Patents

Literature

53results about How to "Eliminate inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

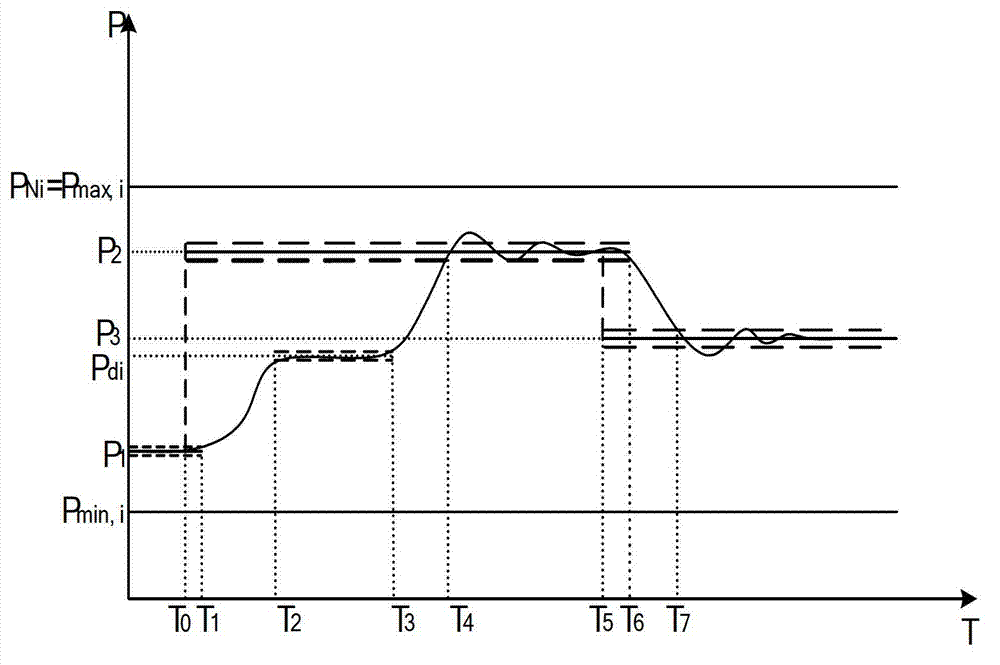

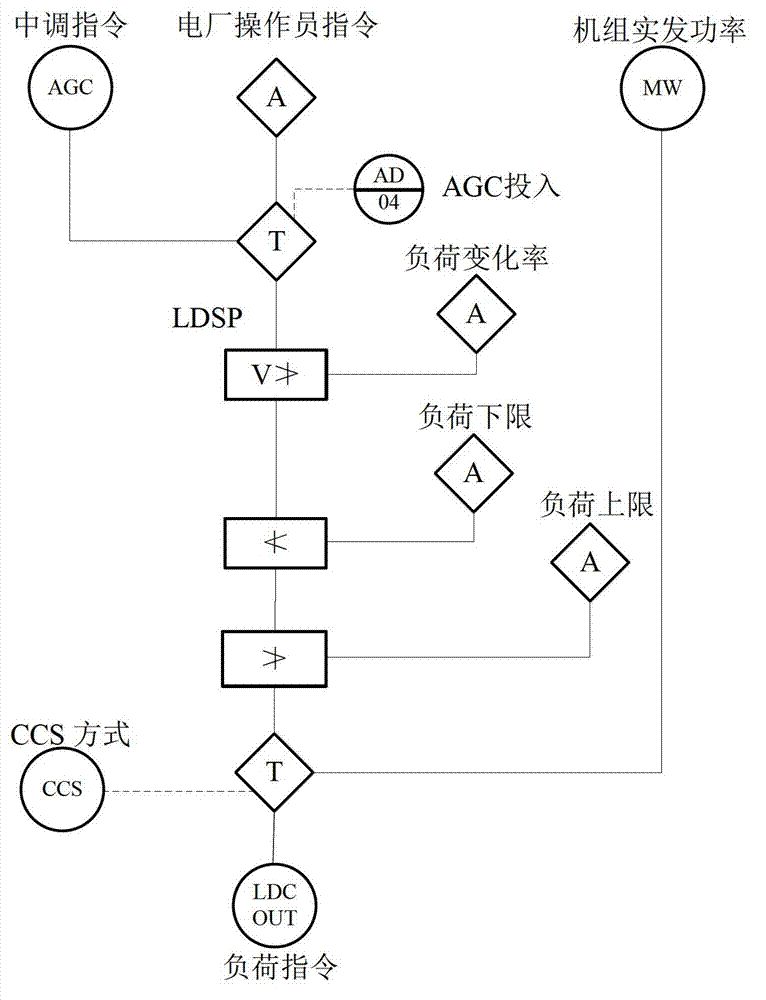

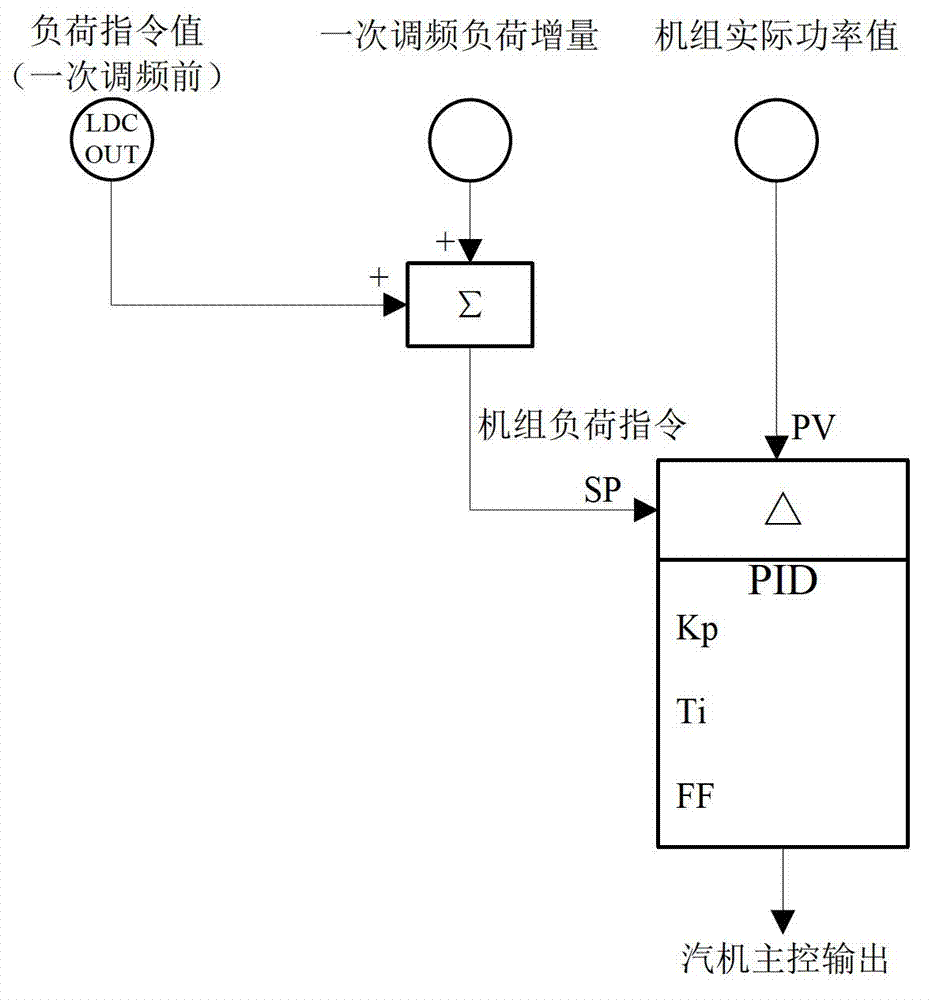

Parameter-varying load optimization control method of thermal power generating unit

ActiveCN103174471ALogical structure optimizationEliminate dead zone and inertiaMachines/enginesEngine startersControl measureParameter control

The invention discloses a parameter-varying load optimization control method of a thermal power generating unit. The method comprises the following specific steps: step 1, generating a judging numerical value through a differentiation element according to a change of a load instruction value; step 2, generating judging conditions of a parameter varying changing-over logic by a high-low amplitude judging module according to the judging numerical value generated by the differentiation element; and step 3, switching a switcher by using a steam engine main controller according to an output command of the high-low amplitude judging module. According to method provided by the invention, a logical structure of the steam engine main controller is optimized and a parameter varying control measure is adopted according to the change condition of load, thereby effectively eliminating the dead zone and inertance of a turbine door regulating executing mechanism, improving the control accuracy and dynamic quality of a system, ensuring a regulating speed, a regulating accuracy and a responsive time of a thermal power generating unit load, and improving the control quality and assessment index of a AGG (automatic gain control) of the thermal power generating unit.

Owner:STATE GRID CORP OF CHINA +1

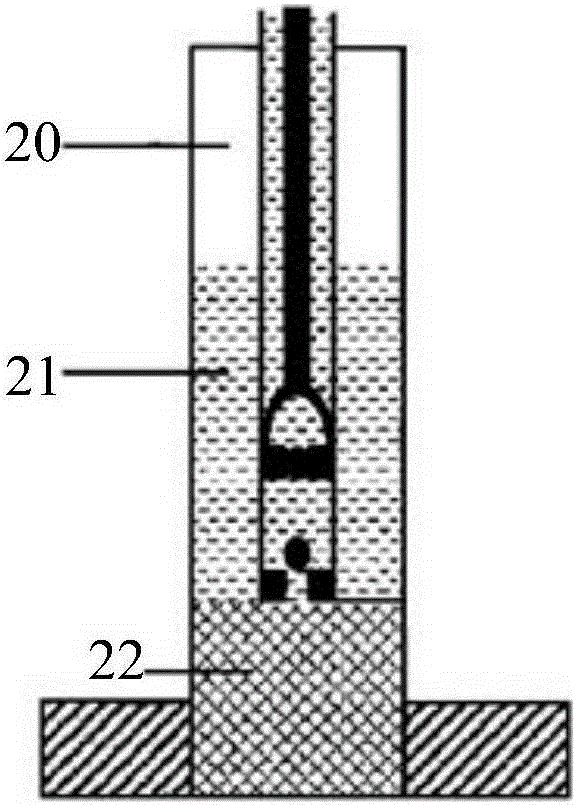

Method for measuring working fluid level of rod-pumped well

The invention discloses a method for measuring the working fluid level of a rod-pumped well. The method comprises the following steps: according to a drag coefficient calculation model, obtaining a drag coefficient; according to the drag coefficient, a sucker-rod string displacement motion model and a sucker-rod string load calculation model, obtaining displacement parameters at different depths and load parameters of a sucker-rod string, and then obtaining displacement parameters and load parameters of a pump; according to the displacement parameters and the load parameters of the pump, obtaining a pump diagram of the pump; according to the pump diagram and a submergence pressure calculation model as well as a fluid property calculation model, obtaining working fluid level parameters of the rod-pumped well. Through adoption of the method, the measurement timeliness can be effectively improved under the circumstance that the calculation precision is ensured; besides, the method is further applicable to an oil well where casing pressure needs to be controlled for production, so that an error in calculation of the working fluid level can be reduced.

