Rotation stopping equipment for transmission shaft and use method of equipment

A transmission shaft and equipment technology, which is applied in the field of transmission shaft stop equipment, and can solve the problems of reduced output accuracy of the drive machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

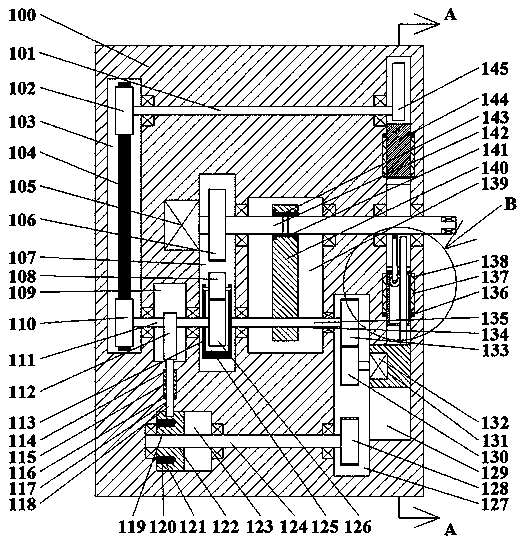

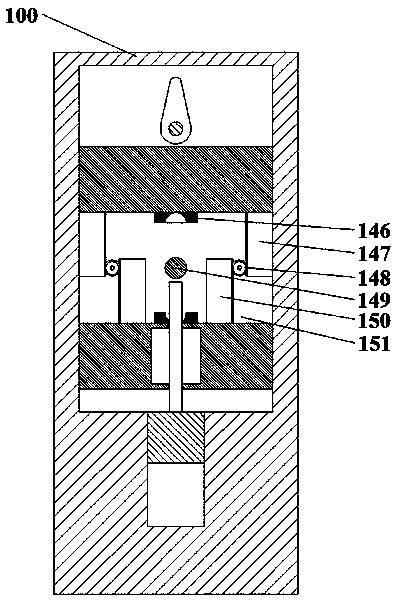

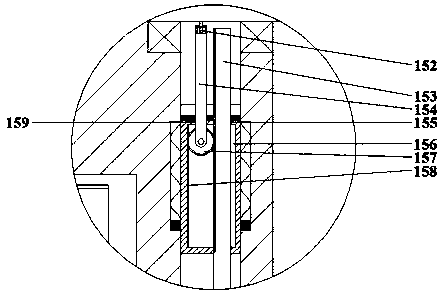

[0014] Such as Figure 1-Figure 3As shown, the stopping device of the transmission shaft of the present invention and its use method include a body 100, a first cavity 107 disposed in the body 100, and a second cavity disposed in the body 100 127, the first cavity 107, a third cavity 139 is arranged in the right end wall of the first cavity 107, and a first sliding block 140 is slidably arranged in the third cavity 139, so A rotating sleeve 143 extending left and right is arranged in the first sliding block 140, and a spline hole 141 penetrating left and right is arranged in the rotation sleeve 143, and a first spline shaft is spline-fitted in the spline hole 141. 142, the left end of the first spline shaft 142 extends through the left end wall of the third cavity 139 and extends into the first cavity 107, and the end is fixedly arranged on the left side of the first cavity 107 The first motor 105 in the end wall is power connected, the outer surface of the first spline shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com