Method for improving CO2 injection capacity through nano-particle composite low-salinity water

A technology of nano-particles and injection ability, applied in the direction of nano-technology, silicon oxide, silicon dioxide, etc., can solve the problems of exacerbating the shedding of formation particles, blocking the pore throat space, and increasing the repulsion of the electric double layer, so as to improve the permeability, Improved injectability and good injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this example, the salt water layer in the ××× Basin is taken as the analysis object. The lithology of the salt water layer is sandstone, the top of the layer is buried at a depth of about 1200m, the thickness is 110m, the initial formation pressure is 12.5MPa, and the formation temperature is 64°C. The formation porosity is between 0.10 and 0.23, the permeability is between 5 and 298 mD, and the salinity of the formation water is 160 g / L. The main components are shown in Table 1.

[0040] Table 1. Analysis of the composition of formation water and its total salinity in the ××× saline layer

[0041] Ingredient Type KCl MgCl 2 ·6H 2 O

CaCl 2 ·2H 2 O

NaCl Na 2 SO 4

total Content (g / L) 4.12 5.23 22.00 139.33 0.52 160

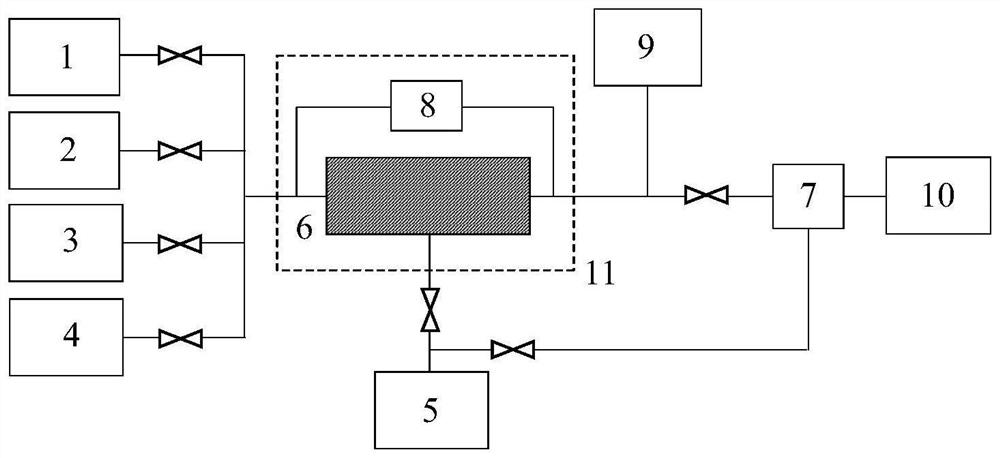

[0042] In this example, the method of indoor core flooding is used to simulate CO 2 In the geological storage process, the selected experimental devices such as figure 1 shown. The experimental device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Formation water salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com