Owner:PETROCHINA CO LTD

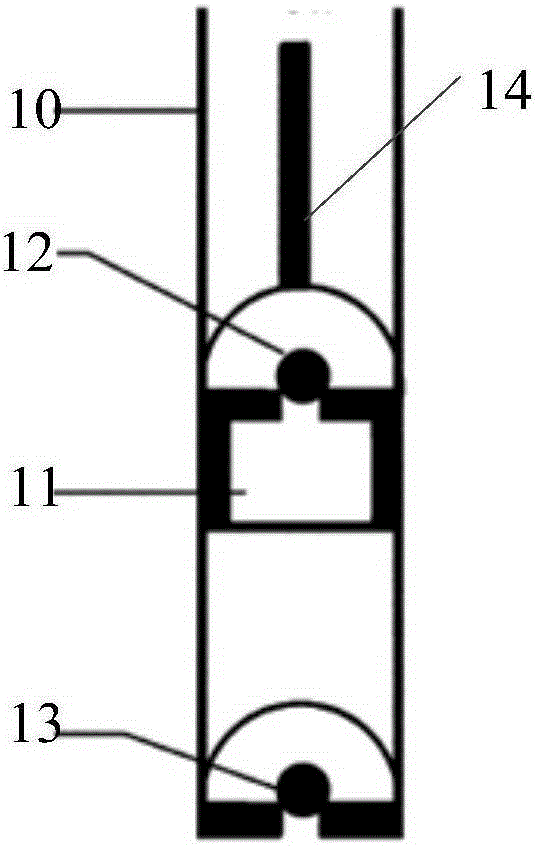

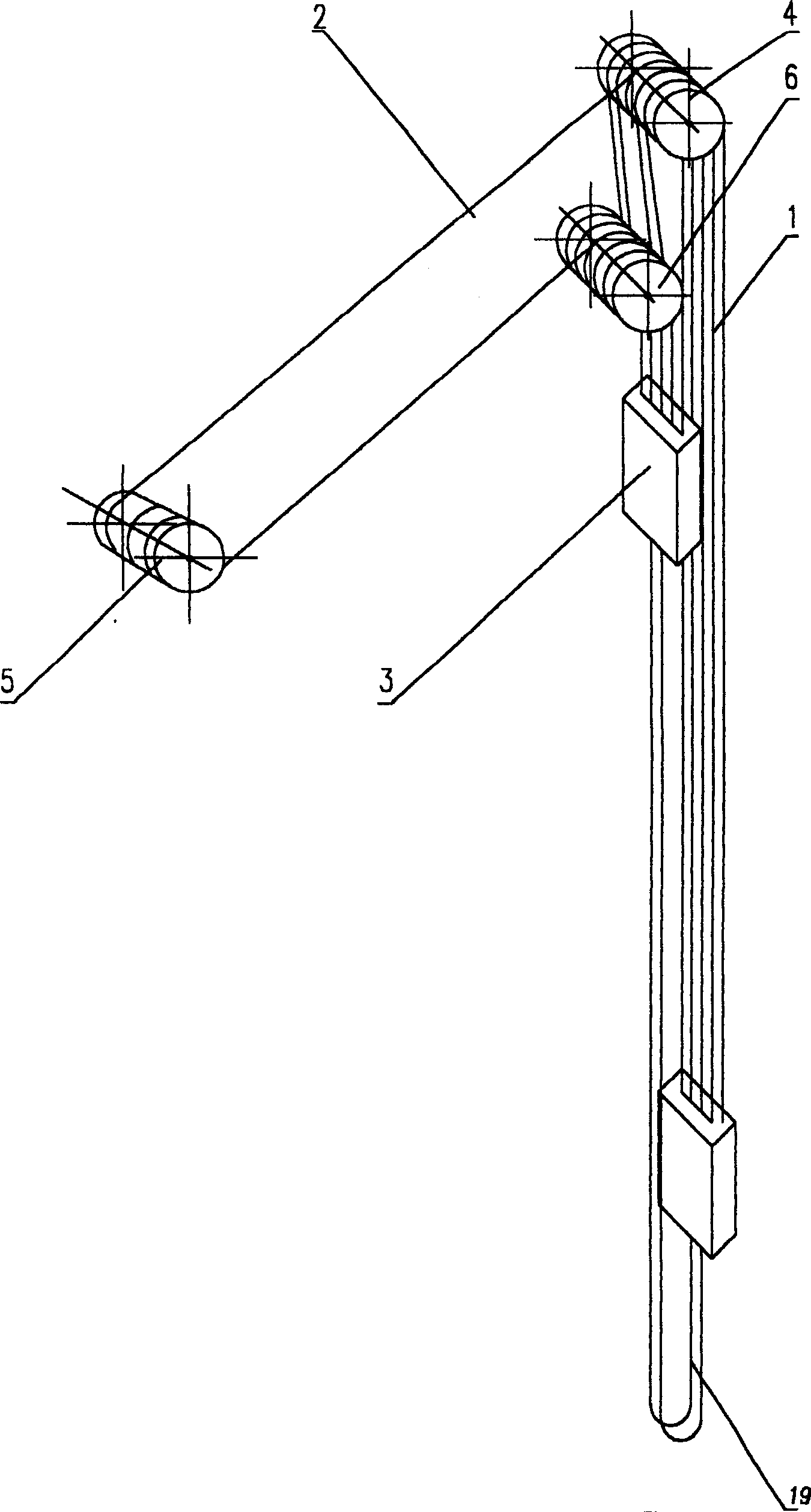

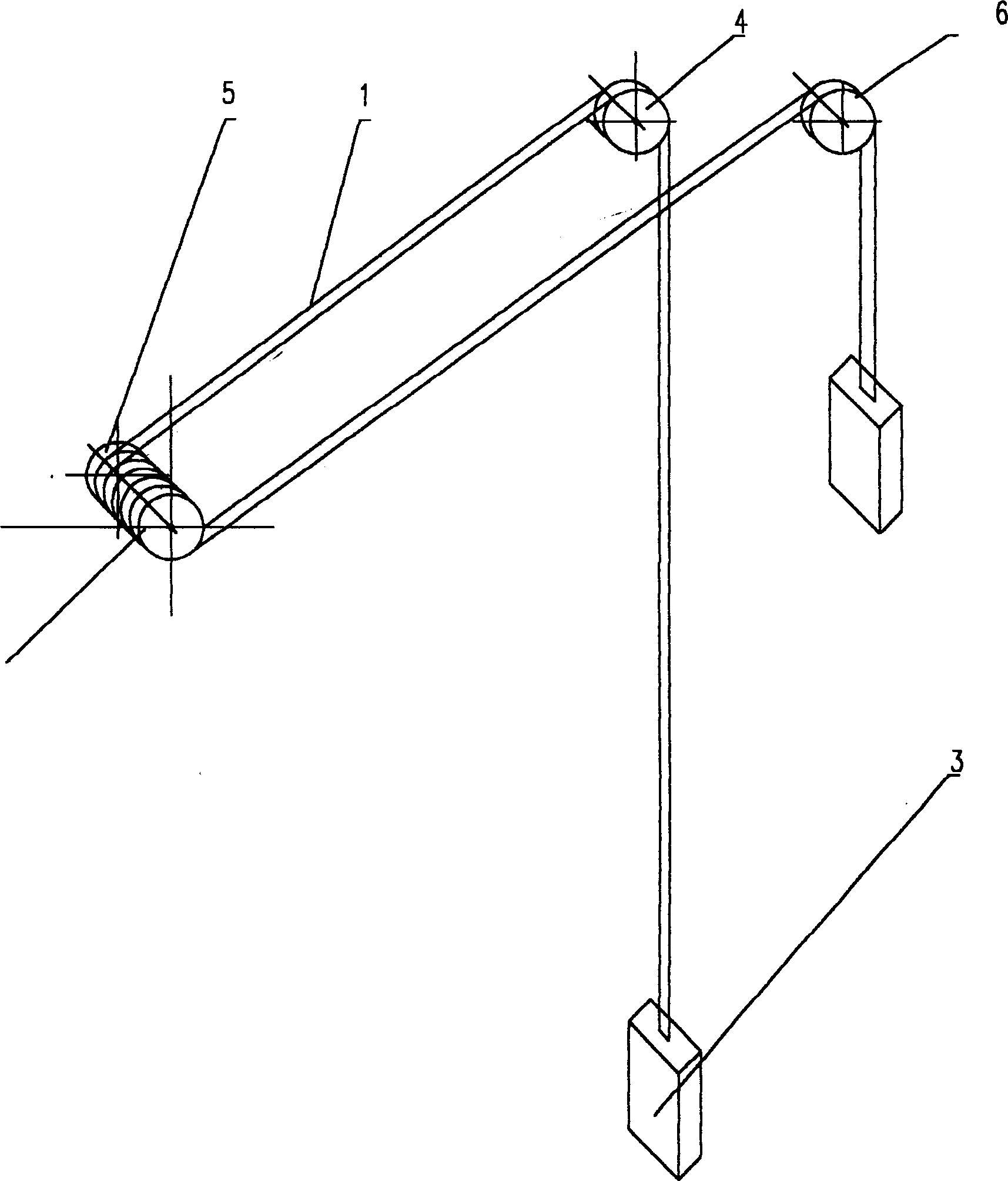

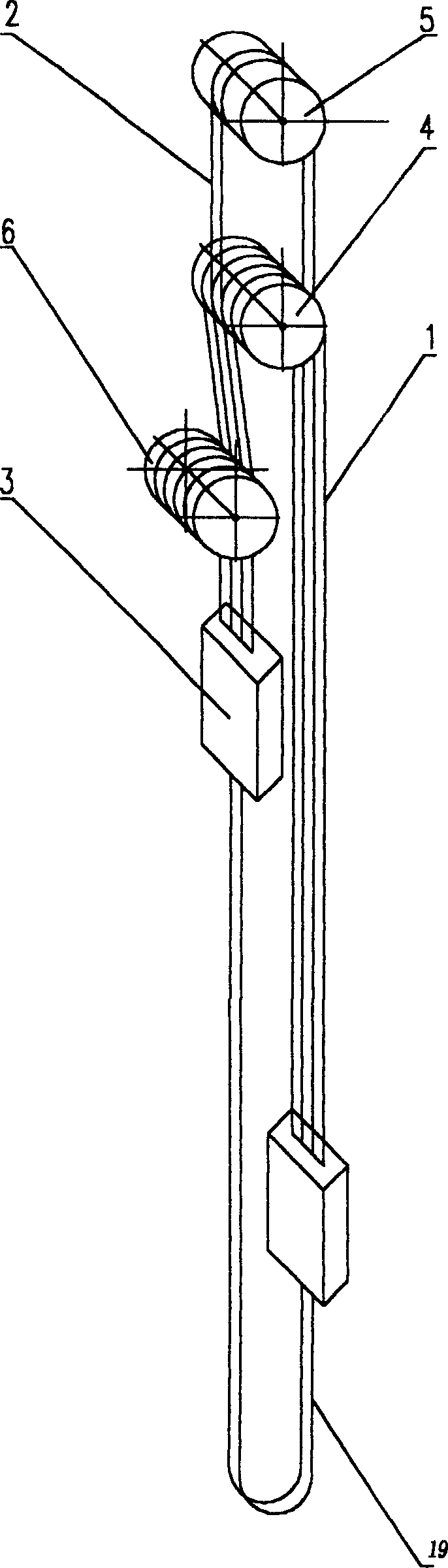

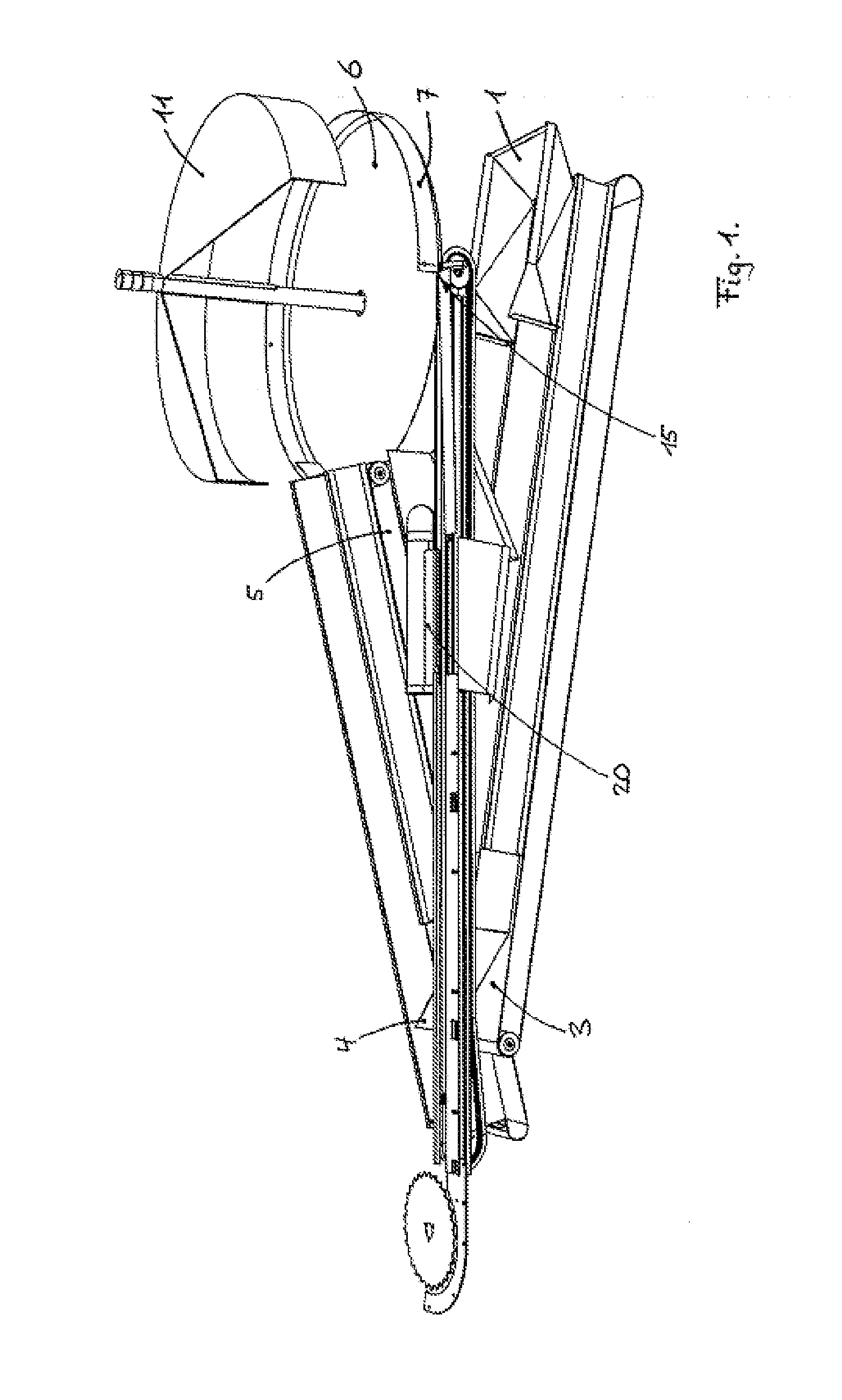

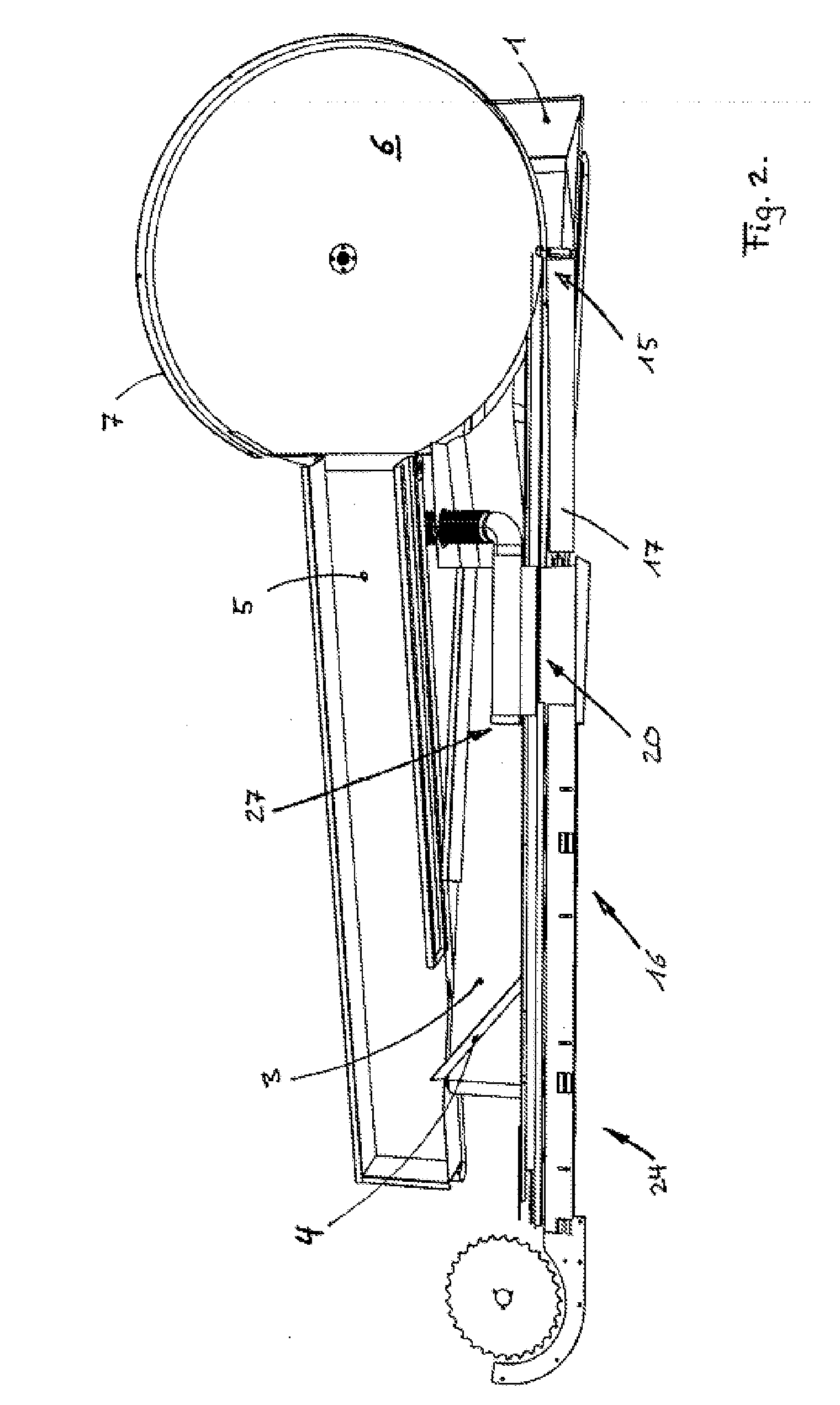

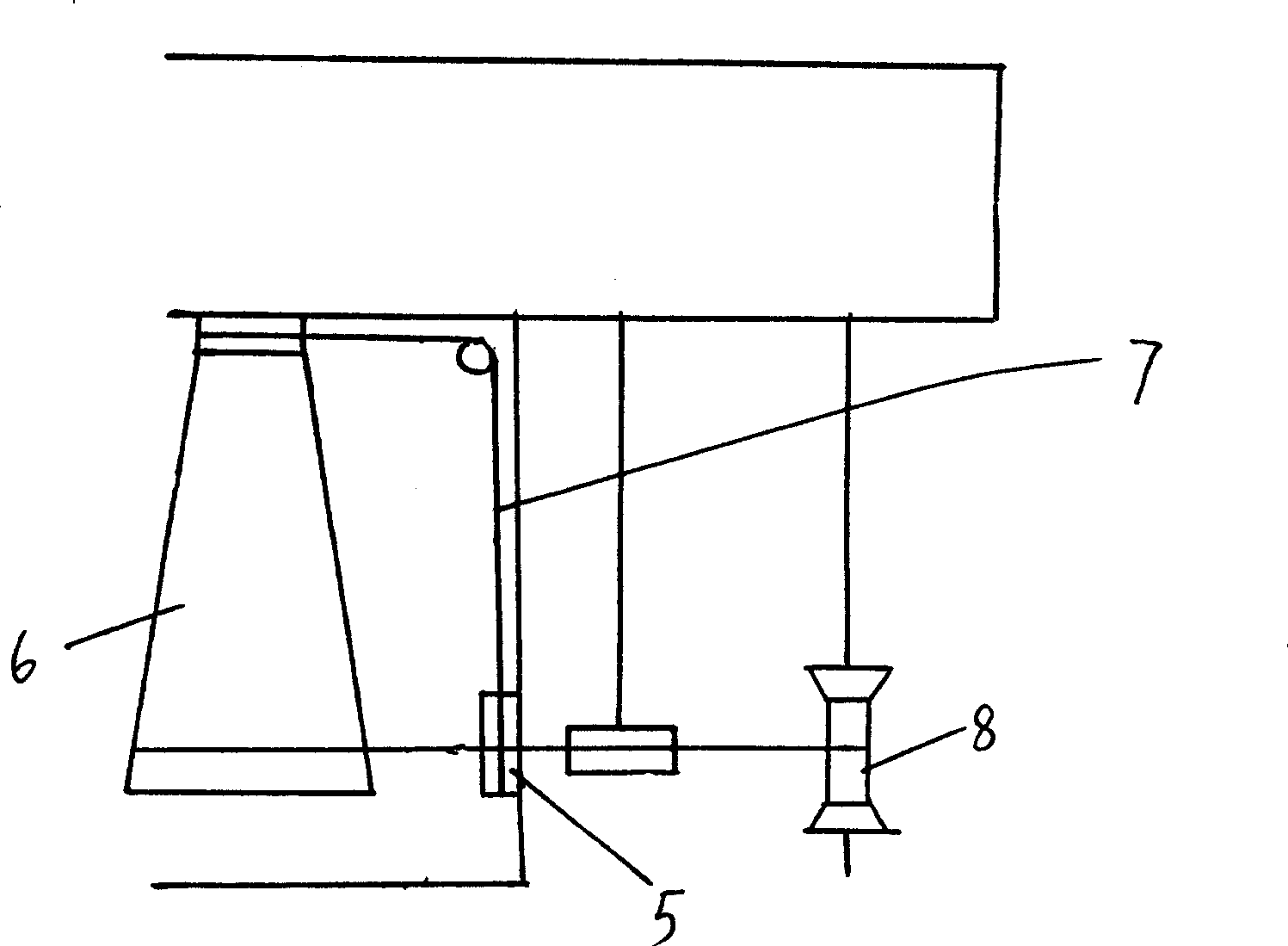

Lifter suspended by multiple cables and balanced by tail cable

A multi-cable suspended lift with tail cable for balancing is composed of drive drum, overhead pulley set for bearing all load of suspending steel cable and lift container, driving steel cable, lift contain and tail cable. The active load of driving steel cable and lift container is borne by drive drum.

Owner:杨光良

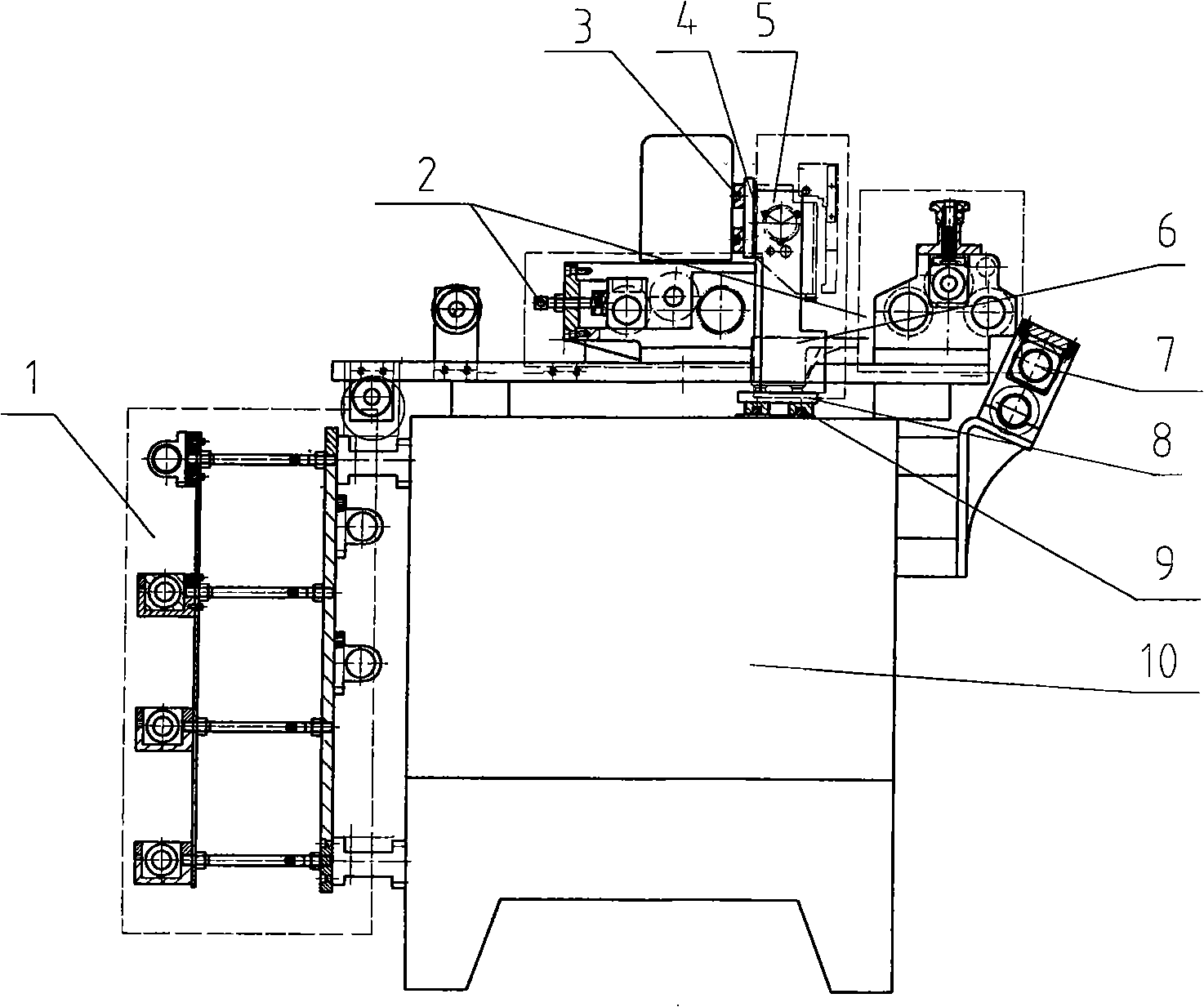

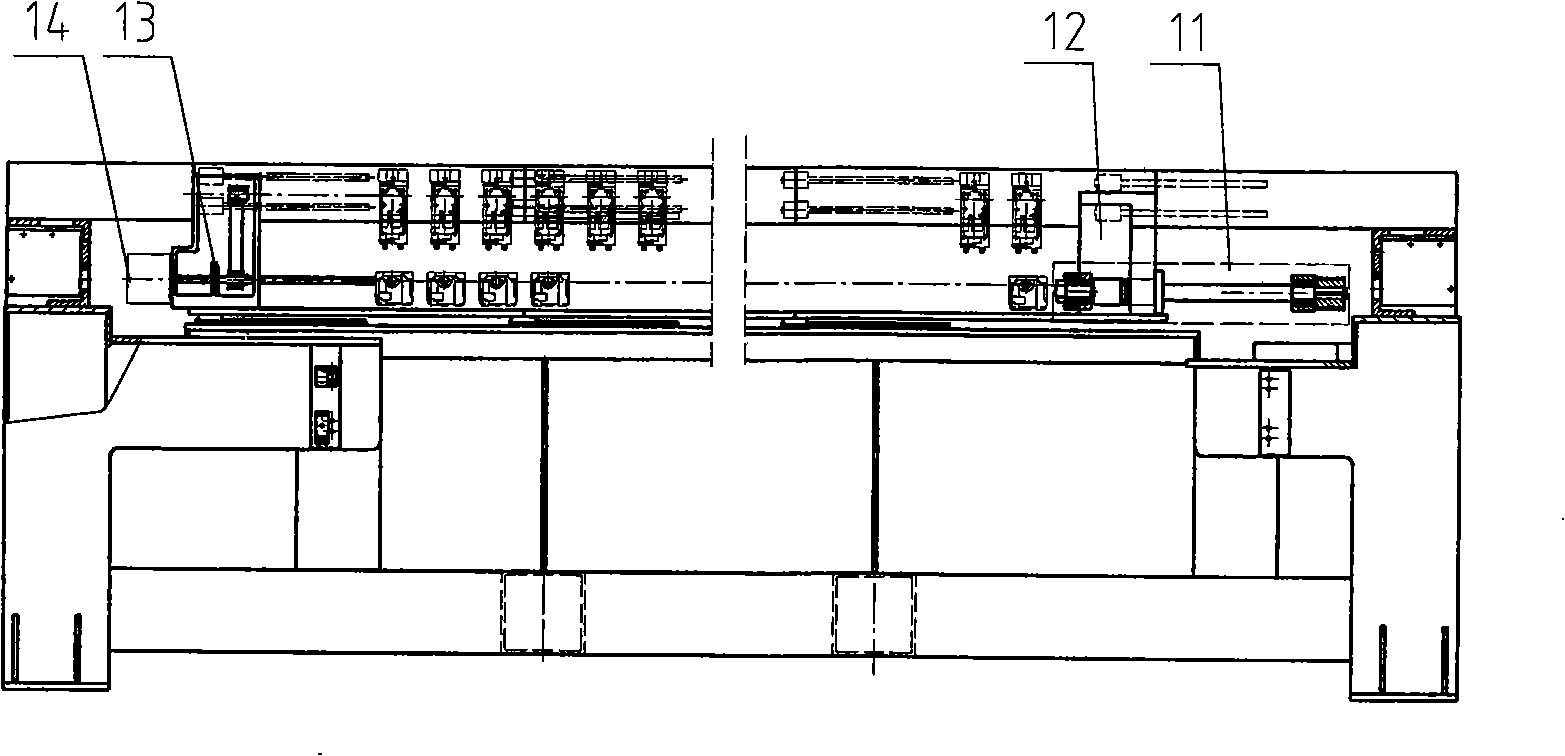

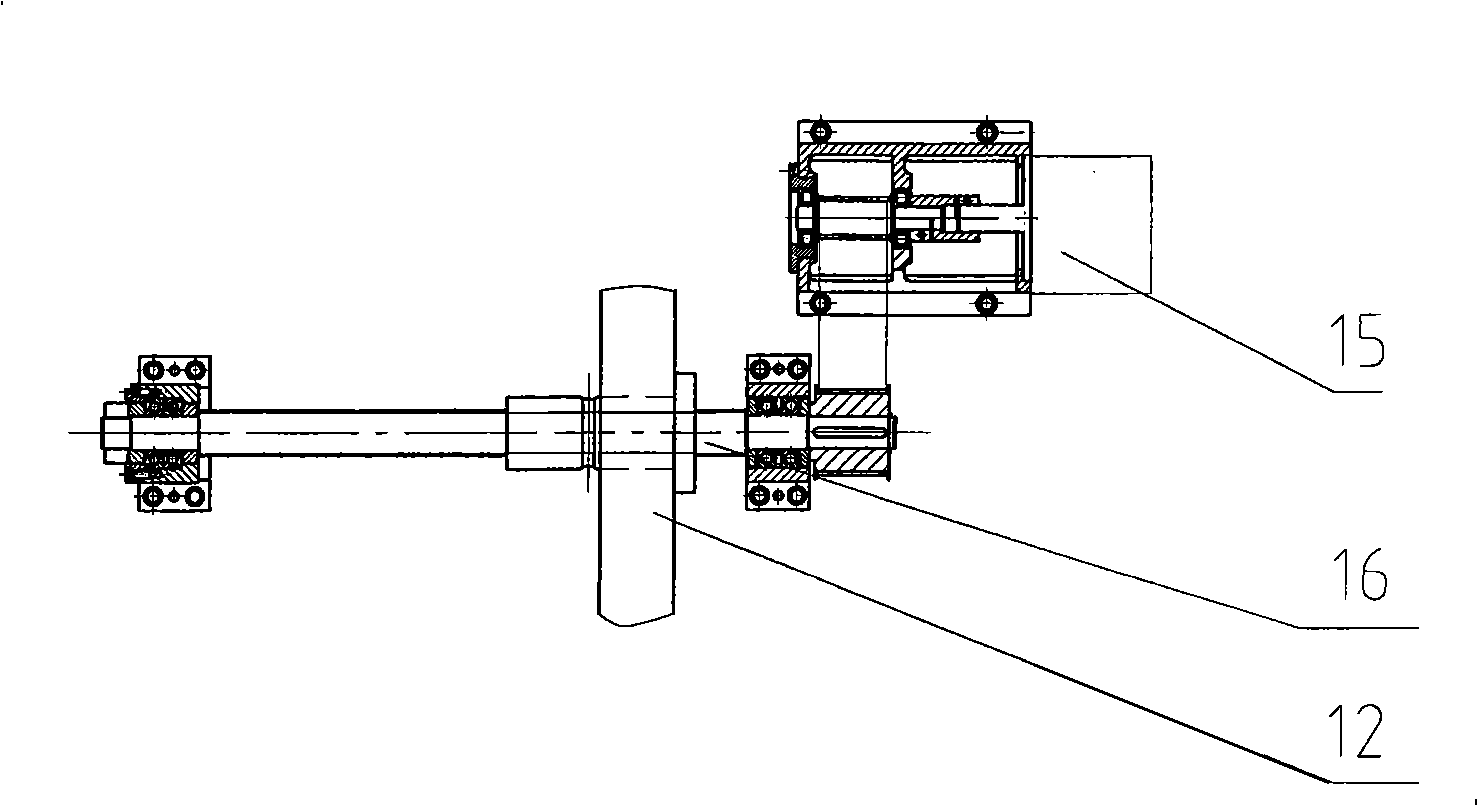

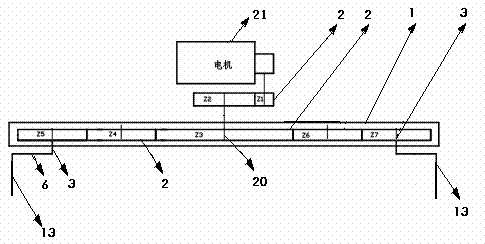

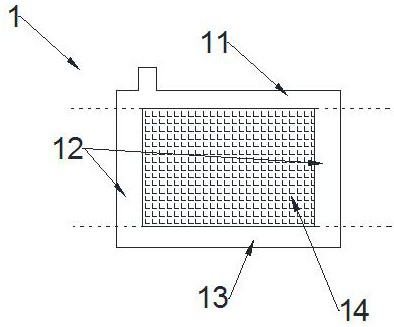

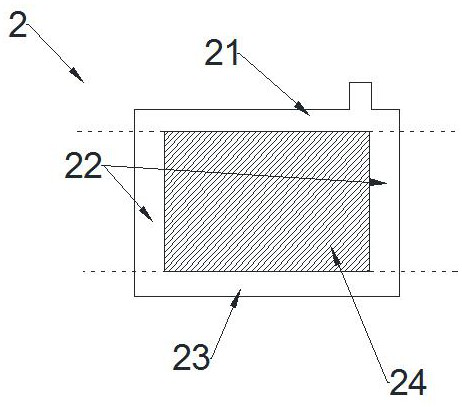

Novel quilting embroidery machine

InactiveCN101319440AShorten the lengthImprove rigidityHem-stitch machinesMattress sewingElectric machineryAutomotive engineering

