An underground hollow oil well pump

A hollow oil well pump technology, which is applied to pumps, pump components, variable capacity pump components, etc., can solve the problems of slow lifting and unloading of oil pipes, restrictions on the outer diameter of hollow oil well pumps, and ball reset lag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and technical effects to be solved by the present invention clearer, the following describes in detail with reference to the drawings and specific embodiments.

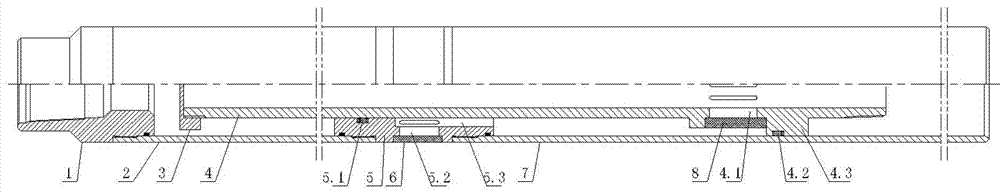

[0022] Such as figure 1 The hollow oil well pump shown in the well includes: a cylinder body composed of upper and lower parts 2 and 7, the upper part 2 of the cylinder body and the lower part 7 of the cylinder body are screwed to the sealing sleeve 5 located in the middle, and the upper part 2 of the cylinder body The upstream end of the barrel is connected to the oil pipe through the upper joint 1, and the lower part of the barrel 7 is connected to the packer near the downstream end.

[0023] A hollow piston rod 4 is arranged in the inner chamber of the barrel, and an anchor is connected to the downstream end of the piston rod 4, and is fixed at a specified position downhole by the anchor. The upstream end of the piston rod 4 is threadedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com