A flow control device for the front box of a gate-type magnesium alloy casting and rolling mill

A magnesium alloy, casting and rolling mill technology, applied in the field of magnesium alloy casting and rolling, to ensure tight closure, accurate flow control, and little influence by thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Based on the solutions in the present invention, all other solutions obtained by those of ordinary skill in the art without creative work are all Belong to the protection scope of the present invention.

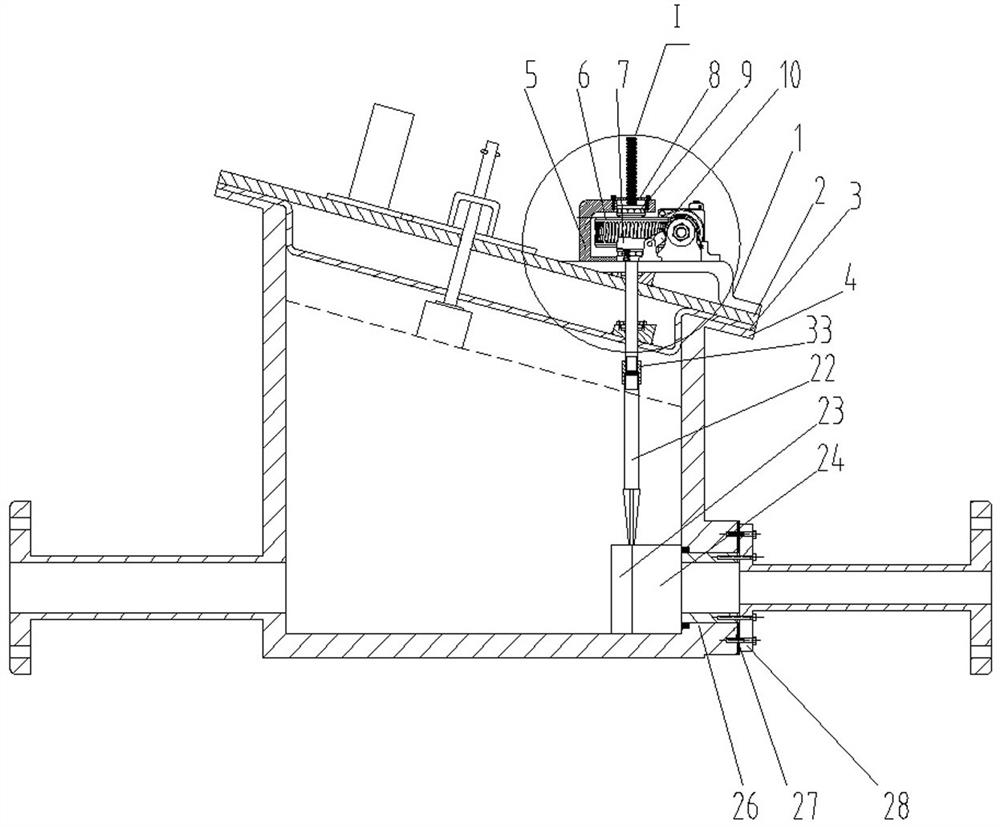

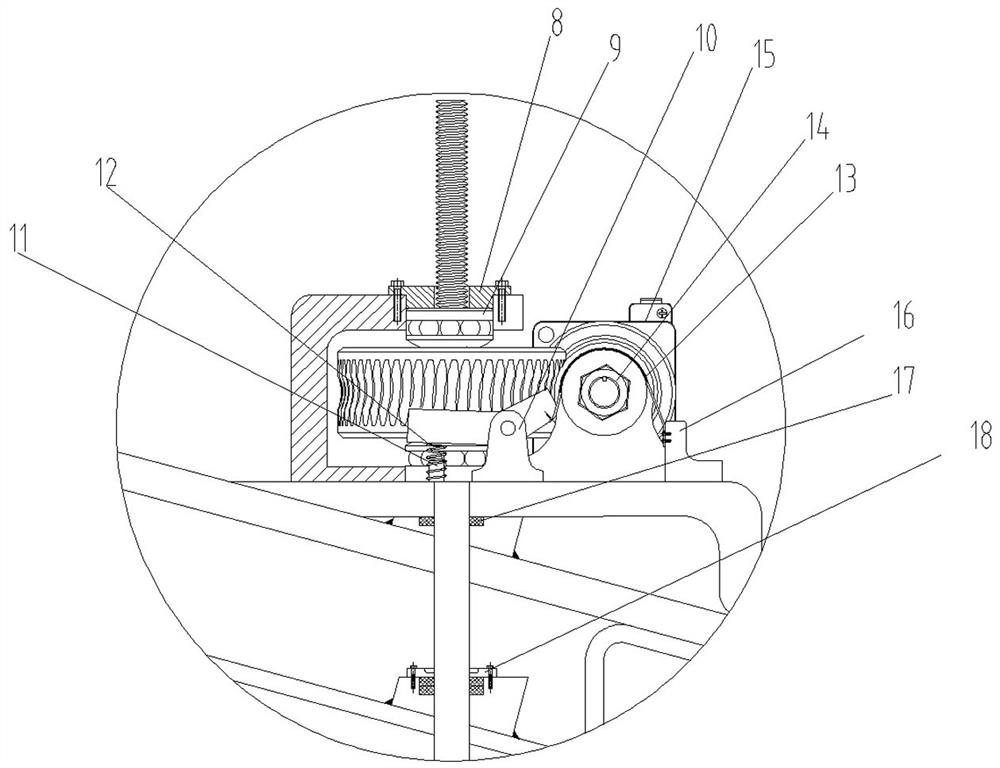

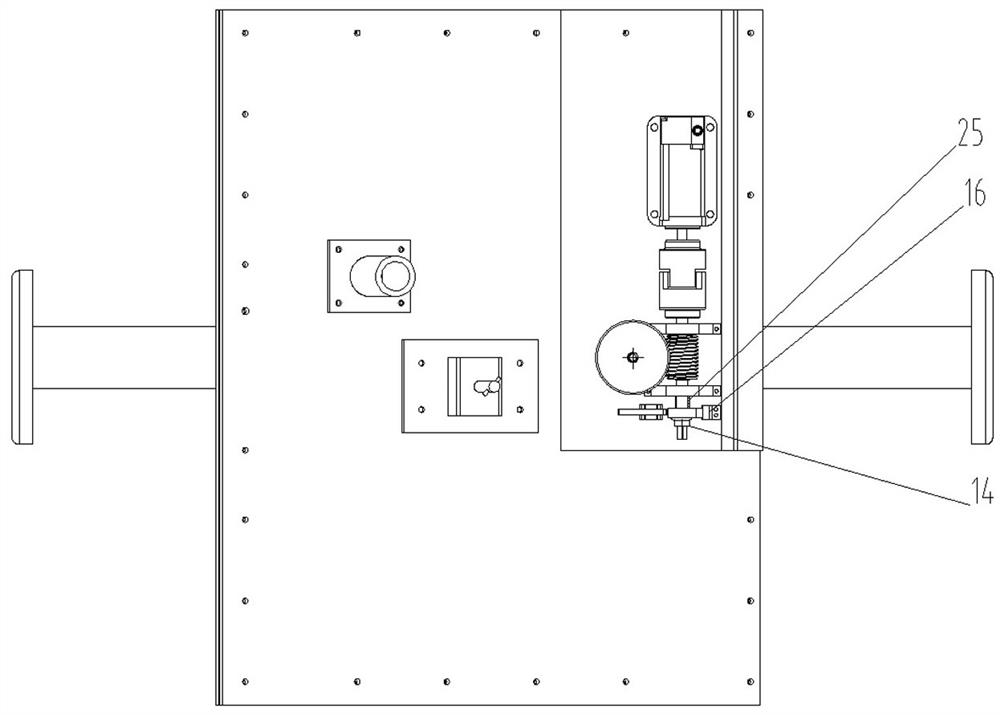

[0022] The present invention will be described below in conjunction with accompanying drawing, as Figure 1-7 As shown, the present invention provides a flow control device for the front box of a gate-type magnesium alloy casting and rolling mill, which is suitable for high-temperature environments, is less affected by thermal deformation, has precise flow control, and good airtightness. It mainly includes a transmission device, a transmission lock Mechanism, detachable gate flow control valve and sealing device, wherein the transmission device is connected with the gate of the detachable gate flow contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com