Method for measuring working fluid level of rod-pumped well

A technology for pumping wells and measurement methods, applied in construction and other directions, can solve the problems of large test error, complicated and cumbersome acquisition of upper and lower static loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

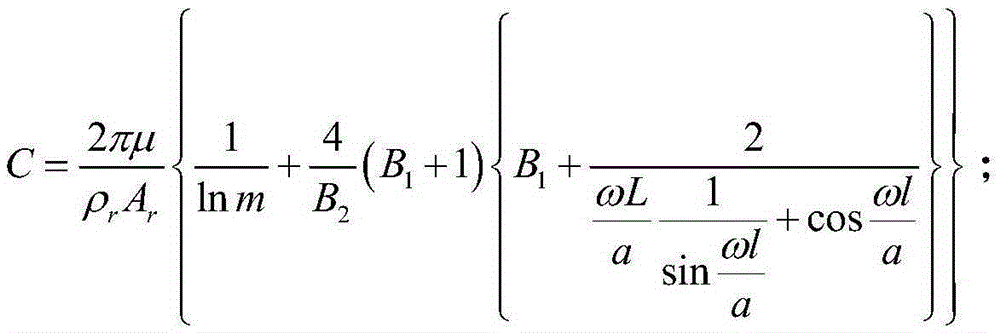

[0039] The invention provides a method for measuring the fluid level of pumping wells, which can effectively improve its timeliness under the condition of ensuring the calculation accuracy, and can also be applied to oil wells that control casing pressure production, so that the calculated fluid level is The error is reduced.

[0040] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings of the specification and specific implementations.

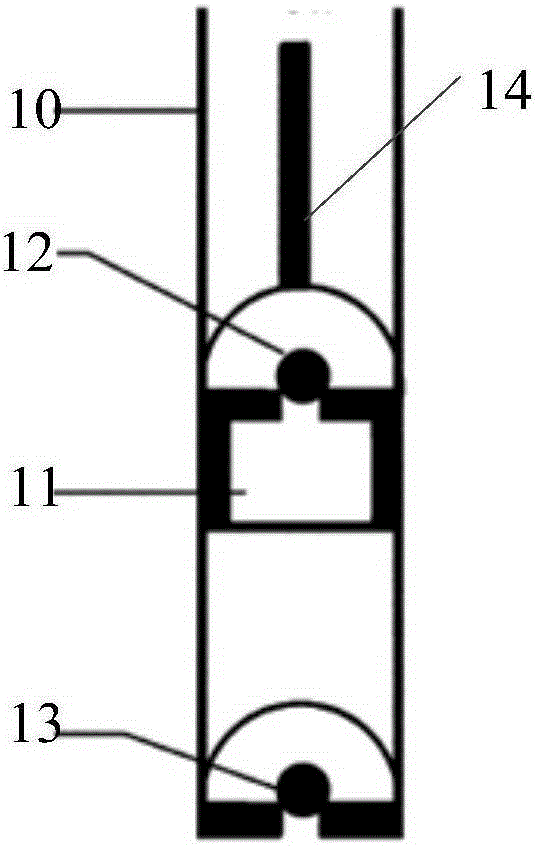

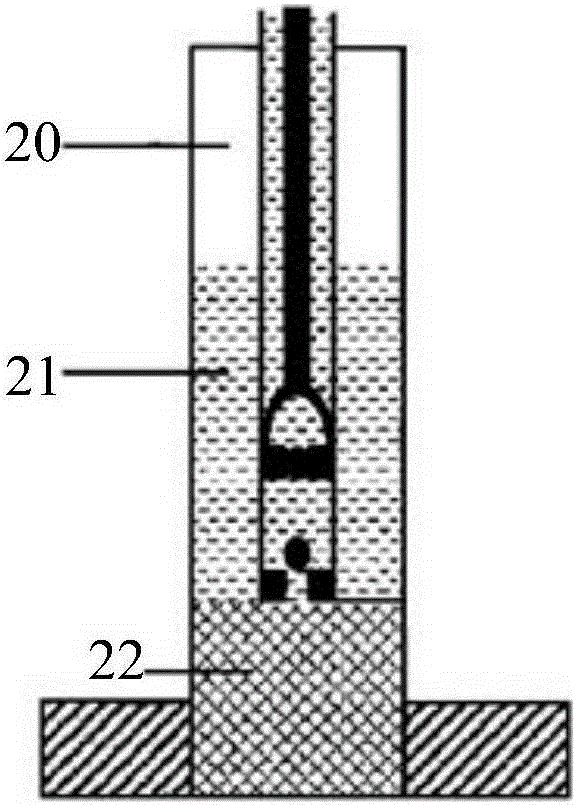

[0041] Before describing the method for measuring the fluid level of a pumping unit well of the present invention, it is first necessary to understand the working principle of the pump. The following is a specific example of a rod pump. For details, see figure 1 , The pump includes a pump cartridge 10, a plunger 11, a traveling valve 12, a fixed valve 13, and a sucker rod 14. During the working process of the pump, the pressure P(t)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com