Turning device for automobile door lock follower plate

A technology for car door locks and rotary devices, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of reducing the free space of the workplace, increasing the volume of the equipment, and occupied space, so as to reduce the occupied space and increase the spare space. The effect of space and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

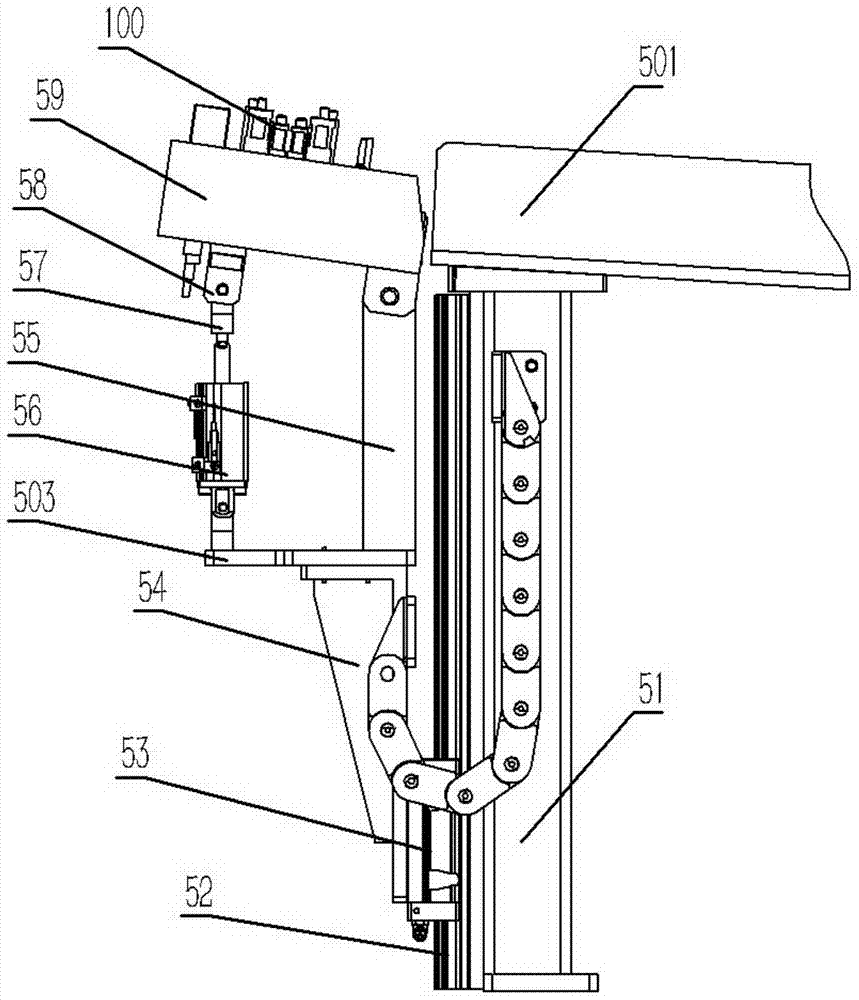

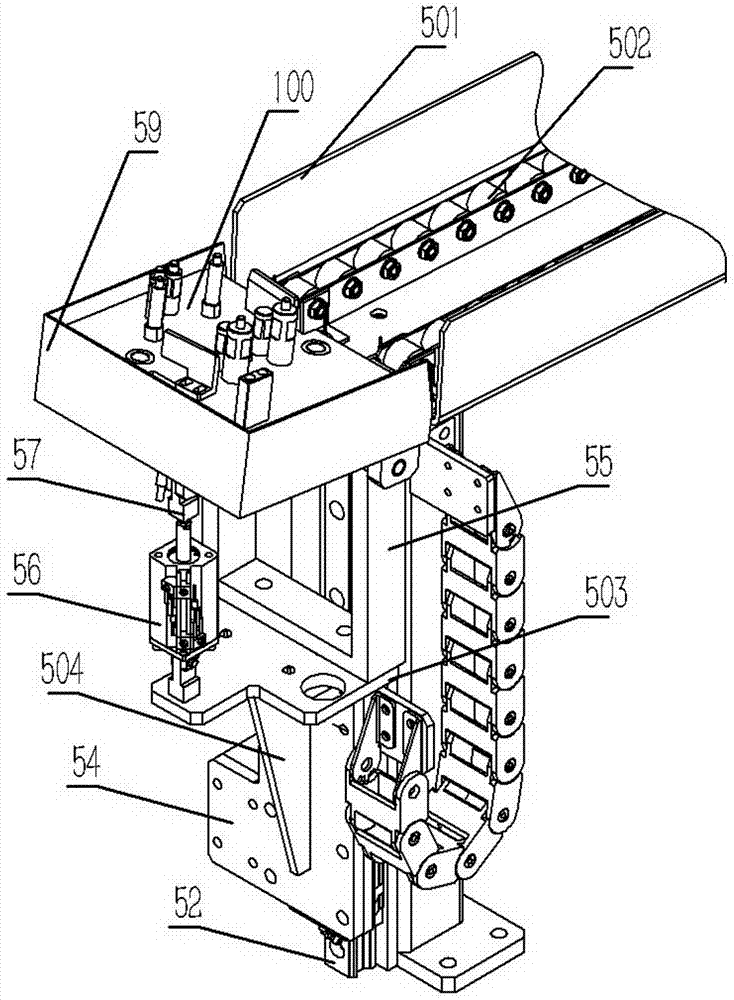

[0015] Example: see Figures 1 to 2 As shown, the rotary device of the accompanying plate of the automobile door lock includes two groups of columns 51 on the left side of the frame of the automobile door lock assembly machine, the two groups of columns 51 are respectively fixed with guide rails 52, and the guide rails 52 are fixed with sliders 53, and the sliders 53 Driven by an electric cylinder, a vertical support plate 54 is fixed on the slider 53, a support plate 503 is fixed on the upper end of the support plate 54, and a turning cylinder 56 is hinged on the left end of the support plate 503, and the piston rod of the turning cylinder 56 is screwed and hinged. Block 57, the hinge block 57 is hinged on the hinge seat 58, the hinge seat 58 fixes the left end of the flip seat 59, the right end of the flip seat 59 is fixed with some hinge seats 58, and the two ends of the U-shaped support 55 are hinged on the hinge of the flip seat 59 right-hand side. On the seat 58, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com