Extrusion and press molding equipment for fin heat exchange pipes

A technology of extrusion molding and heat exchange tubes, applied in heat exchange equipment, forming tools, metal processing equipment, etc., to achieve good heat exchange, avoid dust deposition, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

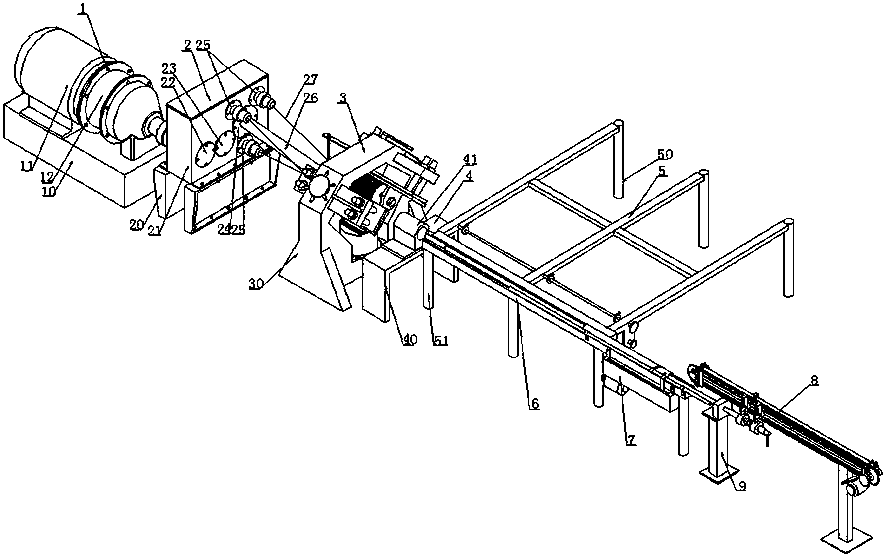

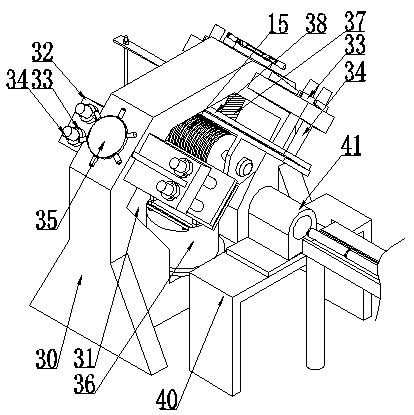

[0024] The present invention will be further described through the following embodiments. A finned heat exchange tube extrusion molding equipment is composed of multiple modules, including a power source module 1, and the power source module 1 and the drive module 2 are directly connected. , the right side of the driving module 2 is connected to the forming module 3, the forming module 3 is adjacent to the heating module 4, the right end of the heating module 4 is connected to the feeding module 6, and the rear side of the feeding module 6 is the material table 5, on the feeding module 6, A metal pipe push module 7 is bolted on its front side, and a support group 9 is on the right side of the feed module 6, and an inner core push module 8 is arranged on the top of the support group 9.

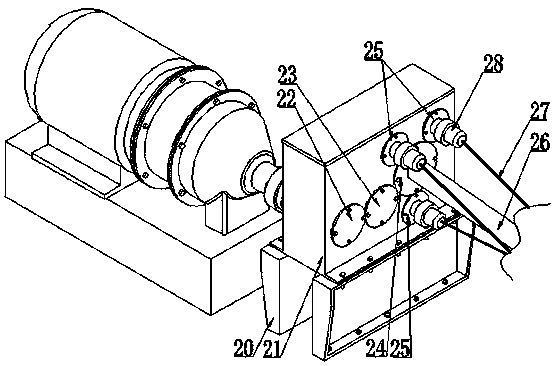

[0025] The power source module 1 includes a motor fixing table 10, the top of the motor fixing table 10 is a drive motor 11, the right side of the drive motor 11 is directly connected to the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com