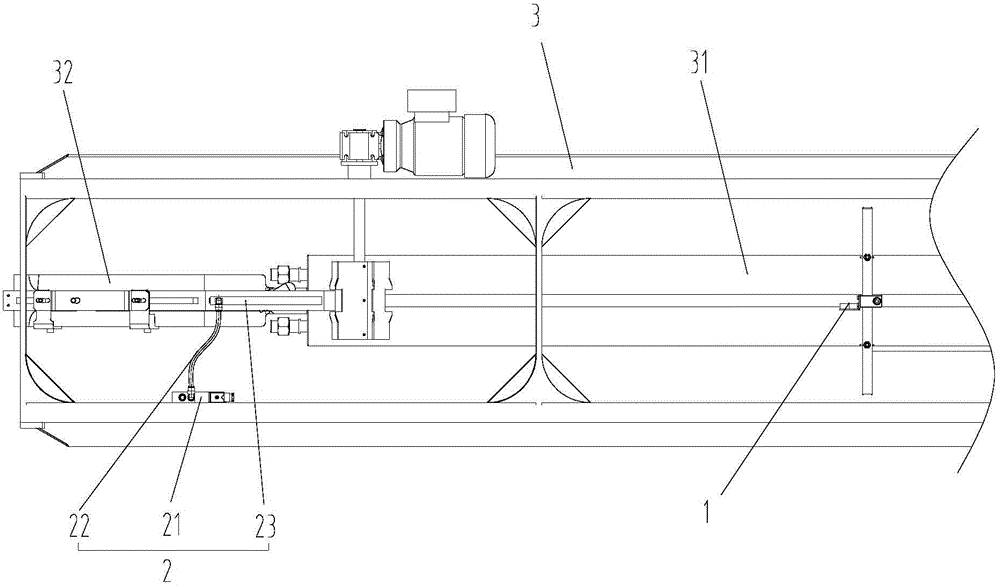

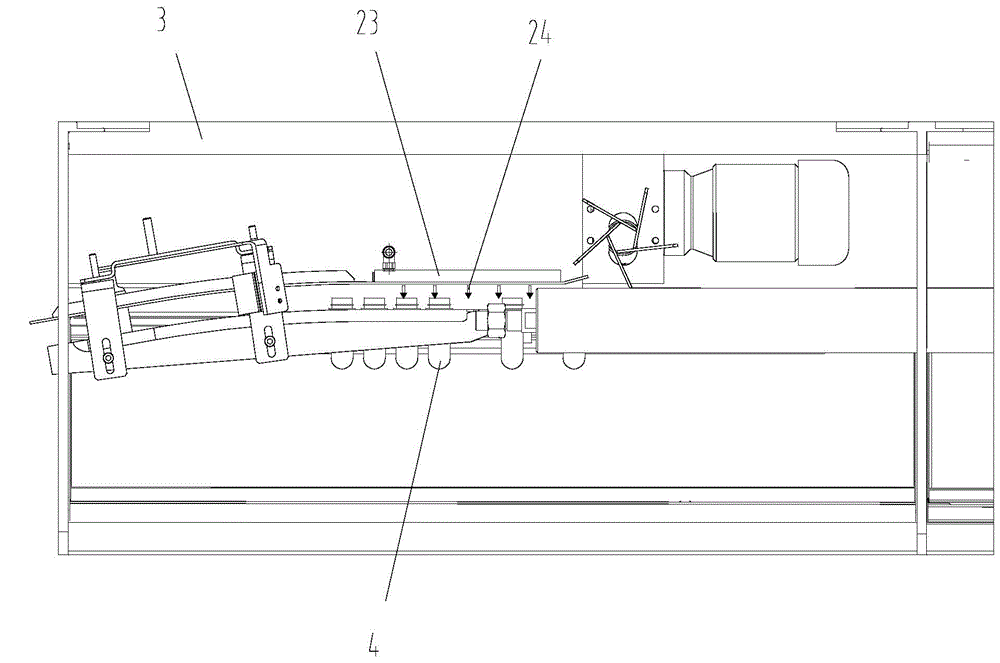

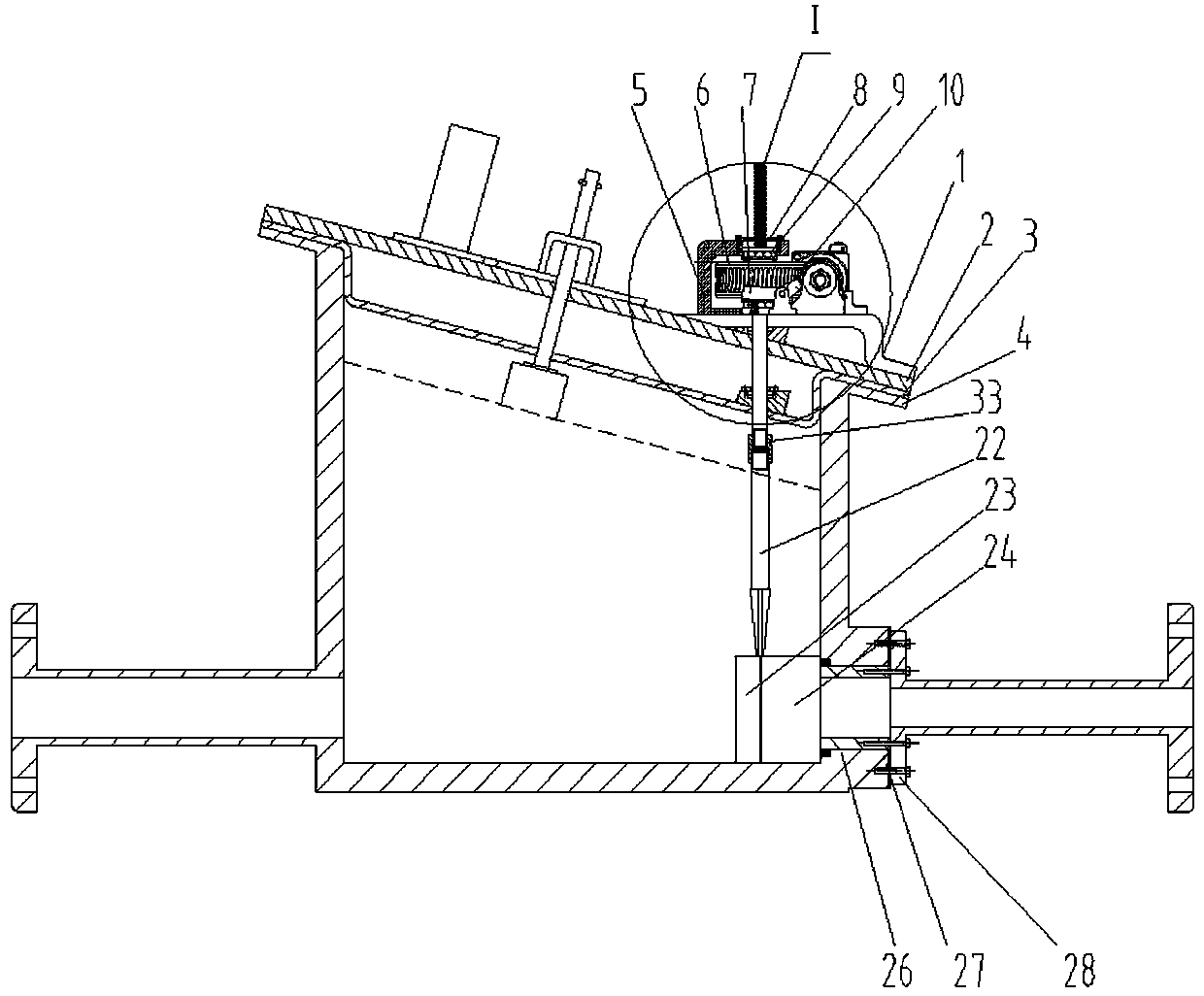

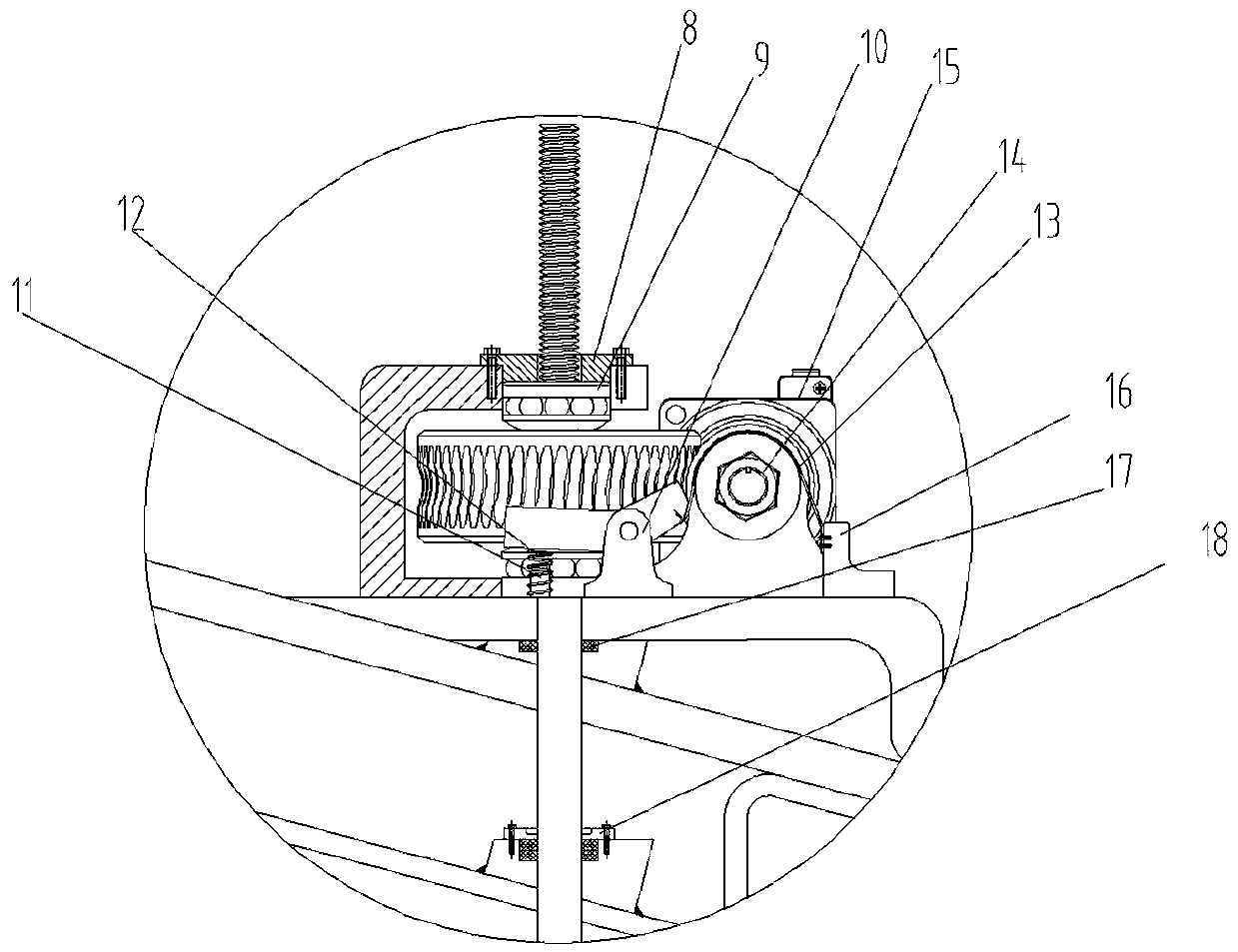

The invention discloses a novel quilting embroidery machine, consisting of a machine frame, as well as a charging system, a discharging system and two sets of rolling systems which are arranged on the machine frame. A servo motor realizes the front and rear rolling and synchronous rotation in a Y direction through a synchronous cog belt; a machine head component and a shuttle box component are also arranged on the machine frame; the machine head component is arranged on a connecting plate; a linear guide rail is arranged on the connecting plate; the shuttle box component is arranged on a shuttle box component connecting plate, and a shuttle box component linear guide rail is arranged on the connecting plate; a driving component is also arranged on the machine frame; the driving component comprises the servo motor, a lead screw and a driving-connecting block; the driving-connecting block is connected with the machine head component connecting plate and the shuttle box component connecting plate; the driving component realizes the movement of the machine in an X direction. The servo motor and a transmission box connected with the servo motor are also arranged on the machine frame; the transmission box connects the machine head component connecting plate with the shuttle box component connecting plate into a whole; the transmission box drives a needle bar of the machine head component to move up and down and also drives the shuttle box component to rotate. The machine is applicable to quilting embroidery machines.

