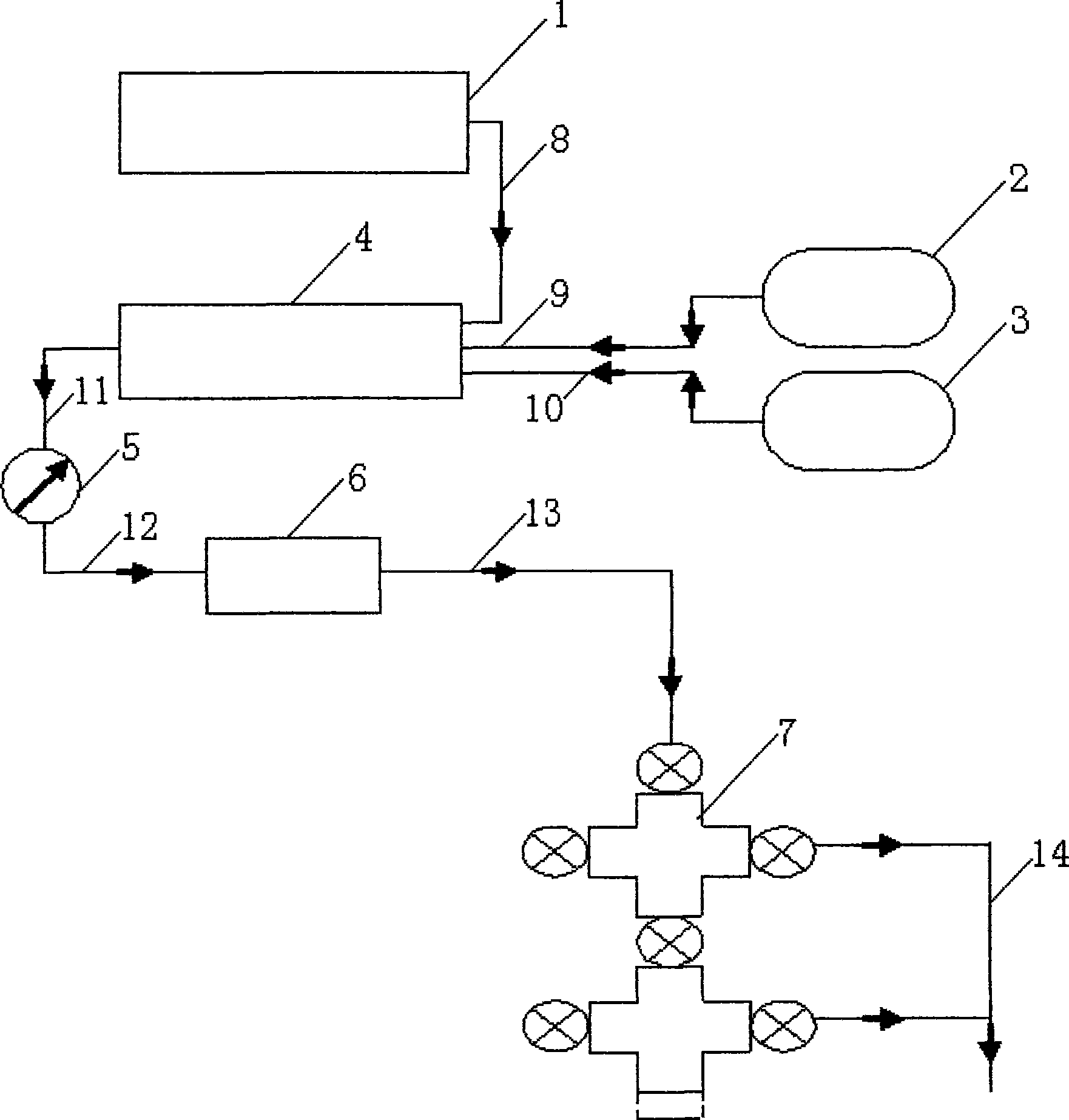

Ultra-deep ultra-thick oil thermal steam-gas (CO2 and N2) well bore viscosity reduction and oil production technology

A super-heavy oil and CO2 technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as uneconomical, increased artificial lift, and small application depth, saving time and cost, reducing Viscosity of heavy oil and the effect of increasing wellbore temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is realized through the following steps:

[0037] 1. Preparation before production:

[0038] (1) Drill a vertical well, deviated well or horizontal well in an ultra-deep heavy oil reservoir, and use a large casing of 9-5 / 8″ or more to complete the well. Use TP110 partial trapezoidal threaded casing with a wall thickness of 19mm. Increase the tensile strength of the casing; there is a ground anchor at the bottom of the completion pipe string, and multiple thermal stress compensators and high-strength centralizers are clamped in the middle of the pipe string according to the engineering design requirements; the thickness of the cement sheath, cement slurry system, annular solid The composition of the well fluid is all cemented according to the thermal production well, so as to improve the protective effect of the cement sheath on the casing and improve the cementing quality;

[0039] (2) Install thermal recovery trees according to construction needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com