Integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate

A technology for electroplating wastewater and waste emulsion, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low cost, low dosage, and poor oil quality. To achieve the effect of compact equipment and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

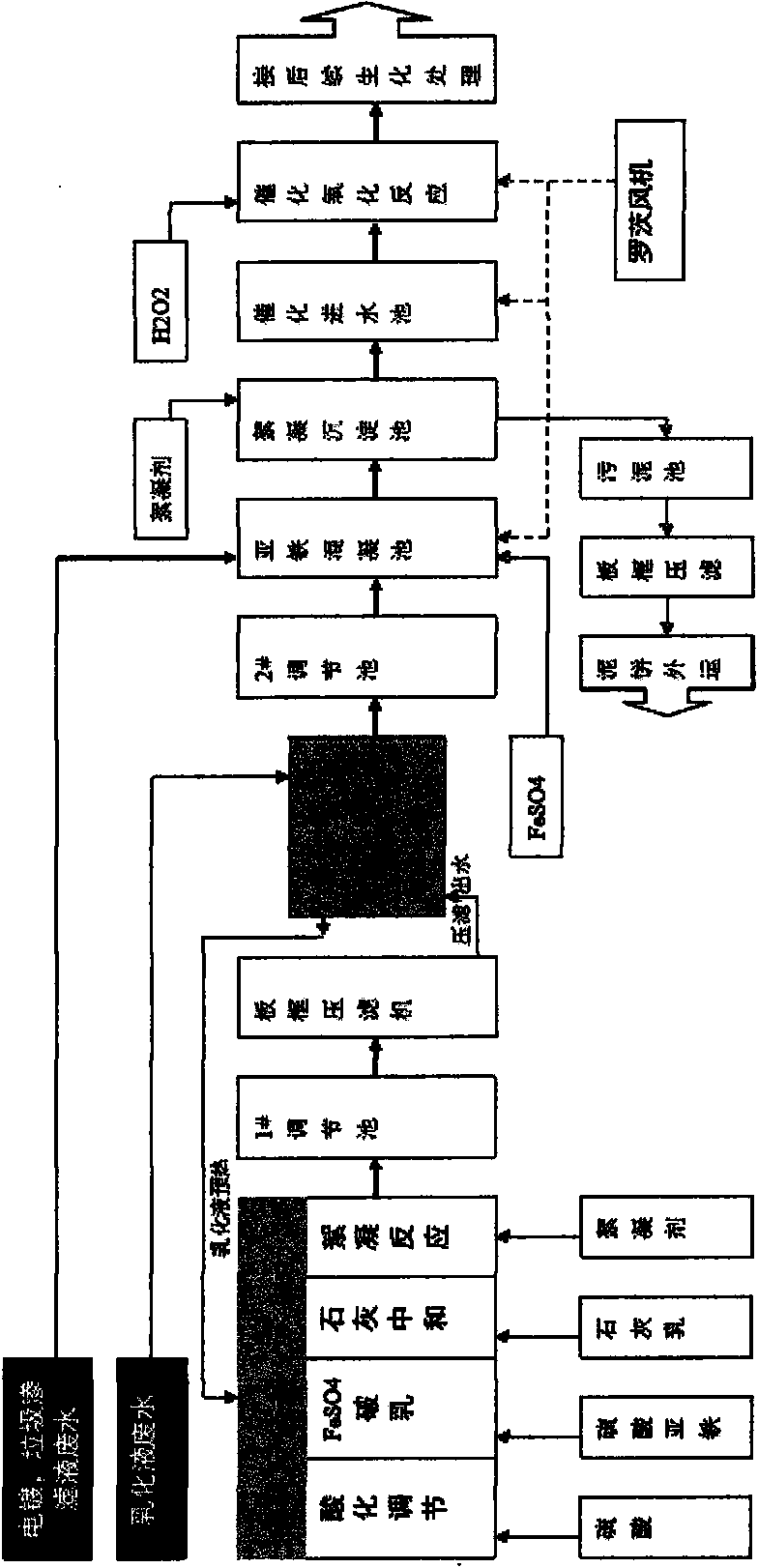

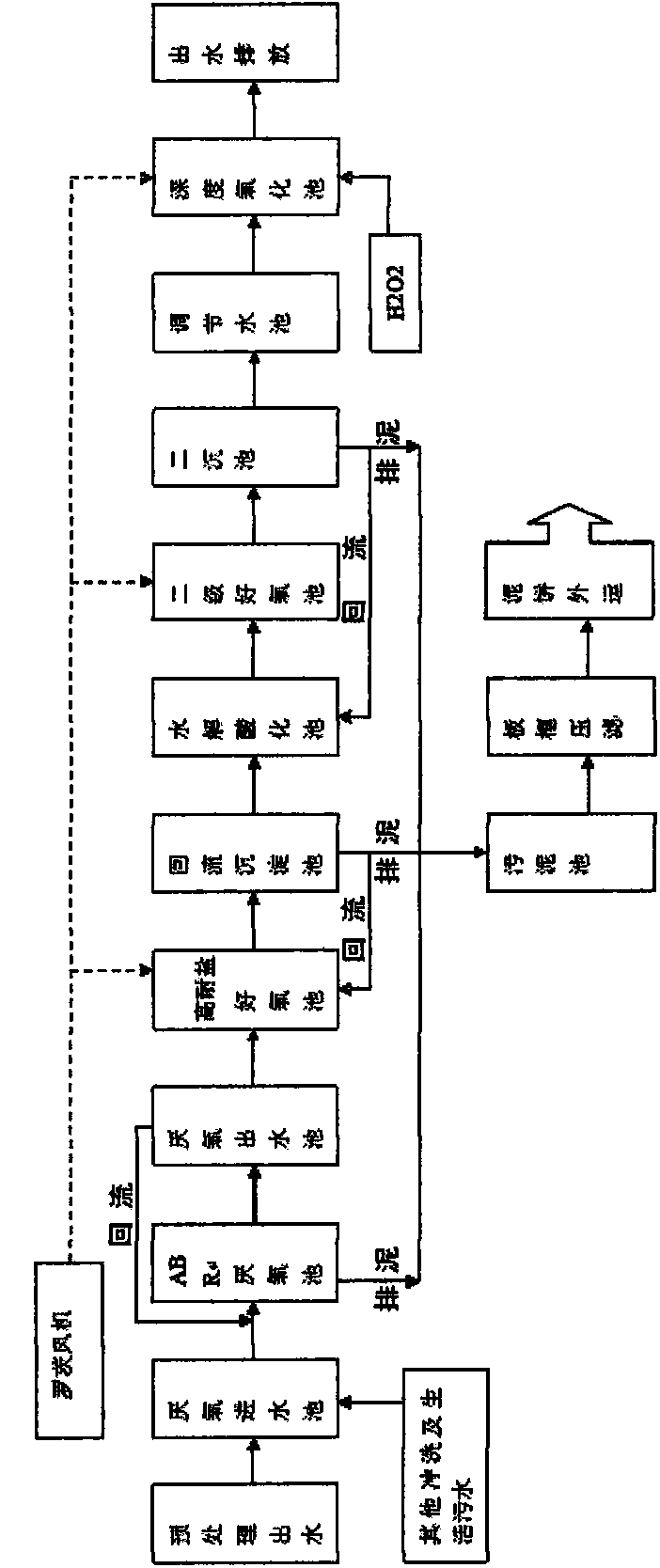

[0028] Such as figure 1 and figure 2 Shown, a kind of waste emulsion of the present invention, electroplating waste water, landfill leachate comprehensive treatment technology, comprises the following several steps:

[0029] 1) Lift the waste water to be treated into the demulsification reaction kettle through the water pump, add sulfuric acid through the dosing device for acidification treatment, the waste water appears milky yellow and turbid, after acidification, steam the waste water in the kettle to heat up, and add a certain amount of sulfurous acid iron;

[0030] 2) When the temperature of the wastewater rises to about 80°C, the emulsified state of the wastewater appears to be cracked, and the pH of the wastewater is adjusted to about 9-10 by adding lime milk solution to maintain the temperature. Ferrous hydroxide floc precipitates appear in the water body, and further PAM is added. The coagulant can completely flocculate the water body, so that the wastewater can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com