Owner:陈桢铭

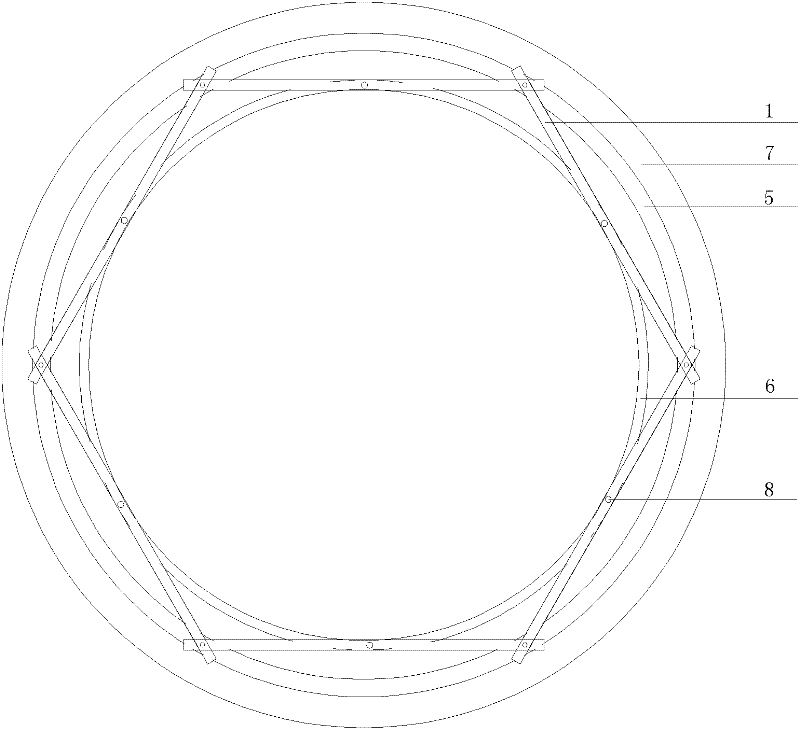

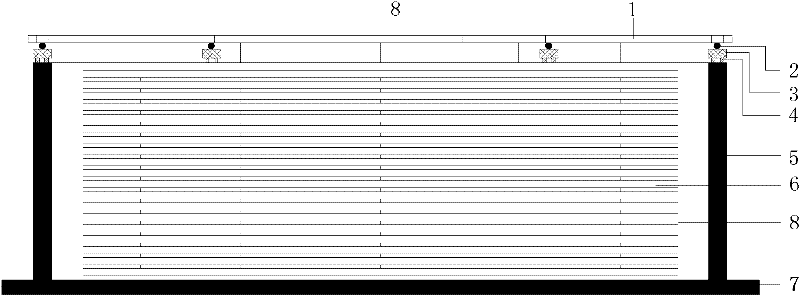

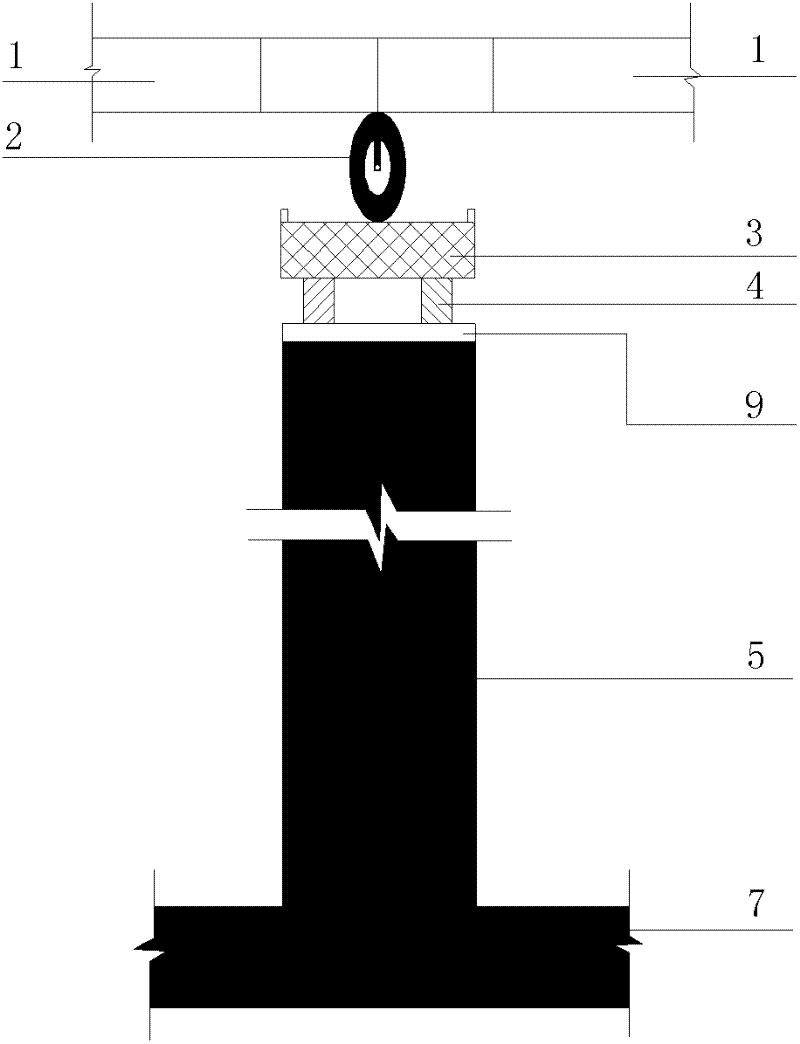

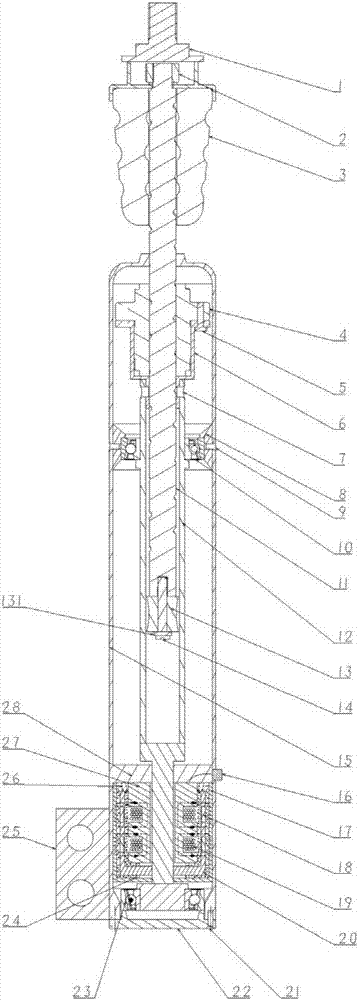

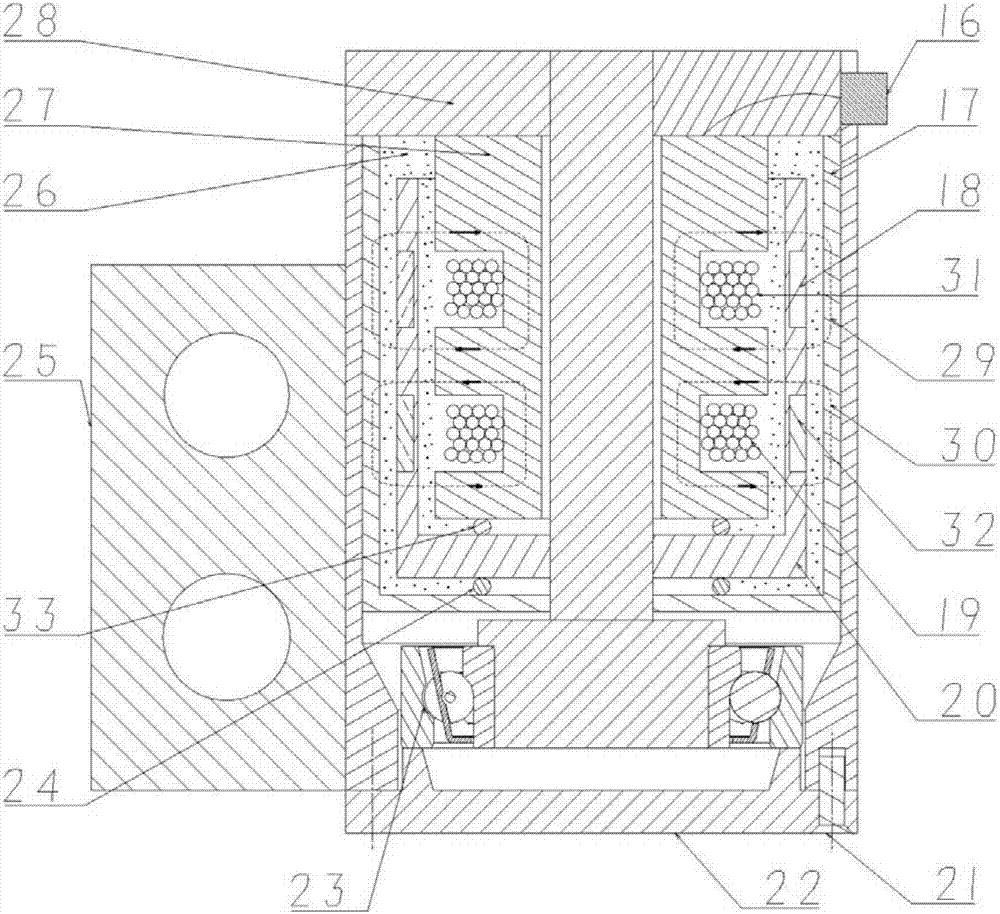

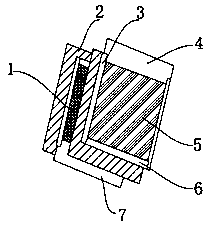

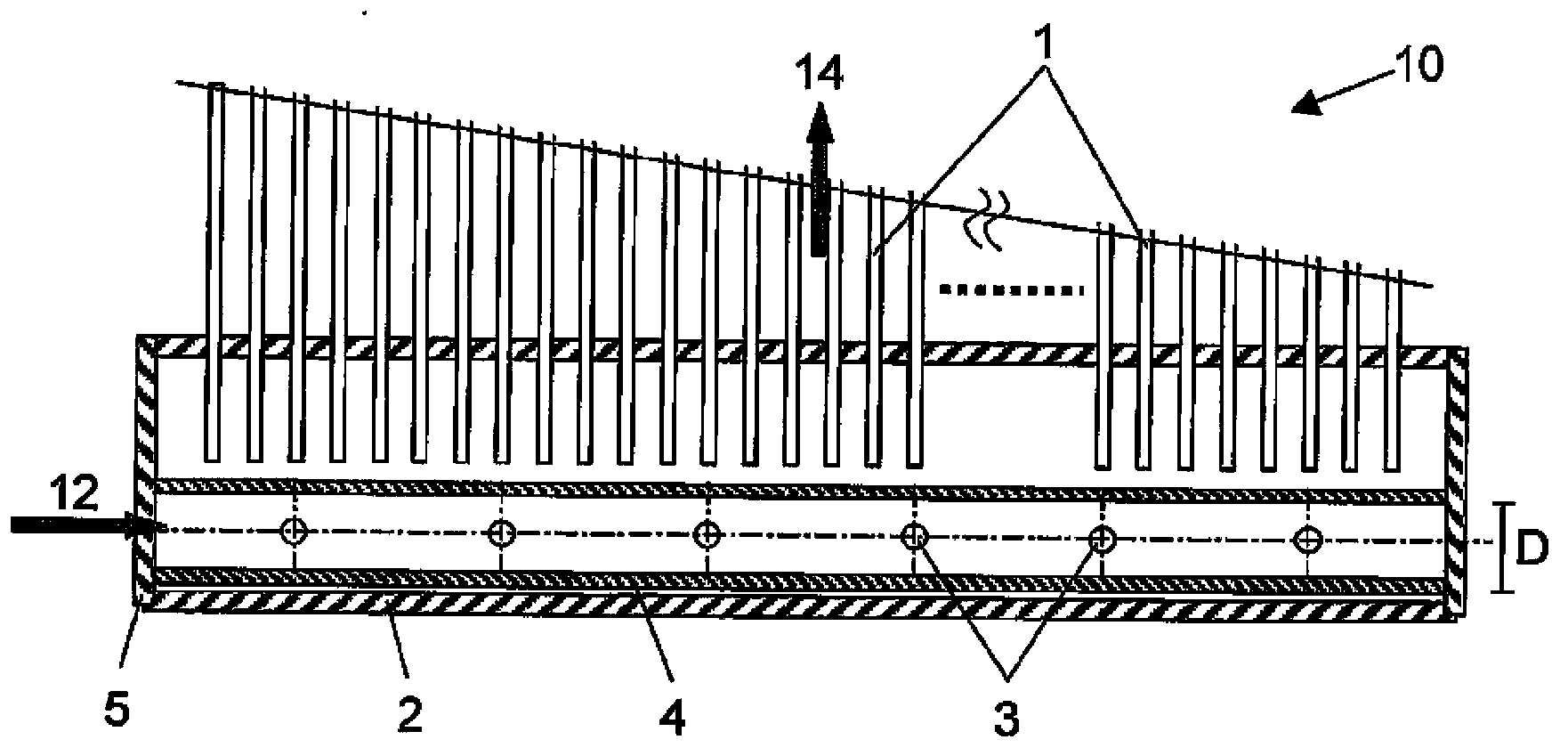

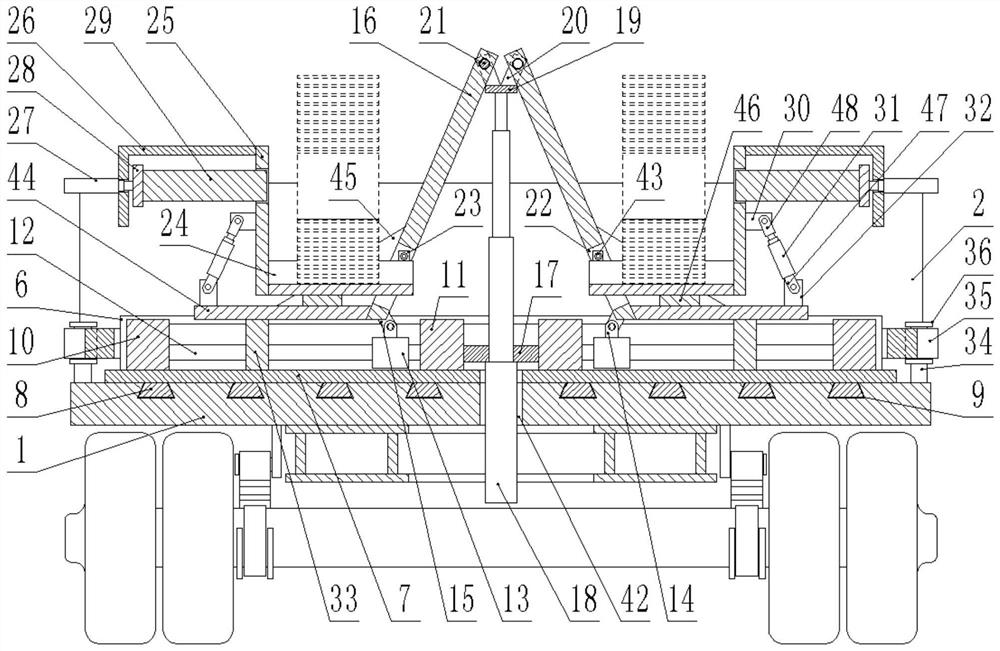

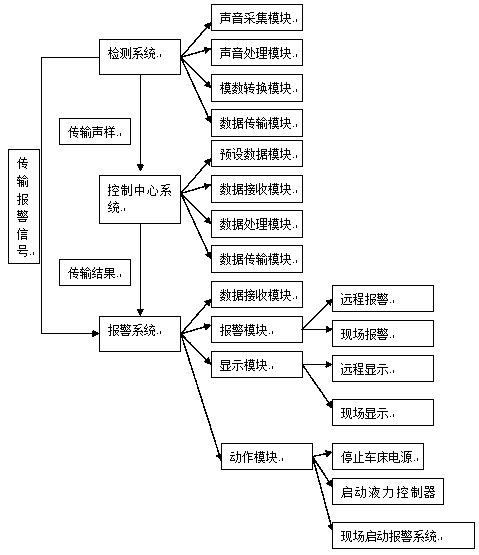

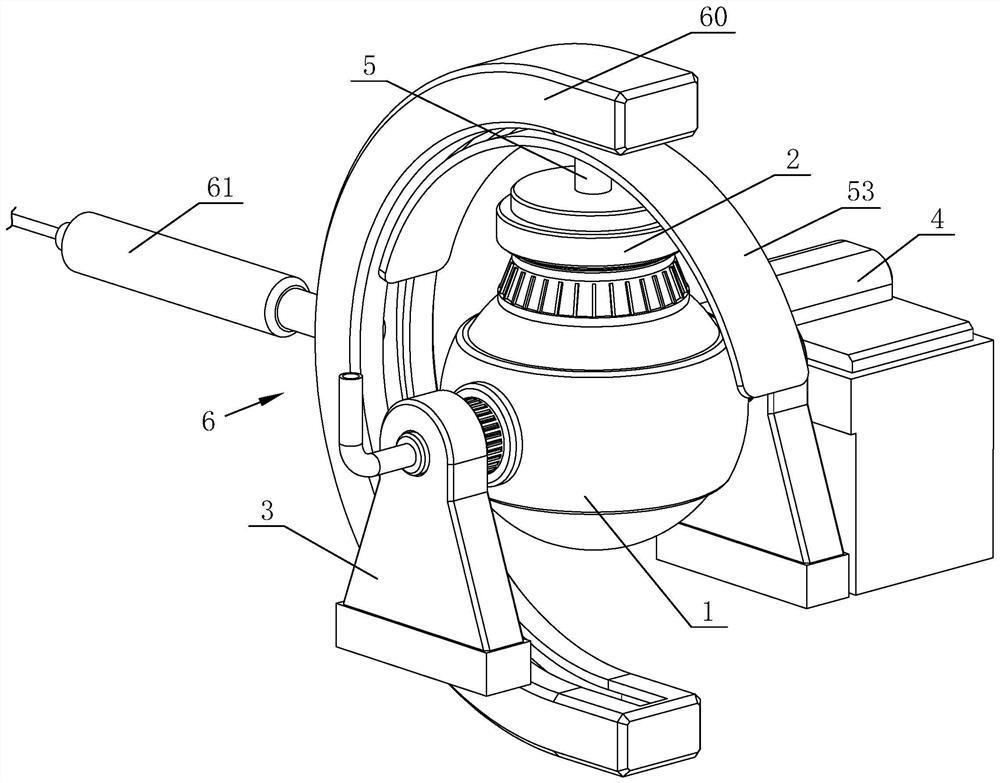

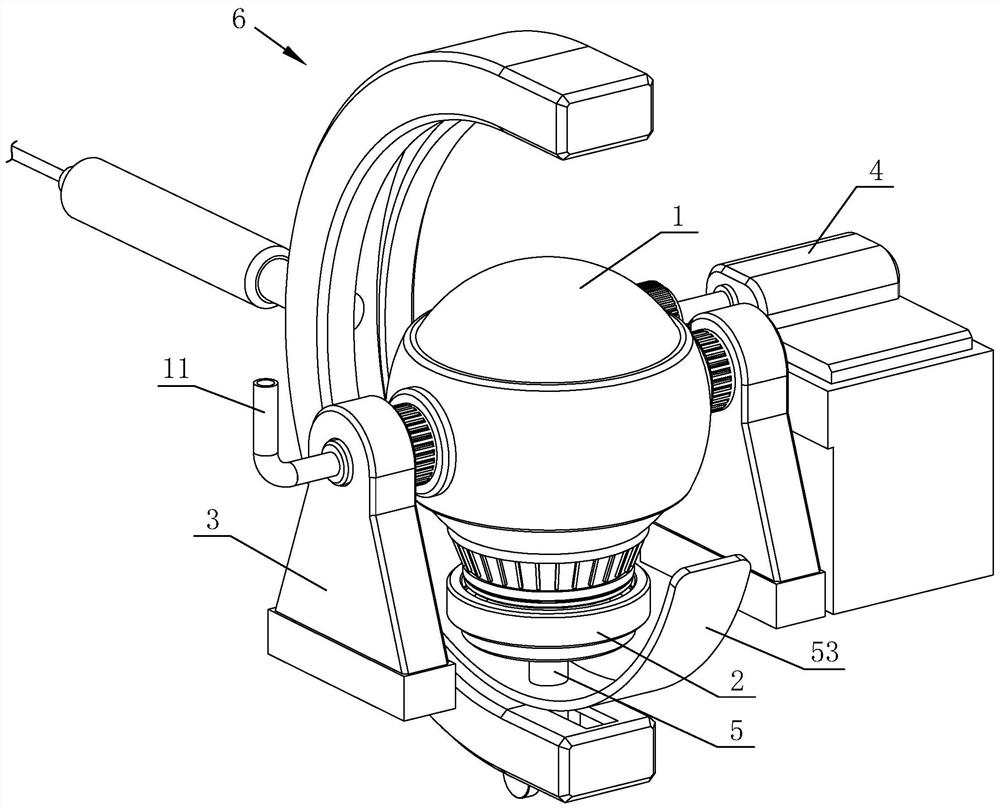

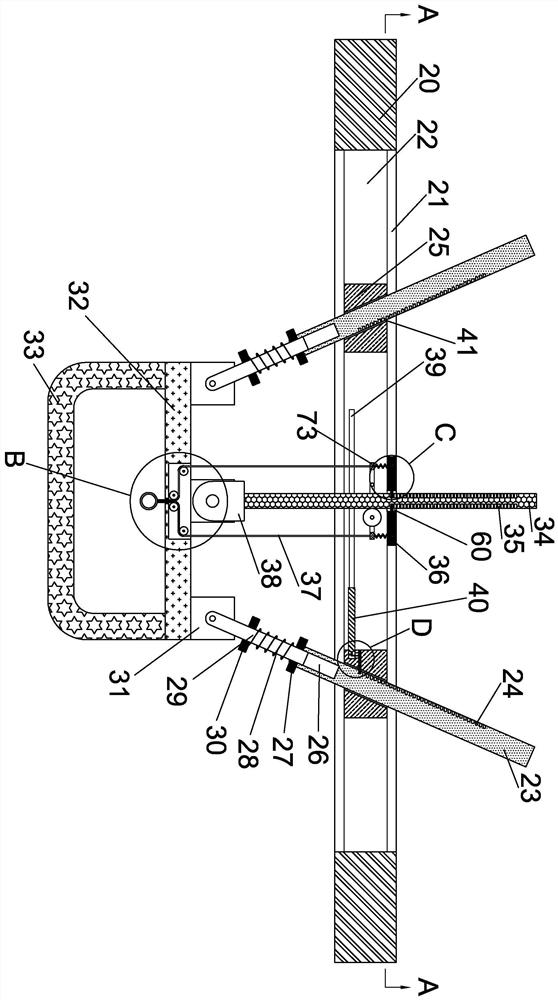

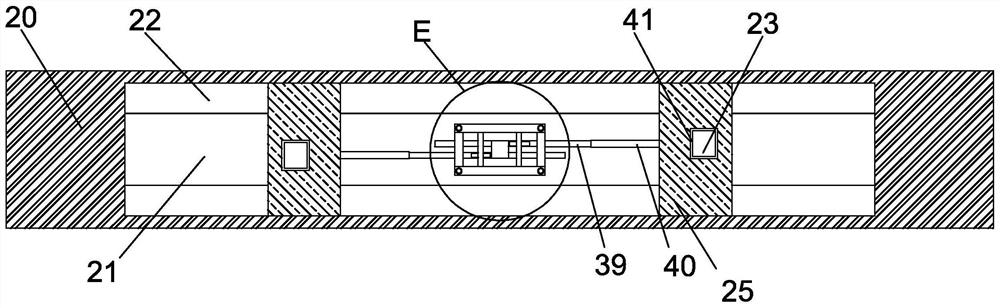

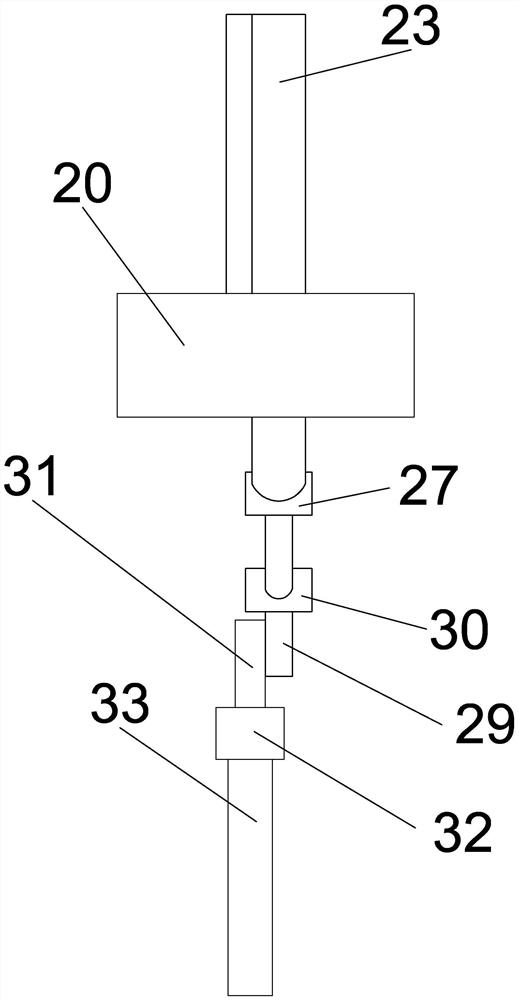

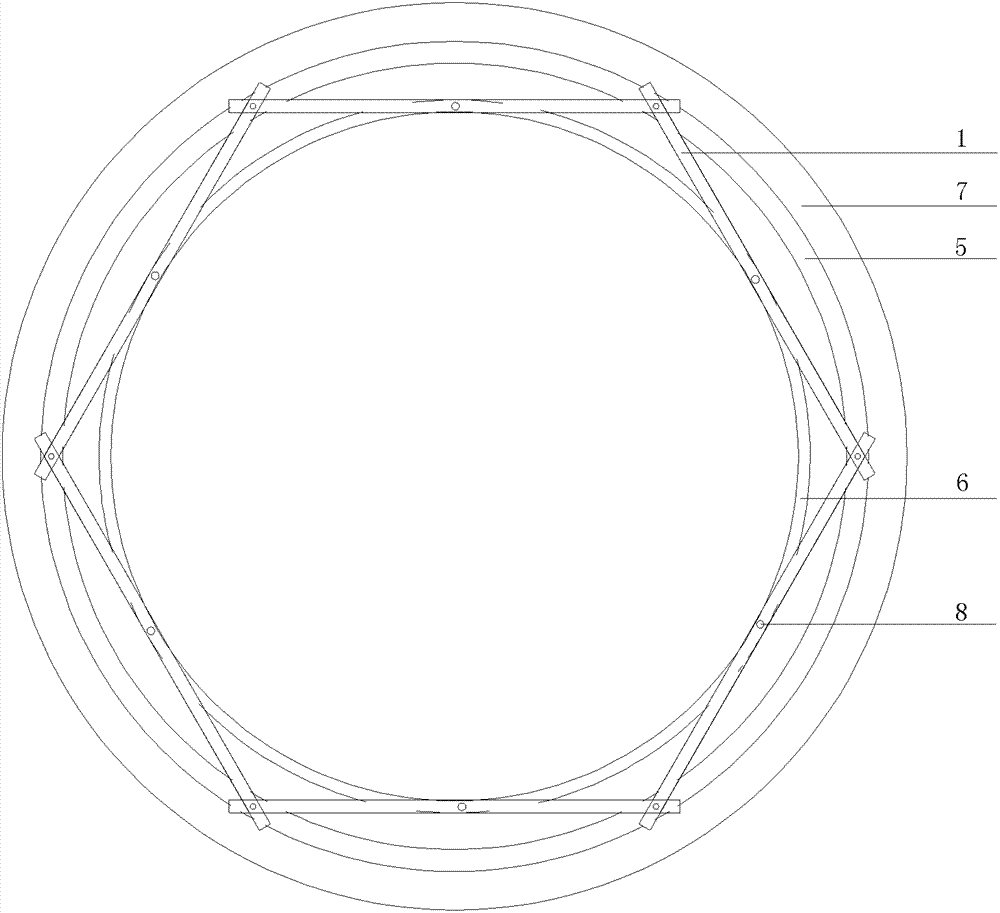

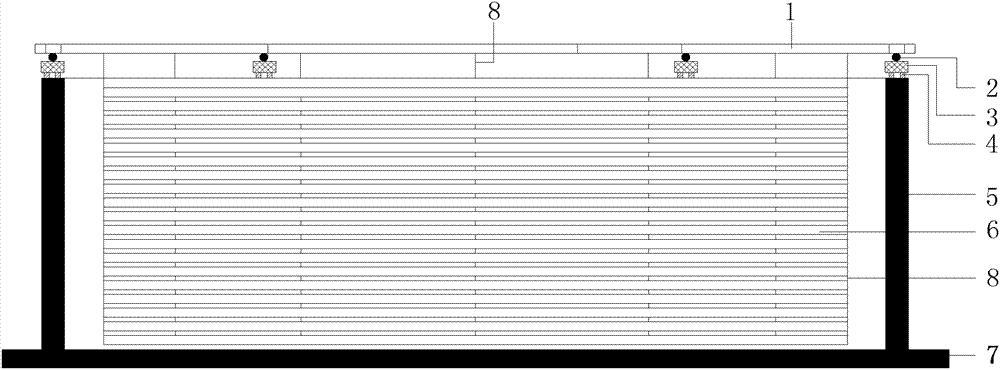

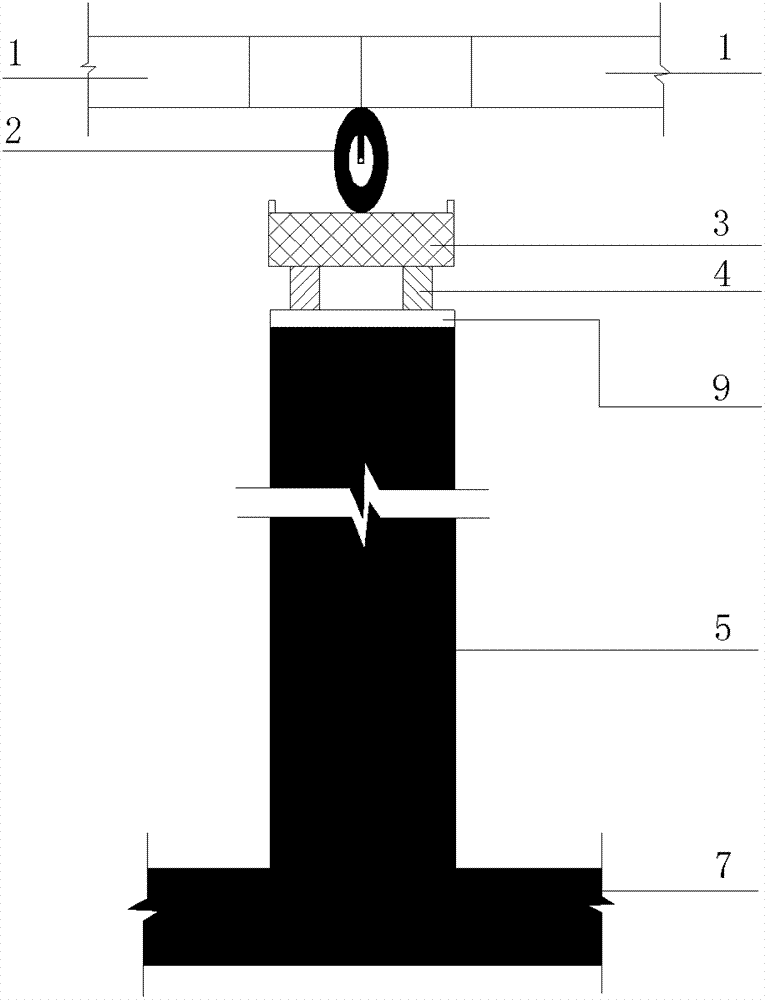

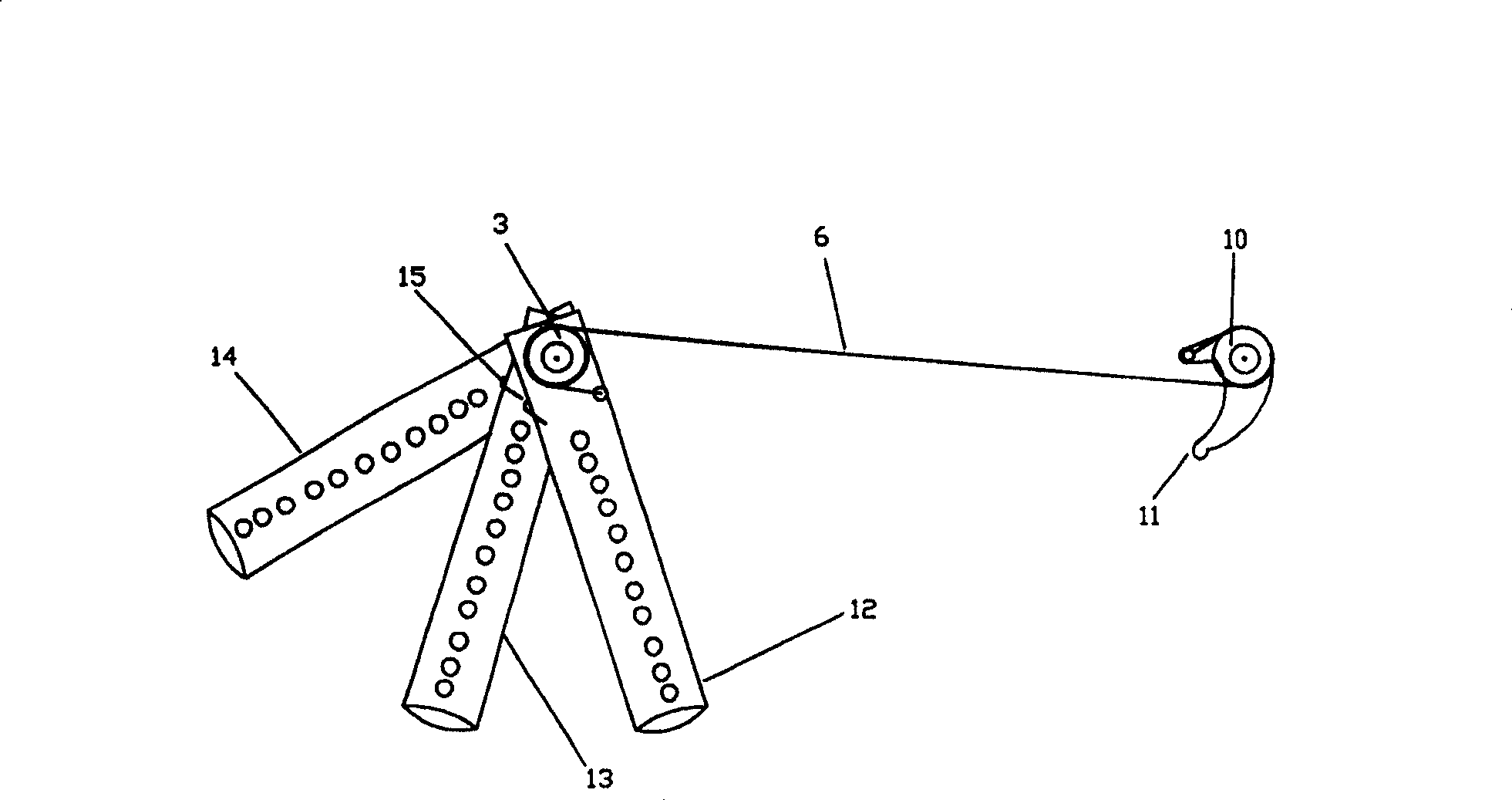

Suspension type multi-dimensional input horizontal multi-directional shearing model casing device

InactiveCN102367674AEliminate inertiaWeaken the effect of vertical vibration characteristicsFoundation testingRigid wallEngineering

The invention discloses a suspension type multi-dimensional input horizontal multi-directional shearing model casing device, belonging to the technical field of civil engineering. The suspension type multi-dimensional input horizontal multi-directional shearing model casing device comprises a rigid suspension bracket, a rigid bottom plate and a model casing body, wherein the top of the model casing body is hoisted by the suspension bracket and is suspended on the rigid bottom plate, the model casing body comprises more than ten layers of layer structures and a beam frame, wherein each layer structure is rigid and light, and planes of the layer structures are of any same shape, all layer structures are vertically arranged in parallel at equal intervals and are serially connected by using a film or cable, and the film or cable is suspended on the rigid beam frame; the rigid bottom plate is fixedly connected with the rigid suspension bracket and connected with a vibration platform surface together; the beam frame is arranged on the suspension bracket through universal trundles or universal joints in a spanning manner; and the suspension bracket is a rigid wall and is fixedly connected with the rigid bottom plate, and the top of the suspension bracket is provided with a vertical vibration isolation support and a height regulating mechanism. According to the invention, the interference of the model casing to model soil is reduced, the vibration simulation in the vertical direction can be tested, and the model casing is tested in a three-dimensional vibrating manner.

