In-situ emulsification tackifying system with high phase transformation point and application in water-drive reservoirs

A phase transition point, in-situ technology, applied in the fields of production fluids, drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult formation propagation, high injection pressure, affecting production, etc., and achieve outstanding economic benefits and injection. Good performance, and the effect of improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Oil-Water Interfacial Tension of In-Situ Emulsification and Viscosification System Containing High Phase Transition Point

[0034] Table 1 Stable interfacial tension between in-situ emulsification system with high phase transition point and crude oil

[0035] Salinity (10 4 mg / L)

Crude oil viscosity (mPa·s) Oil-water interfacial tension (mN / m) 0.1 60.8 0.036 1.0 120.1 0.072 10 303.6 0.043 20 460.7 0.055

[0036] Prepare the total salinity as 0.1×10 4 mg / L number ①, 1.0×10 4 mg / L number ②, 10×10 4 mg / L number ③, 20×10 4 mg / L Mineralized water with number ④ (Ca in ①~④ 2+ , Mg 2+ The mass concentration is 5.0% of the total salinity), stirred for 1.5 hours. In ①, add 0.25% petroleum sulfonate, 0.45% propylene glycol monostearate, 0.05% liquid paraffin, 0.05% carboxymethyl-β-cyclodextrin; in ② add 0.25% Cocamidopropyl betaine, 0.45% polyoxyethylene sorbitan monostearate, 0.05% graphite powder, 0.05% chitosan quat...

Embodiment 2

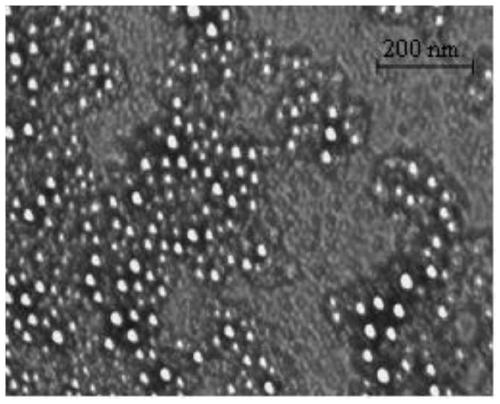

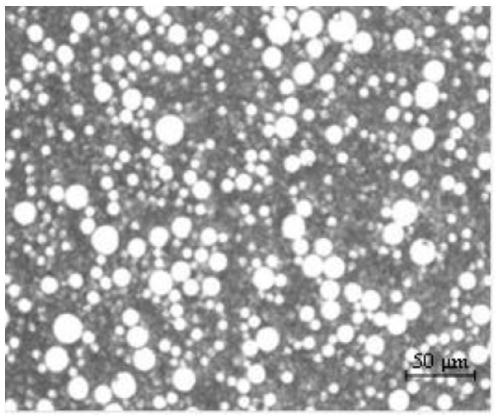

[0038] Example 2 Viscosity of an emulsion formed by an in-situ emulsification viscosity-increasing system containing a high phase transition point and crude oil

[0039] Prepare the total salinity as 0.1×10 4 mg / L number ①, 1.0×10 4 mg / L number ②, 10×10 4 mg / L number ③, 20×10 4 mg / L Mineralized water with number ④ (Ca in ①~④ 2+ , Mg 2+ The mass concentration is 5.0% of the total salinity), stirred for 1.5 hours. In ①, add 0.25% petroleum sulfonate, 0.45% propylene glycol monostearate, 0.05% liquid paraffin, 0.05% carboxymethyl-β-cyclodextrin; in ② add 0.25% Cocamidopropyl betaine, 0.45% polyoxyethylene sorbitan monostearate, 0.05% graphite powder, 0.05% chitosan quaternary ammonium salt; add 0.25% fatty alcohol ether in turn in ③ Sulfonate, 0.45% oleic acid diethanolamide, 0.05% graphite powder, 0.05% xanthan gum; in ④, add 0.25% alkanolamide, 0.45% octadecyl primary amine, 0.05% Cage polysilsesquioxane, 0.05% guar gum; stirring for 2.0 hours to obtain an in-situ emulsi...

