Efficient quick winding machine in construction site

A construction site, high-efficiency technology, applied in the field of high-efficiency fast winding machines, can solve problems such as inability to work effectively, coils are easy to fall off, etc., and achieve the effect of simple structure, guaranteed number of turns, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

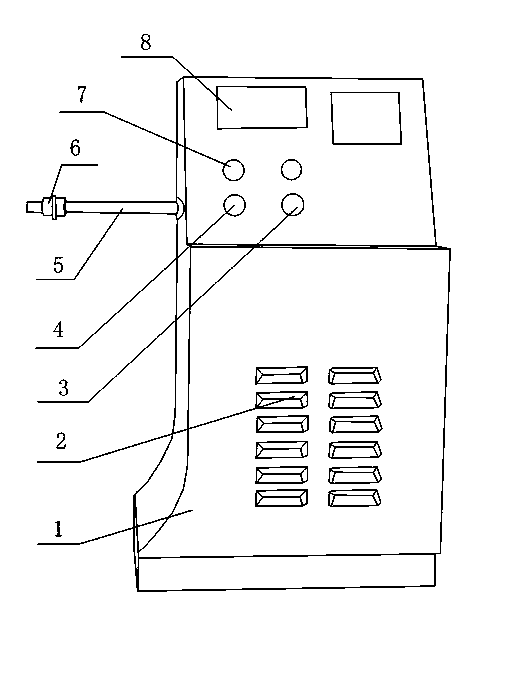

[0017] Such as figure 1 As shown, the high-efficiency fast winding machine on the construction site includes a casing 1, a motor and a control device are arranged in the casing 1, a rotating shaft 5 is arranged on the motor, and an electromagnetic device 6 is installed on the rotating shaft 5, so The motor is connected with the control device. The rotation of the motor is controlled by the control device, and at the same time, the electromagnetic device generates magnetic force on the coil, so that the coil fits tightly.

[0018] The shell 1 is provided with a start button 3 and a stop button 4, and the start button 3 and the stop button 4 are both connected to the control device. The opening and closing of the winding machine is controlled by the start button 3 and the stop button 4 .

[0019] An indicator light 7 is arranged on the shell 1, and the indicator light 7 is connected with the control device. The operation condition of the equipment can be effectively monitored...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com