Owner:BEIJING UNIV OF TECH

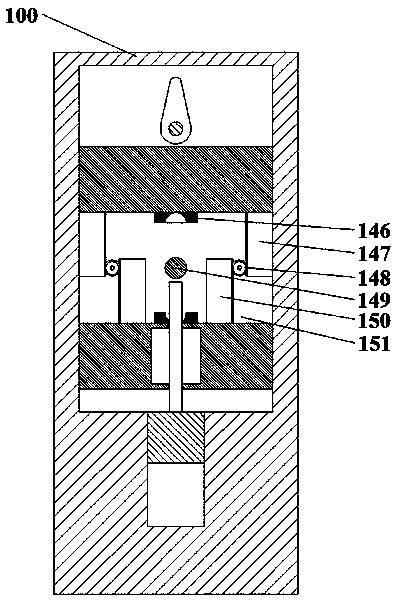

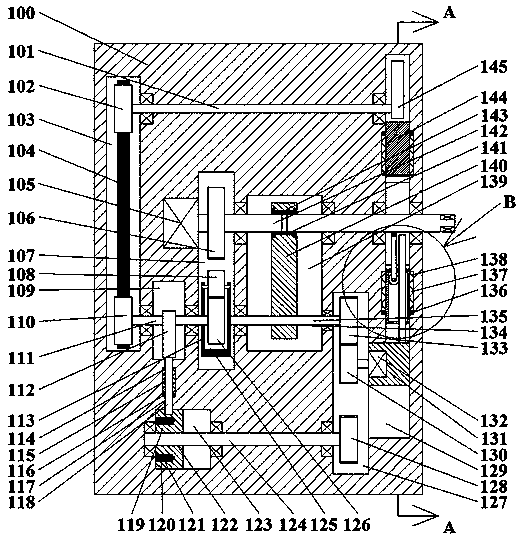

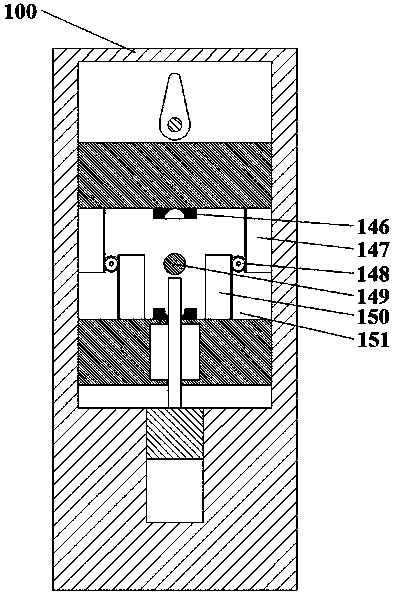

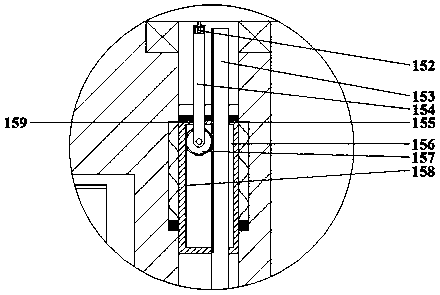

Rotation stopping equipment for transmission shaft and use method of equipment

InactiveCN109236976AEliminate kinetic energyPower removalGearingGearing detailsDrive shaftEngineering

The invention discloses rotation stopping equipment for a transmission shaft and a use method of the equipment. The equipment comprises a machine body, a first cavity formed in the machine body and asecond cavity formed in the machine body, a third cavity is formed in the right end wall of the first cavity, a first sliding block is slidably disposed in the third cavity, a rotating sleeve extending to the left and right is rotatably arranged in the first sliding block, and a spline hole which is communicated with the left and right is formed in the rotating sleeve. The equipment is simple in structure and convenient to operate, a same power source is adopted for driving the power connection of a driving machine and the separation of an output shaft of the driving machine, a locking block is driven to be mechanically connected with the driving machine at the same time, so that the power of the driving machine is utilized to eliminate the inertia of the output shaft, emergent stopping ofthe output shaft of the equipment is achieved, and the output precision of the equipment is improved. Meanwhile, the driving machine can be automatically powered on, powered off and locked after thekinetic energy is achieved, work procedures cooperate with one another without affecting one another, and the practical performance of the equipment is improved.

Owner:袁学锋

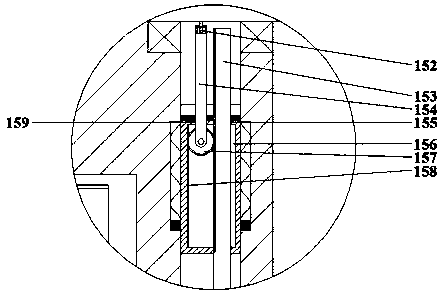

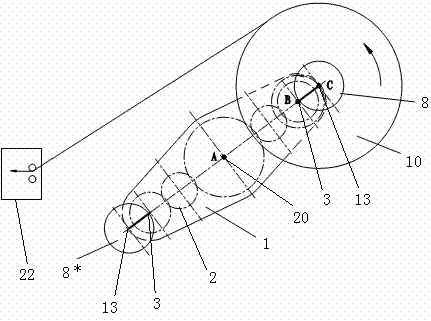

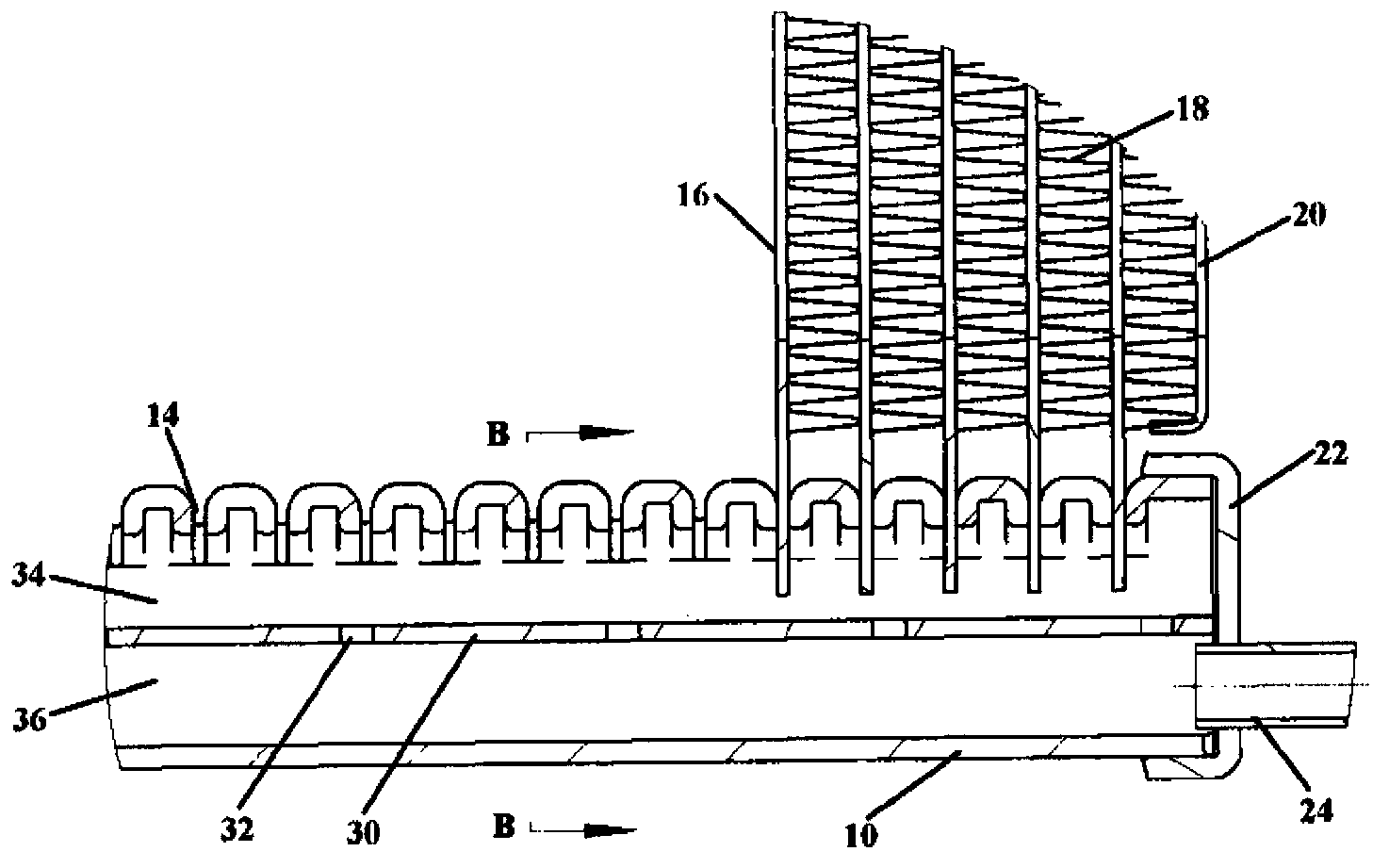

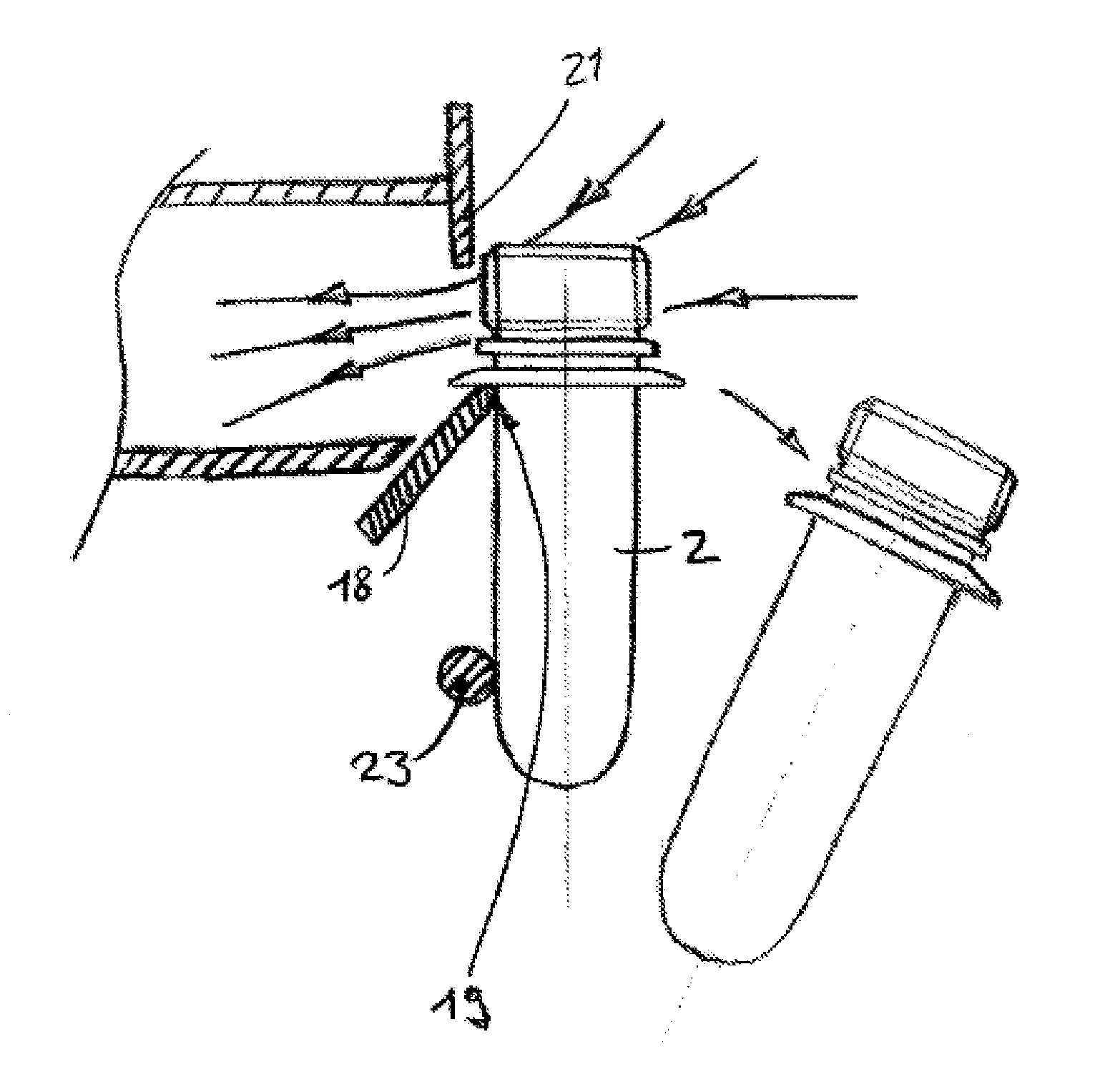

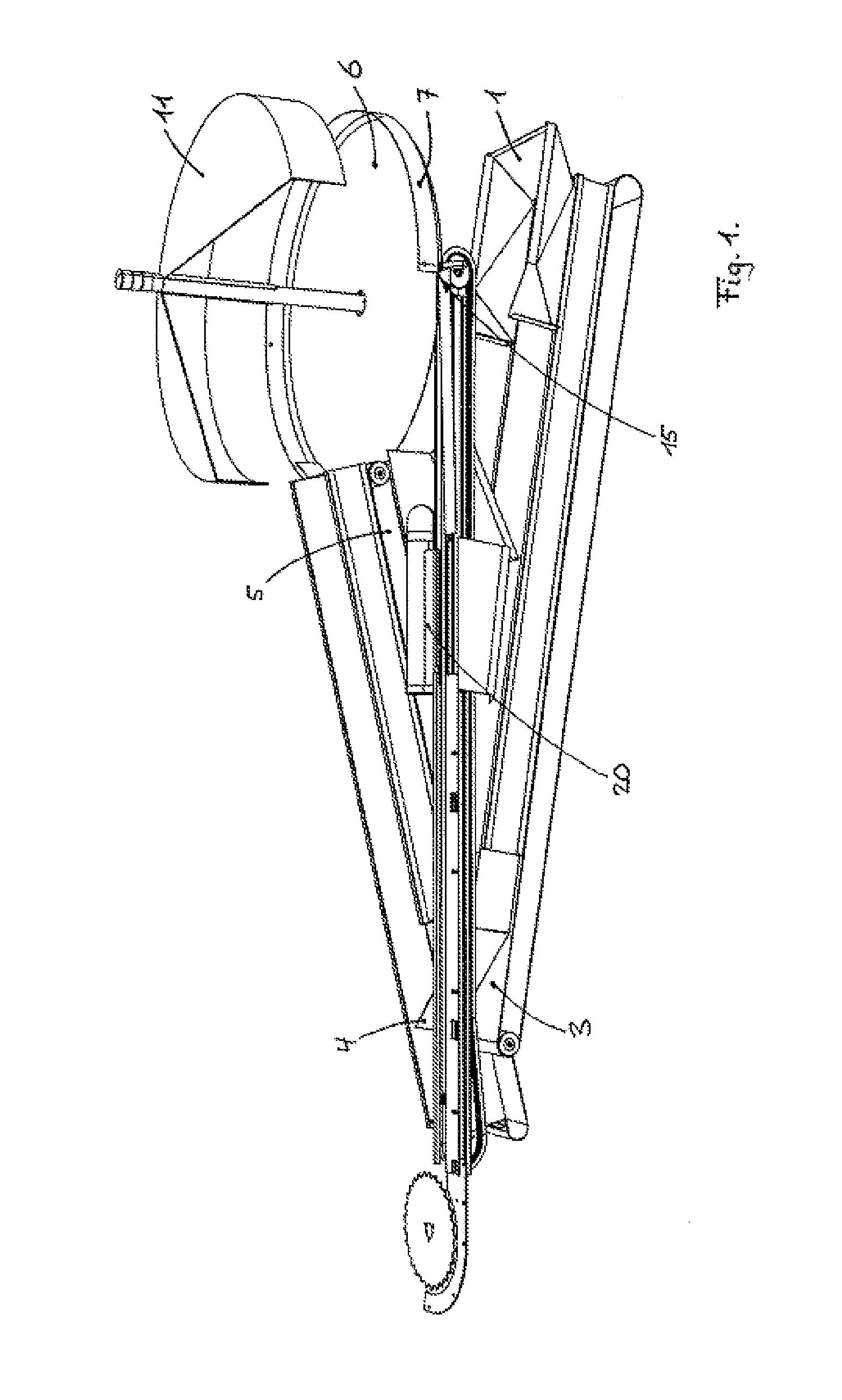

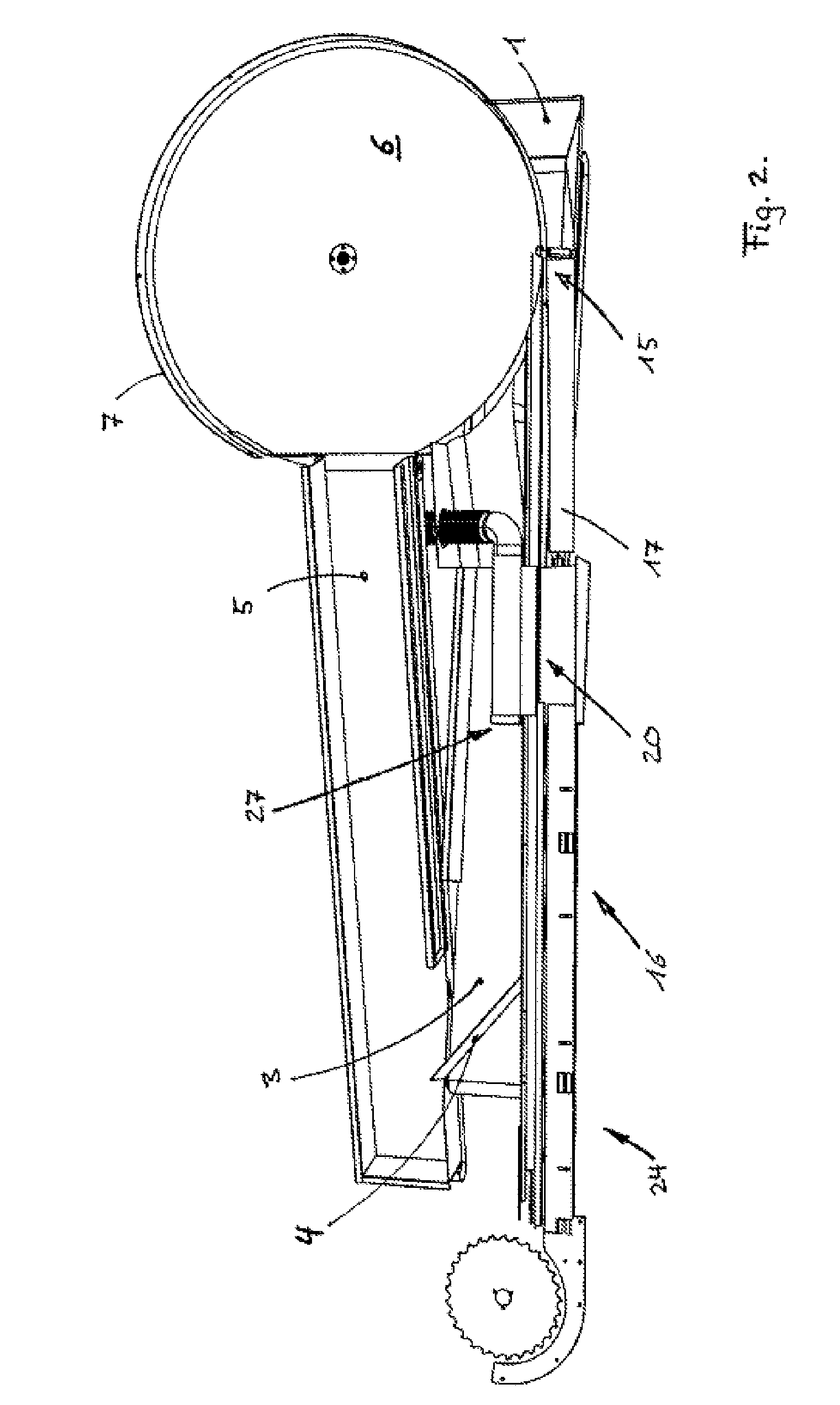

Method and apparatus for transporting articles to a station

ActiveUS20140151189A1Improve dynamic responsivenessContinuous motionRollersRotary conveyorsBlow moldingEngineering

A method for transporting articles (2) to a station, in particular preforms to a blow-molding apparatus, wherein each article has a protrusion (10) and is moved along a guide (16) by a drive means (18), the article (2), along at least part of the guide (16), should be retained on an abutment (19, 21, 23), and advanced along this abutment, by an air stream.

Owner:INTRAVIS GESELLSCHAFT FUR LIEFERUNGEN & LEISTUNGEN VON BILDGEBENDEN & BILDVERARBEITENDEN ANLAGEN & VERFAHREN MBH

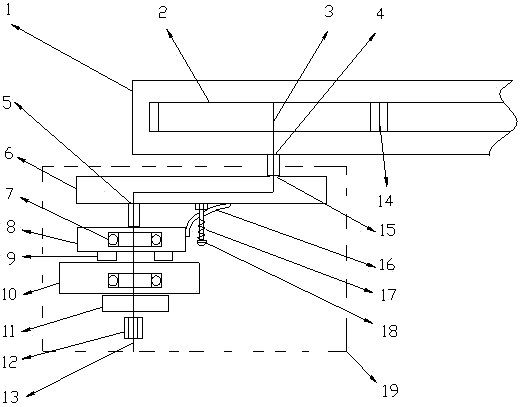

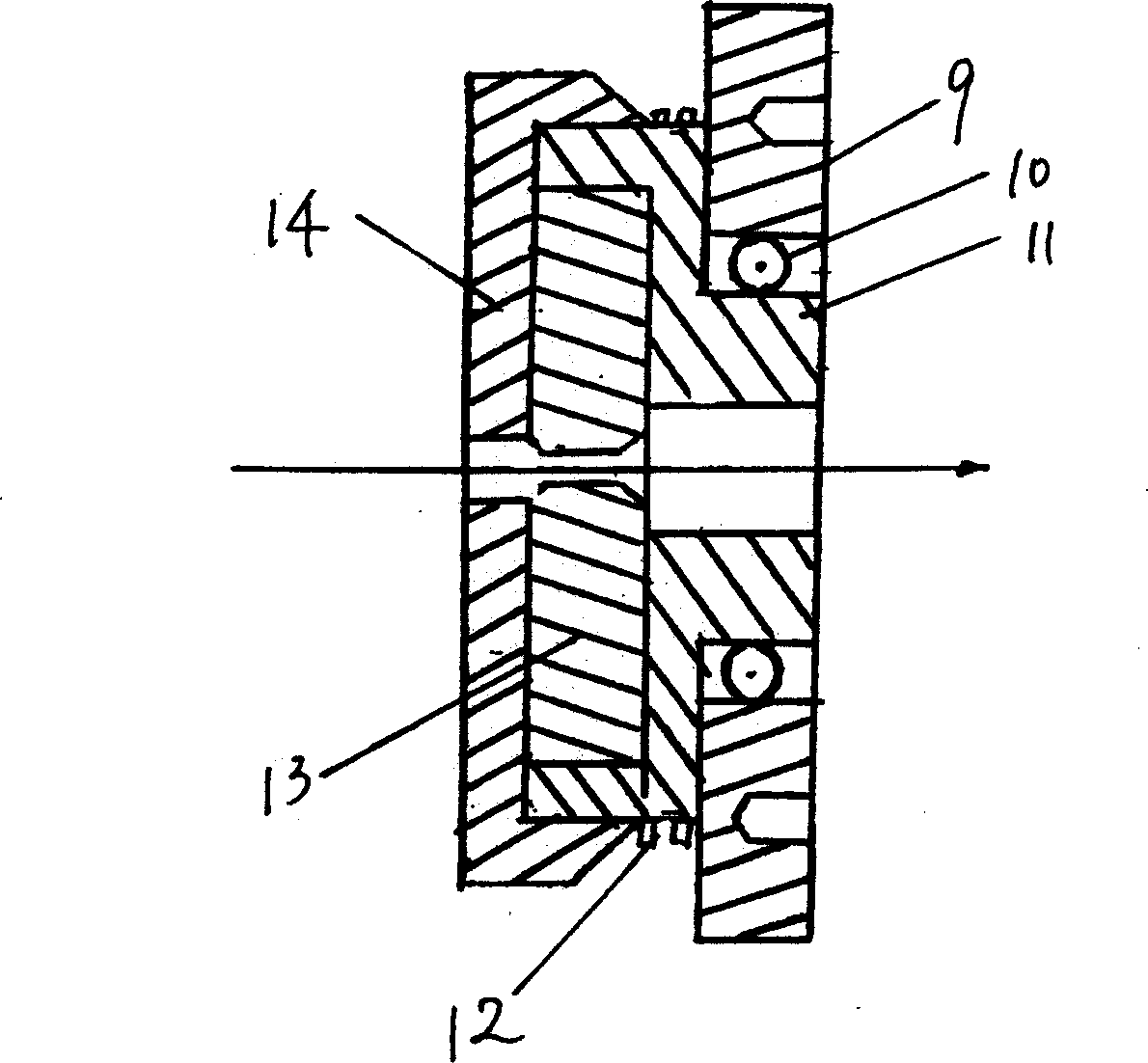

Star wheel bobbin rotary disc

ActiveCN102849495ACompact structureThe connection method is reasonableWebs handlingBobbinMolding machine

The invention provides a star wheel bobbin rotary disc which is used for placing bobbins and providing paper for a molding machine. The star wheel bobbin rotary disc is composed of a rotary disc body, a gear transmission system, two bobbin supports and the like. The rotary disc body is composed of a detachable sealing metal casing, and the gear transmission system is composed of a motor, a central shaft, a plurality of groups of gears meshed or in linkage connection with one another, two transmission shafts and the like. Each bobbin support is formed by an eccentric supporting plate, a bobbin shaft, a bearing, a bobbin base, a braking assembly, a cover cap, an adjusting nut and the like. The rotary disc body can rotate around the central shaft, the motor can drive the central shaft, the gear and the two transmission shafts to rotate. Inner shaft holes of the eccentric supporting plates are sleeved on the transmission shafts, bearing inner rings are sleeved on the bobbin shafts, and bearing outer rings are connected with the bobbin bases in matching mode. The bobbins are arranged between the bobbin bases and the cover caps. The braking assemblies are used for controlling rotating or braking of the bobbin bases and the like, and the adjusting nuts are used for adjusting axial positions of the bobbins. The star wheel bobbin rotary disc is compact in components, small in rotary space, capable of replacing the bobbins automatically, good in splicing stability, and high in efficiency.

