Patents

Literature

37results about How to "Short control time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

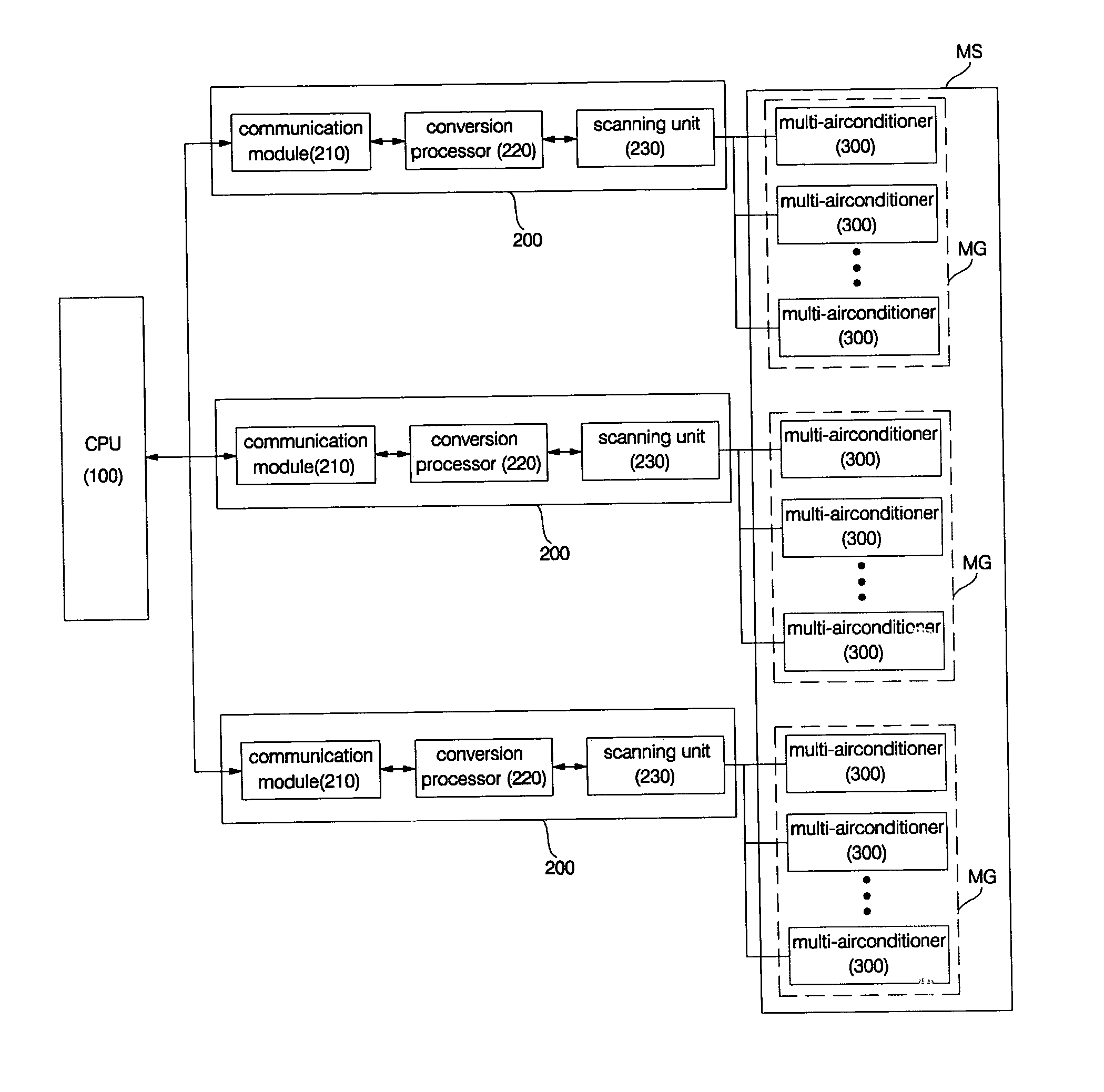

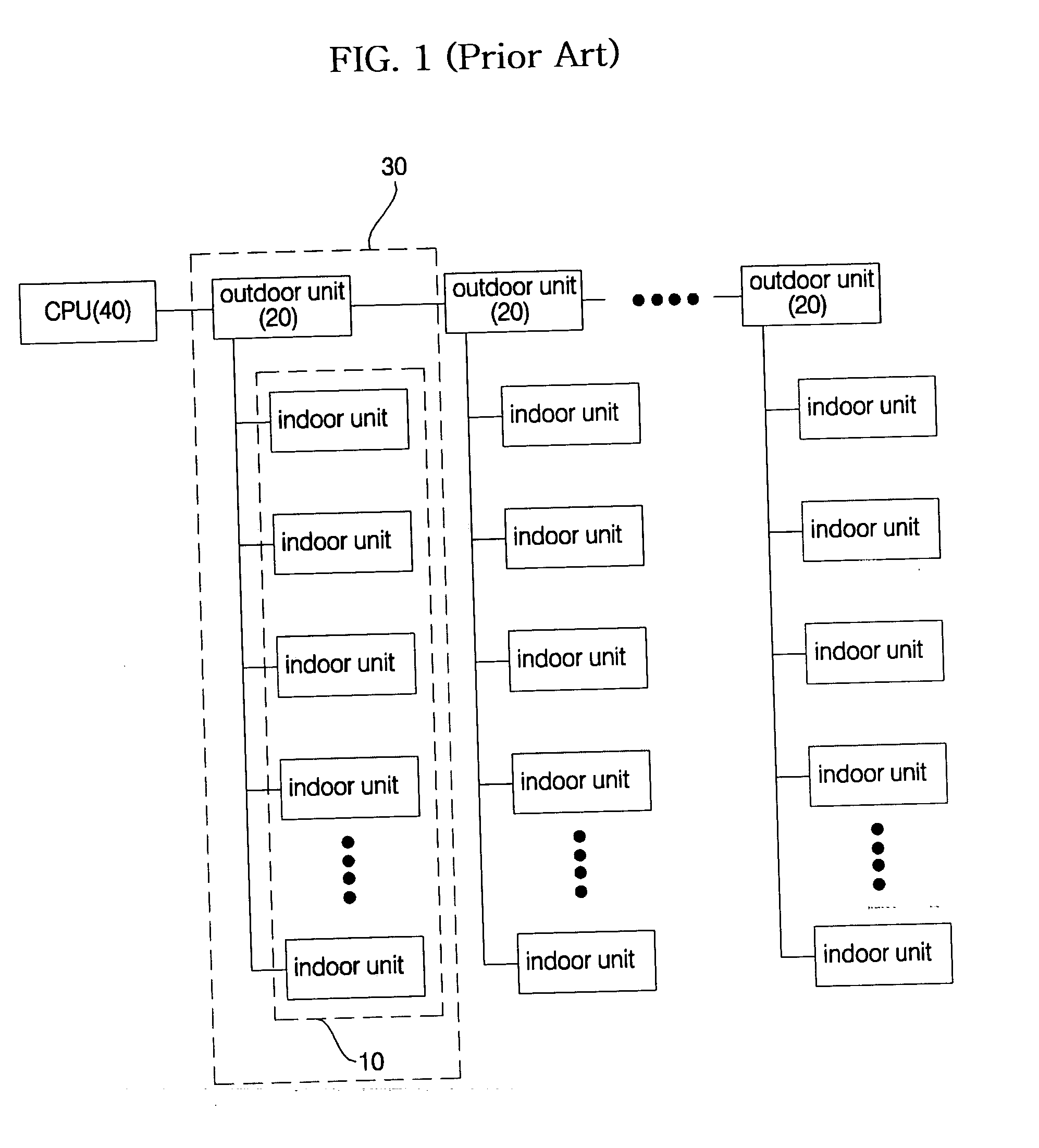

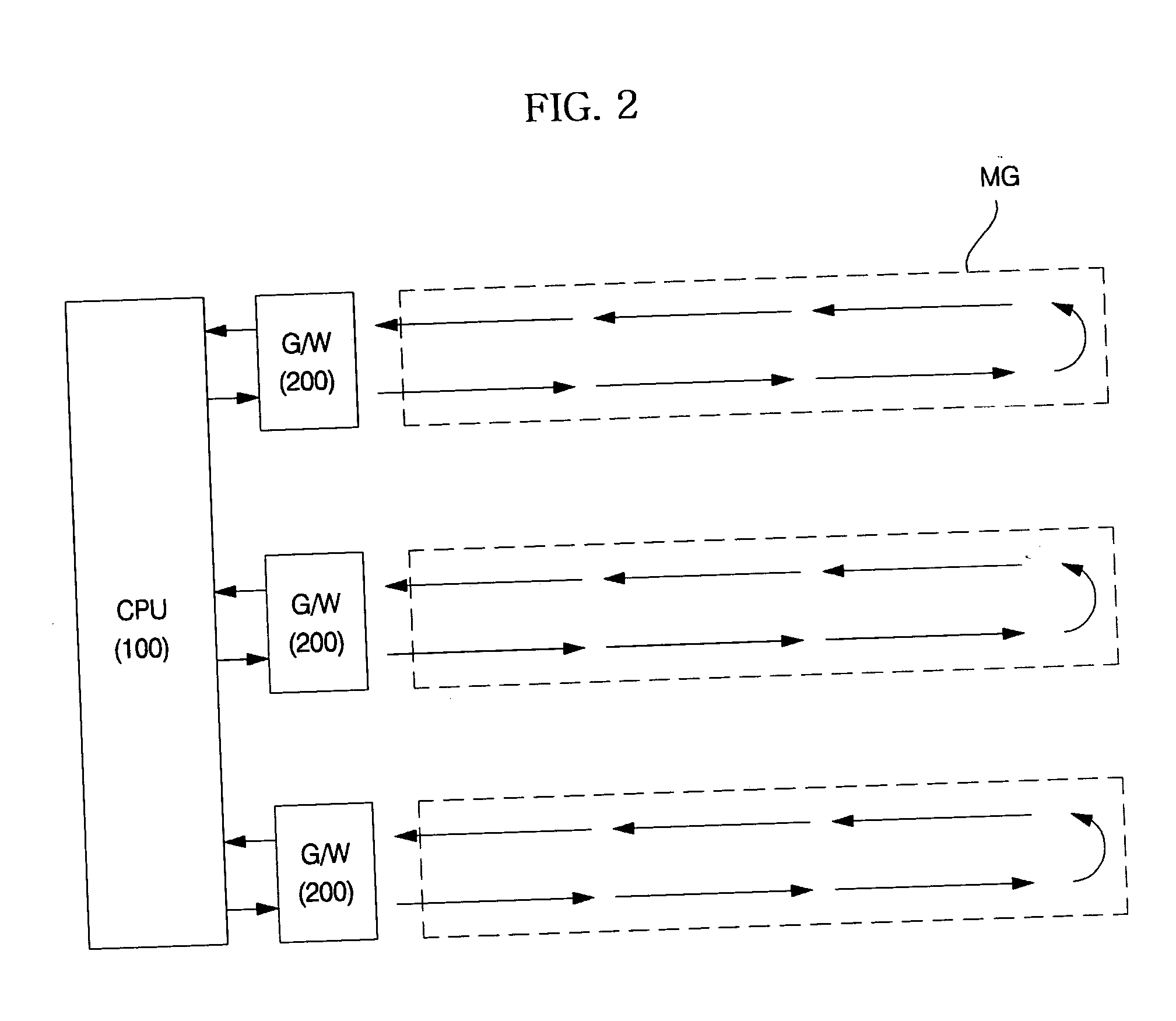

Air-conditioning system for integrating multiple areas

ActiveUS20050209739A1Short control timeImprove stabilityProgramme controlSampled-variable control systemsEngineeringAir conditioning

An airconditioner system for integrating multiple areas. A plurality of multi-airconditioners are grouped into some groups. CPU connected in parallel to individual multi-airconditioner groups, that have been distributed and installed in a wide area or building, controls individual multi-airconditioner groups to be operated simultaneously, resulting in a shorter control time. Although an unexpected communication failure occurs in one multi-airconditioner group, the remaining multi-airconditioner groups other than the erroneous multi-airconditioner group can be normally controlled, resulting in increased stability and reliability of an overall airconditioning system.

