Seal-equipped bearing, and ball bearing

A technology with seals and ball bearings, applied in the direction of ball bearings, rotating bearings, bearings, etc., can solve problems such as difficult management, and achieve the effect of suppressing temperature rise, increasing speed, and reducing sealing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

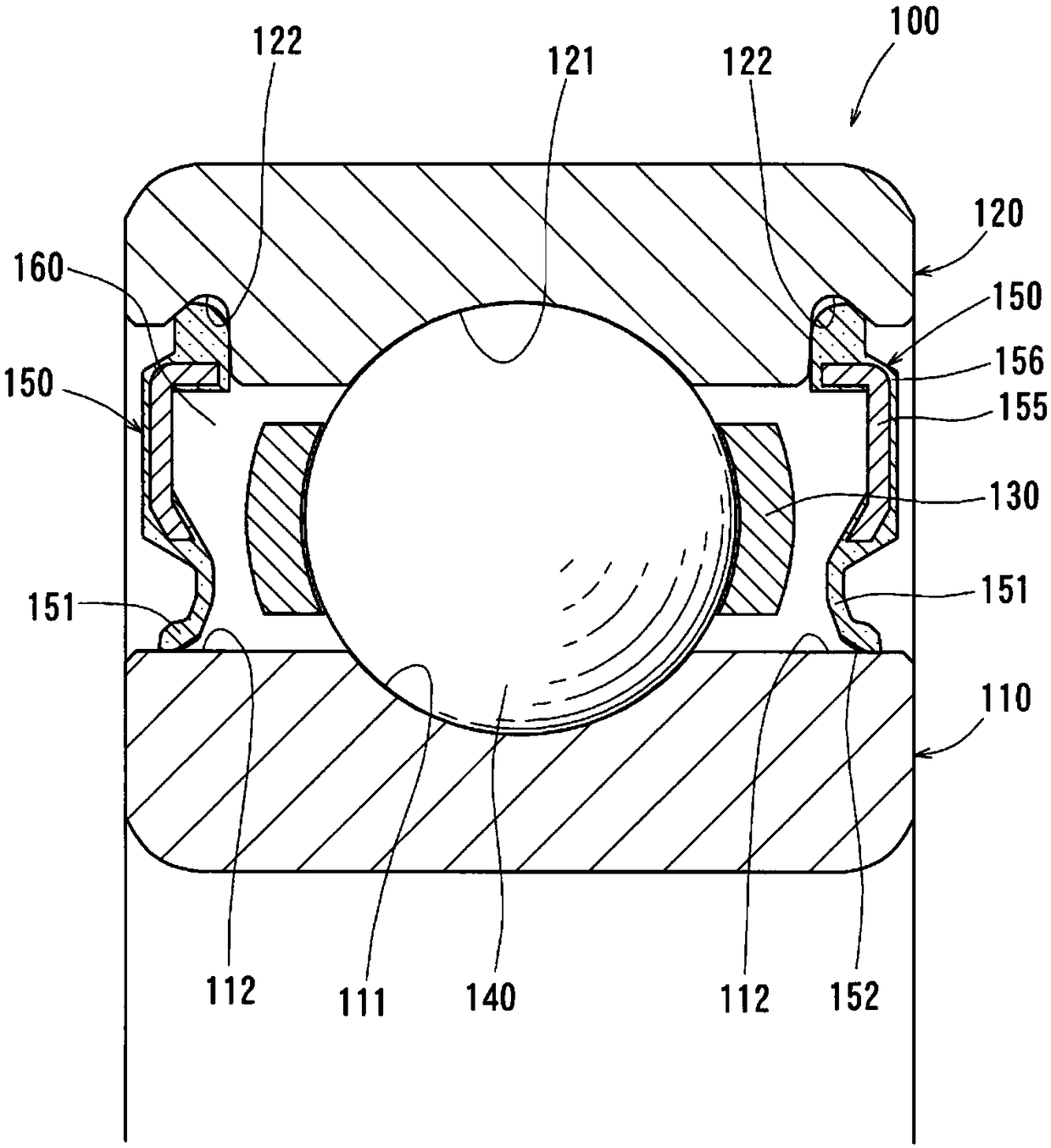

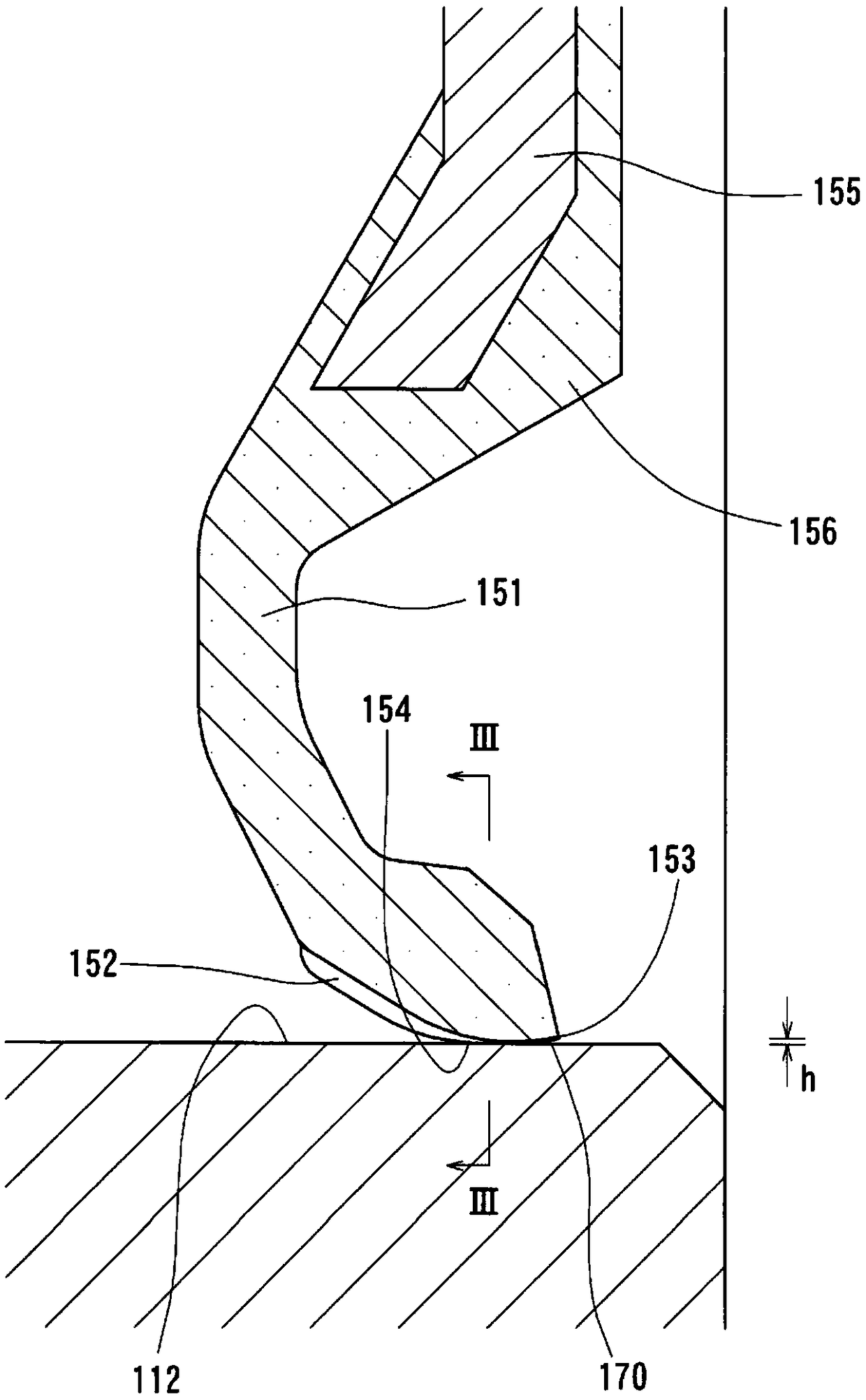

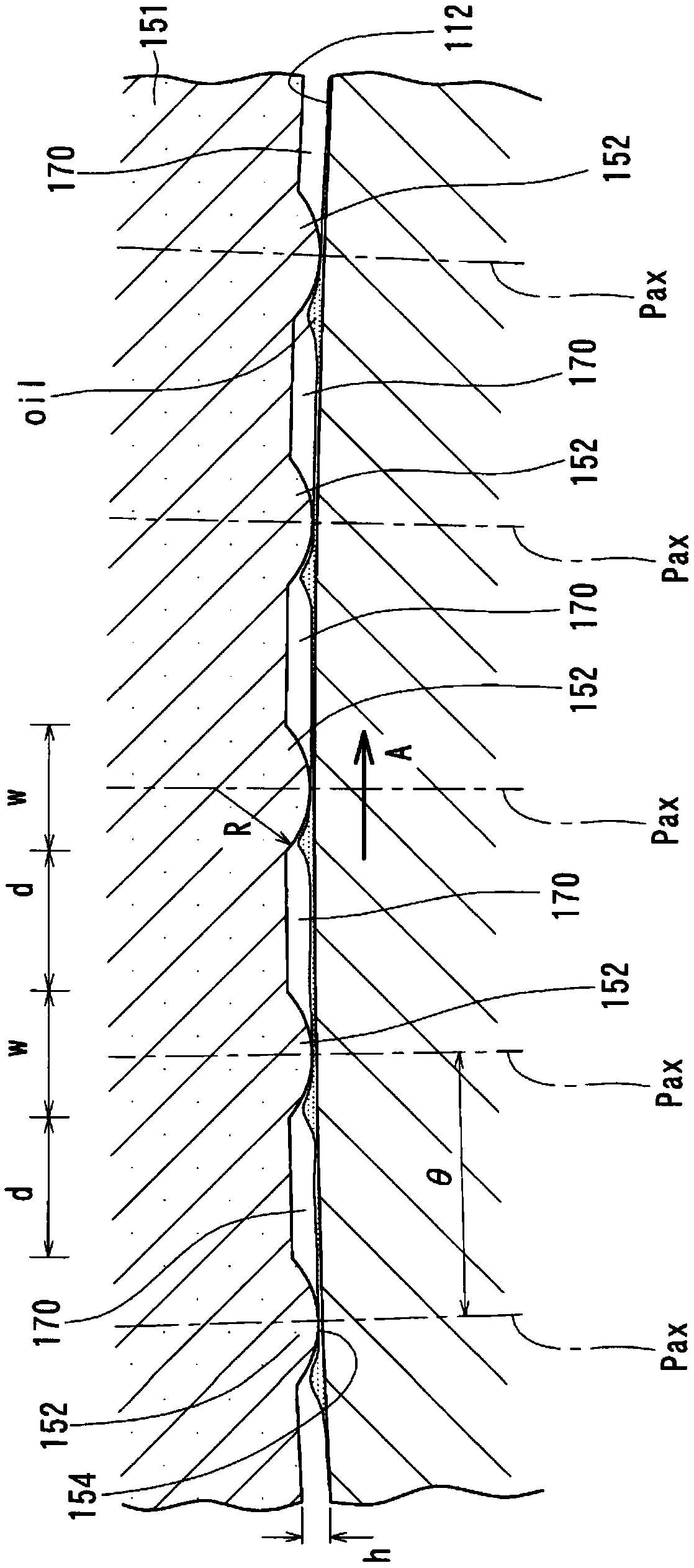

[0072] Below, based on Figure 1 to Figure 10 A first embodiment of the present invention will be described. The first embodiment corresponds to the first invention, and is an example in which the first embodiment and the second embodiment are combined.

[0073] Such as figure 1 As shown, the first embodiment becomes a sealed bearing 100, and the sealed bearing 100 includes an inner ring 110, an outer ring 120, a plurality of rolling elements 140 held by a cage 130, and the inner ring 110 and the outer ring. Two sealing members 150 between 120 seal the two ends of the inner space of the bearing. In addition, below, the direction along the bearing center axis|shaft of the sealed bearing 100 is called "axial direction." The direction perpendicular to the axial direction is called "radial direction". The circumferential direction around the central axis of the bearing is called "circumferential direction".

[0074] An annular bearing interior space 160 is formed by the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com