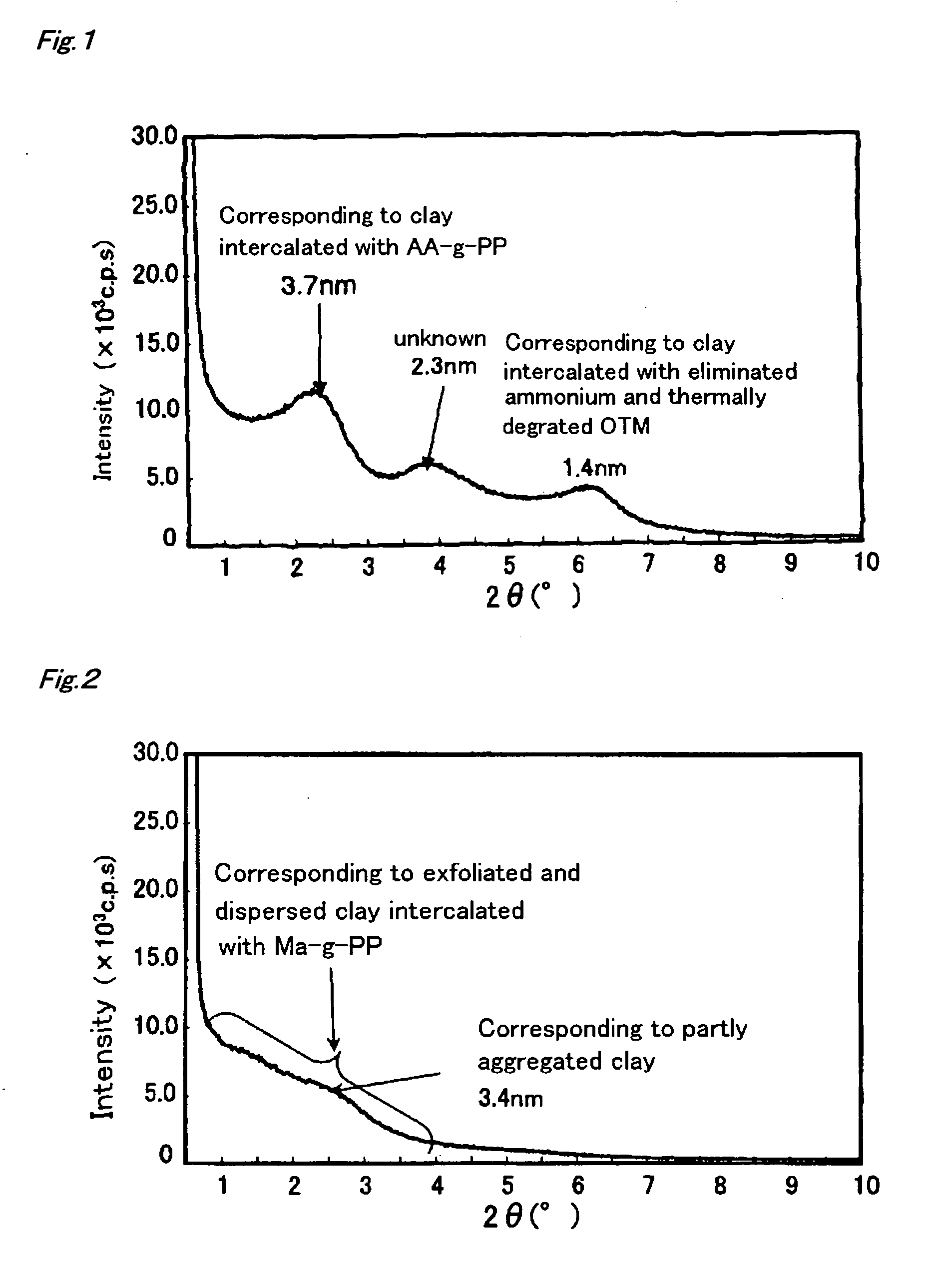

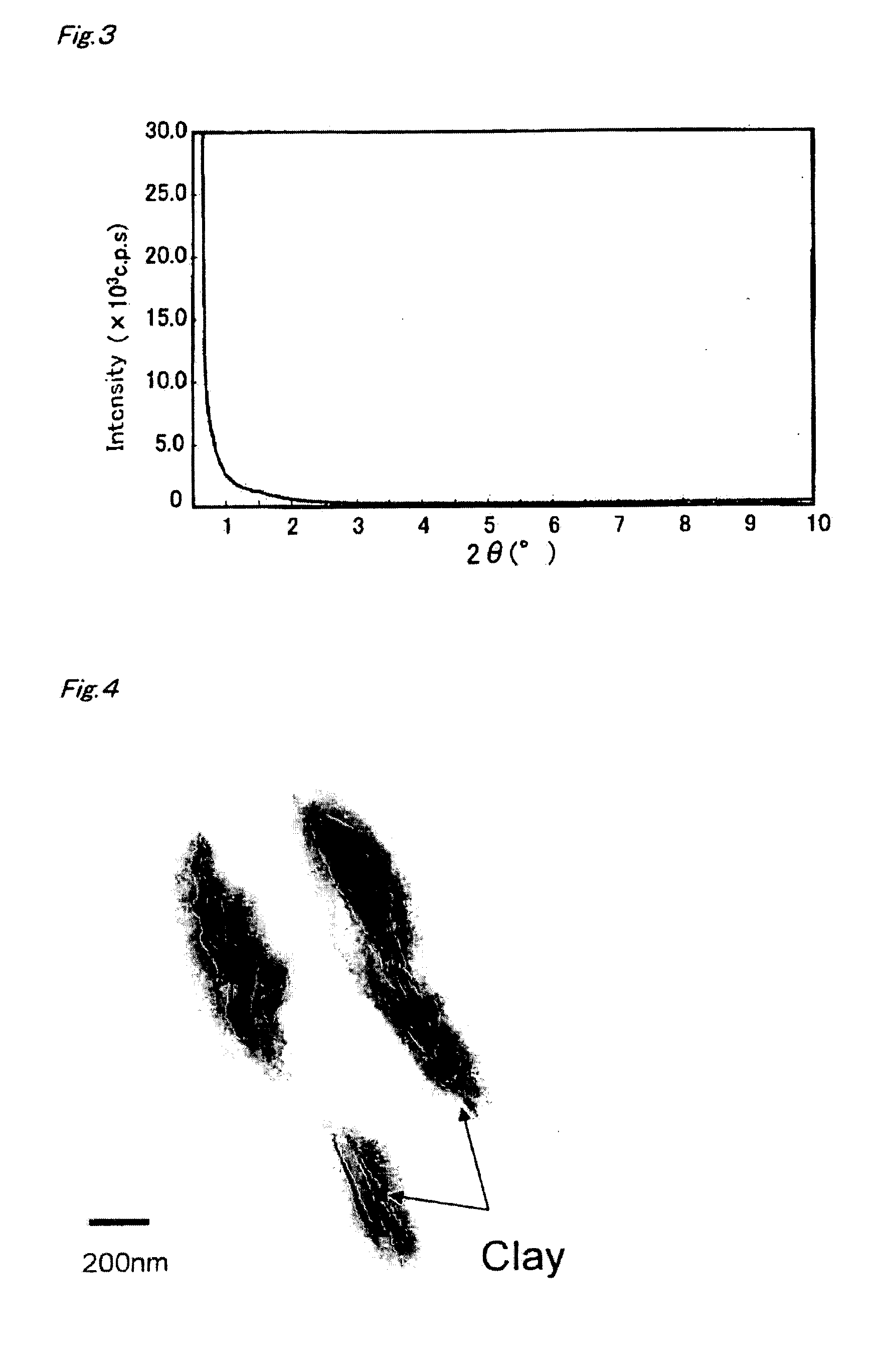

Polyolefin composite material, method for producing same, and formed product thereof

A polyolefin composite material comprising a polyolefin-based resin, an onium-modified low molecular weight polyolefin-based resin containing an organic onium group as a functional group and having a number average molecular weight of 500 to 30,000, and a layered clay mineral.

