Equipment and process for producing water hose

A technology of production equipment and production process, which is applied in the field of production equipment and production process of hose, which can solve the problems of difficult control of hose diameter, undurable seam parts, and use of another machine, etc., to achieve production process operation Easy, stable folding and forming effect, easy to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

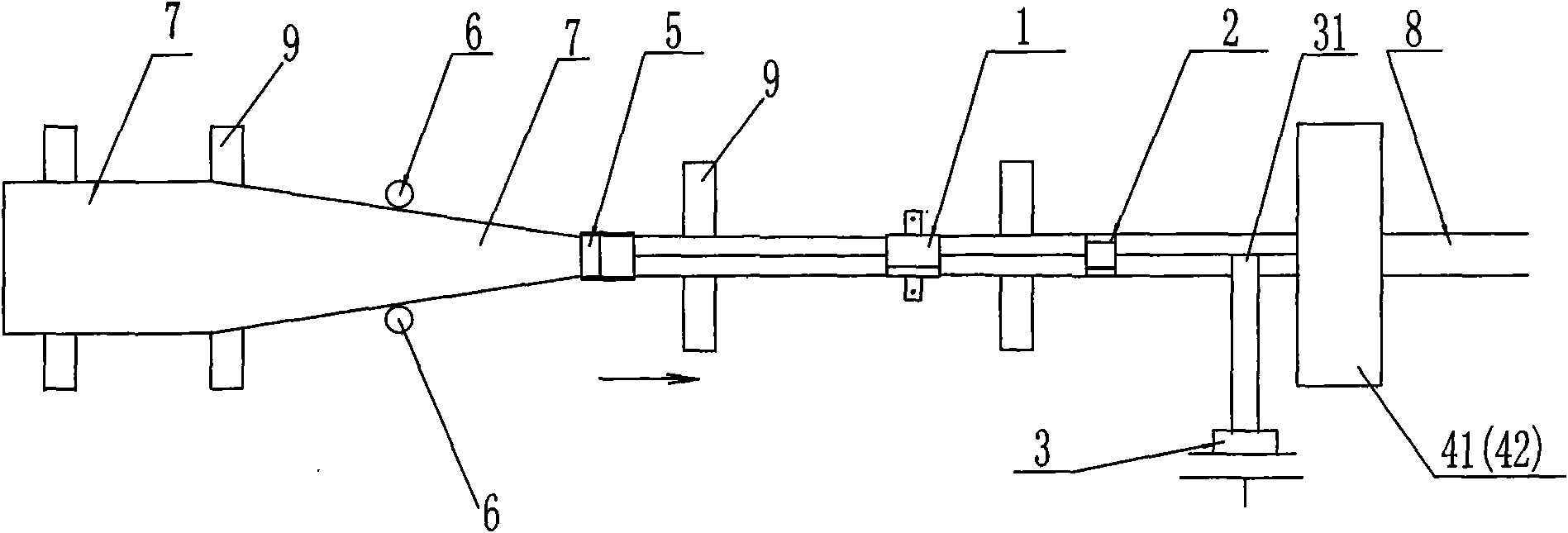

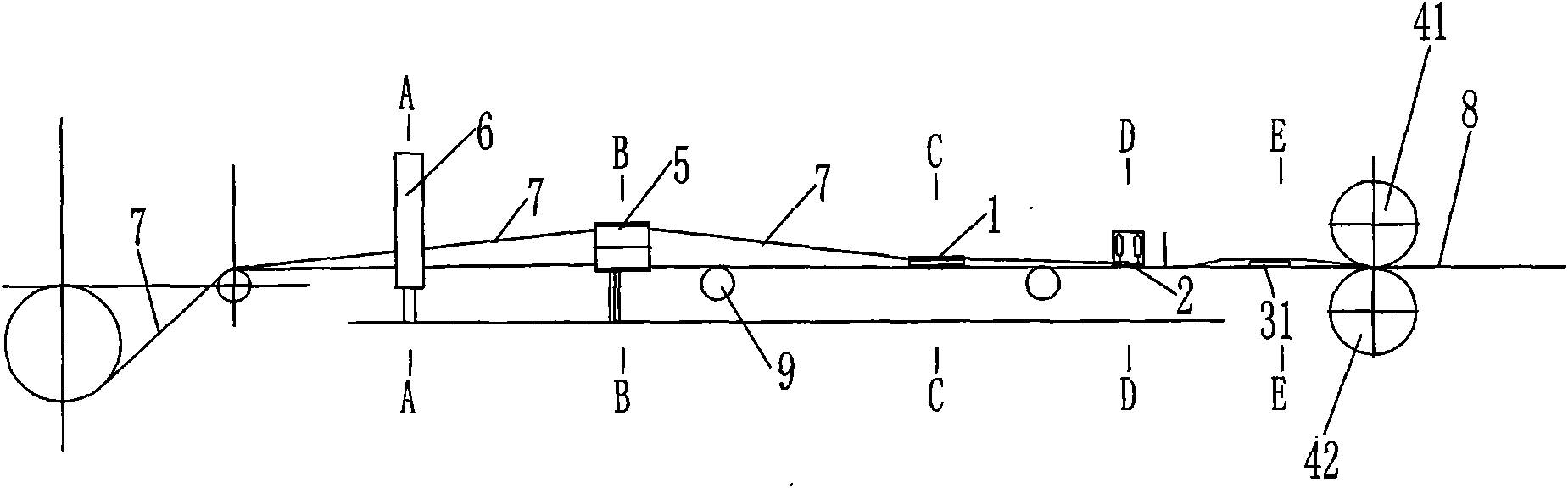

[0033] figure 1 , figure 2 The shown hose production equipment includes a guide roller 9, two left and right inclined rollers 6, an annular die 5, an outer forming die 1, an inner sizing die 2, an extruder 3, and upper and lower paired nip rollers; The paired nip rollers include the rubber pressure roller 41 at the top and the driving roller 42 at the bottom; the diameter of the ring die 5 is close to the diameter of the hose to be produced, and the inclination angles of the left and right oblique rollers 6 and The horizontal distance is adjustable; the extruder 3 is provided with an extruder head 31 . Inclined roller 6, circular ring die 5, outer forming die 1, inner sizing die 2, extruder head 31, and nip rolls are arranged in sequence from back to