Modified fiber reinforced anticorrosive paint, and preparation method and application thereof

A technology for modifying fibers and anti-corrosion coatings, applied in the field of coatings, can solve the problems that the excellent anti-corrosion properties of anti-corrosion coatings cannot be well exerted, the dispersibility of functional filler media is not good, and the impact resistance of coatings is affected. Suitable for mass production and application, the effect of alleviating fatigue cracking and peeling, avoiding fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

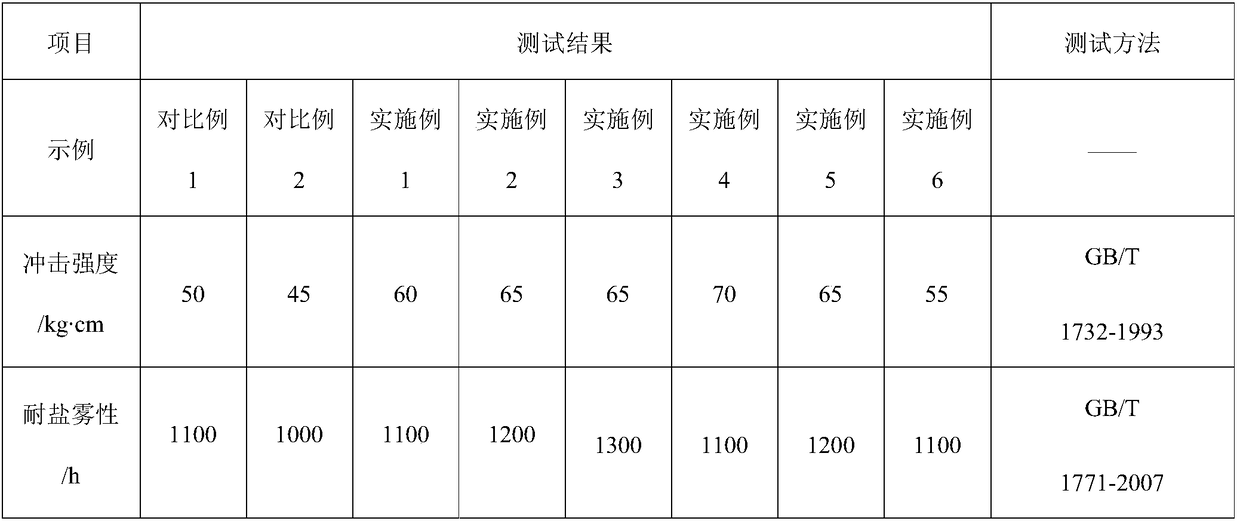

Examples

preparation example Construction

[0021] In some more specific embodiments, the preparation method of the dopamine modified fiber comprises:

[0022] (1) Soak a commercially available polymer fiber in a mixed solution of acetone and tetrahydrofuran with a volume ratio of 1:1-1:3, ultrasonicate for more than half an hour, and dry in an oven at 30-50°C.

[0023] (2) Weigh dopamine and polyethyleneimine with a mass ratio of 3:1-1:1 and dissolve them in Tris buffer solution to form a mixed solution, and then immerse the polymer fiber treated in step (1) in the mixed solution , Stir at room temperature for 2-10h, filter, and dry at room temperature.

[0024] Another aspect of the embodiments of the present invention provides a modified fiber-reinforced anti-corrosion coating, which includes: 30-60 parts by weight of matrix resin, 0.1-0.2 parts by weight of graphene powder, 3-9 parts by weight of polyaniline powder, talc 5-9 parts by weight of powder, 1-2 parts by weight of sodium sulfite, 20-50 parts by weight of ...

Embodiment 1

[0045] (1) Mix acetone and tetrahydrofuran at a volume ratio of 1:1, stir evenly, weigh 2 g of aramid fibers into the mixed solution, ultrasonicate for half an hour, filter, and dry in an oven at 30°C.

[0046] (2) Weigh 3g of dopamine and 1g of polyethyleneimine respectively, dissolve them in 50mL of Tris buffer solution, soak the fibers treated in step (1) in the mixed solution, stir at room temperature for 2h, filter, and Dry to obtain modified fibers.

[0047] (3) Add 1gKH560 and 2mL mixed solvent (composed of xylene and ethyl acetate with a volume ratio of 3:1) into the reaction kettle, and then add 2g of modified fiber, 0.1g of graphene powder, and 5g of talc powder in sequence , sodium thiosulfate 2g, wollastonite powder 2g, stir and moisten evenly, obtain a uniformly dispersed feed liquid, and set aside.

[0048] (4) Weigh 30g of fluorocarbon resin and add it to the reaction kettle, then add the feed liquid obtained in step (3), stir for 0.5h, add 20g of titanium diox...

Embodiment 2

[0051] (1) Mix acetone and tetrahydrofuran at a volume ratio of 1:2, stir evenly, weigh 2 g of acrylic fibers into the mixed solution, ultrasonicate for half an hour, filter, and dry in an oven at 40°C.

[0052] (2) Weigh 2g of dopamine and 1g of polyethyleneimine respectively, dissolve them in 50mL of Tris buffer solution, immerse the fiber treated in step (1) in the mixed solution, stir at room temperature for 4h, filter, and Dry to obtain modified fibers.

[0053] (3) Add 1gKH560 and 3mL mixed solvent (composed of xylene and ethyl acetate with a volume ratio of 3:2) into the reaction kettle, and then add 2g of modified fiber, 0.15g of graphene powder, and 6g of talc powder in sequence , sodium thiosulfate 2g, wollastonite powder 3g, stir and moisten evenly, obtain a uniformly dispersed feed liquid, and set aside.

[0054] (4) Weigh 40g of fluorocarbon resin and add it to the reaction kettle, then add the material liquid obtained in step (3), stir for 1h, add 30g of titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com