Variable-rigidity spherical hinge and variable-rigidity design method

A variable stiffness, spherical hinge technology, applied in computing, mechanical equipment, spring/shock absorber functional characteristics, etc., can solve problems such as low stiffness, achieve the effect of low stiffness, improve fatigue life, and reduce rubber tensile damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

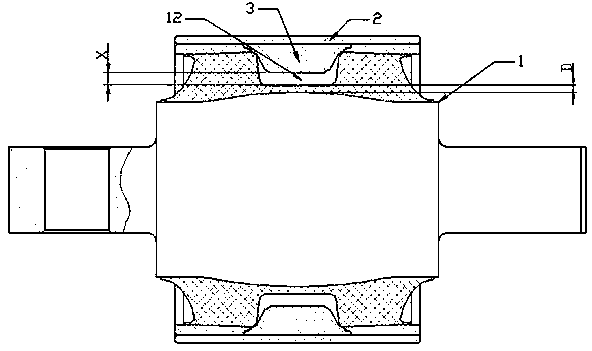

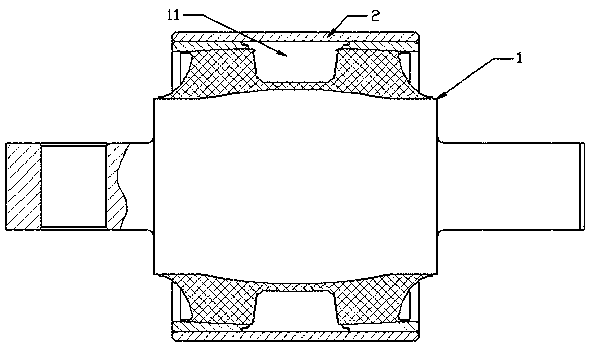

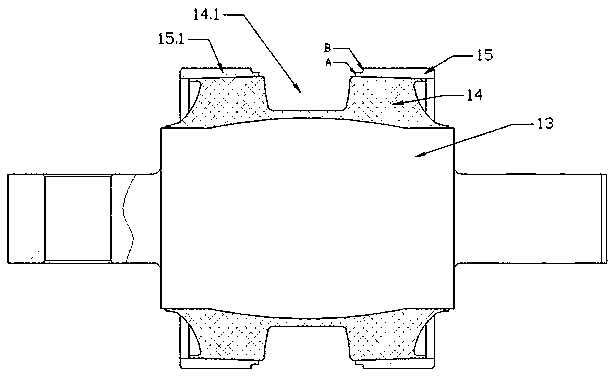

[0032] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0033] The variable stiffness ball joint includes a ball joint body 1 and an outer casing 2 fitted on the ball hinge body 1, and is characterized in that there is a circumferential annular sealing space 11 between the ball hinge body 1 and the outer casing 5 , the annular sealing space 11 goes deep into the rubber layer of the ball joint body 1, and an annular stopper 3 is arranged in the annular sealing space 11. The annular stopper 3 does not completely fill the annular sealing space 11. Between the ball joint body 1 and the annular An annular gap 12 arranged axially is formed between the stoppers 3, and the minimum radial width of the annular gap 12 is X, and 0.5mm

[0034] Such as figure 1As shown, an annular sealed space is provided between the ball joint body 1 and the outer outer casing 2, the annular stopper 3 is located in the annular sealed space, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com