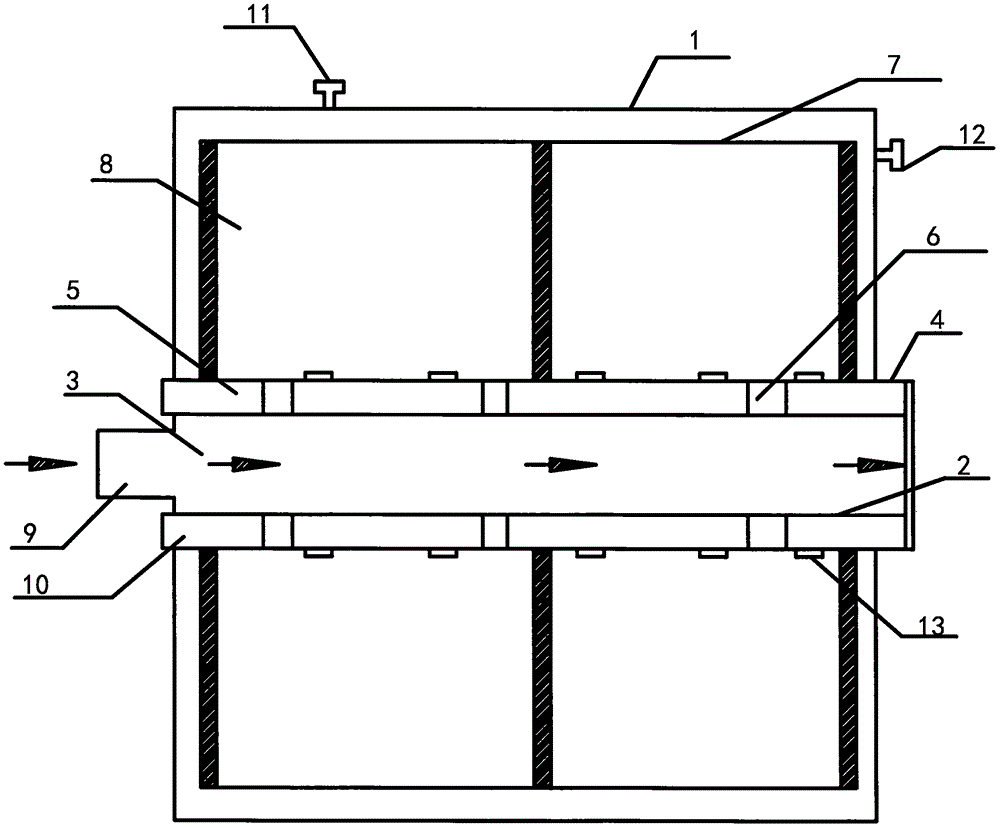

Sulfur tail gas super-gravity desulfurization device

A desulfurization device and supergravity technology, which is applied in the field of sulfur tail gas supergravity desulfurization device, and can solve the problems of sulfur tail gas desulfurization and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment discloses a sulfur tail gas supergravity desulfurization process, which includes the following steps:

[0052] (1) The sulfur tail gas enters the combustion furnace and burns at 500°C;

[0053] (2) Cool down the burned gas until the gas temperature reaches 400°C;

[0054] (3) The gas after cooling enters the first-stage reactor, and under the action of a catalyst, the reaction of preparing sulfur element is carried out, and the temperature is set to 400 ° C during the reaction;

[0055] (4) The gas after the primary reaction enters the secondary reactor for the reaction of preparing sulfur element again, and the reaction temperature is set to 380°C;

[0056] (5) After the reaction, the liquid sulfur is captured by the trap, and the gas enters the hydrogenation reactor, and the hydrogenation reaction is carried out at 320°C under the action of the catalyst;

[0057] (6) Utilize amine liquid to wash and absorb the gas after the hydrogenation reaction;

...

Embodiment 2

[0061] This embodiment discloses a sulfur tail gas supergravity desulfurization process, which includes the following steps:

[0062] (1) The sulfur tail gas enters the combustion furnace and burns at 900°C;

[0063] (2) Cool down the burned gas until the gas temperature reaches 430°C;

[0064] (3) The gas after cooling enters the first-stage reactor, and under the action of a catalyst, the reaction of preparing sulfur element is carried out, and the temperature is set to 380° C. during the reaction;

[0065] (4) The gas after the primary reaction enters the secondary reactor for the reaction of preparing sulfur element again, and the reaction temperature is set to 350°C;

[0066] (5) After the reaction, the liquid sulfur is captured by the trap, and the gas enters the hydrogenation reactor, and the hydrogenation reaction is carried out at 380°C under the action of the catalyst;

[0067] (6) Utilize amine liquid to wash and absorb the gas after the hydrogenation reaction;

...

Embodiment 3

[0070] This embodiment discloses a sulfur tail gas supergravity desulfurization process, which includes the following steps:

[0071] (1) The sulfur tail gas enters the combustion furnace and burns at 1300°C;

[0072] (2) Cool down the burned gas until the gas temperature reaches 450°C;

[0073] (3) The gas after cooling enters the first-stage reactor, and under the action of a catalyst, the reaction of preparing sulfur element is carried out, and the temperature is set to 480 ° C during the reaction;

[0074] (4) The gas after the first-stage reaction enters the second-stage reactor for the reaction of preparing sulfur element again, and the reaction temperature is set to 450° C.;

[0075] (5) After the reaction, the liquid sulfur is captured by the trap, and the gas enters the hydrogenation reactor, and under the action of the catalyst, 420 ℃ for hydrogenation reaction;

[0076] (6) Utilize amine liquid to wash and absorb the gas after the hydrogenation reaction;

[0077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com