Control device and method for morphic gradient of ultrahigh-strength steel

A technology of ultra-high-strength steel and control devices, which is applied in the field of hot stamping and forming, can solve problems such as gradient changes in shape, achieve the effects of reducing surface oxidation, meeting lightweight requirements, and improving forming efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

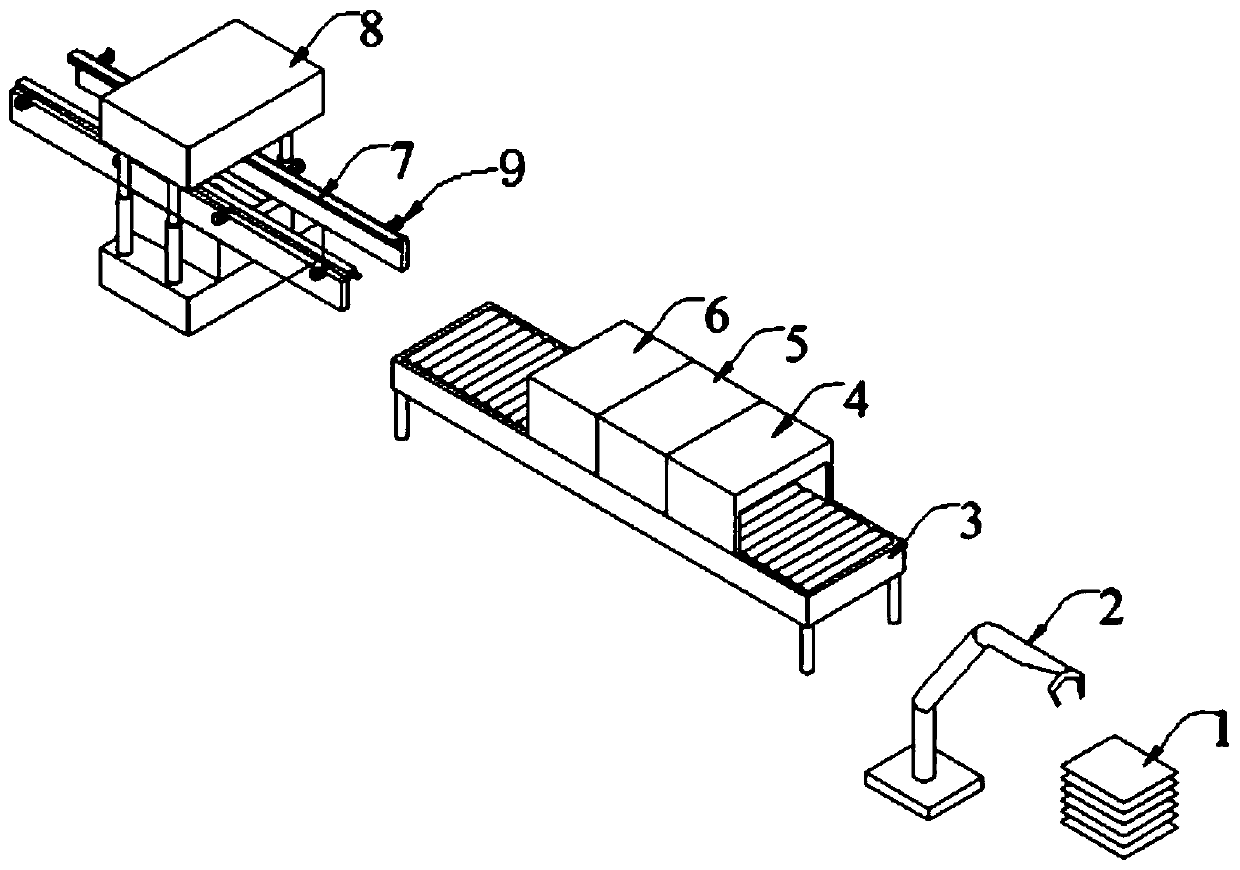

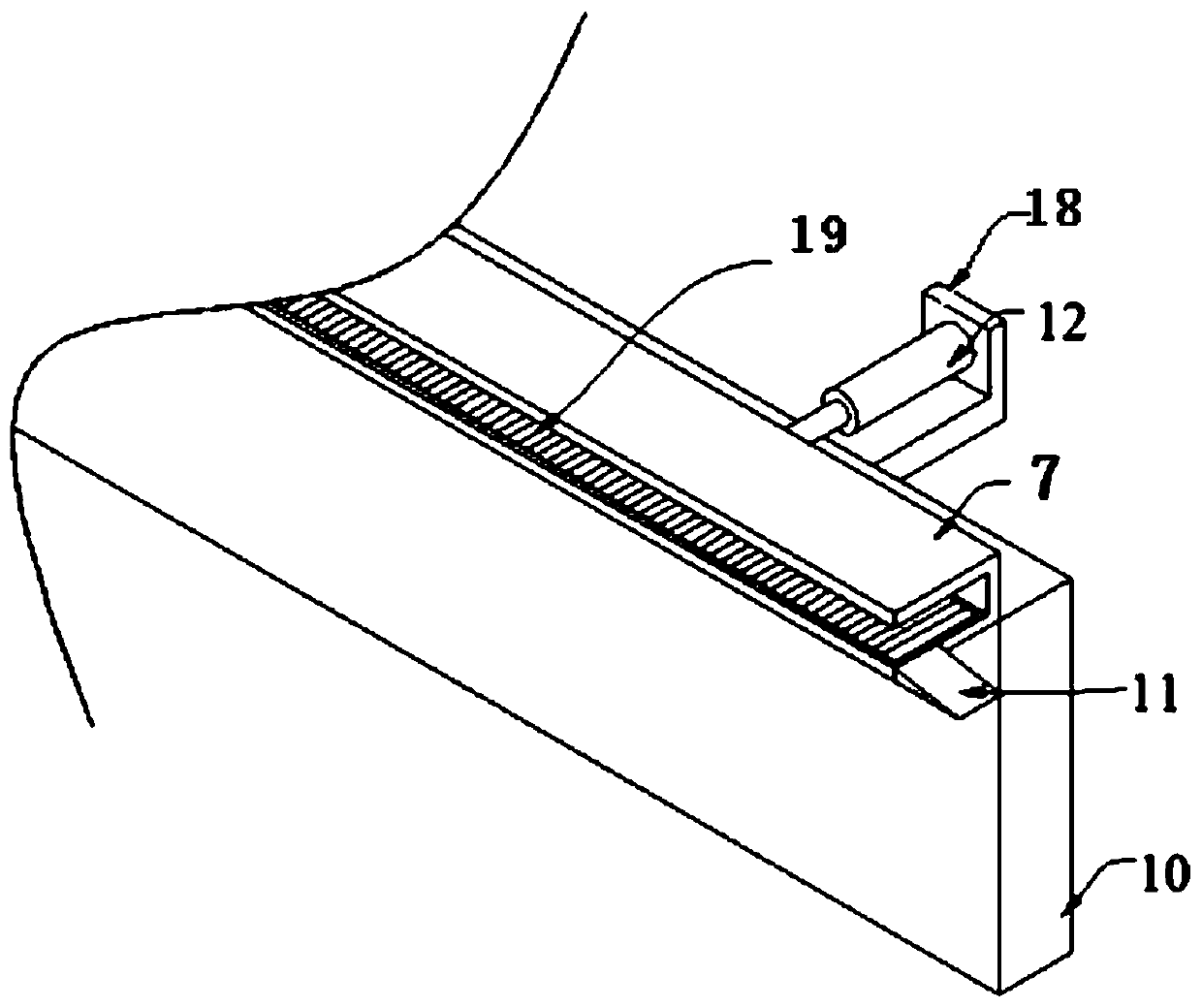

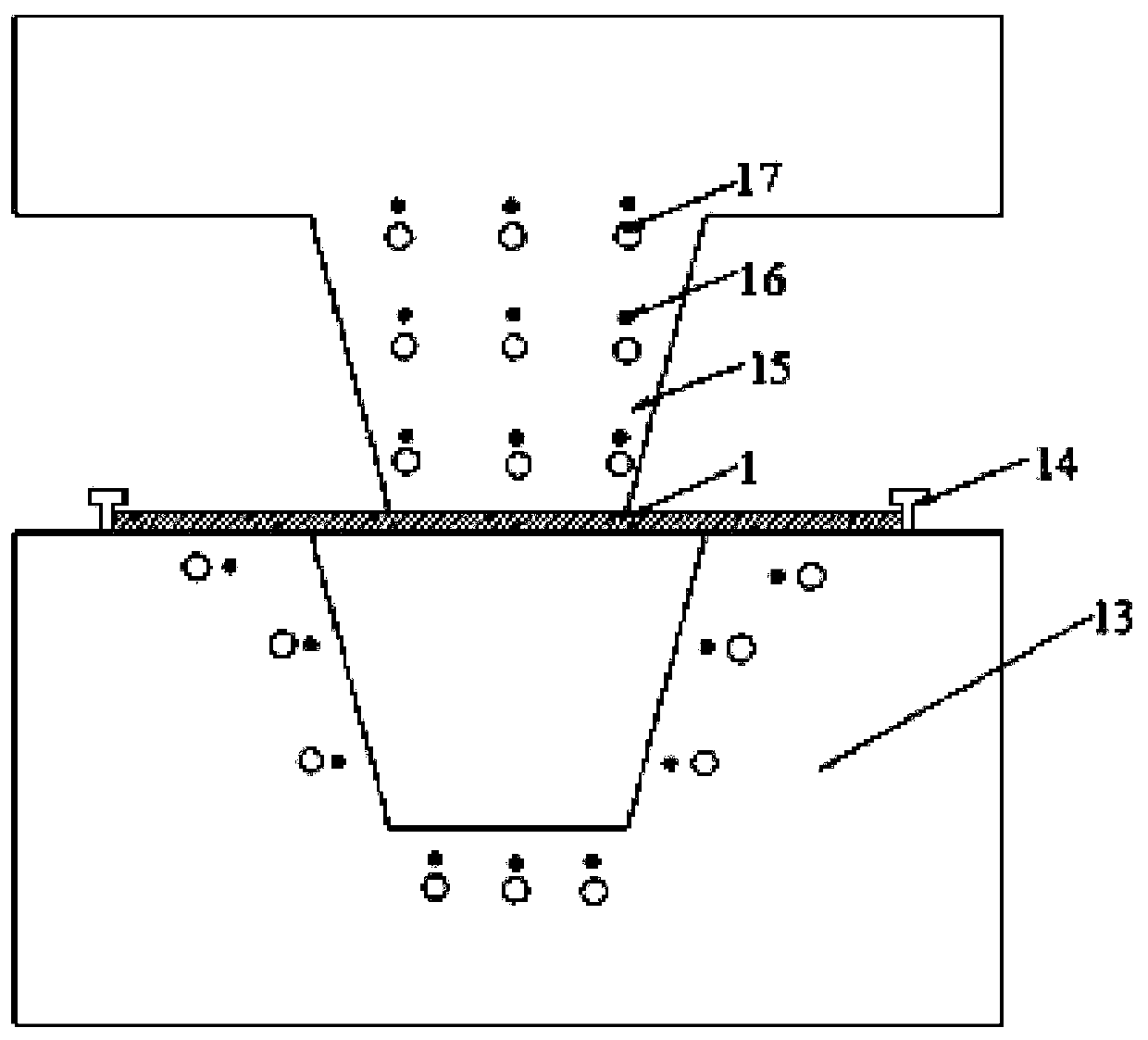

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a shape gradient control device for ultra-high-strength steel, including a transmission frame 3, and transmission rollers are arranged at intervals along the length direction of the transmission frame 3, and the plate to be processed can move on the transmission frame 3 . A first heating furnace 4 , a rolling device 5 and a second heating furnace 6 are sequentially arranged on the transmission frame 3 from the input end to the output end, and the output end of the transmission frame 3 is connected to the stamping device 8 through the side roller track 7 . The first heating furnace 4 is