Auxiliary system and method for blank sorting machine

An auxiliary system and preform unscrambling machine technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as preform jamming, overturning, preform sliding instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below:

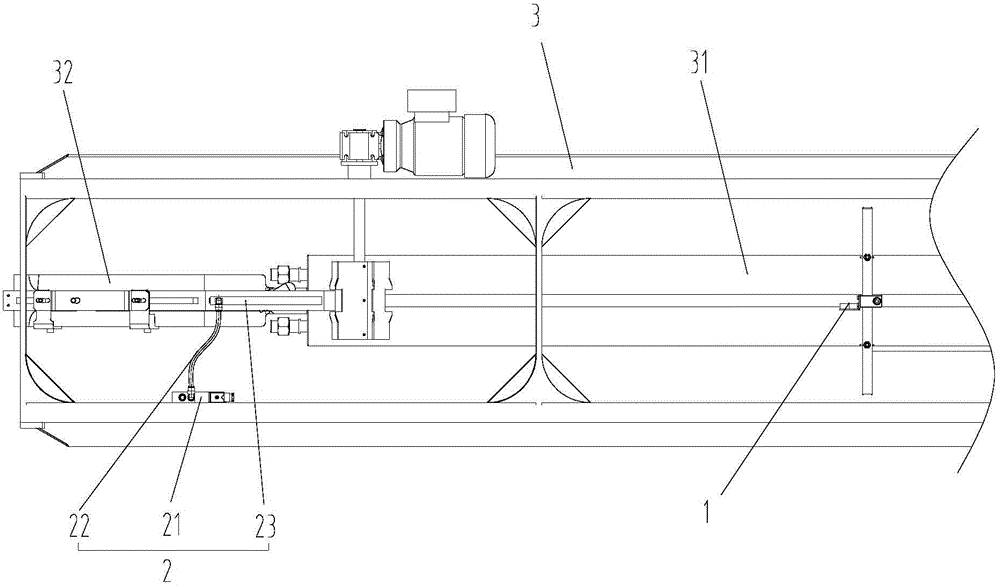

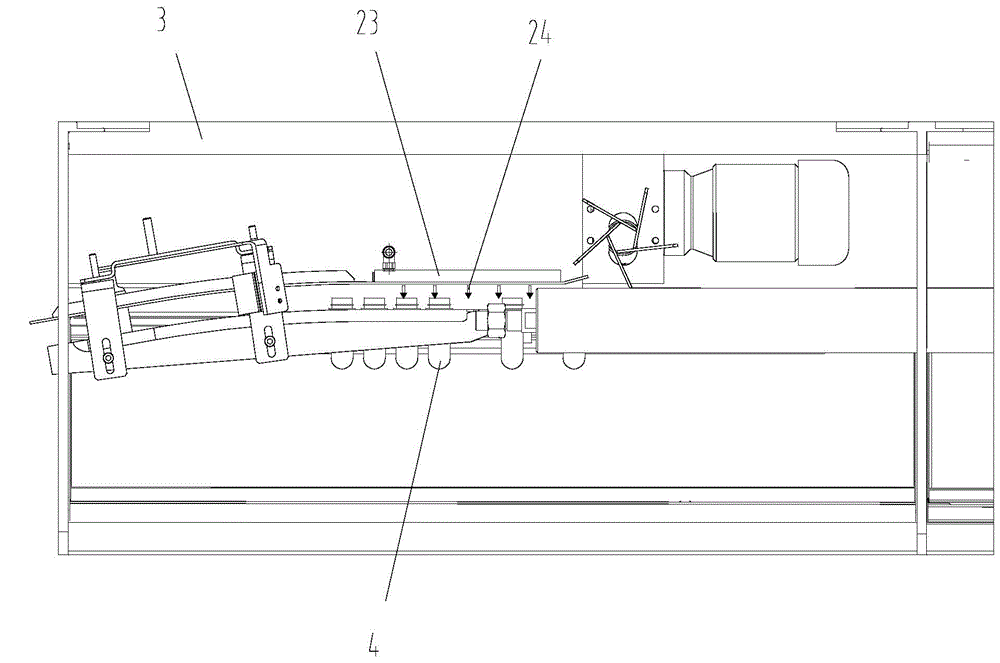

[0027] like Figure 1-2 As shown, it is an auxiliary system of a preform unscrambling machine, including: a preform detection device 1, which is arranged on the alignment mechanism in the preform unscrambling machine 3, and is used to detect whether there is a preform 4 conveyed; an air injection device 2, which is arranged on the The unscrambler 3, which is connected to the alignment mechanism, is used to spray an airflow at a predetermined rate that can stabilize the bottle blank 4; Air supply; controller, which is electrically connected with the preform detection device 1, the air injection device 2, and the air supply device respectively. Wherein, when the preform detection device 1 detects that there is a preform 4 transported on the alignment mechanism in the preform unscrambler 3, the information is transmitted to the controller, and the controller opens the air injection device 2 and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com