Heat exchanger

A heat exchanger and header technology, applied in heat exchange equipment, evaporator/condenser, lighting and heating equipment, etc., can solve the problems of processing cost limitation, uneven secondary distribution, small inertia effect, etc., to achieve Improve flow uniformity and eliminate inertia effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

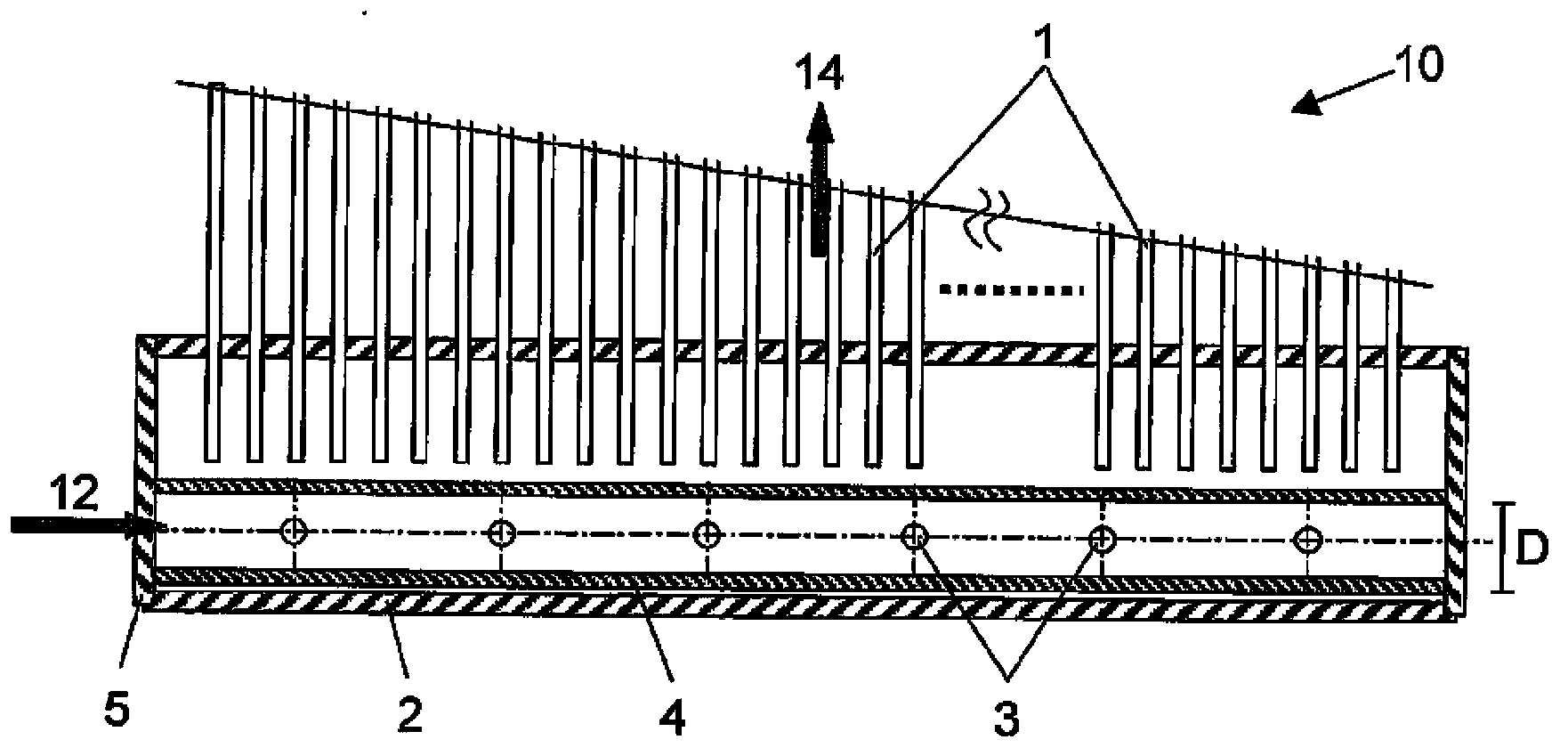

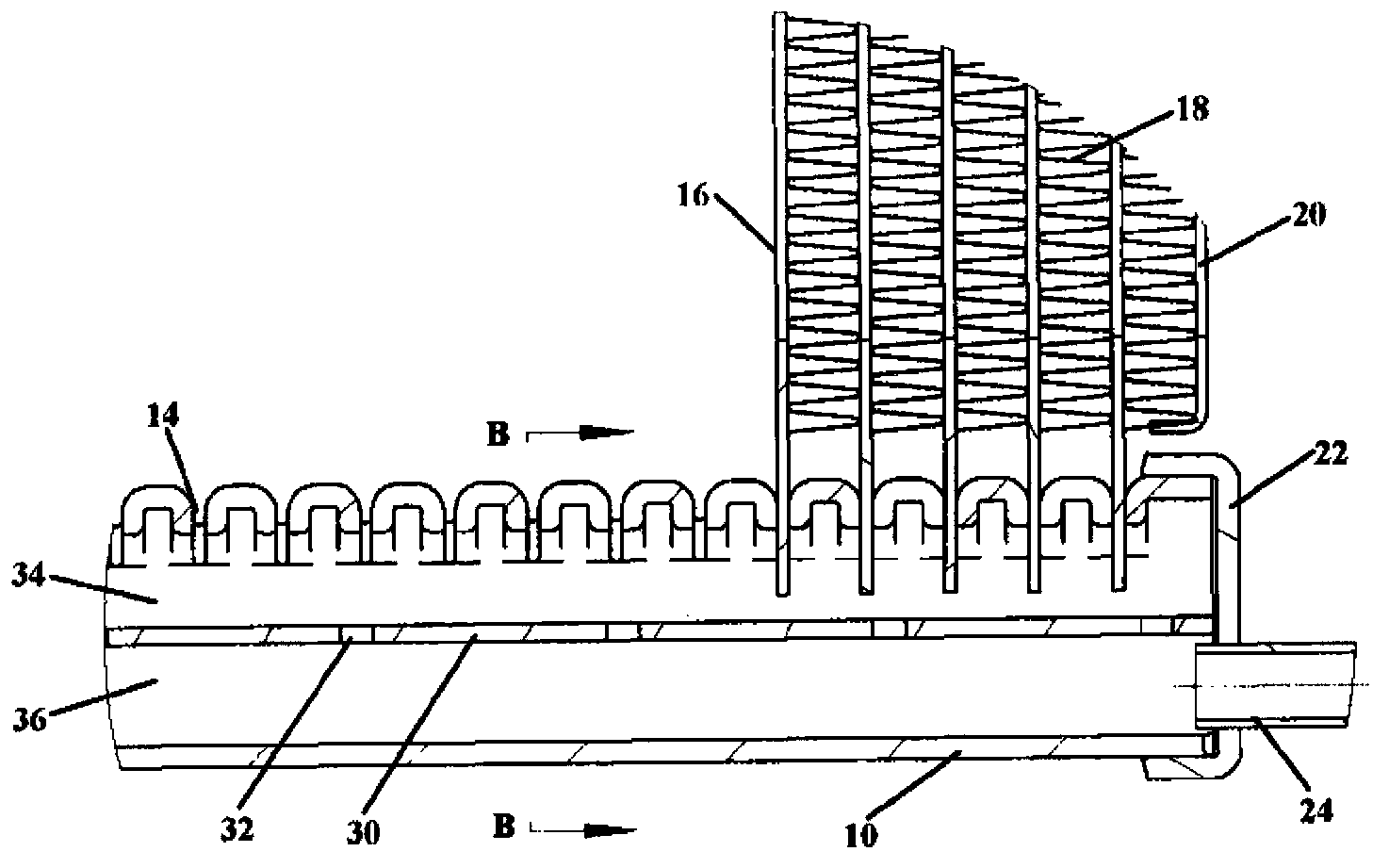

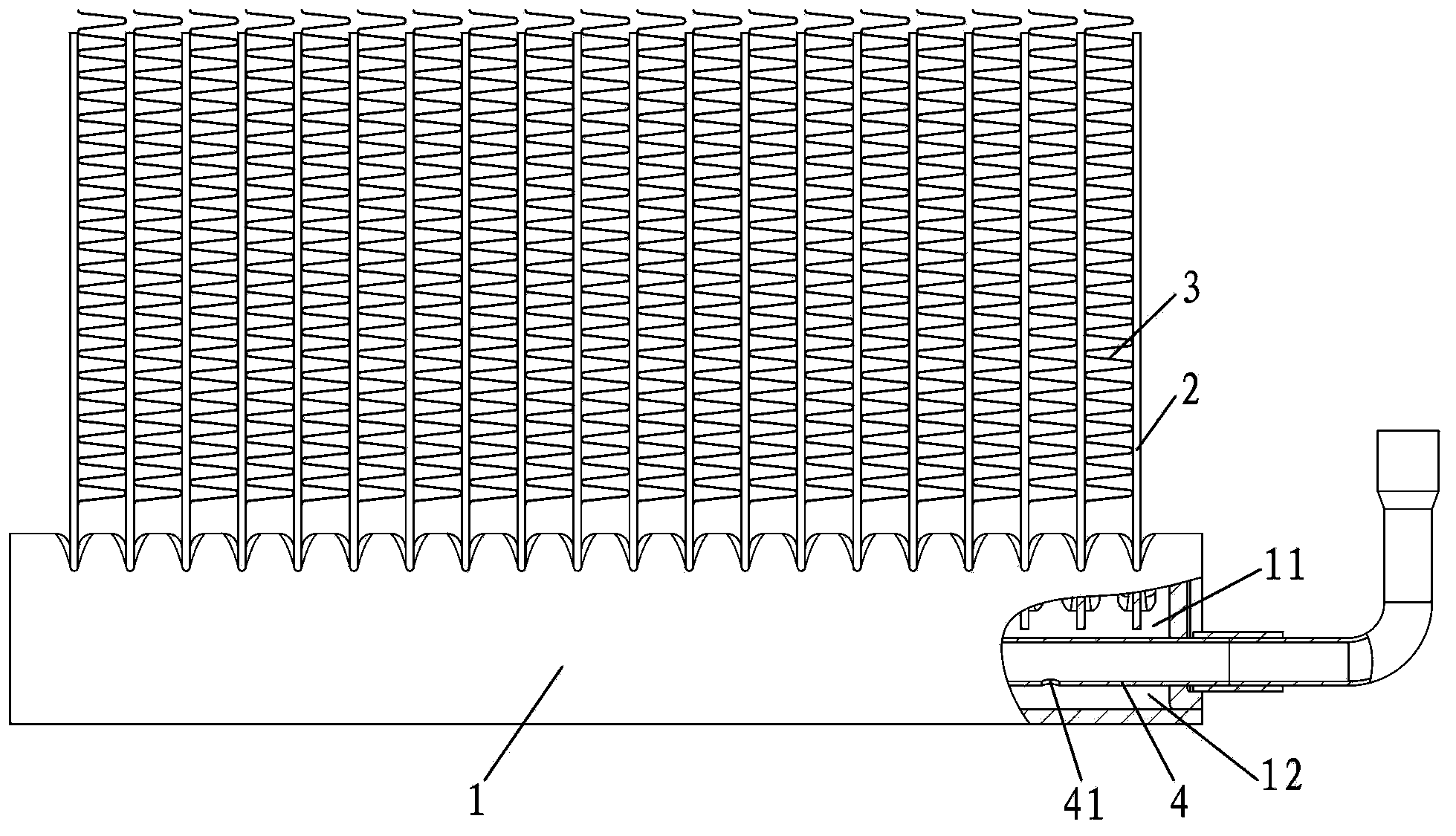

[0034] Reference Figure 3 to Figure 5 , Is a heat exchanger of the present invention, comprising a header 1, a flat tube 2, a fin 3 and a refrigerant distribution device. The flat tube 2 is distributed along the length of the header 1, and the fin 3 is located Between two adjacent rows of flat tubes 2, the refrigerant distribution device includes a liquid dividing tube 4 and a baffle 5, the baffle 5 is arranged along the length of the header 1 and divides the interior of the header 1 into an upper cavity 11 And the lower cavity 12, the flat tube 2 is inserted