Owner:TOYOTA JIDOSHA KK +1

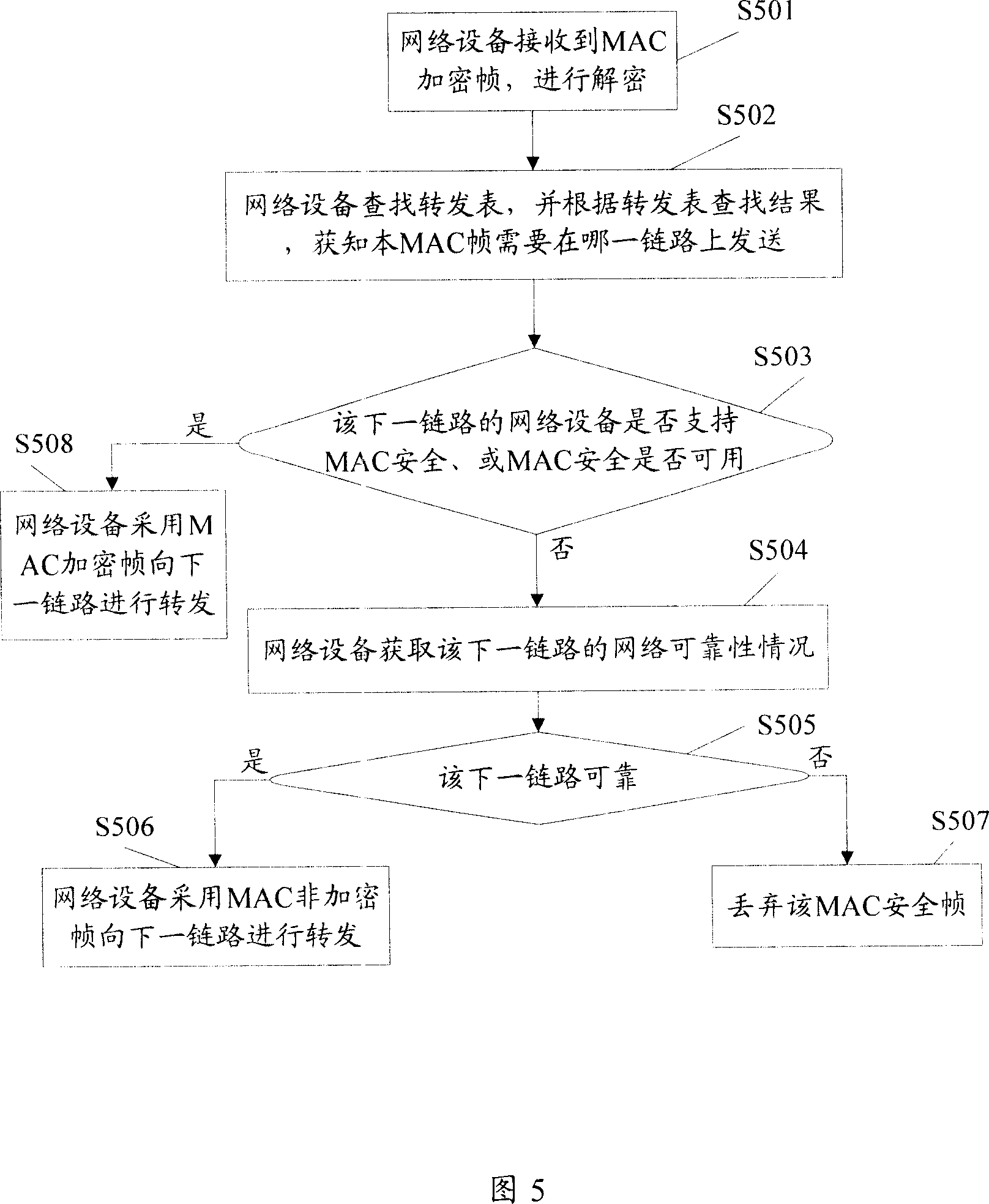

MAC secure network communication method and network device

InactiveCN101145899AEnsure normal communicationGuaranteed confidentialityData switching networksSecuring communicationNetwork communicationCommunication device

The invention discloses a MAC secure network communication method and communication equipment. The MAC secure network communication method includes that network equipment receive a MAC frame; if the MAC frame is of a MAC encrypted frame, decrypt the encrypted MAC frame, and if the network equipment in the next link where the encrypted MAC frame is to be forwarded does not support MAC security or MAC security can not be available, judge whether the link is reliable further, and if yes, forward to the link by using a MAC non-encrypted frame; otherwise, discard the MAC encrypted frame. The invention realizes to ensure the normal communication of network based on the security protection of the MAC frame.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com