Forming method and device for simultaneously thickening pipe end shrinkage mouth

A necking and pipe end technology, which is applied in the field of forming methods and devices for simultaneously realizing shrinking and thickening of aluminum alloy pipe ends, can solve the problems of low connection strength of aircraft, increased difficulty in necking, and increased production costs, and achieves cooling effect. Better, reduce machining allowance, prevent inward instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

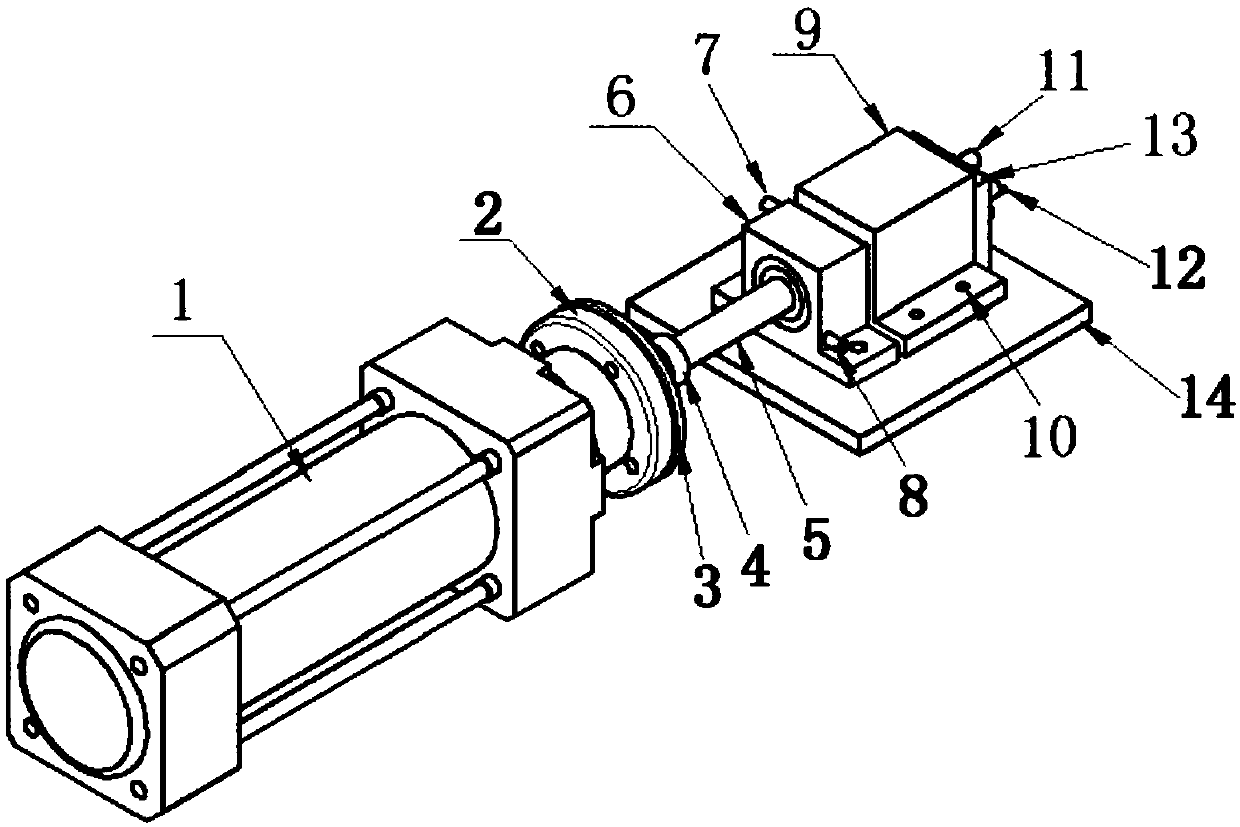

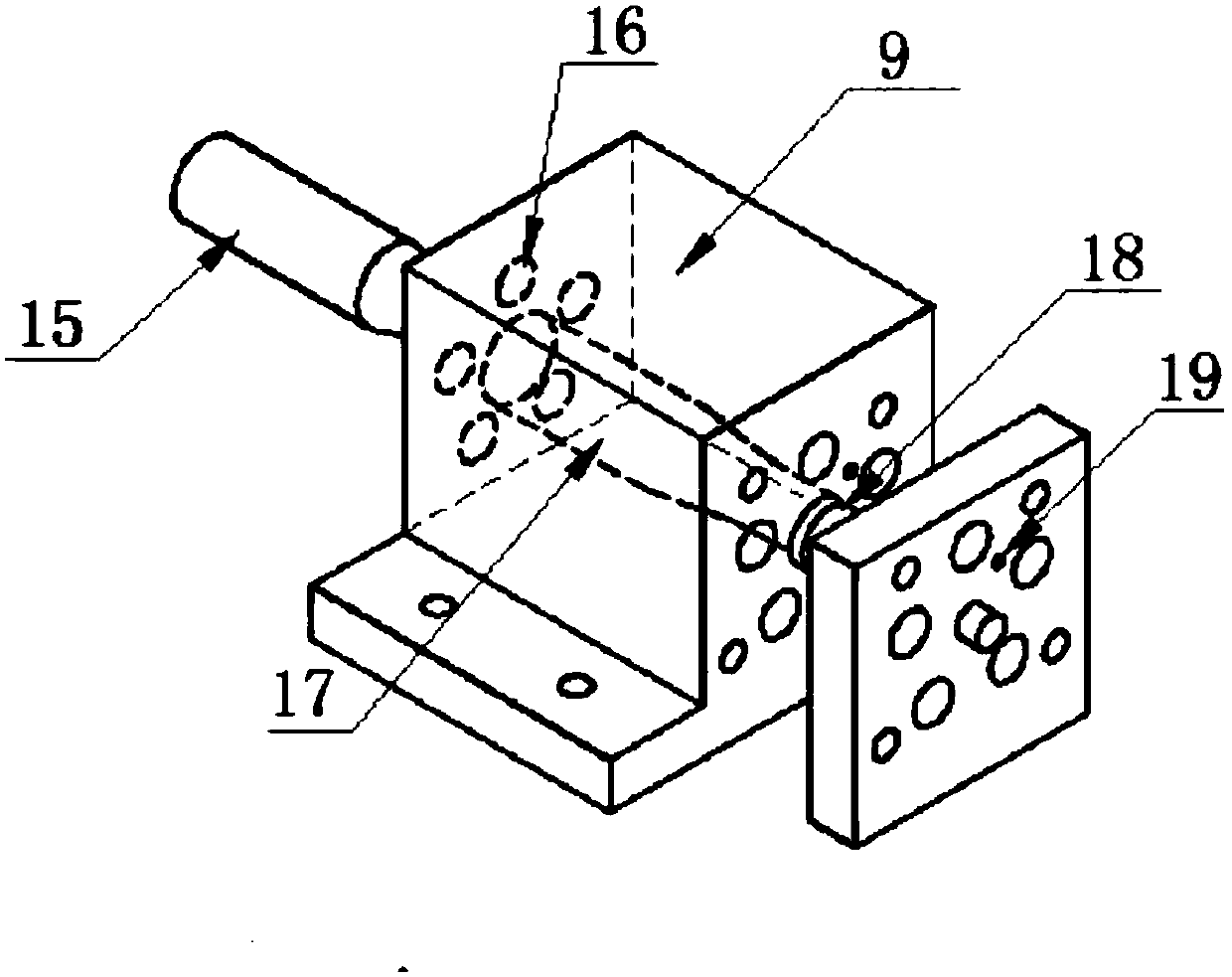

[0045] Such as Figure 1-6 As shown, this embodiment is a detailed description of the structure and technical principle of a forming method and device for simultaneously realizing pipe end shrinkage and thickening according to the present