Preparation method of in-situ nano emulsifier and oil reservoir application method

An application method and emulsifier technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of aggravated agglomeration behavior and easy agglomeration, and achieve good injectability, low processing difficulty, The effect of enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

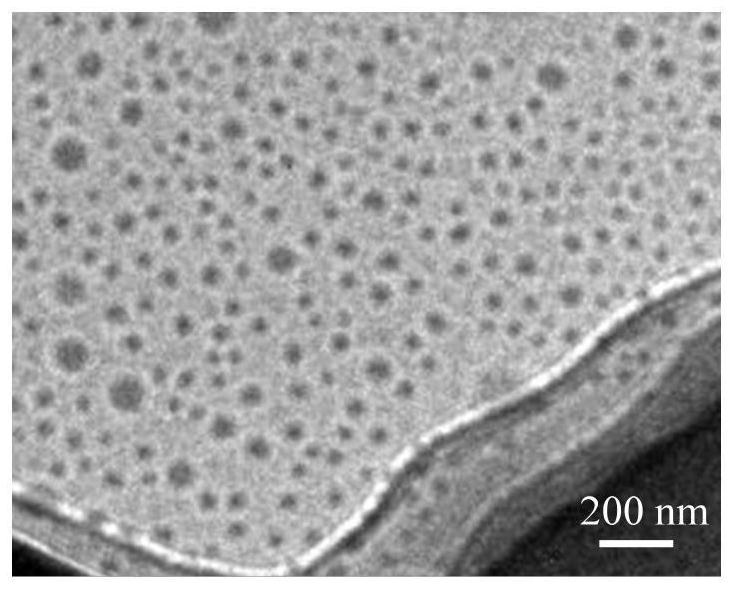

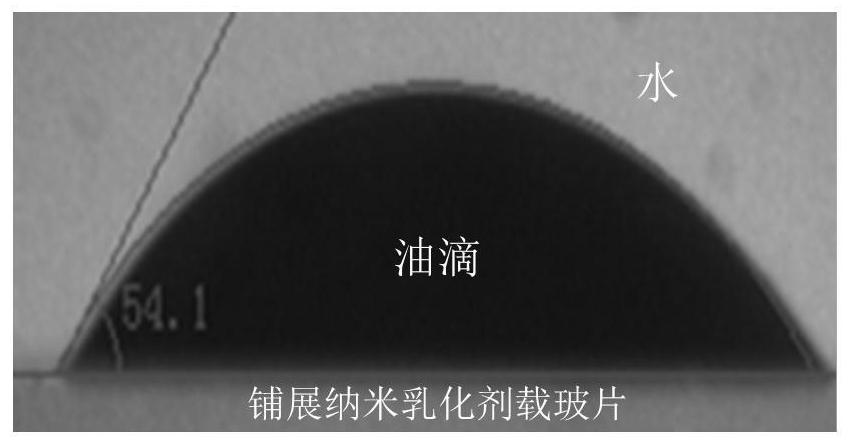

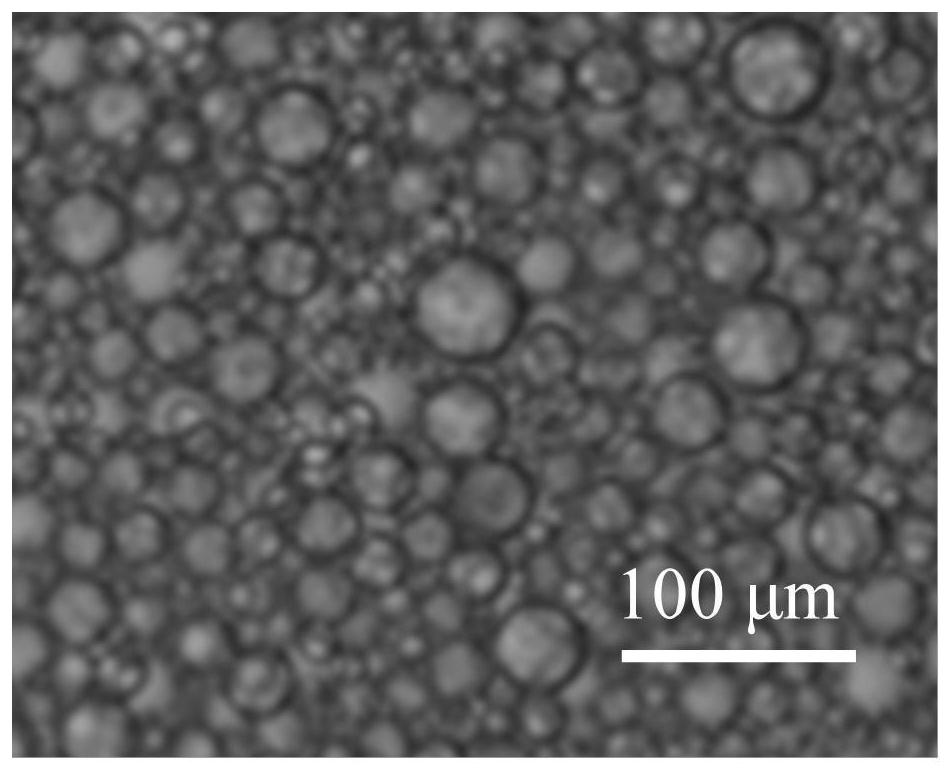

[0044] (1) Synthesis of an in-situ nanoemulsifier

[0045] (a) Synthesis of in situ nanoemulsifier 1

[0046] Add 80g of deionized water to a 500mL three-necked bottle, then add 5g of ferric chloride hydrate and 1.2g of ferrous sulfate hydrate in sequence, and stir at room temperature for 45min to 60min to ensure full dissolution. Dissolve 0.75 g of oleic acid diethanolamide in 12 g of ethanol under ice-salt bath conditions, seal and stir for 15 min to ensure full dissolution. Under the protection of nitrogen, add 25% 75mL ammonia water and ethanol solution dissolved with oil-soluble surfactant to the three-necked bottle through two dropping funnels at a constant speed for 2 hours, and stir rapidly during the dropping process to ensure that the reaction system is mixed. uniform. Stirring was continued for 1 h after the dropwise addition. After the reaction was completed, the reaction product was suction-filtered, and the solid product was collected, dried in vacuum at 50° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com