Chromium-plated tooling

A tooling and processed technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of high cost, scrapped parts, and electric shocks, and achieve the effect of avoiding electric shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

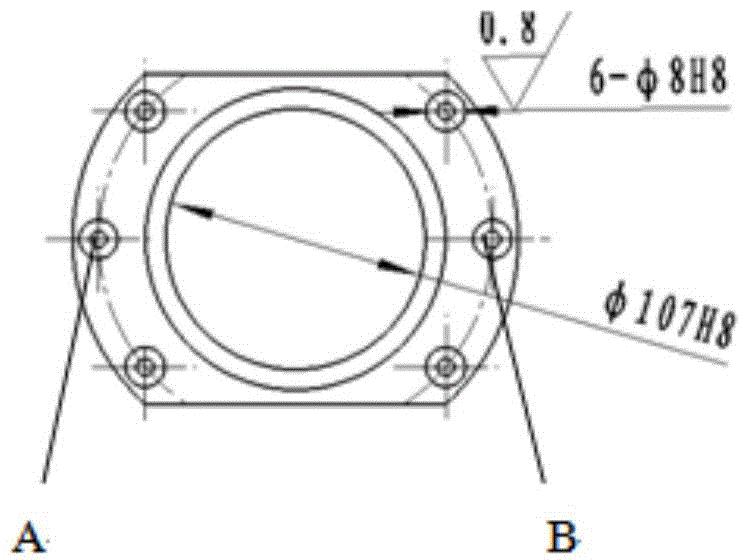

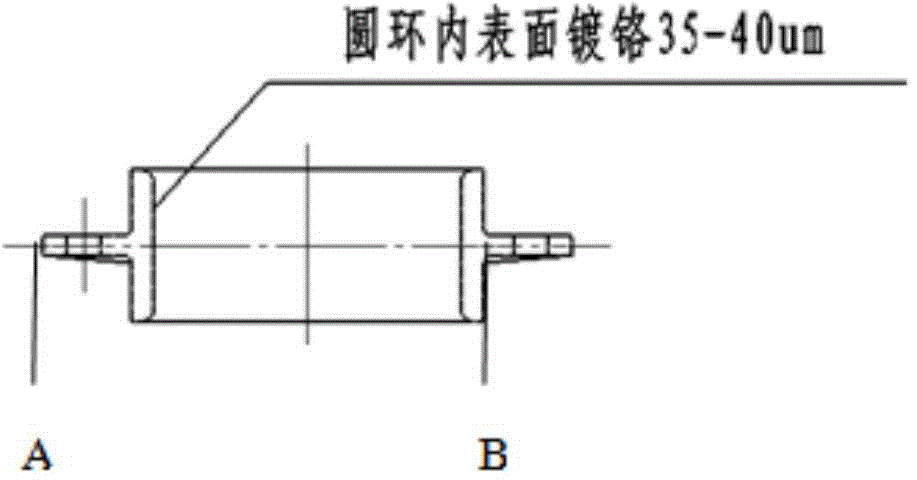

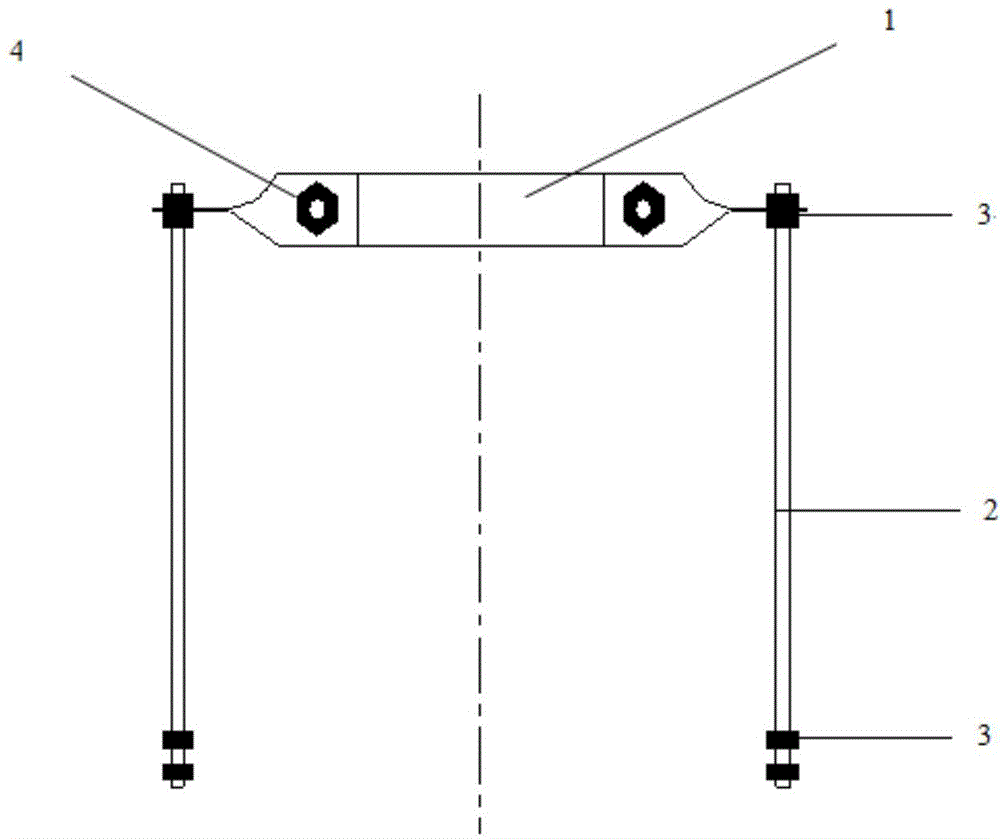

[0012] A chrome-plated tooling is used for chrome-plating the inner surfaces of multiple flange parts at the same time. Processed parts and welding frame 1; knurled nuts 3 fix the processed parts on the welding frame 1, and ensure good electrical conductivity; welding frame 1 fixes the auxiliary anode through the pin 4 and keeps the two insulated, and the auxiliary anode is in the hole of the part axis position.

[0013] Production of chrome-plated tooling

[0014] Material: Q275

[0015] Require:

[0016] (1) Clean the weld after welding.

[0017] (2) Rounding of sharp edges.

[0018] (3) The cylindrical surface of the bolt is knurled.

[0019] Chrome-plated mounting operation sequence

[0020] (1) Insert the double-headed studs of the mounting bracket into the A and B holes of the part respectively.

[0021] (2) Use a knurled nut to secure the position of the part.

[0022] (3) If multiple parts are plated at the same time, repeat (1) and (2) operations.

[0023] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com