Tube shaped electric machine brake device

A technology of braking device and tubular motor, which is applied to electromechanical devices, electric components, brake types, etc., can solve the problems of inability to meet the needs of braking and braking, unsatisfactory braking effect, unsuitable for light load and no-load, etc., and achieves a simple assembly process. Reliable, guaranteed service life, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

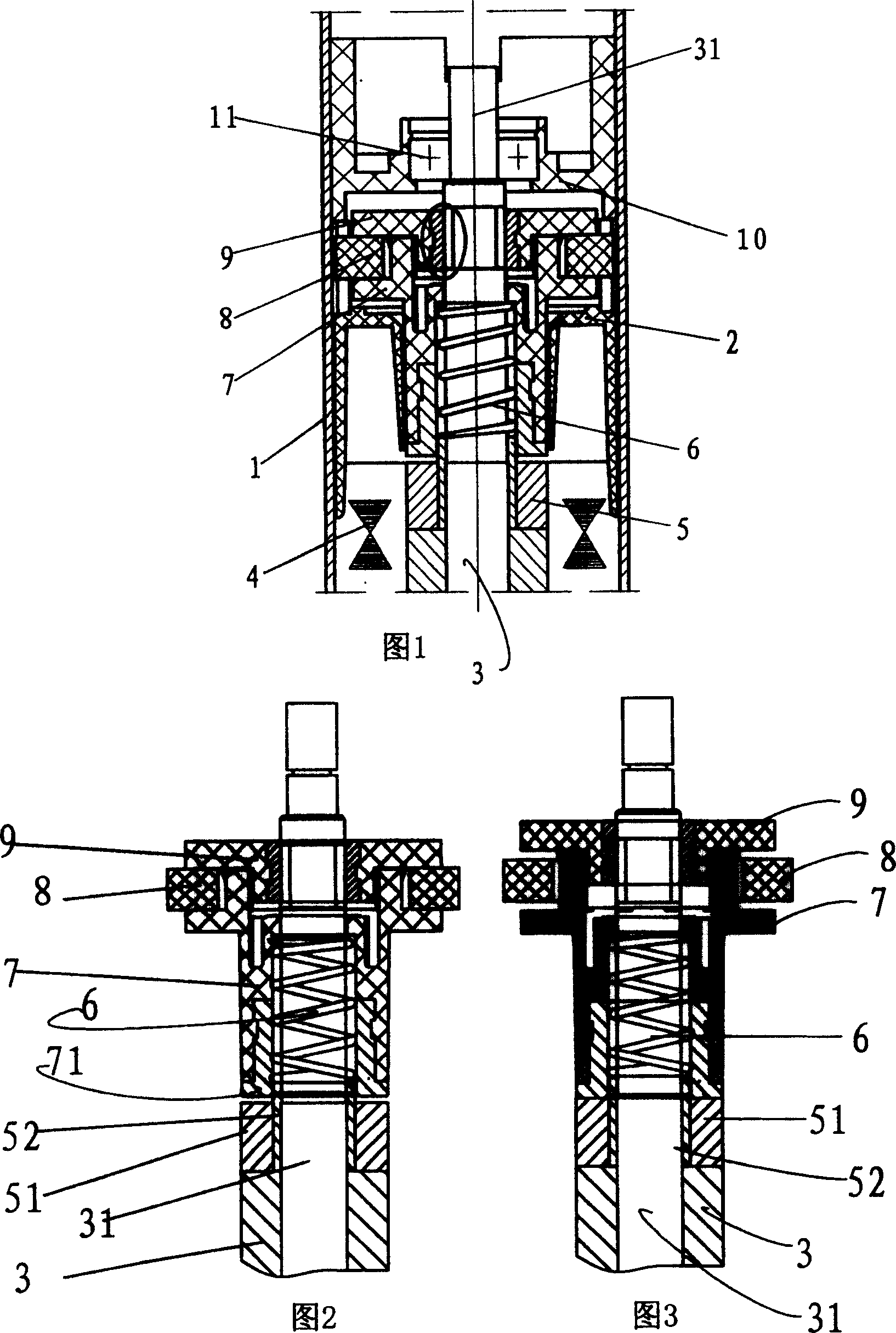

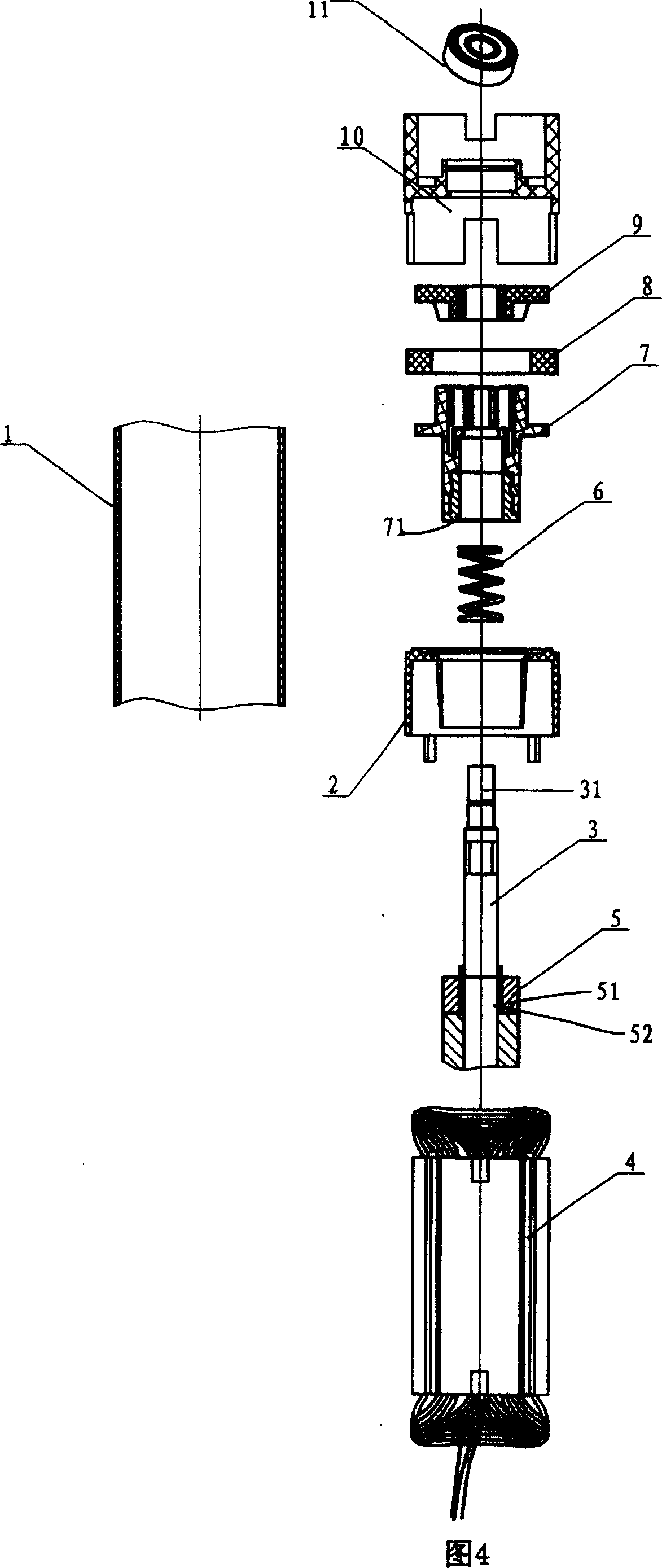

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] As shown in Fig. 1 to Fig. 4, the icons illustrate, the motor casing 1, the motor sheath 2, the motor rotor 3, the motor stator 4, the motor shaft iron absorption assembly 5, the brake spring 6, the lower brake assembly 7, the middle brake assembly 8, the upper Brake assembly 9, brake bearing seat 10, bearing 11.

[0018] Tubular motor brake brake device, including motor rotor assembly, motor stator assembly, and brake assembly fitted in the cavity of the motor housing 1, the brake assembly includes a brake spring 6 and a brake assembly, the brake spring 6 is set on the motor rotor assembly The upper rod portion of the rotor shaft 31, the brake assembly includes a lower brake assembly 7 and an upper brake assembly 9 that match and have a braking effect, and the lower brake assembly 7 is embedded with a metal iron 71; the bottom end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com