used for preheating the ultra-high-strength steel plate 1; the rolling device 5 is used for rolling the preheated plate on-line with variable thickness; the second heating furnace 6 is used for rolling the rolled plate Stress relief during tentenitization and synchronous shaping; the stamping device 8 is used for...

Embodiment 2

[0036]Based on the same inventive concept as that of Embodiment 1, an embodiment of the present invention provides a method for controlling the shape gradient of ultra-high-strength steel, including the following steps:

[0037] Move the blanked ultra-high-strength steel plate to the first heating furnace, and preheat it under the protection of nitrogen. The heating temperature is 720-760 ° C, and keep it for a period of time; the holding time is t, t=d×n; In the formula: d is the thickness of the plate, the unit is mm; the unit of t is s; n is a constant, and the value of n is 60-65.

[0038] The preheated ultra-high-strength steel plate is moved out of the first heating furnace, and rolled on-line, so that the thickness of the ultra-high-strength steel plate has a gradient.

[0039] Move the rolled ultra-high-strength steel plate to the second heating furnace, continue heating under the protection of nitrogen, the heating temperature is 910-940 ° C, and keep it for a period ...

Embodiment 3

[0042] An embodiment of the present invention provides a method for controlling the shape gradient of ultra-high-strength steel, which specifically includes the following steps:

[0043] 1) Preheating: move the blanked ultra-high-strength steel plate to the first heating furnace, preheat to 720-760°C under the protection of nitrogen; keep it warm for a period of time, t=d×n; where: d is the thickness of the plate, the unit is mm; the unit of t is s; n is a constant, and the value of n is 60~65.

[0044] 2) On-line rolling with variable thickness: the ultra-high-strength steel sheet is moved out of the first heating furnace through the conveying roller, and rolled on-line to make the thickness gradient; the deformation of some areas of the online rolling with variable thickness is controlled at 30% to 50%, while the thinning area does not exceed 30%.

[0045] 3) Austenitization and simultaneous shaping and stress relief: move the rolled ultra-high-strength steel plate to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com