Owner:LG ELECTRONICS INC

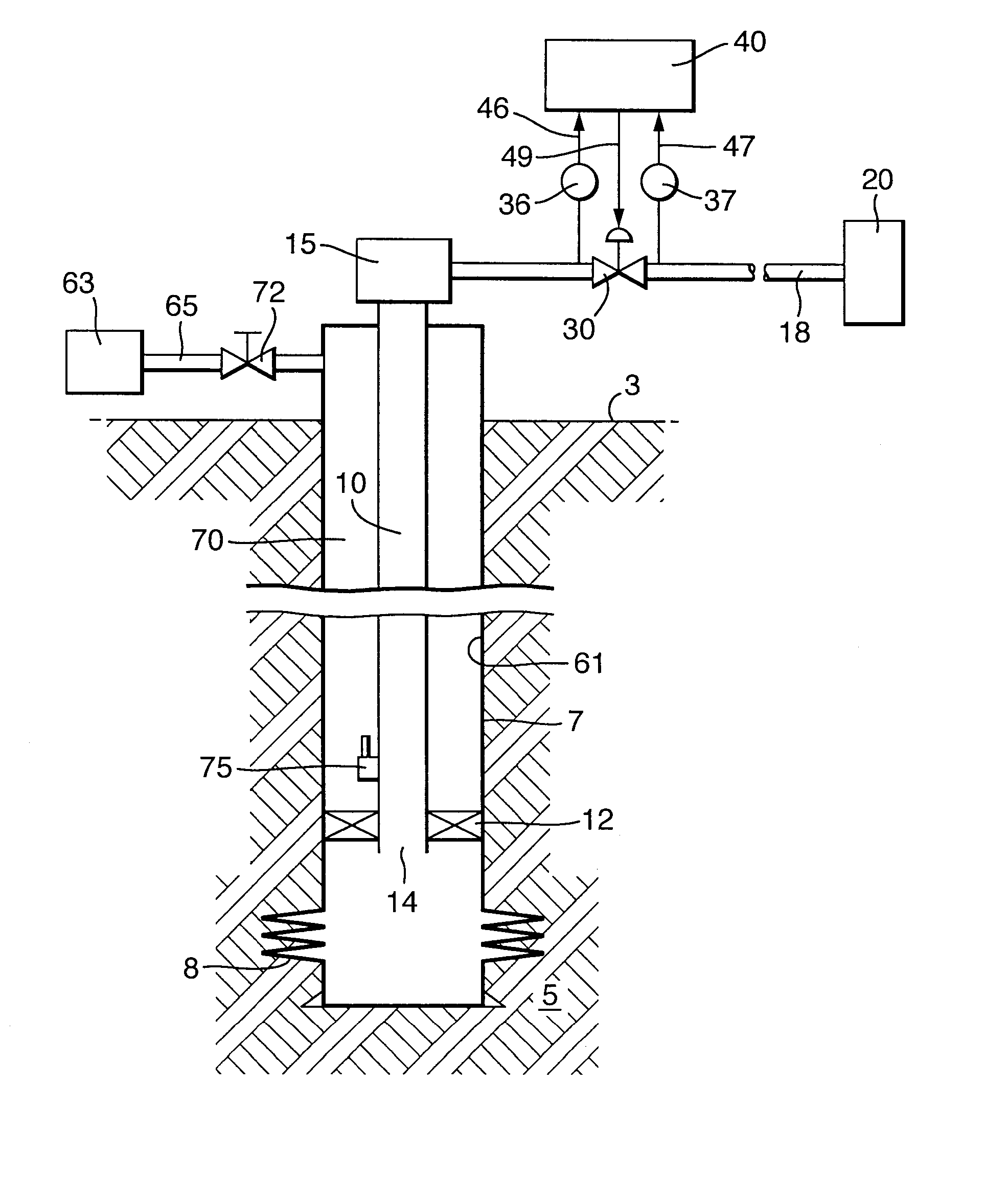

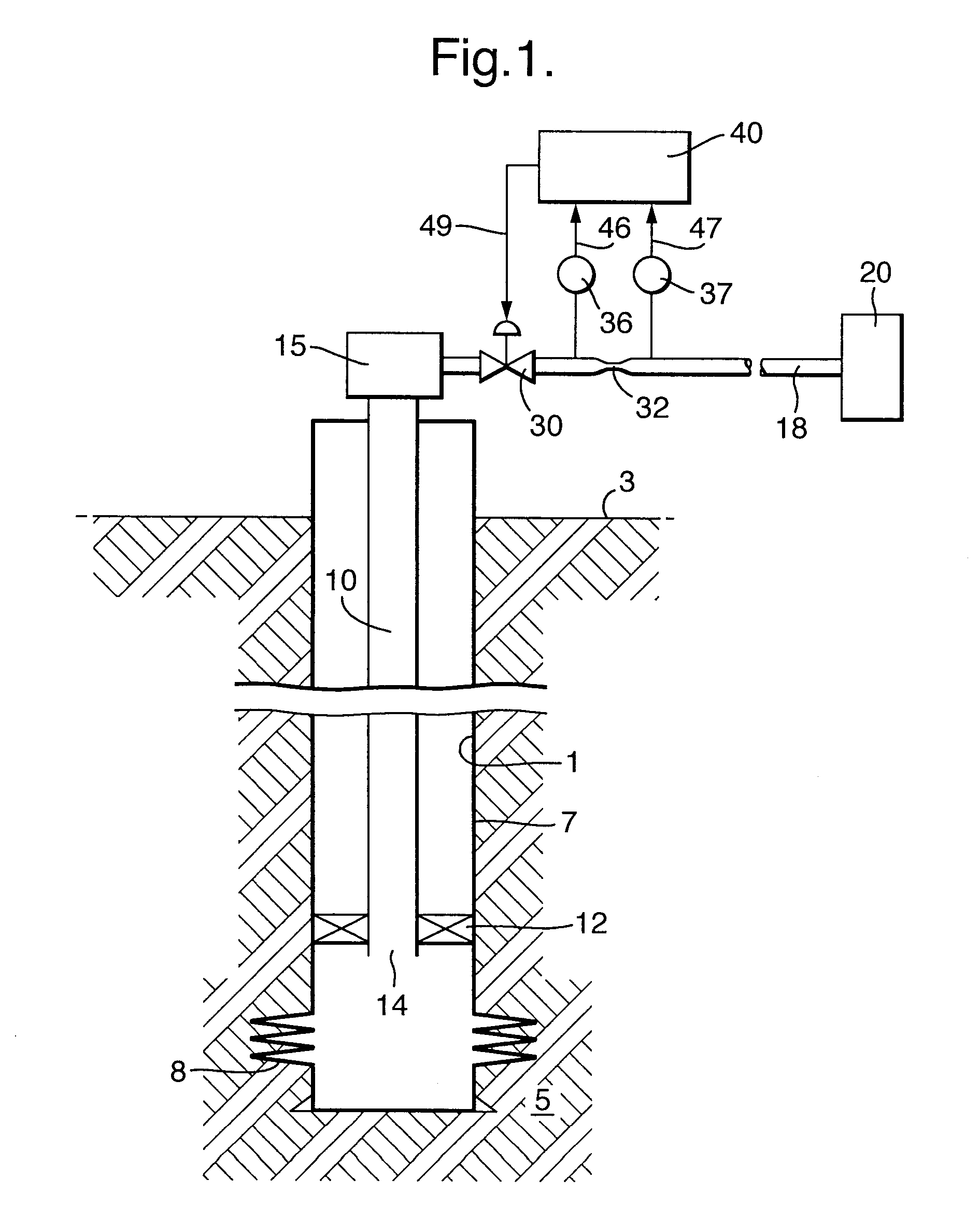