Embodiment 3

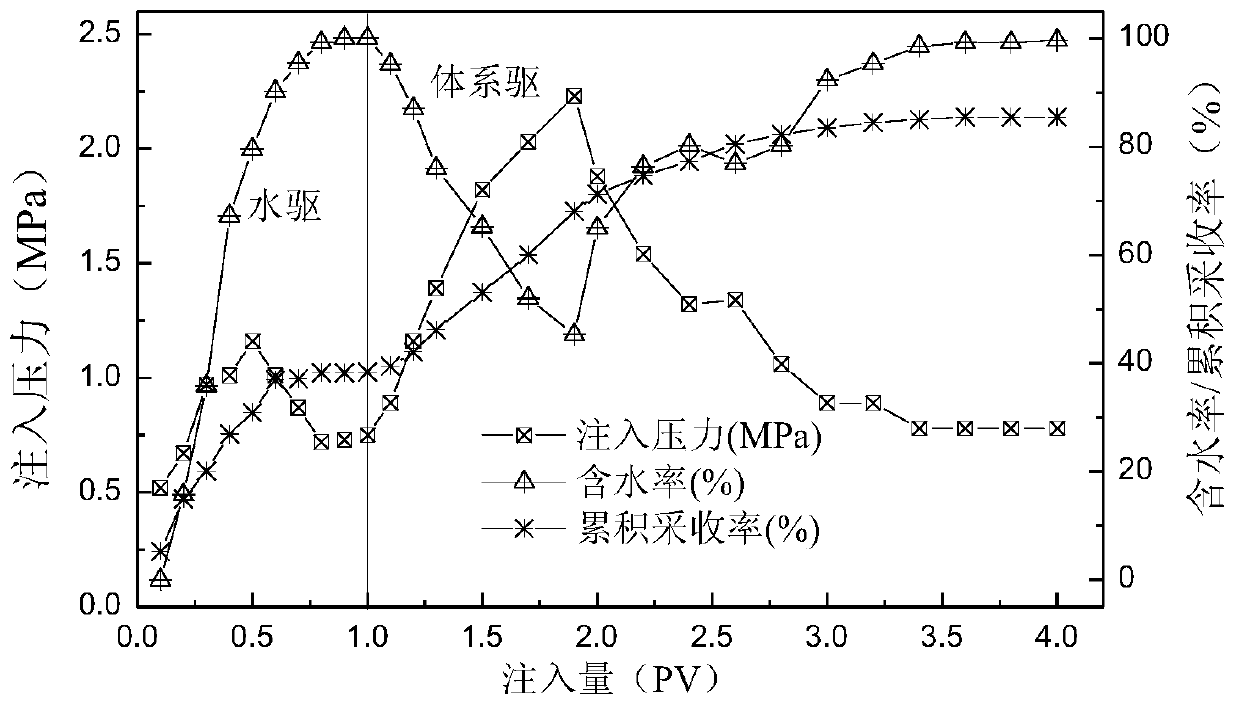

[0049] Example 3 Enhanced oil recovery performance of in-situ emulsified viscosity-increasing system with high phase transition point

[0050] The prepared salinity is 20×10 4 mg / L (Ca 2+ , Mg 2+ The mass concentration is 5.0% of the total salinity) of mineralized water, stirred for 1 hour, and then added 0.25% alkanolamide, 0.15% octadecyl primary amine, 0.30% oleic acid diethanolamide, 0.05 % cage polysilsesquioxane, 0.05% xanthan gum; stirred for 2.0 hours to obtain an in-situ emulsified viscosity-increasing system with a high phase transition point. Artificial simulated core (45×45×300mm long core, porosity 25%, gas permeability 2000mD), temperature 90°C, crude oil viscosity 60.8mPa·s, original oil saturation 72%. 2.0mL / min), affected by the unfavorable water-oil mobility ratio, the oil recovery degree of water flooding is low, and the recovery rate of 98% water cut is about 40%; Viscous system (injection rate 2.0mL / min), the injection pressure increases during the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com