into the upper cavity of the header, the liquid distribution tube 4 is inserted into the lower cavity of the header and penetrates the header 1 along the length of the header 1. The tube side of the liquid distributor 4 The wall is provided with a liquid outlet 41, the heat exchanger is installed vertically, the two sides of the liquid distribution pipe 4 in the width direction are respectively provided with baffles 5, an...

Embodiment 2

[0036] Please refer to Image 6 The difference of this embodiment is that the heat exchanger is installed vertically, the two sides of the liquid distribution pipe 4 in the width direction are provided with baffles 5, and the baffle 5 on one side is between the pipe wall of the collecting pipe 1. An overcurrent gap 51 is formed. This side is the windward side of the heat exchanger. The arrow direction in the figure is the wind direction. Since the overcurrent gap 51 is arranged on the windward side, the microchannel holes in the flat tube 2 near the windward side correspond to each other. More refrigerant is distributed than the microchannel holes of the flat tube 2 on the side far from the windward side, and the heat exchange efficiency of the windward side refrigerant is higher than that of the leeward side refrigerant, thus improving the overall heat exchange efficiency of the heat exchanger. The outlet direction of the outlet hole 41 is consistent with the direction of gravi...

Embodiment 3

[0038] Please refer to Figure 7 The difference of this embodiment is that the heat exchanger is installed vertically, the baffle 5 is arranged above the liquid distribution pipe 4, and an overflow gap 51 is formed between both sides of the baffle 5 and the pipe wall of the header 1. The outlet direction of the outlet hole 41 faces ten o'clock. In addition, the outlet direction of the outlet hole 41 can also be other directions, preferably the straight line distance from the outlet port 41 to the overflow gap. It is the maximum value. At this time, the refrigerant flow distance is long, which is conducive to full mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com