Preparation method of quadrate foil type coil insulation paper roll

A coil insulation and paper tube technology, which is applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problems of copper foil deviation, affecting coil quality and appearance, and increasing coil size. The effect of deviation and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, further illustrate the present invention through embodiment.

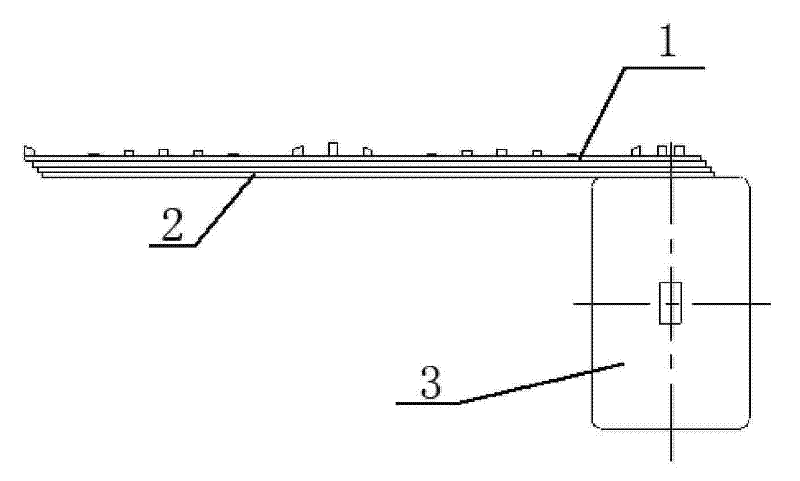

[0018] In an embodiment, a manufacturing method of a square foil coil insulating paper tube includes the following process:

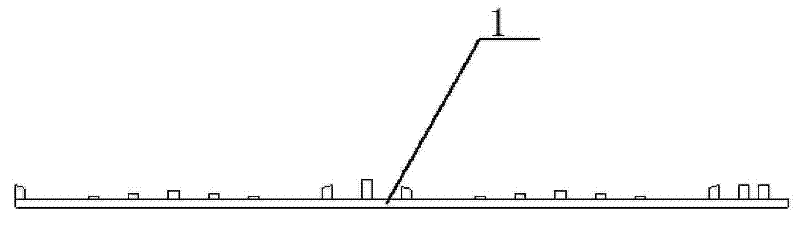

[0019] ①The paper tube is composed of a curtain oil passage 1 and several sheets of insulating cardboard 2. According to the insulation strength, the number and thickness of the cardboard can be increased or decreased; the cardboard is cut into the width required by the drawing, and the length of the cardboard is 5-8mm less than the circumference of the mold ; Bond the curtain oil passage well. Seen from the lead wire end, the first stay on the right side of the copper bar is closely bonded to the left edge of the cardboard, and the rest of the stays are glued in sequence according to the spacing of the curtain oil passage development diagram. OK, refer to attached figure 1 ;

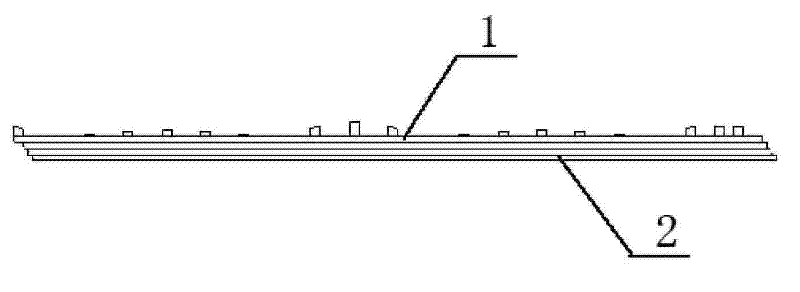

[0020] ②Stack the curtain oil channel and the cardboard us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com