front; Figure 10 , Figure 8As shown, the cross-sectional shape of the outer molding die 1 includes two horizontal U-shaped jackets 15, 16 up and down, and the upper wing 11 of the upper U-shaped jacket 15 and the lower wing ...

Embodiment 2

[0038] figure 1 , figure 2 The shown hose production process adopts the hose production equipment of Embodiment 1, including the following steps:

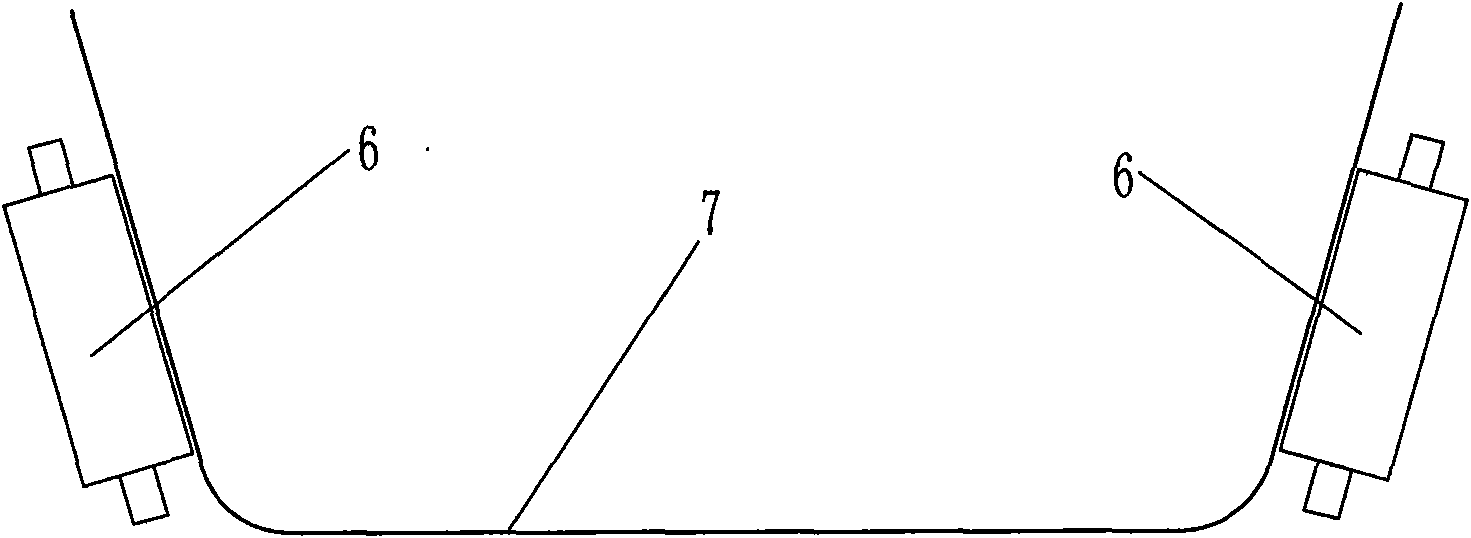

[0039] (1), pull the planar and strip-shaped wall material 7 forward, and gradually make the left and right side edges of the strip-shaped wall material close together during the advancing process; wherein the wall material is first pulled to pass between the left and right two oblique rollers 6, Make the wall material 7 preliminarily bend, such as image 3 Shown; Draw the wall material again and pass through the annular die 5, make the wall material 7 bend and become nearly circular, as Figure 4 shown;

[0040] (2), pull the curved wall material 7 to move forward and pass through the outer forming die 1, so that when the wall material passes through the outer forming die, the cross section of the wall material 7 is along the fold line A 1 A 2 A 3 A 4 A 5 A 6 The indicated path collapses, as in Figure 5 shown; Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com