Owner:NANTONG CIGARETTE FILTER

Novel magnetorheological damper

ActiveCN107120378AReduce dosageIncrease dampingSpringsNon-rotating vibration suppressionBall bearingClosed chamber

The invention discloses a novel magnetorheological damper comprising an outer cylinder, a rotor cylinder located in the outer cylinder and a ball lead screw located in the rotor cylinder. One end of the ball lead screw stretches out of the outer cylinder, and a compression buffering block and a connecting screw rod are installed at the end of the ball lead screw, and meanwhile, the ball lead screw is further sleeved with a ball nut and a nut seat; the nut seat is fixedly connected with the top end of the rotor cylinder; the bottom end of the rotor cylinder penetrates through an upper partitioning plate, an outer stator and an inner stator and is connected with a rotor; the rotor cylinder and the rotor are supported on a pair of angular contact ball bearings to conduct rotating motion; the upper partitioning plate, the outer stator, the inner stator and the rotor form a closed chamber; the chamber is filled with magnetorheological fluids; two annular grooves are formed in the inner stator; coils are wound in the two annular grooves correspondingly; and two magnetic fields are produced after the coils are electrified. The novel magnetorheological damper has performance that the magnetorheological fluids are small in using amount, the damping is high , and the high damping is achieved even at a low frequency, the smoothness of a vehicle can be improved, and the control stability of the vehicle can be also controlled.

Owner:NANJING FORESTRY UNIV

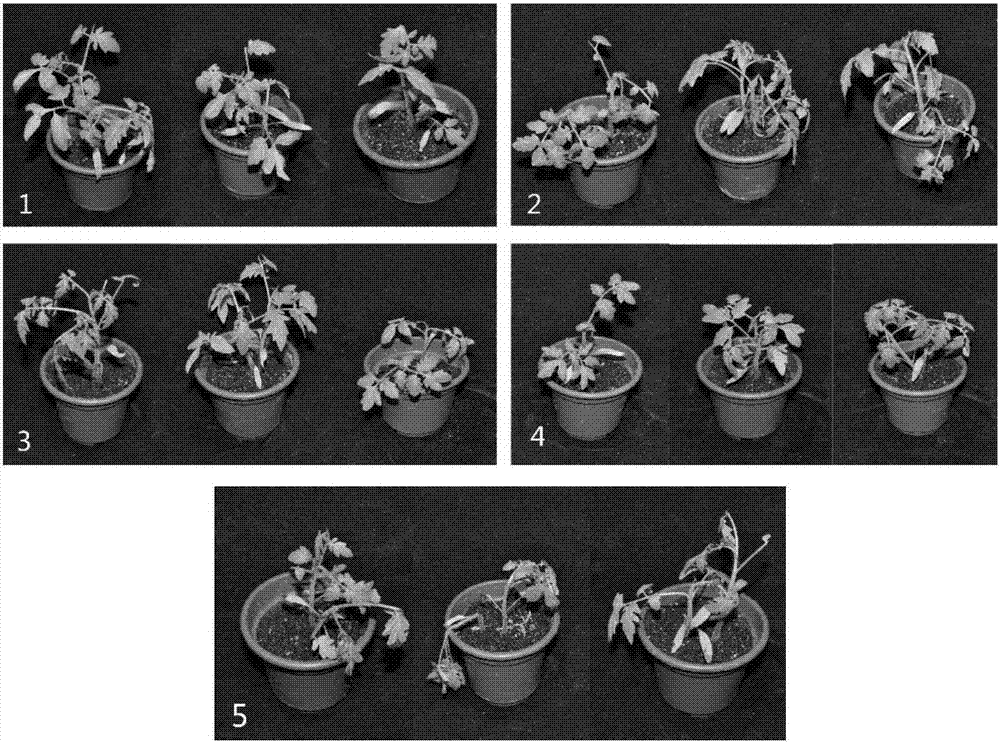

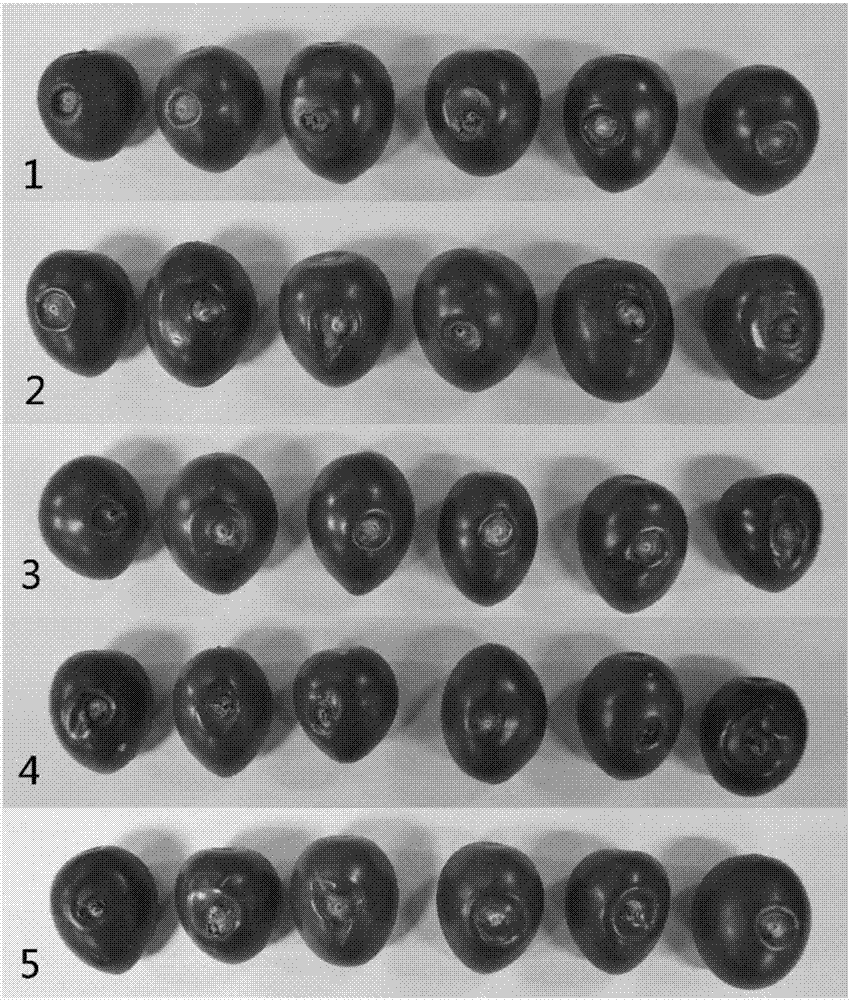

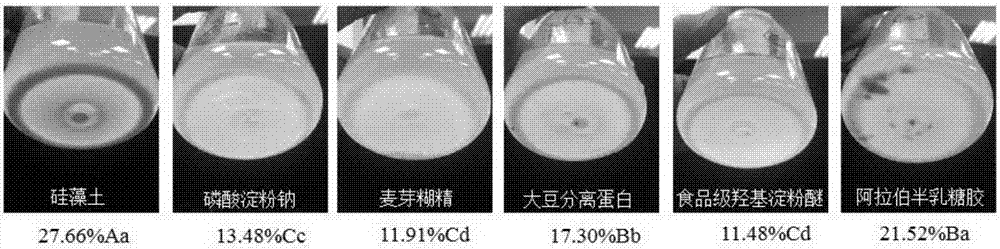

Trichoderma*brassinolide wettable powder as well as preparation method and application thereof

ActiveCN106879585APromote growthImprove self-protection functionBiocidePlant growth regulatorsBrassinolideEther

The invention discloses a trichoderma*brassinolide wettable powder as well as a preparation method and application thereof. The wettable powder is prepared from powder obtained by mixing a sporular hyphal homogenate of trichoderma, brassinolide and food-grade hydroxy starch ether, wherein the mass ratio of the sporular hyphal homogenate of the trichoderma to the food-grade hydroxy starch ether in the powder is 2 to 1; the wettable powder is also prepared from dextrin, sodium lignosulphonate, a dispersing agent NNO (Sodium Methylenebisnaphthalenesulfonate), methylcellulose, carboxymethylcellulose and chitosan. The wettable powder provided by the invention has the advantages of being convenient to confect and easy to coat, being high-efficiency and low-toxicity, being relatively safe to an environment, and having a favorable prevention effect on botrytis cinerea.

Owner:SHANGHAI JIAO TONG UNIV

Stalling equipment of transmission shaft

InactiveCN109185364AEliminate kinetic energyPower removalAxially engaging brakesBrake actuating mechanismsDrive shaftEngineering

The invention discloses stalling equipment of a transmission shaft. The stalling equipment comprises a machine body, a first cavity formed in the machine body, and a second cavity formed in the machine body. A third cavity is formed in the end wall of the right side of the first cavity, a first sliding block is slidingly arranged in the third cavity, a rotary sleeve stretching left and right is rotationally arranged in the first sliding block, and a spline hole which is through left and right is formed in the rotary sleeve. The equipment is simple in structure and convenient to operate, the same power source is adopted for driving power-on of a driver and separation of an output shaft of the driver, meanwhile, a locking block is driven to be mechanically connected with the driver, thus, the inertia of the output shaft is eliminated through power of the driver, sudden stop of the output shaft of the equipment is achieved, the output precision of the equipment is improved, meanwhile, thedriver can be automatically powered on, powered off and locked after kinetic energy is achieved, all the procedures cooperate but do not affect one another, and the practical performance of the device is improved.

Owner:袁学锋

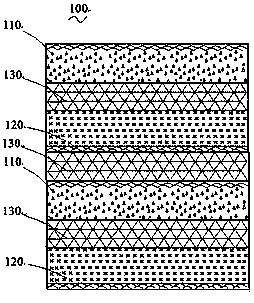

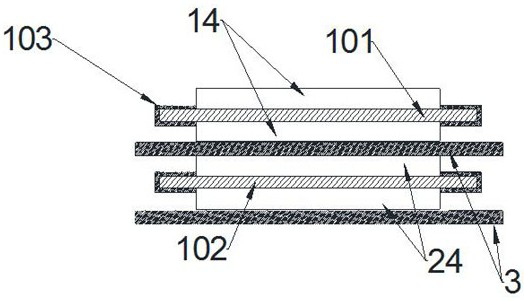

Rapid charging and discharging and safe low-temperature lithium ion battery and preparation method thereof

InactiveCN111276733AShorten migration distanceImprove migration speedFinal product manufactureSecondary cellsElectrolytic agentPolymer adhesive

The invention discloses a rapid charging and discharging and safe low-temperature lithium ion battery and a preparation method thereof. The low temperature is -45 DEG C. The multiplying power of rapidcharging is 3C and 5C respectively, and the multiplying power of rapid discharging is 1C and 10C respectively. The battery mainly consists of five parts, namely a positive plate, a negative plate, aceramic diaphragm, electrolyte and a battery shell, and is prepared by sequentially stacking the positive plate, the ceramic diaphragm, the negative plate and the ceramic diaphragm in sequence, putting the stacked parts into the battery shell, injecting the electrolyte, performing formation, performing sealing and performing capacity grading. The beneficial effects of the lithium ion battery are fully explained through preferred materials such as positive / negative materials, a ceramic diaphragm, an electrolyte, a battery case, a nano-microporous carbon-coated aluminum mesh, a nano-microporouscopper mesh, a polymer adhesive, a high-temperature insulating tape, a macromolecular plasticizer and the like and a preferred process technology. The process is simple and convenient, low in production cost and very suitable for application in the fields of electric vehicles, large-scale energy storage, military starting power supplies and the like.

Owner:LONG POWER SYST NANTONG CO LTD

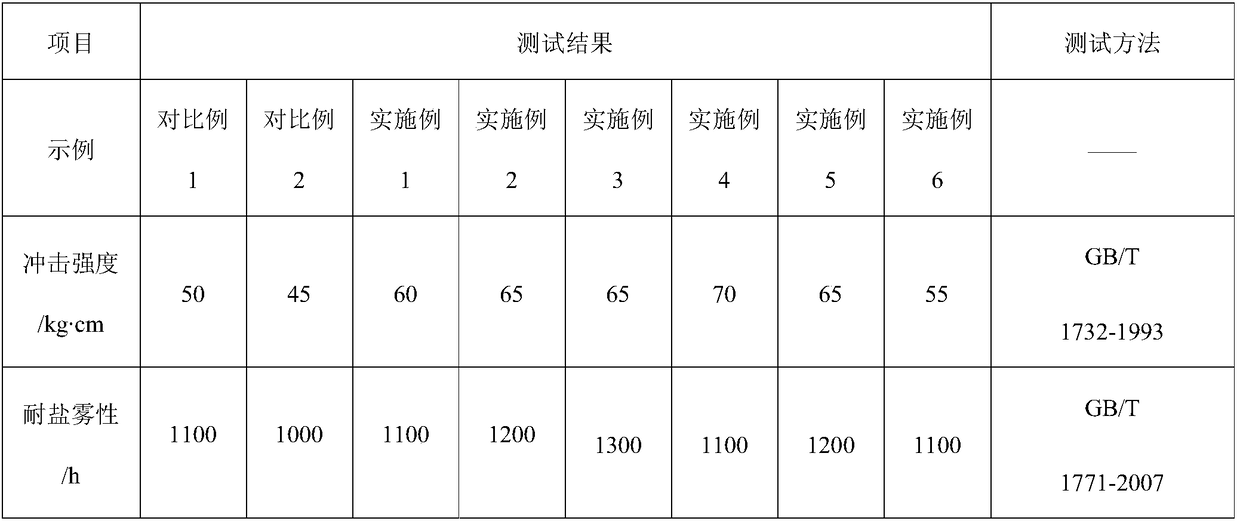

Modified fiber reinforced anticorrosive paint, and preparation method and application thereof

ActiveCN108299996AEliminate inertiaImprove bindingAnti-corrosive paintsPolyurea/polyurethane coatingsFatigue damagePolymer science

The invention discloses a modified fiber reinforced anticorrosive paint, and a preparation method and application thereof. The modified fiber reinforced anticorrosive paint comprises matrix resin, graphene powder, talcum powder, sodium thiosulfate, titanium white powder, dopamine modified fibers, a coupling agent, wollastonite powder, a solvent and the like. The anticorrosive paint of the invention uses dopamine-modified polymer staple fibers as a functional filling material, so the bonding force between the polymer staple fibers and the resin can be enhanced through modification of dopamine,and the impact resistance of a coating formed by the anticorrosive paint can also be effectively improved by utilizing the toughness of the polymer; and thus, when used in the spray-splashing zones ofmarine facilities, the coating is effectively reduced in fatigue cracking and peeling caused by the impact of spray, and in particular, the coating can effectively absorb and transform impact force to protect the coating from fatigue damage caused by the impact force during impacting and beating of the spray. The preparation method for the anticorrosive coating of the invention is simple in process, easily controllable in conditions and suitable for large-scale production, and has good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

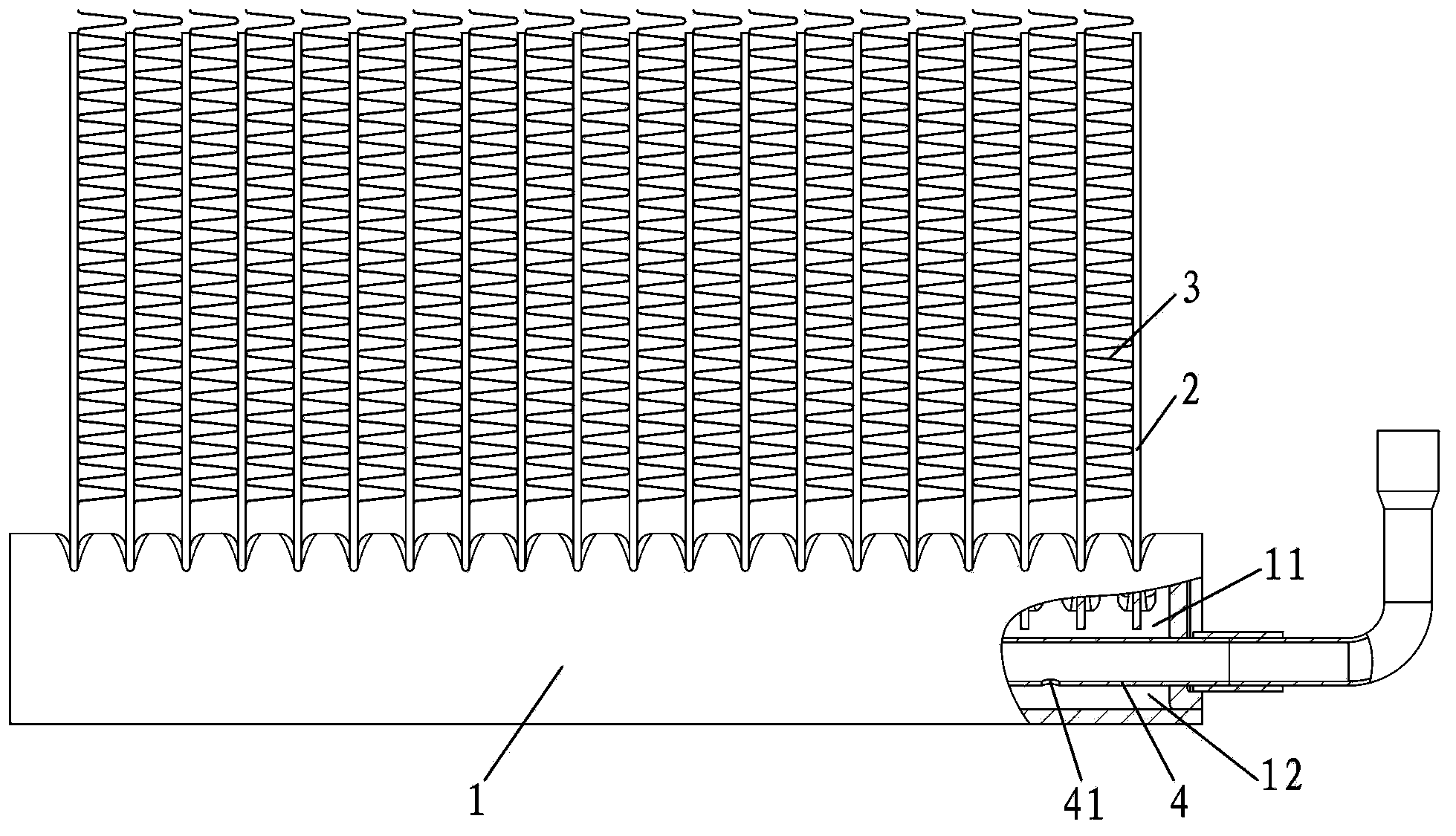

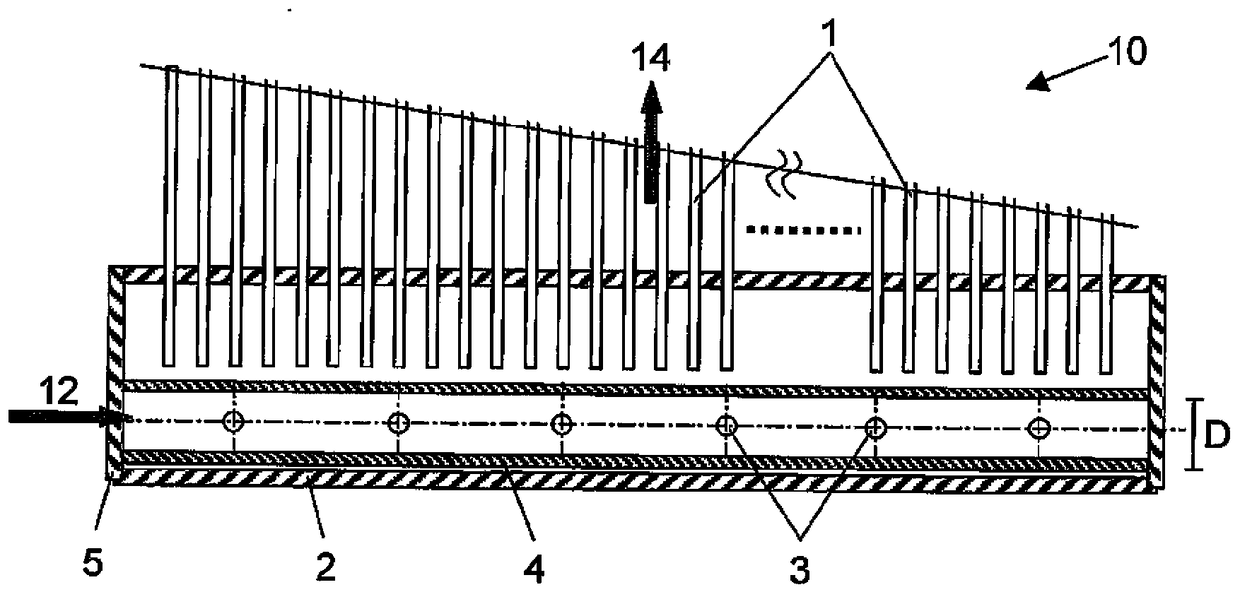

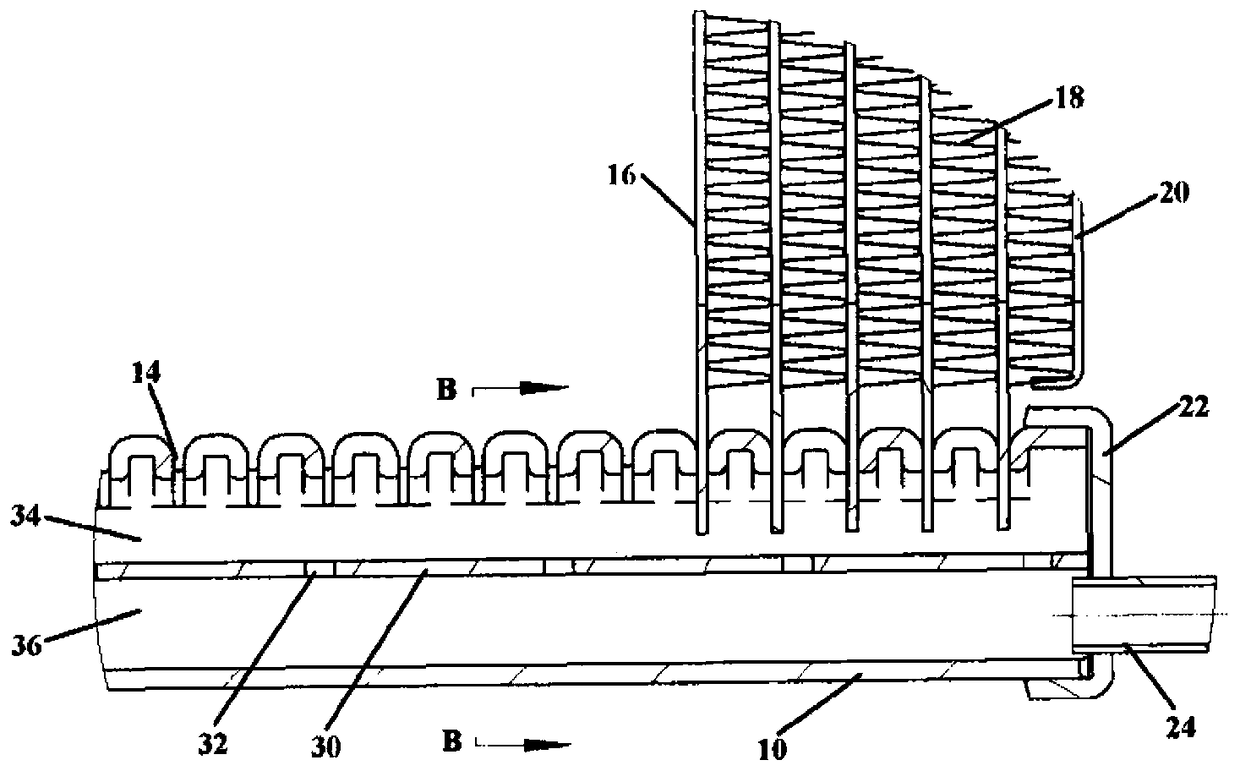

Heat exchanger

ActiveCN104344607AEliminate inertiaImprove flow uniformityEvaporators/condensersTubular elementsRefrigerant distributionEngineering

The invention discloses a heat exchanger which comprises a collecting pipe, flat tubes, a fin and a refrigerant distribution device; the flat tubes are distributed in the length direction of the collecting pipe; the fin is positioned between the two lines of flat tubes; the refrigerant distribution device comprises a liquid distribution pipe and a baffle; the baffle is arranged in the length direction of the collecting pipe and divides the interior of the collecting pipe into an upper cavity and a lower cavity; the flat tubes are inserted in the upper cavity of the collecting pipe; the liquid distribution pipe is inserted in the lower cavity of the collecting pipe and penetrates through the collecting pipe in the length direction of the collecting pipe; a liquid outlet allowing a refrigerant to be fed into the lower cavity is formed in the side wall of the liquid distribution pipe; a flowing clearance is formed between one side in the width direction of the baffle at least and the pipe wall of the collecting pipe; the refrigerant flows out through the liquid outlet and enters the upper cavity through the flowing clearance. After flowing through the liquid outlet, the refrigerant is well mixed in the lower cavity and then enters the upper cavity through the flowing clearance, so that the technical problem in the prior art that a perforated plate or a perforated pipe is used, and after the refrigerant flows out through the perforated plate, secondary liquid distribution is non-uniform can be solved. The invention is applied to the field of air-conditioning heat exchangers.

