Oil-gas field oil-containing sludge treatment method

A treatment method and oil and gas field technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, hydrocarbon oil treatment, etc., can solve the problems of complicated treatment process, difficult recovery and reuse of carbon dioxide, high treatment cost, etc., and achieve the treatment process Simple, high recovery rate of crude oil, low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The oily sludge samples come from the sludge pool of an oilfield in Xinjiang. The oil field stores the oil sludge generated during crude oil production in a sludge pool of 80m×80m×2.5m. After years of discharge, the sludge pool has formed a nearly 2m deep oily sludge pool. , water, mud and sand oily sludge emulsified suspended matter;

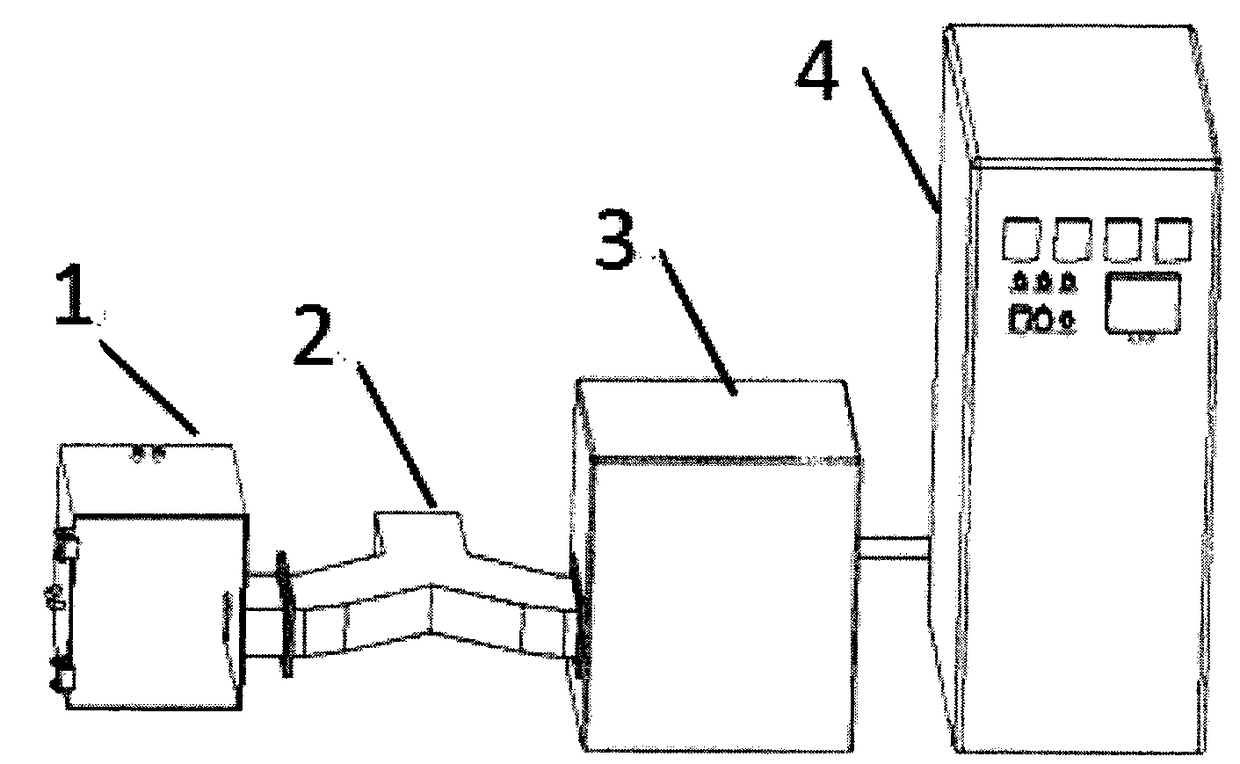

[0023] A treatment method for oily sludge in an oil and gas field according to the present invention, the treatment device for oily sludge involved in the method is composed of a microwave reaction chamber 1, a waveguide 2, a microwave generator 3 and a power supply 4, the microwave reaction chamber 1 The waveguide 2 is connected to the microwave generator 3, the microwave generator 3 is connected to the power supply 4, and a microwave protection device is arranged in the middle of the waveguide 2. The specific operation is carried out according to the following steps:

[0024] a, turn on the power supply 4, adjust the power of the micro...

Embodiment 2

[0030] The treatment device of oily sludge involved in this embodiment is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0031] a, turn on the power supply 4, adjust the power of the microwave generator 3 to a set value of 1.5kW, and the frequency is 915 ± 50MHz, add catalyst sodium hypochlorite 100ppm to the oily sludge and fully stir and mix, the power of the microwave generator 3 is continuous. tuned;

[0032] b. After the microwave generator 3 runs stably, put the ceramic cup containing 500ml oily sludge container into the microwave reaction chamber 1;

[0033] c. After 60s of microwave irradiation, turn off the power supply 4, open the door of the microwave reaction chamber 1, and take out the sample, wherein the microwave irradiation time is inversely proportional to the power of the microwave;

[0034] d. Let the sample stand for 5 minutes at normal temperature and pressure, and the oily sludge in th...

Embodiment 3

[0037] The treatment device of oily sludge involved in this embodiment is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0038] a, turn on the power supply 4, adjust the power of the microwave generator 3 to a set value of 1.5kW, and the frequency is 915 ± 50MHz, add catalyst potassium permanganate 200ppm to the oily sludge to fully stir and mix, the power of the microwave generator 3 is continuously adjustable;

[0039] b. After the microwave generator 3 runs stably, put the quartz cup containing the 500ml oily sludge container into the microwave reaction chamber 1;

[0040] c. After 60s of microwave irradiation, turn off the power supply 4, open the door of the microwave reaction chamber 1, and take out the sample, wherein the microwave irradiation time is inversely proportional to the power of the microwave;

[0041] d. Let the sample stand for 5 minutes at normal temperature and pressure, and the oily s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com