Light emitting container for high-pressure discharge lamp and manufacturing method thereof

A technology of high pressure discharge lamps and manufacturing methods, which is applied in the manufacture of discharge tubes/lamps, components of gas discharge lamps, and electrode systems, and can solve problems such as uneven wall thickness of light-emitting containers, achieve high transmittance, improve Excellent mechanical strength and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

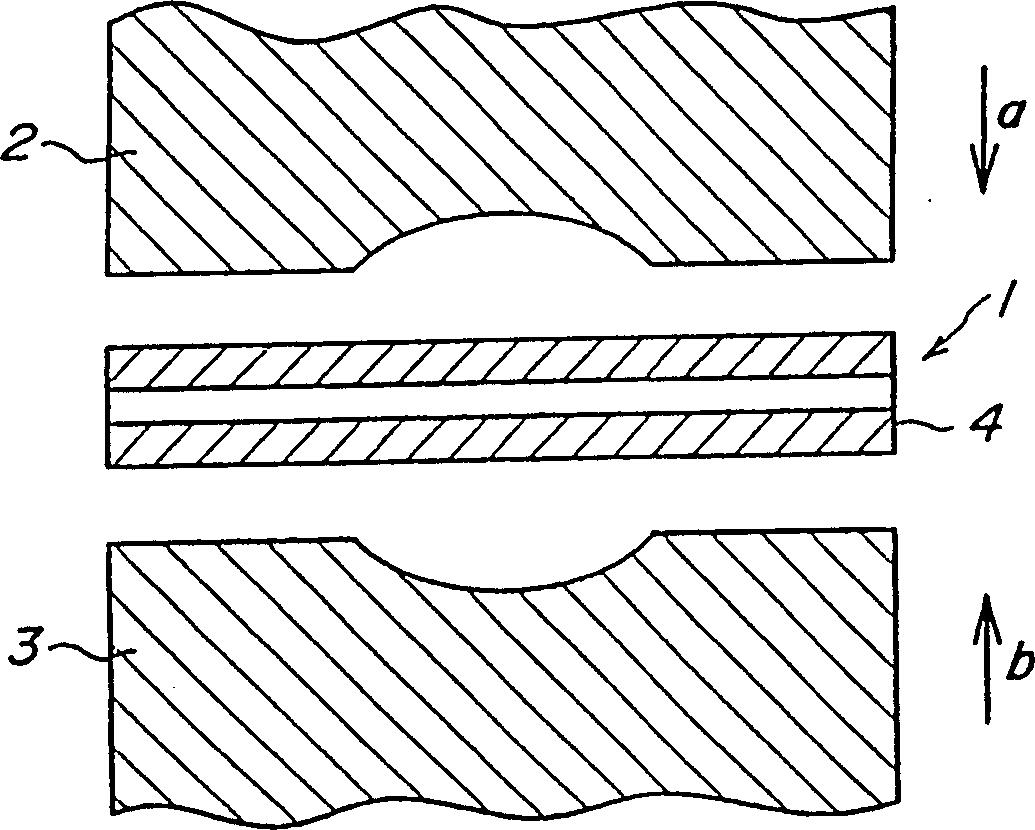

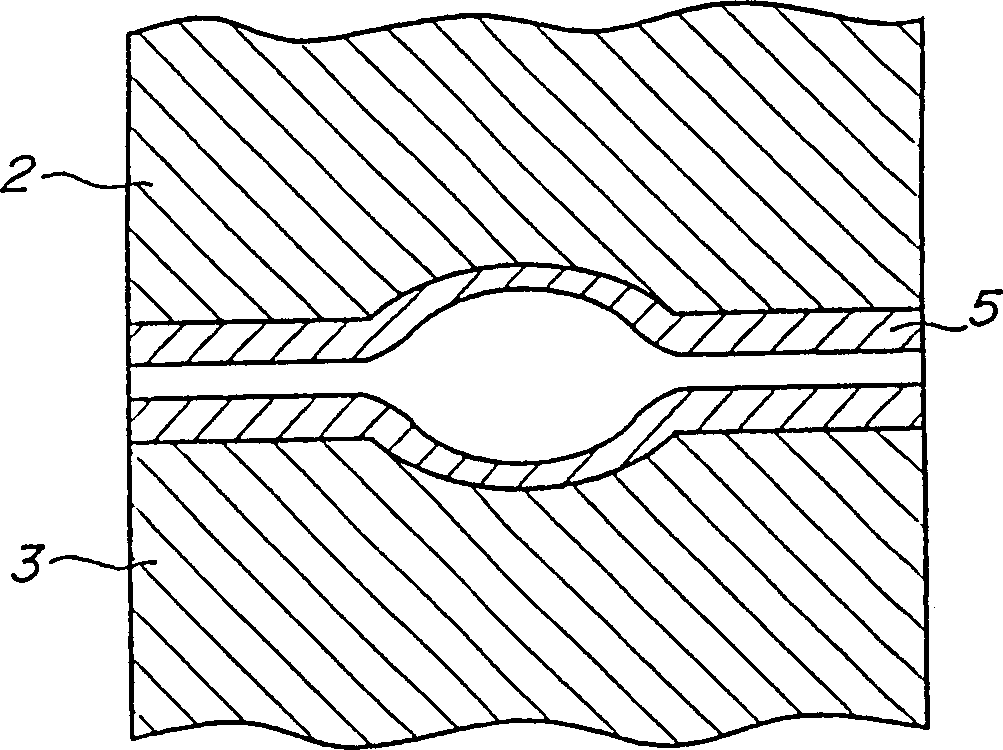

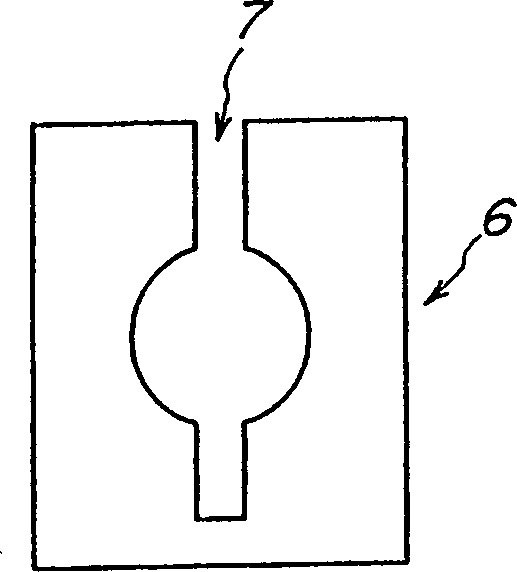

[0036] The light-emitting container and its manufacturing method of the present invention will be described in detail with reference to the drawings.

[0037] image 3 It is a cross-sectional view of an embodiment of the light-emitting container of the present invention. The luminescent vessel includes a substantially spherical body 1 forming a discharge space and end portions 2a, 2b into which electrode members are inserted, which are integrally formed of alumina as a light-transmitting ceramic material.

[0038] In this embodiment, the outer diameter A, inner diameter a and axial length B of the torso 1 are respectively set at 2-30 mm, 1-15 mm and 2-50 mm.

[0039] The end portions 2a, 2b each have an axial length L of 10-20 mm and an inner diameter d of 0.5-2.5 mm. Therefore, the ratio of the length L to the inner diameter d is 4-40. The reason why the ratio of the length L to the inner diameter d is set to such a value is that this value is suitable.

[0040] The wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com