Electromagnetic induction heating cylinder

An electromagnetic induction heating and electromagnetic heater technology, applied in induction heating, induction heating devices, etc., can solve the problems of heat dissipation, heat conduction loss, environmental temperature rise, etc., and achieve the effect of long service life, fast heating rate, and reduced maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

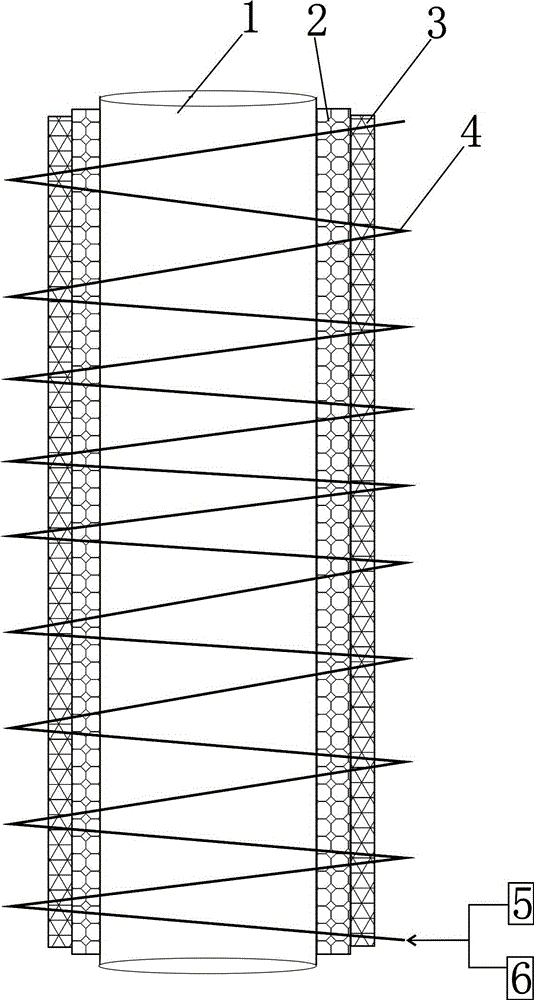

[0012] Such as figure 1 Shown is an electromagnetic induction heating barrel. The barrel 1 is wrapped with an insulation layer 2 , the insulation layer 2 is wrapped with an epoxy resin layer 3 , and an electromagnetic heating coil 4 is wound outside the epoxy resin layer 3 . Cartridge 1 is a metal cartridge. Barrel 1 includes conveying pipelines and grading circulation pipes for finished product silos in the most important link of production. The thermal insulation layer 2 is thermal insulation cotton, and the thermal insulation cotton is fastened and fixed on the periphery of the barrel 1 by high temperature resistant cable ties. The epoxy resin plate layer 3 is fastened and fixed on the periphery of the insulation layer 2 by high-temperature-resistant cable ties. The purpose of wrapping the epoxy resin plate is to smooth the outside of the insulation cotton and to insulate it from the electromagnetic heating coil 4 at the same time.

[0013] The electromagnetic heating coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com