Induction coil winding device and use method thereof

A technology of induction coil and winding device, applied in coil device, coil manufacturing, induction heating and other directions, can solve the problems of long time consumption, uneven distribution of turn pitch, affecting subsequent use of the coil, etc., achieving simple structure, preventing deformation, Ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

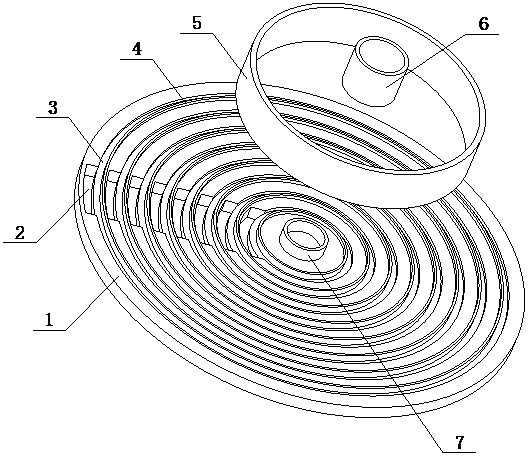

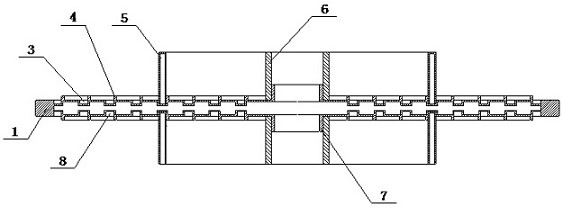

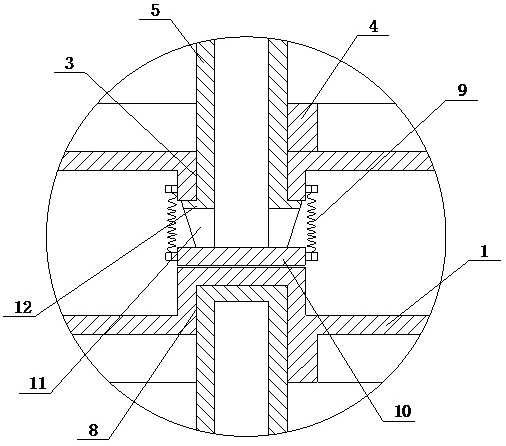

[0041] An induction coil winding device of the present invention is realized in the following way: it includes a supporting assembly, a cooling winding sleeve (5) arranged on the supporting assembly and a delivery pipe (6) arranged on the supporting assembly, the cooling winding sleeve (5) The side wall is a hollow structure,

[0042] It is characterized in that the cooling winding sleeve (5) has a variety of different specifications, and can be assembled according to different winding requirements with the support component, and the delivery pipe (6) can transport the cooling medium to the cooling winding with the support component. The induction coil is cooled and shaped in the wire sleeve (5),

[0043] The support assembly consists of a support tray (1), a threading slot (2), an upper clamping slot (3), an upper fixing plate (4), a connecting pipe (7), a lower clamping slot (8), and a strong tension spring (9) and arc-shaped sealing plate (10),

[0044] The support tray (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com