Lifter suspended by multiple cables and balanced by tail cable

A hoist, balanced technology, which is applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems of no obvious improvement in equipment weight and energy consumption, and limitations that are difficult to overcome, and achieve safe operation and reliable technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

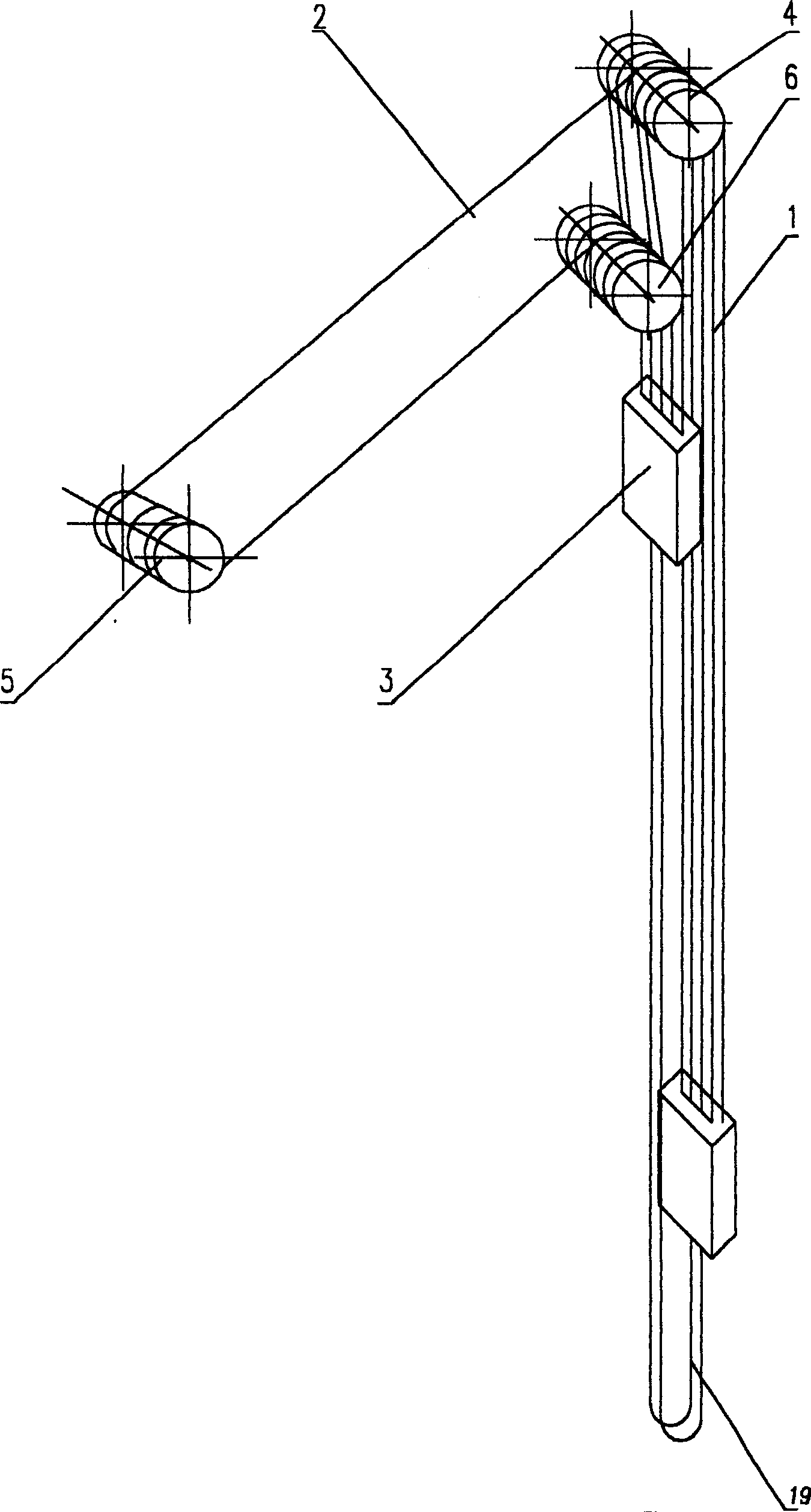

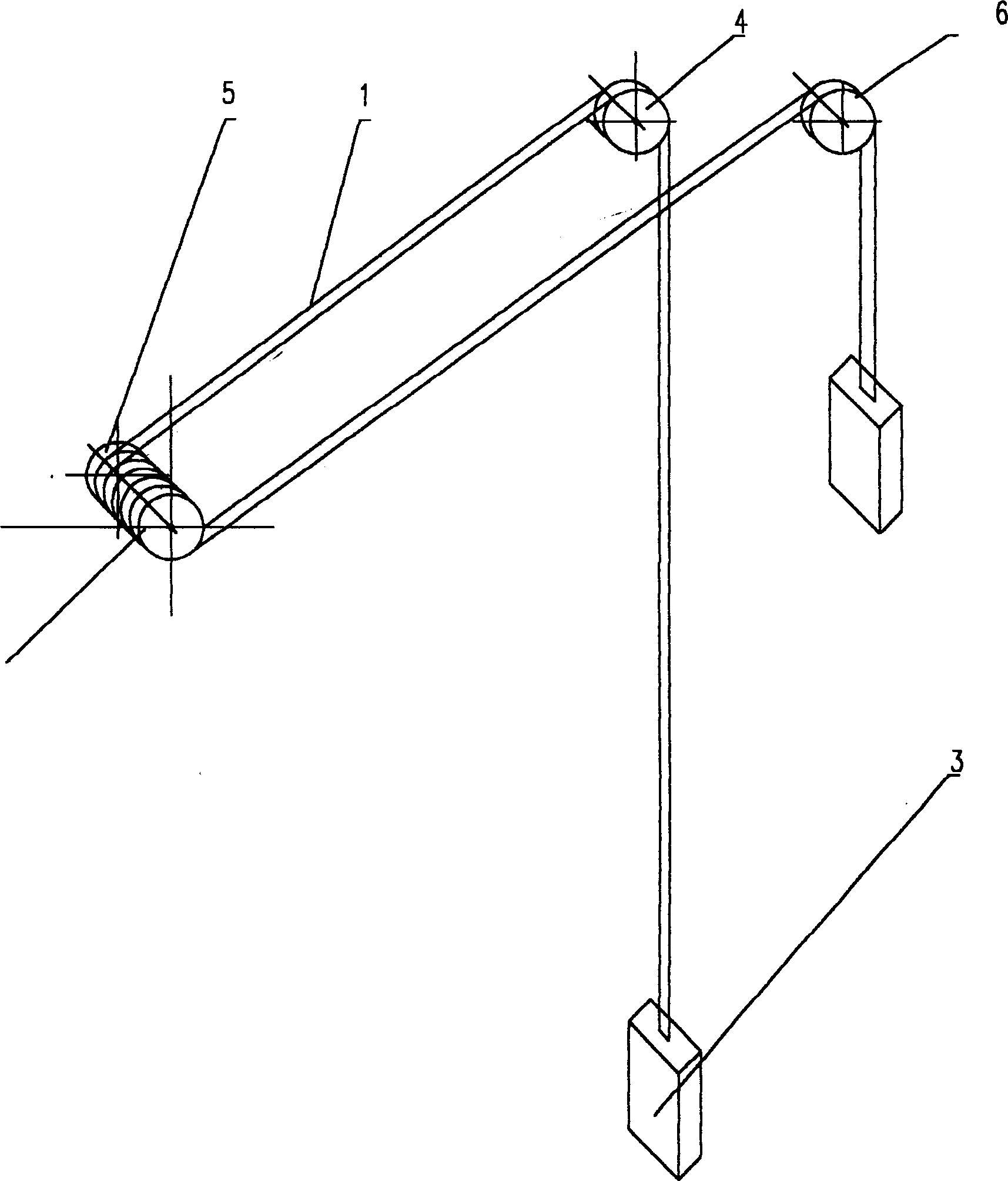

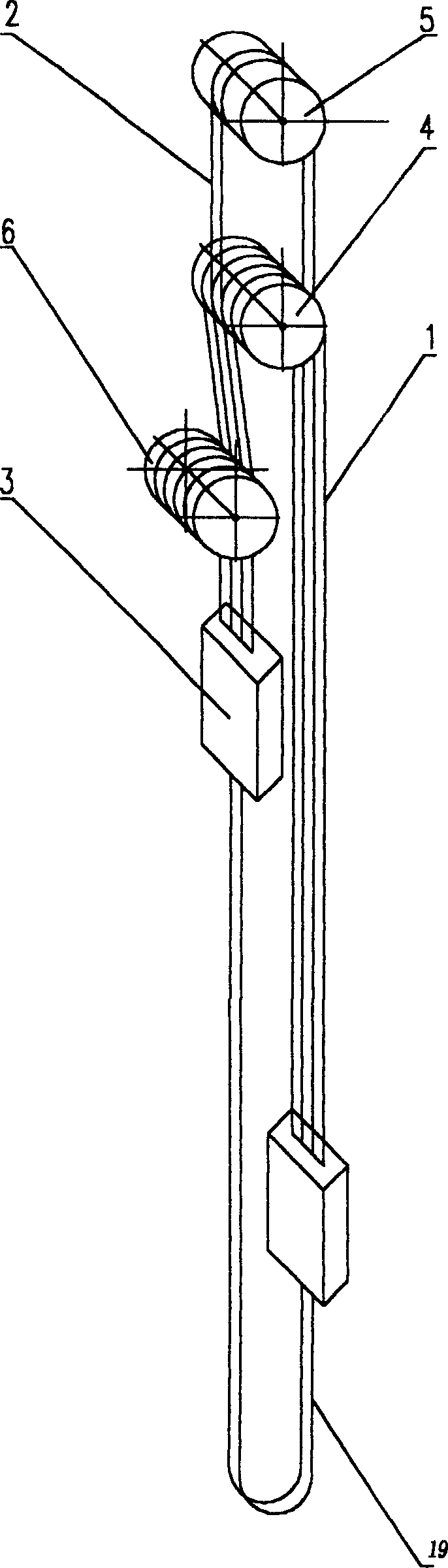

[0029] The structure of the hoist of the present invention is shown in the accompanying drawings. One end of the driving steel rope (single-rope winding drive or multi-rope winding drive) is fixedly connected to the driving drum of the winding hoist according to the upper and lower ropes respectively. The other end of rope is articulated with the hoisting container through the upper sky wheel set (or balance wheel). The other end of going out rope is articulated with another hoisting container through lower sky wheel group around. The two ends of the tail rope are connected with the lower parts of the two hoisting containers respectively. The even-numbered suspension steel ropes are placed on the upper sky wheel group (or balance wheel), and its two ends are respectively articulated with the steel rope connectors of the steel rope tension full-automatic balancing devices on the two hoisting containers. The sky wheel set (or balance wheel) bears the whole weight of the hoistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com