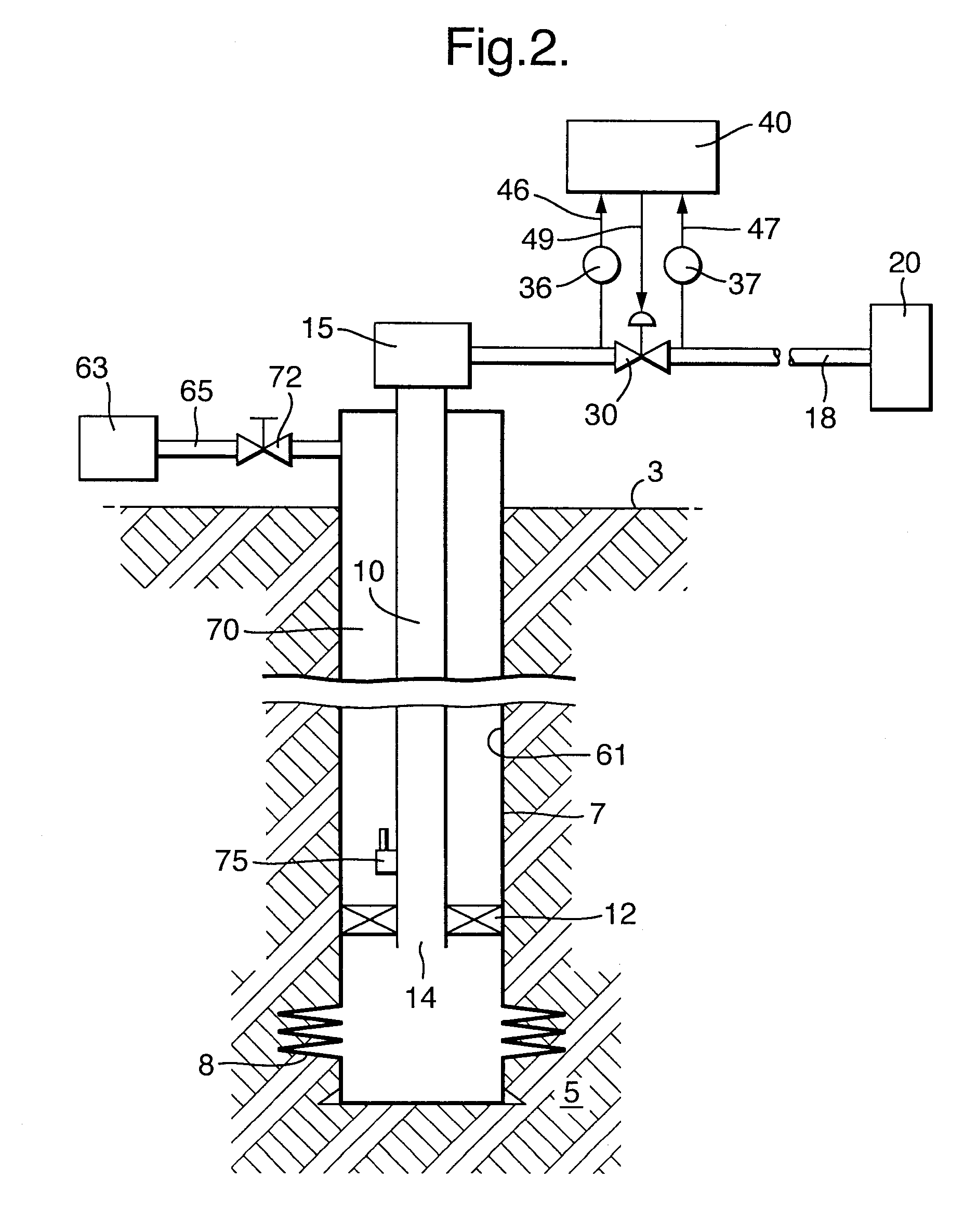

Controlling The Flow Of A Multiphase Fluid From A Well

InactiveUS20080041586A1Short control timeEasy to controlSurveyFluid removalLiquid ratioControl system