invention. This embodiment takes an aluminum alloy pipe as an example to realize the Shrinkage and thickening temperature difference forming.

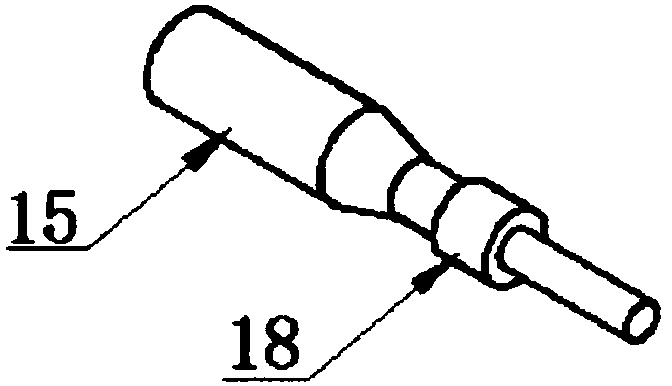

[0046] Such as figure 1 As shown, this embodiment provides a forming device for simultaneously realizing the necking and thickening of the aluminum alloy pipe end, including a hydraulic cylinder 1, a push head 3, a die 9, a lining block 15, a heating rod 11, a cooling device 6 and a heating device; the hydraulic cylinder 1 is used as the main power source to generate the extrusion force that pushes the aluminum alloy tube billet 5 to be formed; On the hydraulic cylinder 1 and through the guide sleeve 4, the guide sleeve 4 is used to fix the axial position of the aluminum alloy tube blank 5 and stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com