Split blade hydraulic-magnetic transmission well hole cleaning tool

A technology of cleaning tools and magnetic transmission, which is applied in the direction of flushing boreholes, boreholes/well components, earthwork drilling and mining, etc., can solve the problems of ineffective suppression of cuttings beds and poor cleaning effect of borehole cuttings, and achieve Improve drilling efficiency, inhibit the formation of cuttings beds, and improve the effect of peripheral velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further explained below:

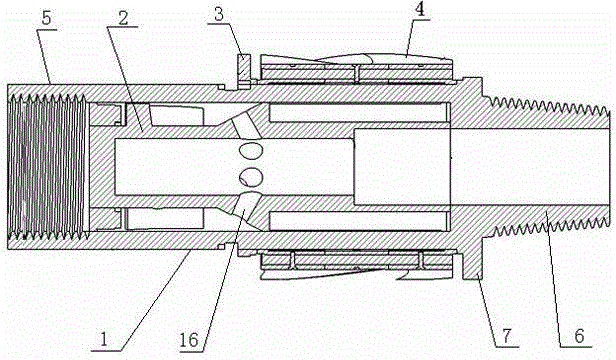

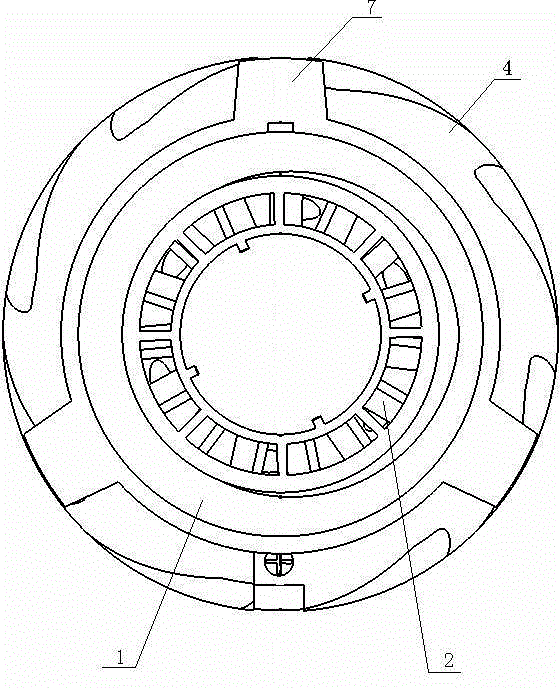

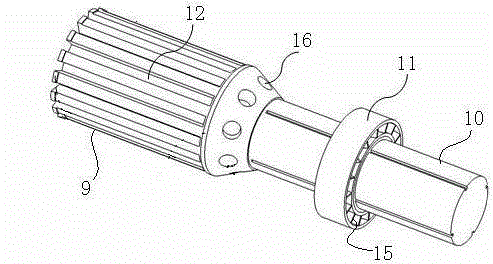

[0042] Combine figure 1 , figure 2 As shown, this split blade hydraulic-magnetic drive wellbore cleaning tool is composed of a flow cylinder housing 1, a rotating magnetic core 2, an upper gauge body 3, and a rotating blade 4. The rotating magnetic core 2 is installed in the flow cylinder housing In 1, the rotating cylinder 9 communicates with the outlet of the flow cylinder shell 1, the rotating blade 4 is sleeved outside the flow cylinder shell 1, the rotating blade 4 is located between the upper gauge body 3 and the lower gauge body 7, the rotating blade 4 and the rotating Tube 9 is correspondingly set.

[0043] Combine Image 6 , Figure 7 , Picture 8 As shown, the inlet end 5 of the flow cylinder housing has internal threads (female joint), and the outlet end 6 has external threads (male joint). The outer wall of the flow cylinder housing 1 is provided with a lower gauge body 7 near the external threads. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com