Micro-speaker and its vibration system manufacturing method

A technology of micro-speaker and vibration system, applied to sensors, electrical components, etc., can solve the problems of performance loss, large tolerance of voice coil skeleton, cumbersome voice coil winding, etc., to improve acoustic performance, reduce harmonic distortion, save energy The effect of human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

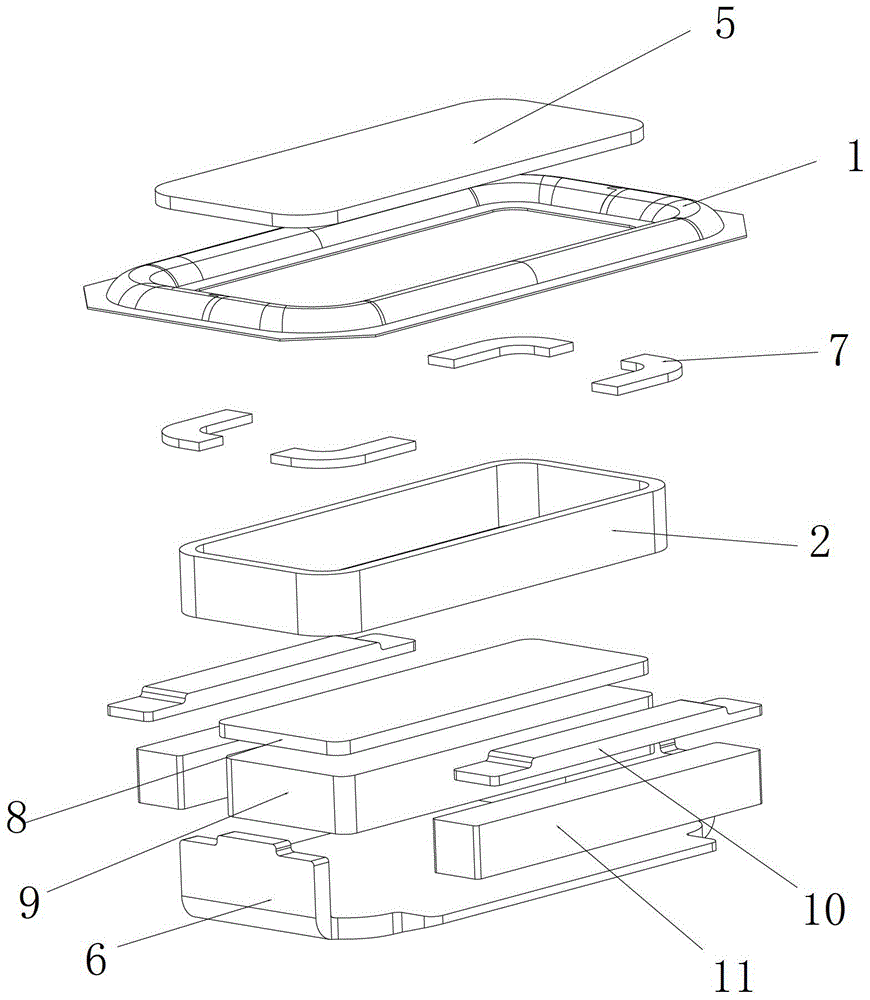

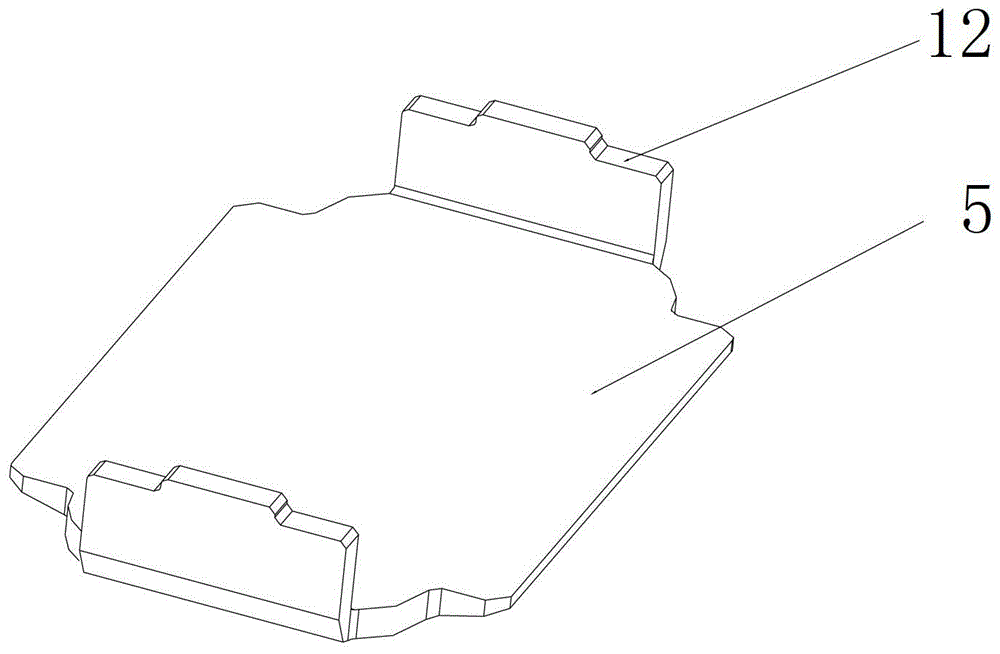

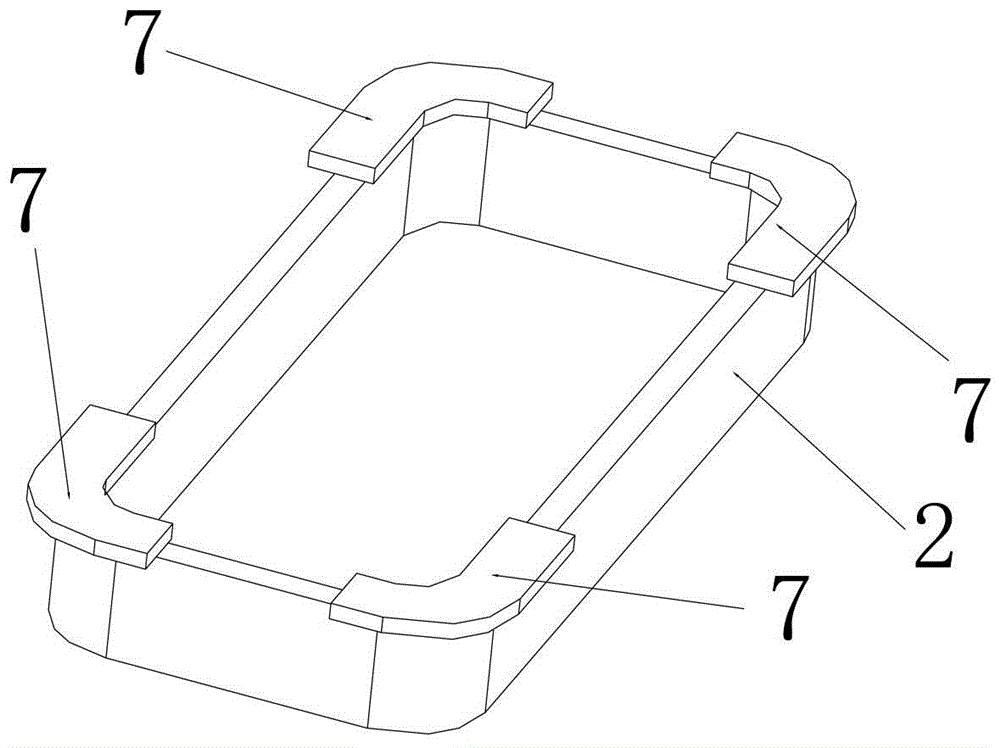

[0036] figure 1 It is an exploded schematic view of the structure of the micro-speaker of the present invention. Such as figure 1 As shown, the micro-speaker provided by the present invention includes a vibration system, a magnetic circuit system, and an auxiliary system for accommodating the fixed vibration system and the magnetic circuit system. Among them, the auxiliary system includes a composite layer 5 located at the center of the diaphragm 1 for improving the high-frequency curve of the diaphragm and a frame 6 for accommodating a fixed vibration system and a magnetic circuit system.

[0037] The vibration system includes a vibrating membrane 1 and a voice coil 2 combined on the lower side of the vibrating membrane 1; wherein the vibrating membrane 1 includes a spherical top 3 with a certain rigidity located at the center of the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com