Owner:ZHEJIANG DUNAN THERMAL SCI & TECH

Efficient asphalt rotating film drying oven

InactiveCN104062423AEliminate inertiaRapid heating and coolingMaterial testing goodsTemperature controlEngineering

The invention discloses an efficient asphalt rotating film drying oven which comprises a working chamber, an electromagnetic induction heating device, a hot air outflow receiving device, a rotating disc frame, multiple rotating discs and an automatic temperature control device. The electromagnetic induction heating device is arranged at the bottom of the working chamber, the hot air outflow receiving device is arranged at the top of the working chamber, the automatic temperature control device is arranged on the electromagnetic induction heating device, the rotating disc frame is arranged in the working chamber, and the multiple rotating discs are arranged on the rotating disc frame. By means of the mode, the efficient asphalt rotating film drying oven has the advantages that heating inertia can be eliminated, temperature rise and temperature reduction are rapid and efficient, and the efficient asphalt rotating film drying oven does not need to be installed in a room good in ventilation or a fuming cupboard for use, and is convenient to use and practical.

Owner:无锡市鑫路道路材料有限公司

Method and apparatus for transporting articles to a station

ActiveUS9561614B2Improve dynamic responsivenessContinuous motionConveyorsConveyor partsBlow moldingEngineering

Owner:INTRAVIS GESELLSCHAFT FUR LIEFERUNGEN & LEISTUNGEN VON BILDGEBENDEN & BILDVERARBEITENDEN ANLAGEN & VERFAHREN MBH

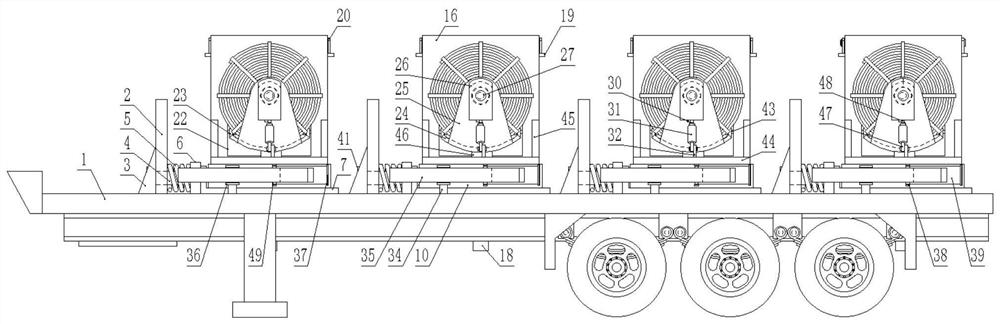

High-safety trailer special for steel coil transportation

ActiveCN113119834AEasy loading and unloadingImprove securityLoad securingReel unit transportationStructural engineeringMechanical engineering

Owner:重庆万马汽车制造(集团)有限公司

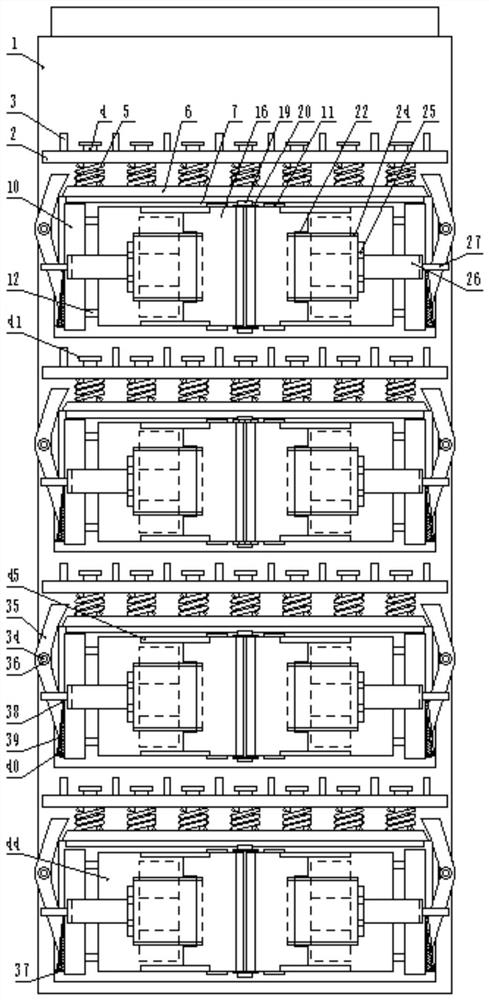

Lathe safety control system based on sound identification

InactiveCN108983684AEliminate inertiaAchieve emergency stop effectProgramme controlTransmission systemsControl systemData transmission

The invention relates to a lathe safety control system based on sound identification. The system comprises a detection system, a control center system and an alarm system. The detection system comprises a sound acquisition module, a sound processing module, an analog-to-digital conversion module and a data transmission module. The control center system comprises a preset data module, a data receiving module, a data processing module and a data transmission module. The alarm system comprises a data receiving module, an alarm module, a display module and an action module. The detection system transmits sound samples to the control center system; and the alarm system responds to the alarm signals sent by the detection system and the control center system. When a lathe injury accident occurs to a worker in a workshop, even if one or other workers cannot come to rescue in time, the system can stop the lathe and send out a rescue signal based on fast and flexible quality of the sound, thereby improving rescue success rate.

Owner:HEZHOU SITONG INFORMATION TECH CO LTD

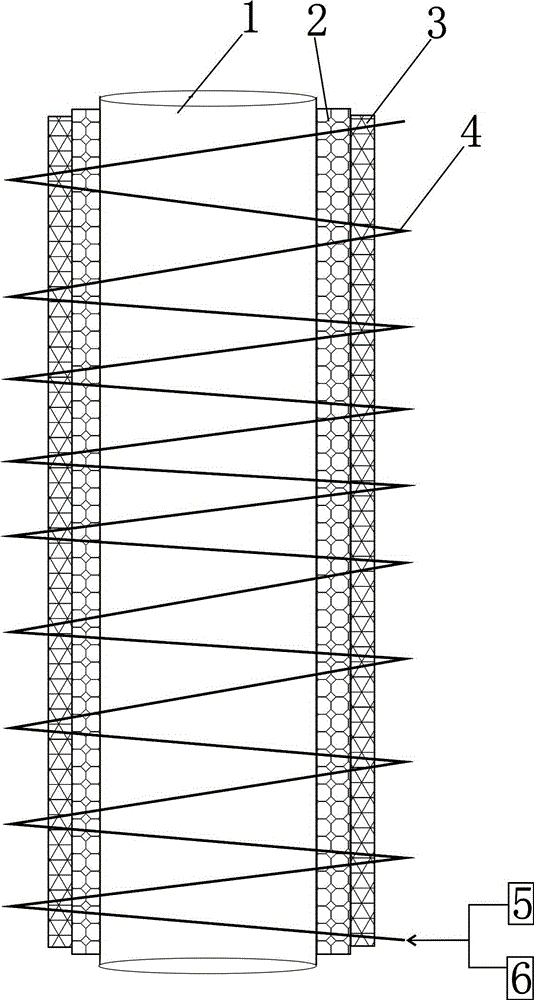

Electromagnetic induction heating cylinder

InactiveCN105163411AEliminate inertiaRapid heating and coolingInduction heating apparatusThermal insulationMetal cylinder

The invention discloses an electromagnetic induction heating cylinder. A thermal insulation layer coats outside the cylinder; an epoxy resin board layer coats outside the thermal insulation layer; an electromagnetic heating coil winds the outer side of the epoxy resin board layer; the thermal insulation layer is insulated cotton; the insulated cotton is tightened and fixed on the periphery of the cylinder through a high-temperature-resistant ribbon; and the epoxy resin board layer is tightened and fixed on the periphery of the thermal insulation layer through the high-temperature-resistant ribbon. According to the electromagnetic induction heating cylinder, a metal cylinder is self-heated through the electromagnetic induction principle; and a thermal insulating material with a certain thickness can coat outside the cylinder according to the specific circumstance, so that the heat loss is greatly reduced; and the thermal efficiency is improved. Therefore, the electricity-saving effect is very significant and can reach 30%-75%.

Owner:NEWORLD PHARMA

Top-blowing and bottom-blowing dual-purpose smelting device

ActiveCN113005256AIncrease the degree of stirringSimple structureManufacturing convertersProcess efficiency improvementStructural engineeringMechanical engineering

The invention discloses a top-blowing and bottom-blowing dual-purpose smelting device which comprises a converter, a converter cover, a support, a driving mechanism for driving the converter to rotate and a converting mechanism, a converter body of the converter is spherical, the converter is rotatably connected with the support, a refractory lining is arranged in the converter, a discharging pipe for discharging smoke is arranged at the connecting position of the converter and the support, the converting mechanism comprises a top-blowing pipe, a bottom-blowing structure and an air-inlet pipe, the top-blowing pipe and the bottom-blowing structure are both fixed to the converter cover, the top-blowing pipe and the converter cover are coaxially arranged, the top-blowing pipe is provided with a fireproof wrapping layer, the bottom-blowing structure is arranged at the inner side of the converter cover, the bottom-blowing structure is cylindrical and can be inserted into a converter opening of the converter, the outer wall of the bottom-blowing structure is tightly attached to the inner wall of the converter opening, the bottom-blowing structure is made of the same material as the refractory lining, a plurality of air holes are reserved in the bottom-blowing structure, all the air holes communicate to the air-inlet pipe, the converter cover and the converting mechanism can synchronously move along with rotation of the converter, and the converting mechanism is further provided with a pipeline control mechanism used for limiting the movement path of the air-inlet pipe.

Owner:浙江友谊新材料有限公司

Superfine stainless steel fibre producing tech.

This invention discloses a preparation method of ultra-fine stainless steel fibre, it includes the processes as fellows: (1) making rough drawing semi product by rough wire drawing machine, (2) making semi fibre product when the rough drawing semi product pass through the fine wire drawing machine, (3) making finished fibre when the semi fibre out of the annealer. The improvement of this invention is that the spinning of the rough drawing semi product is immersed in the lubricating liquid. There is a guide ring at the outlet of the fine wire drawing machine, the semi fiber passes through the guide ring which rotated continuously to furbish and eliminate the burr of the semi fibre.

Owner:NINGYOU SPECIAL METALLIC FIBER PRODS ANHUI

Low-temperature high-power lithium-manganese battery and preparation method thereof

InactiveCN112086655AStable structureLarge specific surface areaElectrode rolling/calenderingElectrode thermal treatmentCarbon compositesEngineering

The invention discloses a low-temperature high-power lithium-manganese battery and a preparation method thereof, the low-temperature high-power lithium-manganese battery is applied to a temperature environment of -40 DEG C, and the discharge current is greater than 3C. The lithium-manganese battery comprises a positive plate, a negative plate, a ceramic diaphragm, an electrolyte and a battery shell, wherein the positive plate, the ceramic diaphragm, the negative plate and the ceramic diaphragm are sequentially and repeatedly laminated to form a dry cell; the lithium-manganese battery is prepared by putting a dry battery cell into a battery shell, injecting an electrolyte, ageing, sealing and ageing, the positive plate and the negative plate are respectively a graphene-based manganese dioxide positive plate and a lithium-carbon composite negative plate, and positive plate reserved tabs are arranged on the front surface and the back surface of the positive plate; and the front and back surfaces of the negative plate are provided with negative plate reserved tabs. According to the present invention, with the application of the optimal material and the optimal process technology, the beneficial effects are completely explained, the high-power discharge performance of the battery in the ultra-low temperature environment is effectively improved, and the lithium ion battery is suitable for the application in the fields of power consumption type electronic digital, special exploration, starting power supplies, military equipment power supplies and the like.

Owner:LONG POWER SYST NANTONG CO LTD

Height-adjustable bus handle

InactiveCN112406660APrevent dumpingImprove anti-roll effectVehicle arrangementsMachineControl theory

The invention discloses a height-adjustable bus handle which comprises a machine body, a first sliding groove is formed in the machine body, second sliding grooves are formed in the upper side wall and the lower side wall of the first sliding groove in a communicating mode respectively, the first sliding groove is communicated with an external space through the second sliding grooves, and two sliding blocks are connected into the first sliding groove in a bilateral symmetry and sliding mode. A limiting buffer device is arranged in each sliding block, the two limiting buffer devices are in central symmetry by taking the center of the first sliding groove as the center, a user can adjust the comfortable height according to the height, and due to arrangement of the buffer devices, when the user topples over, part of inertia can be eliminated, the handle plays a certain role in preventing a human body from toppling to a certain extent, and compared with a completely rigid handle, the anti-toppling handle is more durable in use and better in anti-toppling effect.

Owner:陈良宾

Suspension type multi-dimensional input horizontal multi-directional shearing model casing device

InactiveCN102367674BEliminate inertiaWeaken the effect of vertical vibration characteristicsFoundation testingVertical vibrationUniversal joint

The invention discloses a suspension type multi-dimensional input horizontal multi-directional shearing model casing device, belonging to the technical field of civil engineering. The suspension type multi-dimensional input horizontal multi-directional shearing model casing device comprises a rigid suspension bracket, a rigid bottom plate and a model casing body, wherein the top of the model casing body is hoisted by the suspension bracket and is suspended on the rigid bottom plate, the model casing body comprises more than ten layers of layer structures and a beam frame, wherein each layer structure is rigid and light, and planes of the layer structures are of any same shape, all layer structures are vertically arranged in parallel at equal intervals and are serially connected by using a film or cable, and the film or cable is suspended on the rigid beam frame; the rigid bottom plate is fixedly connected with the rigid suspension bracket and connected with a vibration platform surface together; the beam frame is arranged on the suspension bracket through universal trundles or universal joints in a spanning manner; and the suspension bracket is a rigid wall and is fixedly connected with the rigid bottom plate, and the top of the suspension bracket is provided with a vertical vibration isolation support and a height regulating mechanism. According to the invention, the interference of the model casing to model soil is reduced, the vibration simulation in the vertical direction can be tested, and the model casing is tested in a three-dimensional vibrating manner.

Owner:BEIJING UNIV OF TECH

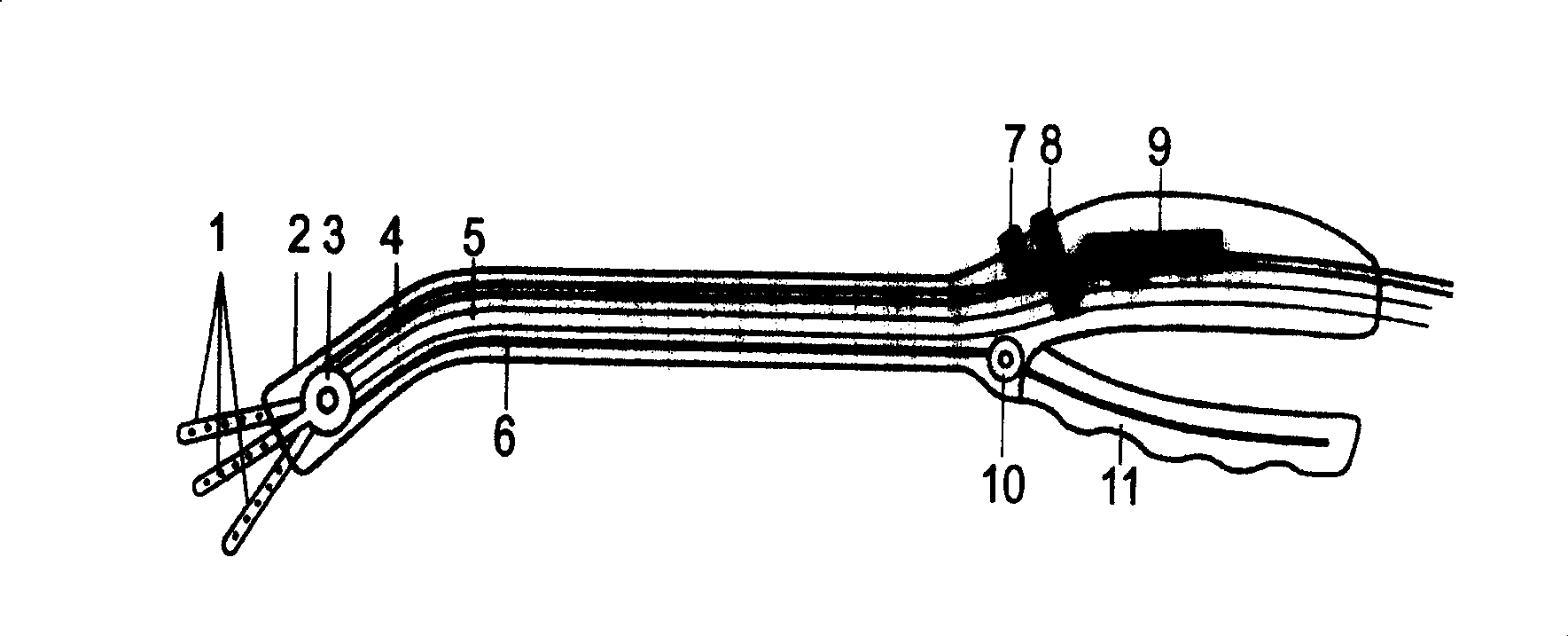

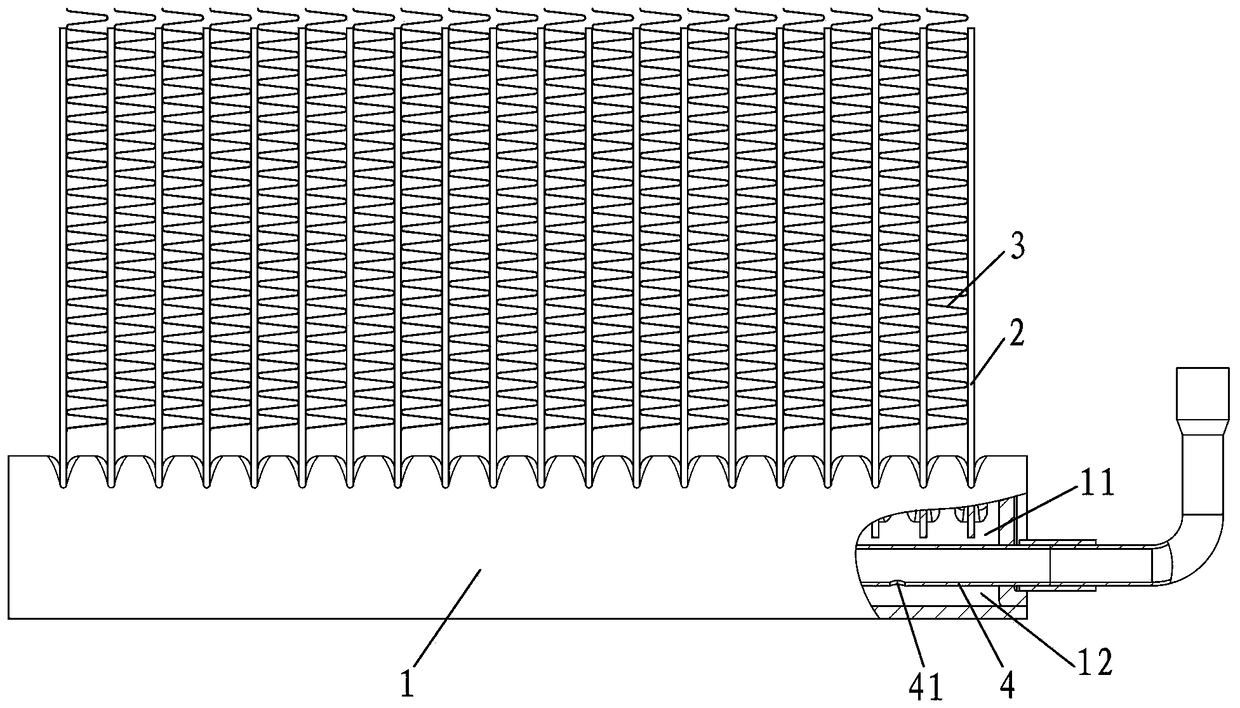

Forked RF liver exsector

InactiveCN100459948CEliminate inertiaSurgical precisionIncision instrumentsWound drainsLiver tissueWater flow

The forked RF liver exsector has one hollow trinacriform obtuse exsector head with side hole and made of conductive material, one main operating button, one circuit board and one HF power source connected together via connecting wires; one water pipe and one water flow regulating button communicated to the exsector head; one rotating joint set on the exsector bar and connected to the exsector head; and one clamping handle connected via one power pull rod and one handle joint on the exsector bar to the exsector head for controlling. During operation, the exsector head is first inserted into liver tissue to be exsected, and the clamping handle is then used to control the closing of the exsector head to exsect obtusely and cure liver tissue. The operation is accurate, fast and safe, and the forked RF liver exsector has compact structure, small size and easy operation.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

a heat exchanger

ActiveCN104344607BEliminate inertiaImprove flow uniformityEvaporators/condensersTubular elementsRefrigerant distributionEngineering

The invention discloses a heat exchanger which comprises a collecting pipe, flat tubes, a fin and a refrigerant distribution device; the flat tubes are distributed in the length direction of the collecting pipe; the fin is positioned between the two lines of flat tubes; the refrigerant distribution device comprises a liquid distribution pipe and a baffle; the baffle is arranged in the length direction of the collecting pipe and divides the interior of the collecting pipe into an upper cavity and a lower cavity; the flat tubes are inserted in the upper cavity of the collecting pipe; the liquid distribution pipe is inserted in the lower cavity of the collecting pipe and penetrates through the collecting pipe in the length direction of the collecting pipe; a liquid outlet allowing a refrigerant to be fed into the lower cavity is formed in the side wall of the liquid distribution pipe; a flowing clearance is formed between one side in the width direction of the baffle at least and the pipe wall of the collecting pipe; the refrigerant flows out through the liquid outlet and enters the upper cavity through the flowing clearance. After flowing through the liquid outlet, the refrigerant is well mixed in the lower cavity and then enters the upper cavity through the flowing clearance, so that the technical problem in the prior art that a perforated plate or a perforated pipe is used, and after the refrigerant flows out through the perforated plate, secondary liquid distribution is non-uniform can be solved. The invention is applied to the field of air-conditioning heat exchangers.

