A corrugated plate welding control system based on beckhoff system

A control system and corrugated plate technology, applied in the field of corrugated plate welding control system and corrugated plate welding equipment system, can solve the problems of high operation threshold, complicated communication methods, low reliability, etc., and achieve high tracking accuracy and scalability Strong and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

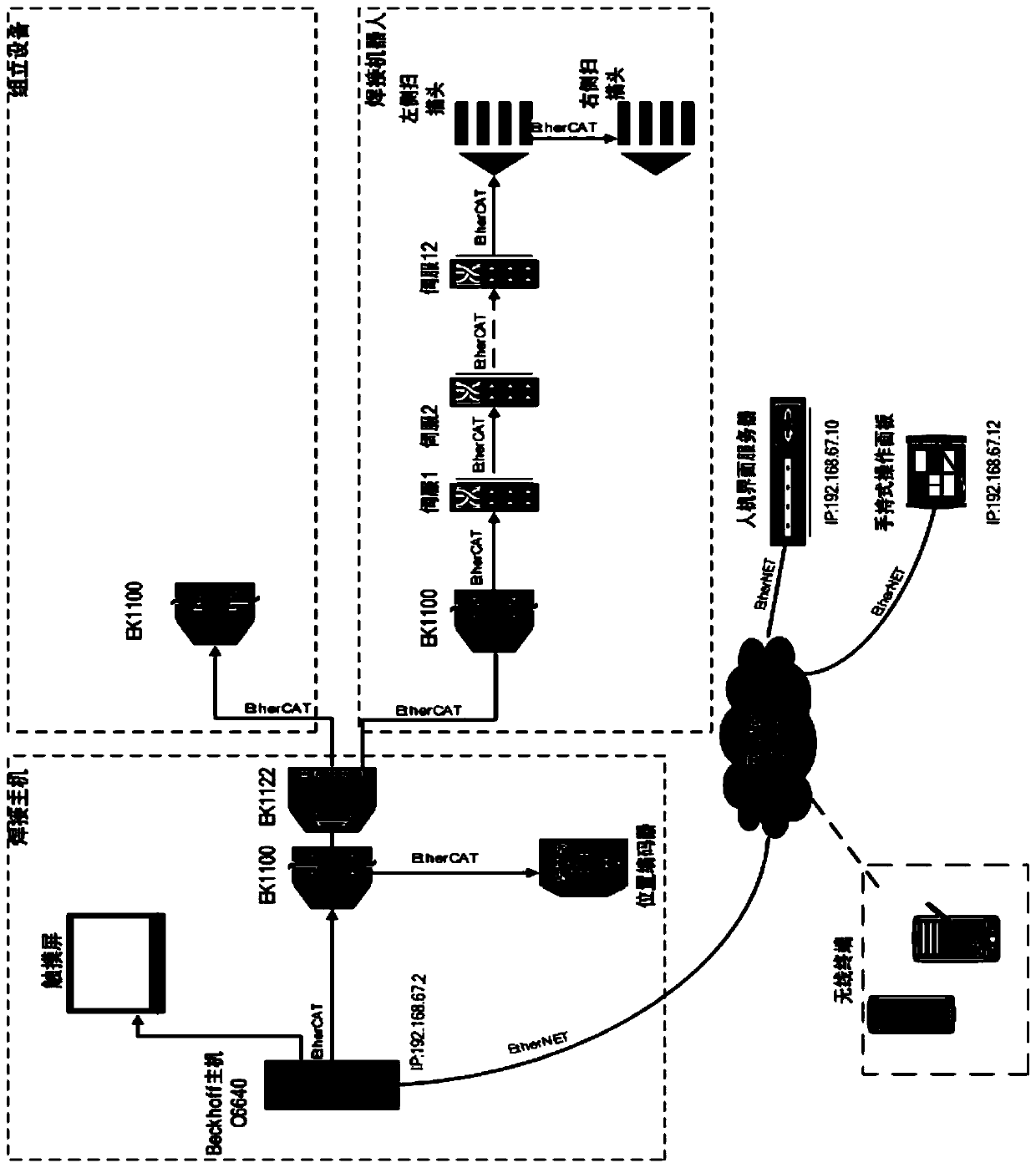

[0015] Please refer to the attached figure 1 As shown, the present invention is a corrugated plate welding control system based on the Beckhoff system, which is composed of welding host, BECKHOFF host, assembly equipment, welding robot, wireless router, and man-machine exchange equipment. The control object is corrugated Plate welding production line.

[0016] Wherein, the BECKHOFF host is arranged in the welding host, which is connected to several Beckhoff remote bus coupling modules through the EtherCAT communication protocol. The Beckhoff remote bus coupling modules are respectively arranged in the welding host, the assembly equipment and the welding robot.

[0017] The welding robot includes several servo motors and scanning devices, and the servo motors and scanning devices are also connected to the Beckhoff remote bus coupling module through the EtherCAT communication protocol. In this embodiment, there are 12 servo motors, which communicate with the BECKHOFF host thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com