Method and device for melt-blowing, forming and plaiting finite fibres to produce a fibrous nonwoven

A non-woven fabric and fiber-forming technology, which is used in melt spinning, textile and papermaking, fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

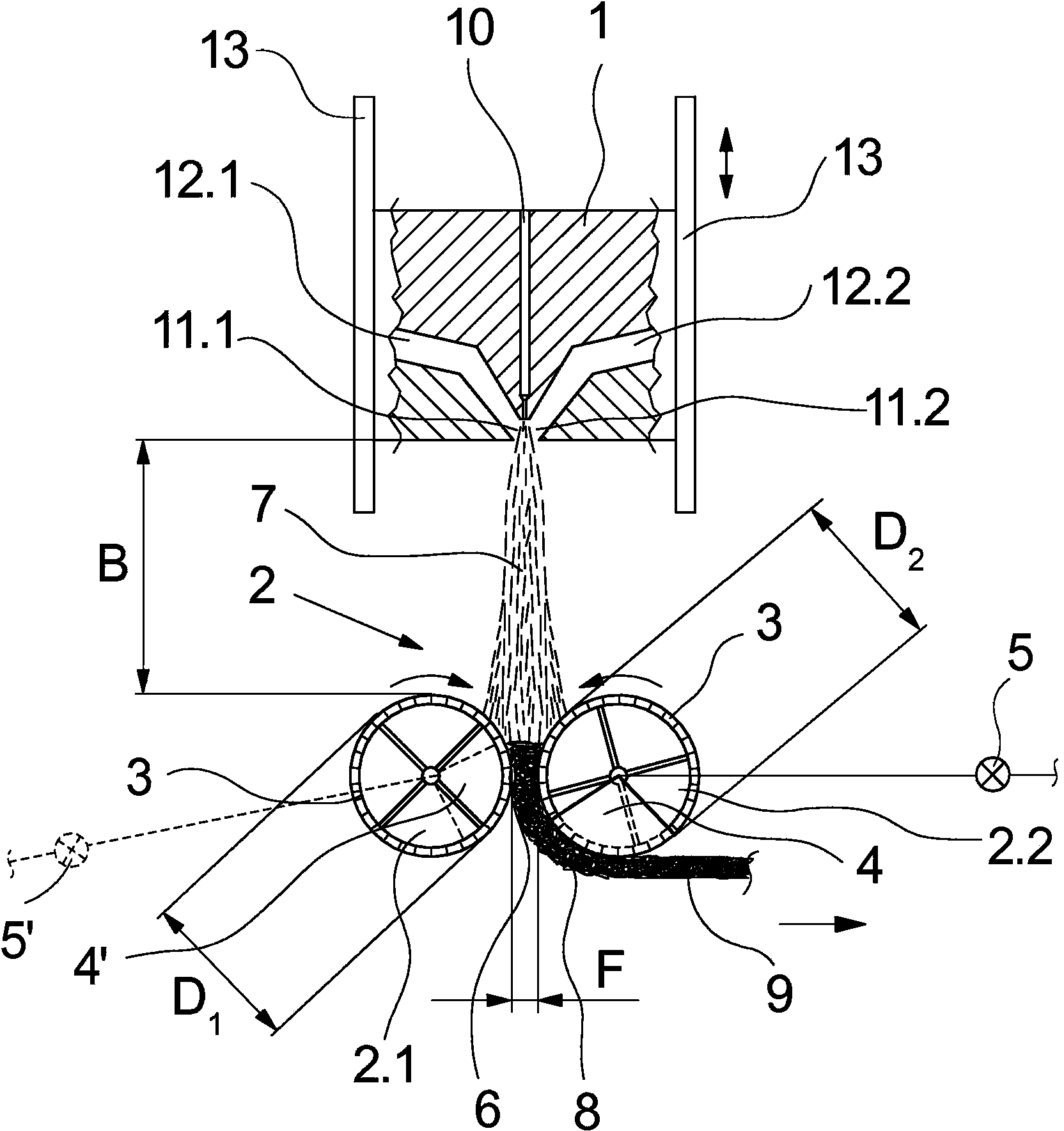

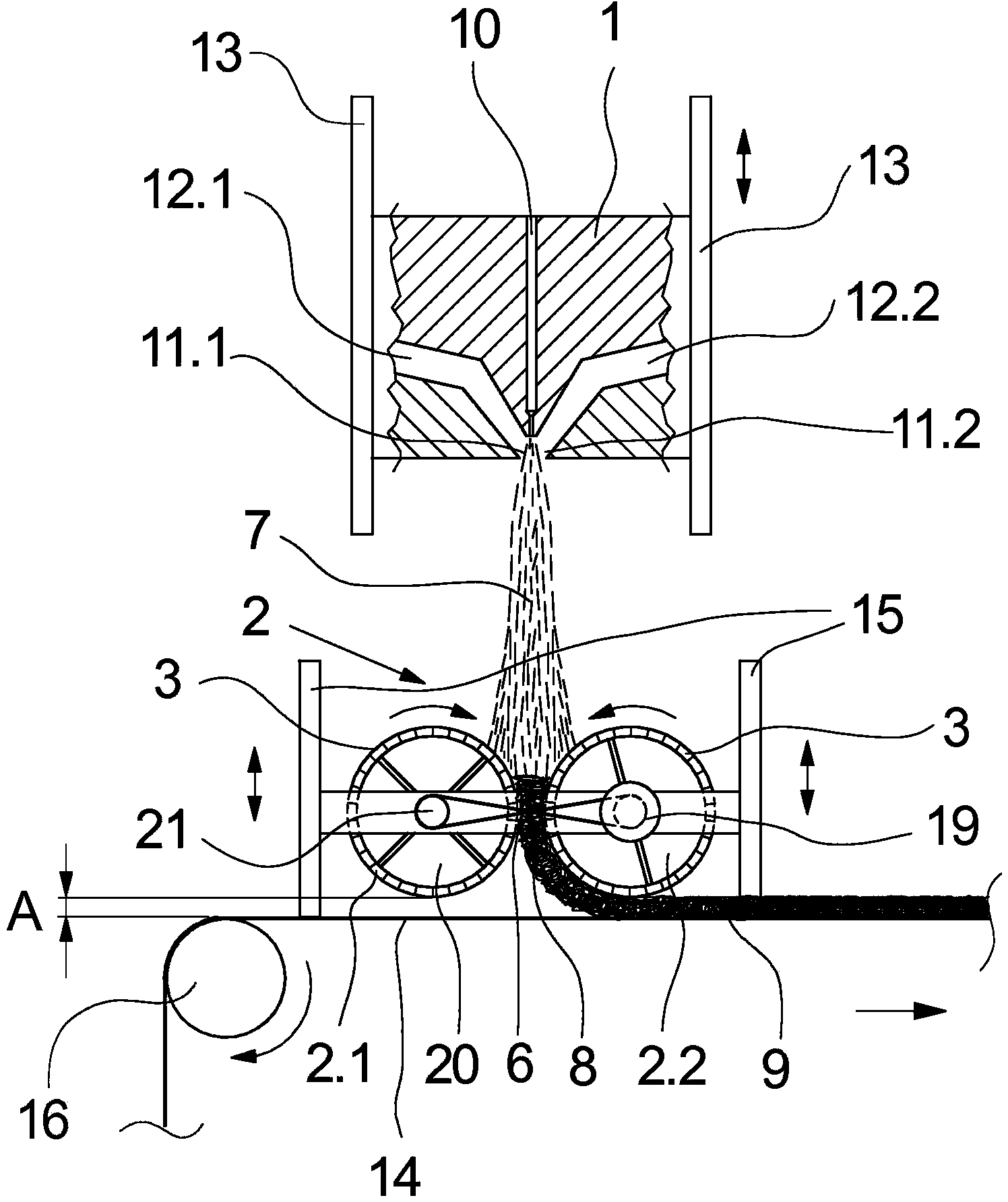

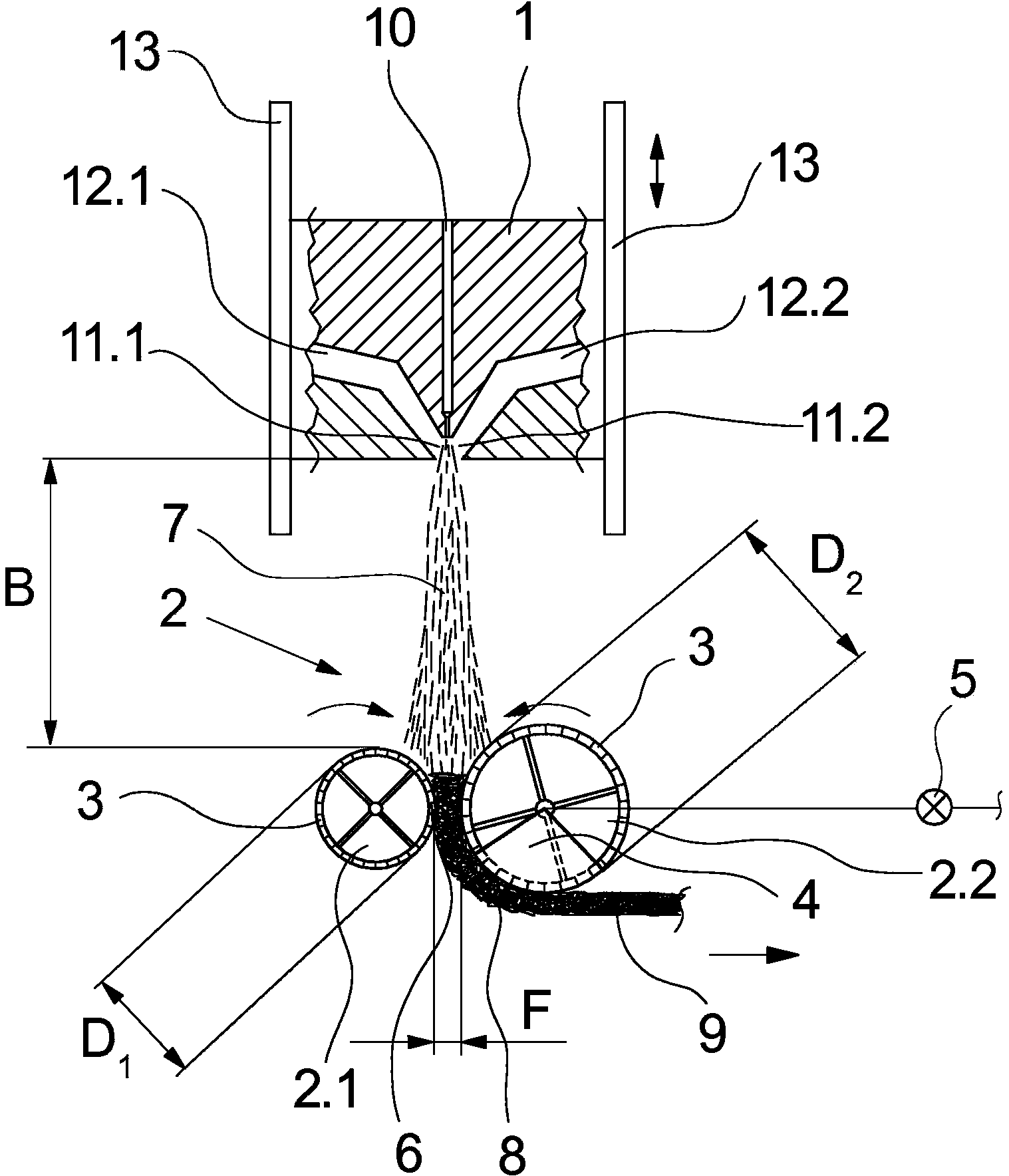

[0022] in figure 1 A cross-sectional view schematically shows the first embodiment of the device of the present invention. This embodiment has a melt blow nozzle 1 and a forming element 2 held under the melt blow nozzle 1. The forming element 2 is formed by two rollers 3 driven towards each other, between which a forming gap 6 is formed. The forming gap 6 extends in the vertical direction between the rollers 2.1 and 2.2, wherein the rollers 2.1 and 2.2 are symmetrical about the longitudinal axis of the melt blowing nozzle 1. The driving devices of the drums 2.1 and 2.2 are not shown in detail here and can be realized by a driving group or an independent driving device. The drums 2.1 and 2.2 each have an air-permeable drum wall 3 which rotates in the fiber blowing direction at a circumferential speed given by the driving device of the drums 2.1 and 2.2.

[0023] The melt blowing nozzle 1 is arranged on the frame 13 in a height adjustable manner above the drums 2.1 and 2.2. Here...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com