Owner:ZHEJIANG DUNAN THERMAL SCI & TECH

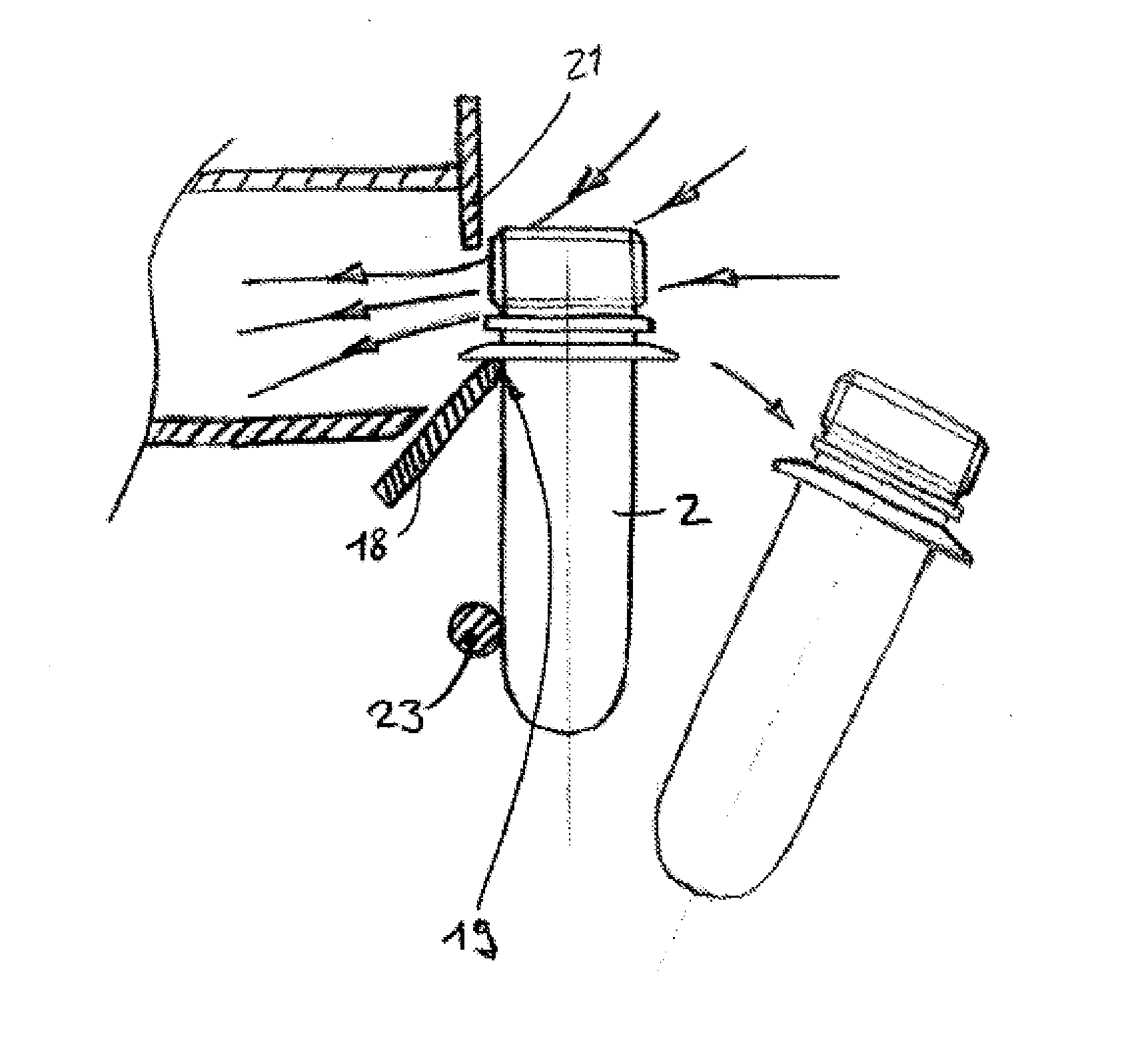

Auxiliary system and method for blank sorting machine

The invention discloses an auxiliary system and method for a blank sorting machine. The auxiliary system for the blank sorting machine comprises a bottle blank detection device, an air injection device, an air supplying device and a controller. The bottle blank detection device is arranged on a column sorting mechanism in the blank sorting machine and used for detecting whether bottle blanks are conveyed or not. The air injection device is arranged on a blank discharging mechanism in butt joint with the column sorting mechanism in the blank sorting machine and used for injecting airflow at the preset speed rate to stabilize the bottle blanks. The air supplying device is communicated with the air injection device and used for supplying air to the air injection device. The controller is electrically connected with the bottle blank detection device, the air injection device and the air supplying device. By means of the auxiliary system and method for the blank sorting machine, blank blocking of the blank sorting machine can be eliminated, and production efficiency is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

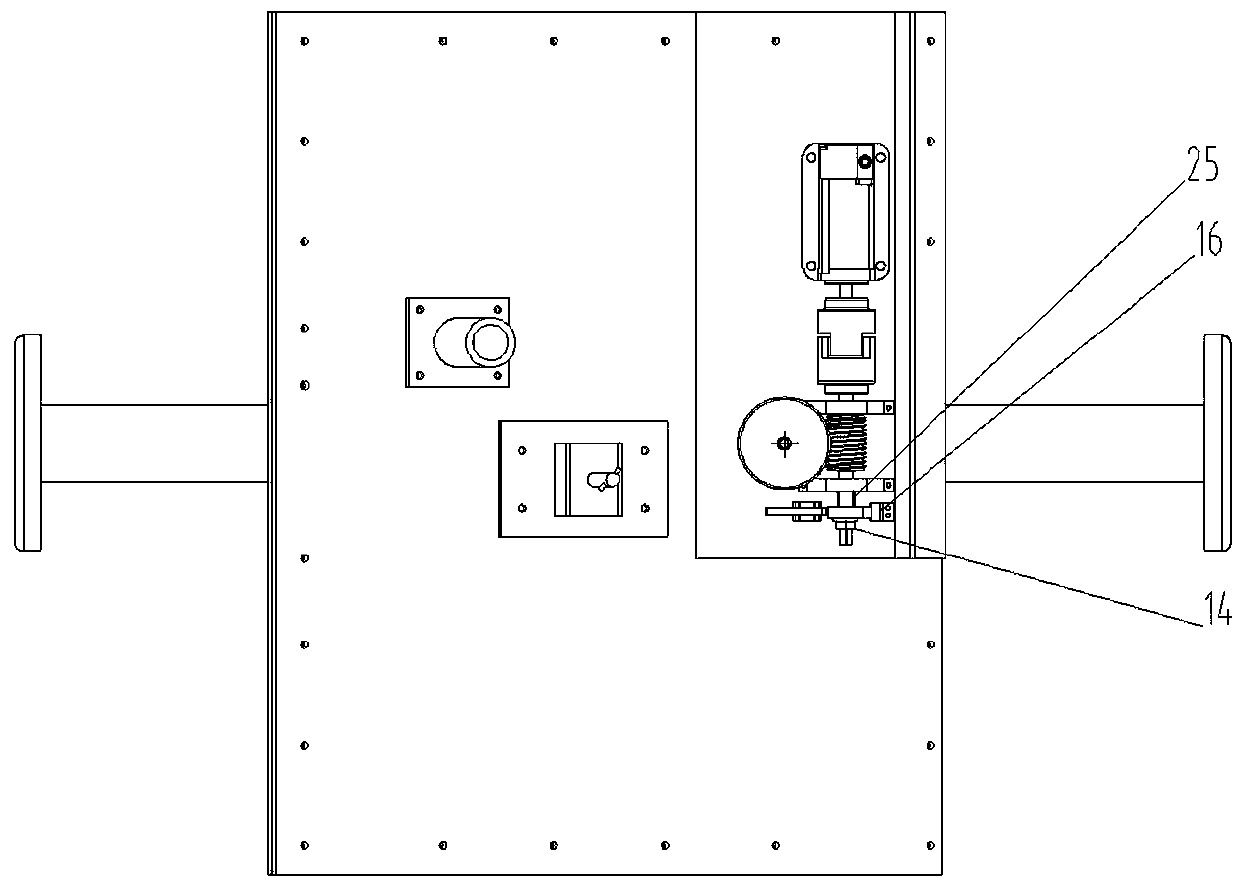

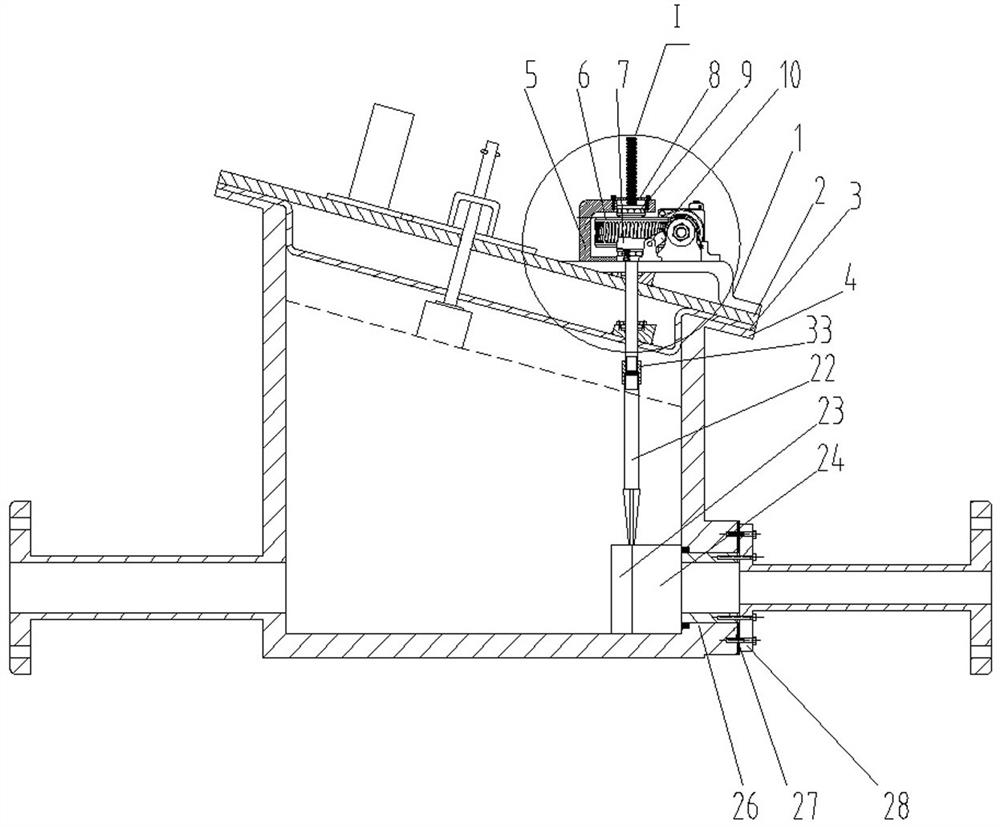

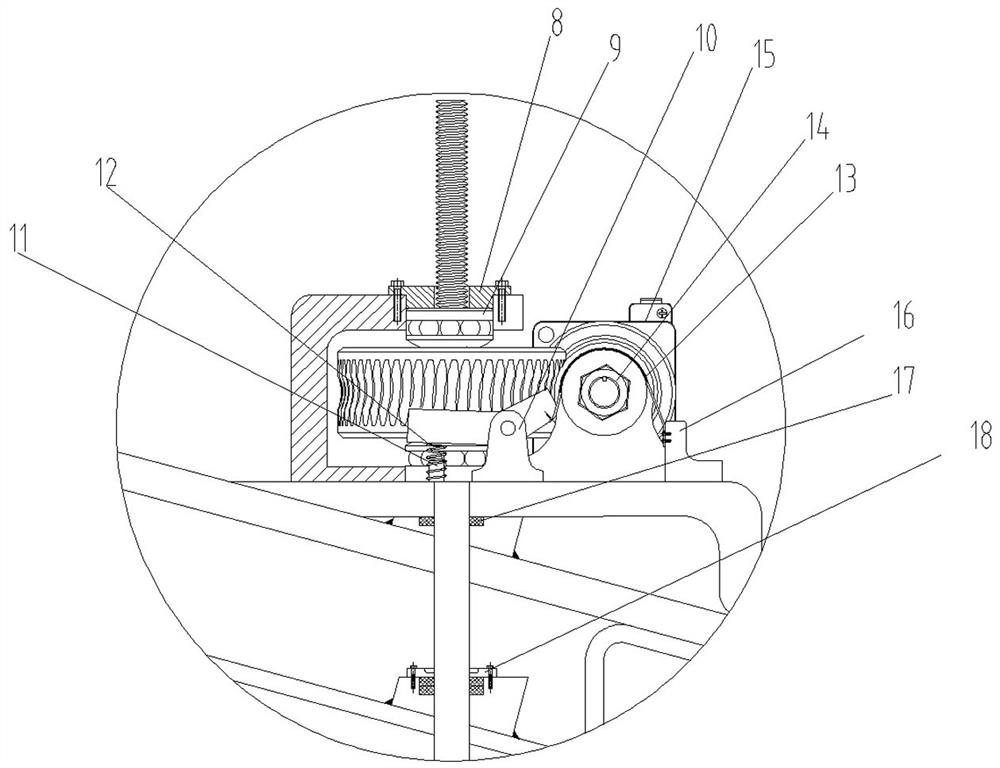

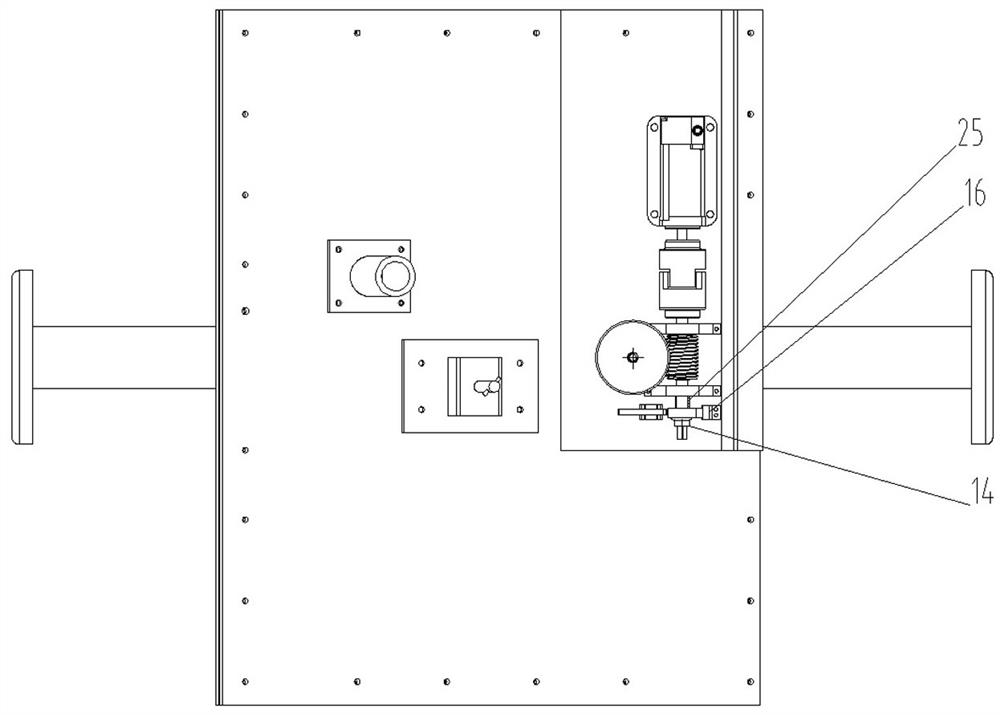

Flow controlling device of gate type magnesium alloy cast rolling machine front box

InactiveCN110394441ALess affected by thermal deformationAccurate flow controlMolten metal pouring equipmentsLocking mechanismMaterials science

The invention provides a flow controlling device of a gate type magnesium alloy cast rolling machine front box, and belongs to the field of magnesium alloy cast rolling. The device mainly comprises atransmission device, a transmission locking mechanism, a detachable gate flow controlling valve and a sealing device, wherein the transmission device is connected with a gate of the detachable gate flow controlling valve to drive the gate to move up and down, the transmission device is connected with the transmission locking mechanism in series and is arranged on the upper side of the outer surface of the front box, and the sealing device is arranged on a gate connecting rod of the detachable gate flow controlling valve in a sleeved mode. According to the device, the gate is driven by the transmission device to move up and down, the transmission locking mechanism is connected with the transmission device in series, so that accurate control to the flow of a valve port is ensured; the improved detachable gate flow controlling valve solves the sticking problem generated after the valve is thermally deformed, the replacement is convenient, so that the labor intensity of workers is reduced,and the production efficiency is improved; and according to the overall structure of the flow controlling device, a good way is provided for a simple, safe and reliable sealing mode, and under a high-temperature environment, the device has outstanding advantages in the aspects of flow controlling precision and overall sealing performance of the structure.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

A flow control device for the front box of a gate-type magnesium alloy casting and rolling mill

InactiveCN110394441BLess affected by thermal deformationAccurate flow controlMolten metal pouring equipmentsEngineeringGate control

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

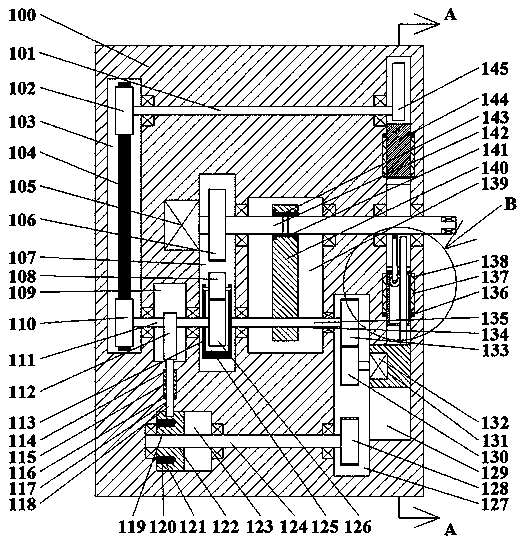

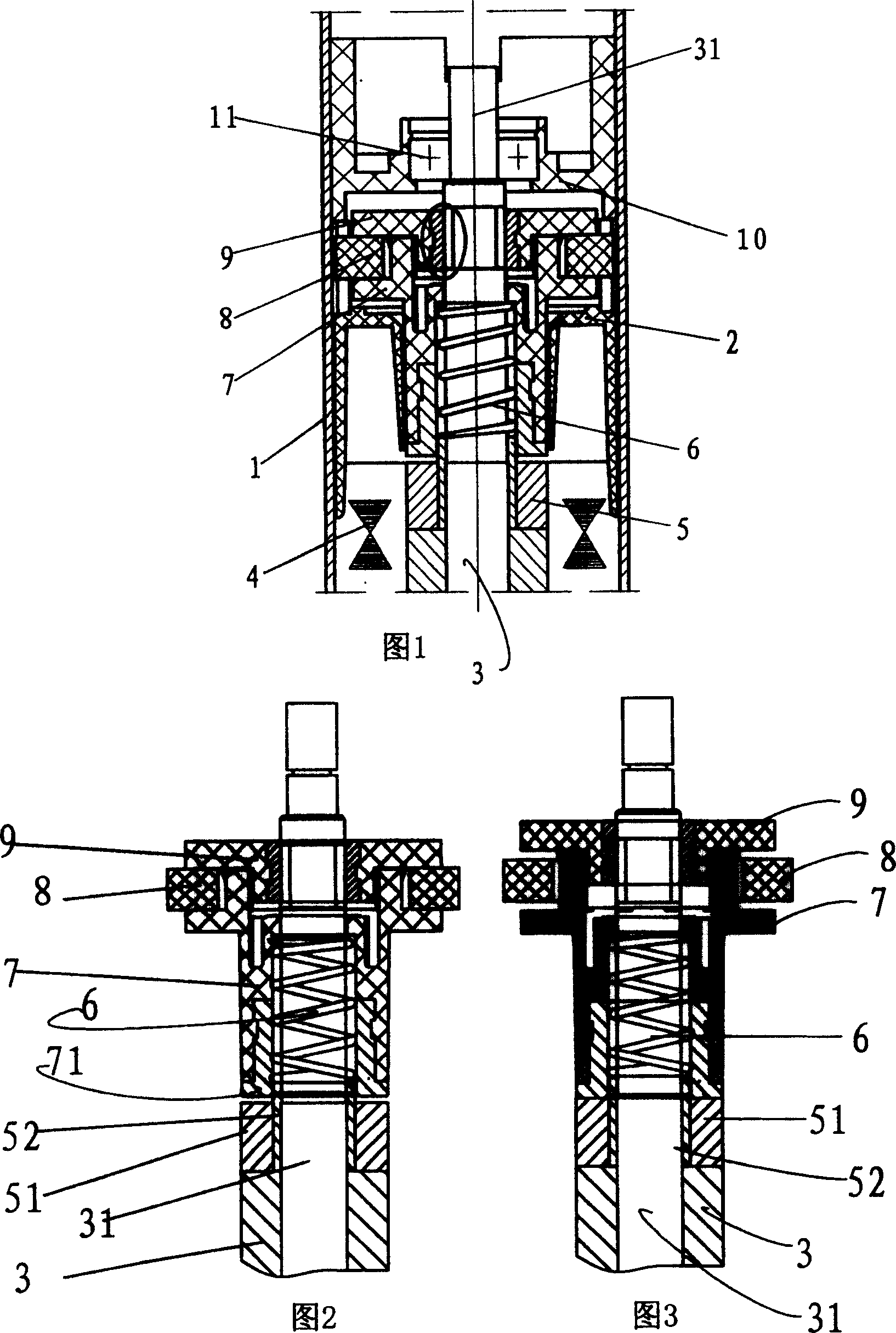

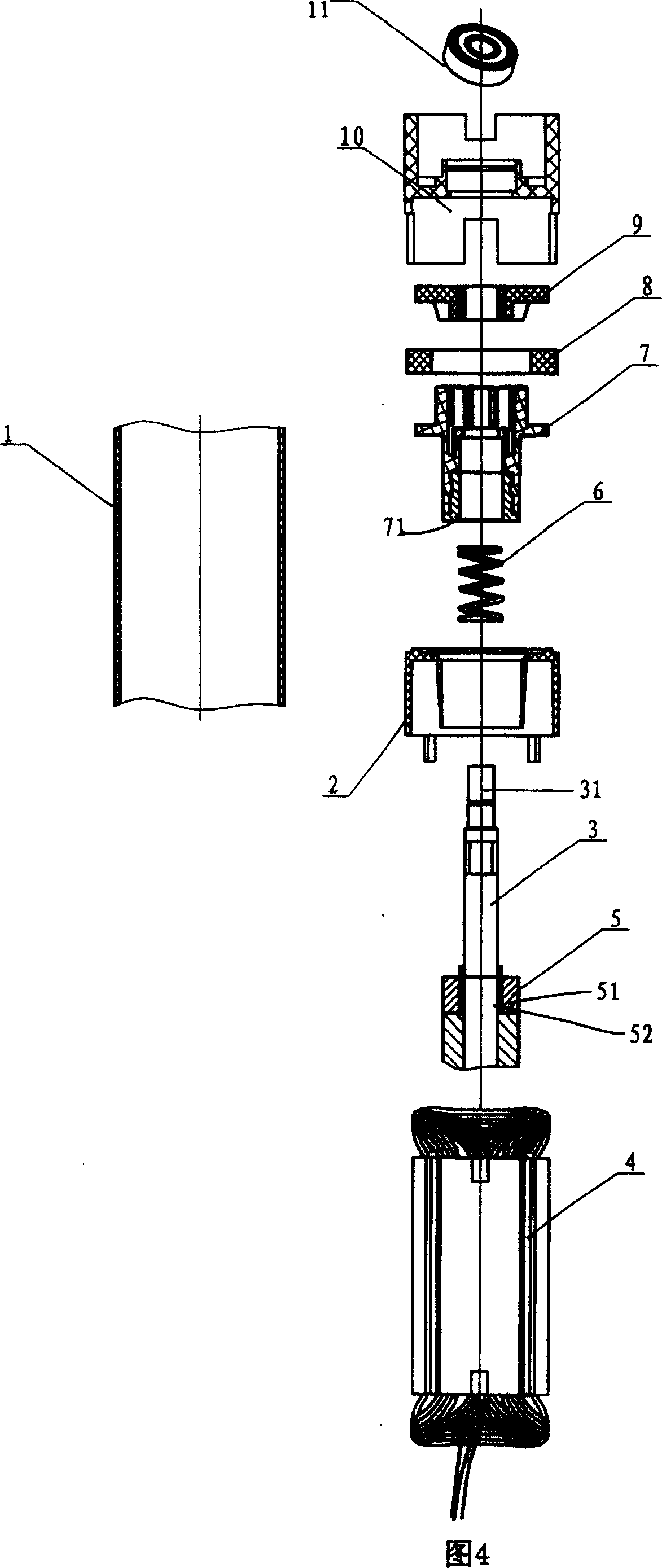

Tube shaped electric machine brake device

InactiveCN1333179CEliminate inertiaControl stallAxially engaging brakesBrake actuating mechanismsElectric machineMetal

The invention is a tubular electric machine arrester, comprising rotor component, stator component and brake assembly equipped in an electric machine casing, where the brake assembly comprises brake spring and brake component, the braking spring is jacketed on the upper rod of rotor shaft of the rotor component; the brake component cooperating lower and upper brake components, the lower brake component is installed with metal iron; the bottom end of the upper rod of the rotor shaft is embedded with an iron-attracting electric machine shaft component whose lower end surface is jointed with the upper end surface of the rotor; the iron-attracting electric machine shaft component uses the magnetic force generated by the rotor to attract the metal iron in the lower brake component to be closed; the lower brake component compresses the brake spring to make it break away from the upper brake component. The invention has an advantage of simultaneously generating damping forces on two surfaces and can accurately and quickly brake and save energy and reduce noises.

Owner:华如祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com