A method for controlling the flow of a multiphase fluid from a well extending into a subsurface formation, which well is provided at a downstream position with a valve having a variable aperture, which method comprises allowing the multiphase fluid to flow at a selected aperture of the valve; selecting a flow parameter of the multiphase fluid, which flow parameter is responsive to changes in a gas / liquid ratio of the multiphase fluid at an upstream position in the well, and a setpoint for the flow parameter; and monitoring the flow parameter; controlling the flow parameter towards its setpoint by manipulating the aperture of the valve; wherein the control time between detection of a deviation from the setpoint and the manipulation of the aperture is shorter than the time needed for the multiphase fluid to travel 25% of the distance between the upstream and downstream positions. Further a well extending into a subsurface formation for producing a multiphase fluid to surface, which well is provided at a downstream position with a valve having a variable aperture, and with a control system for controlling the multiphase flow.

Owner:SHELL OIL CO

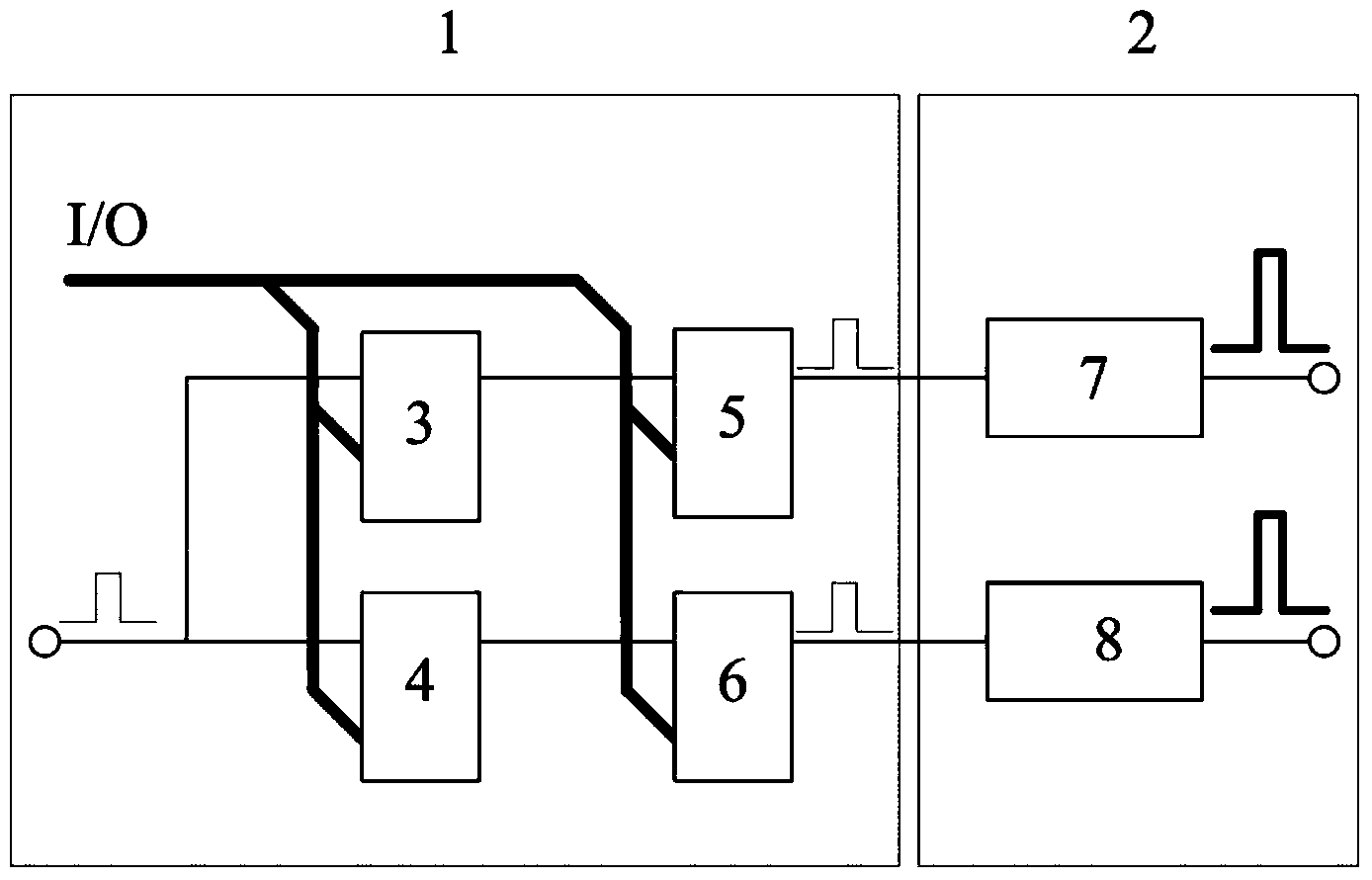

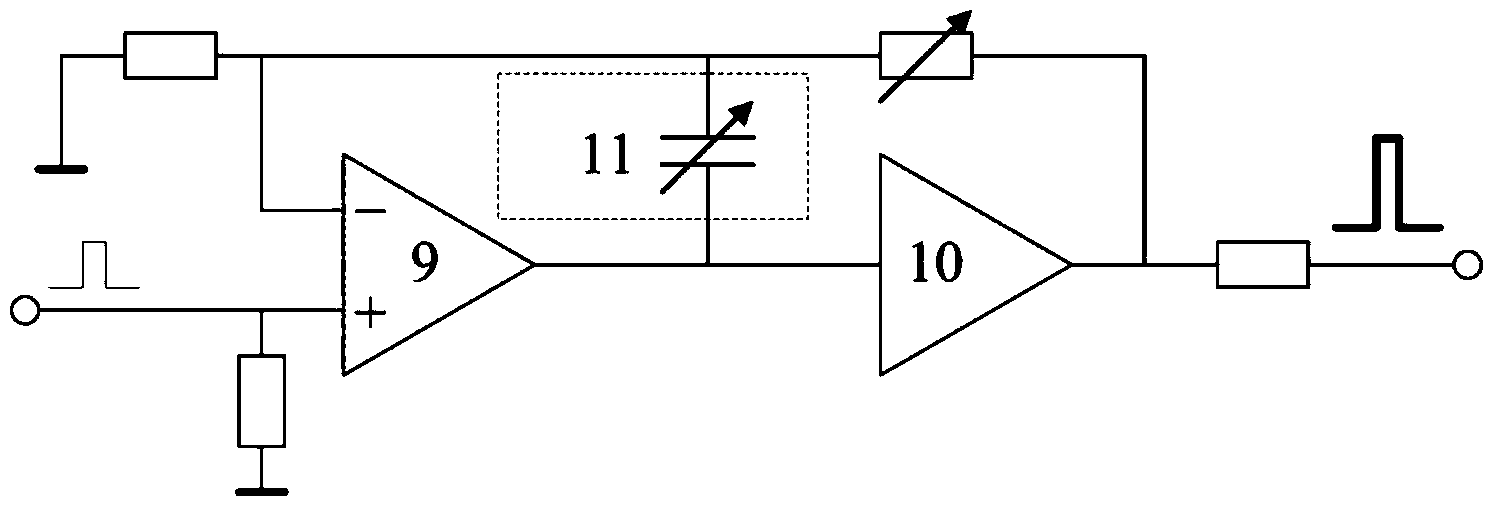

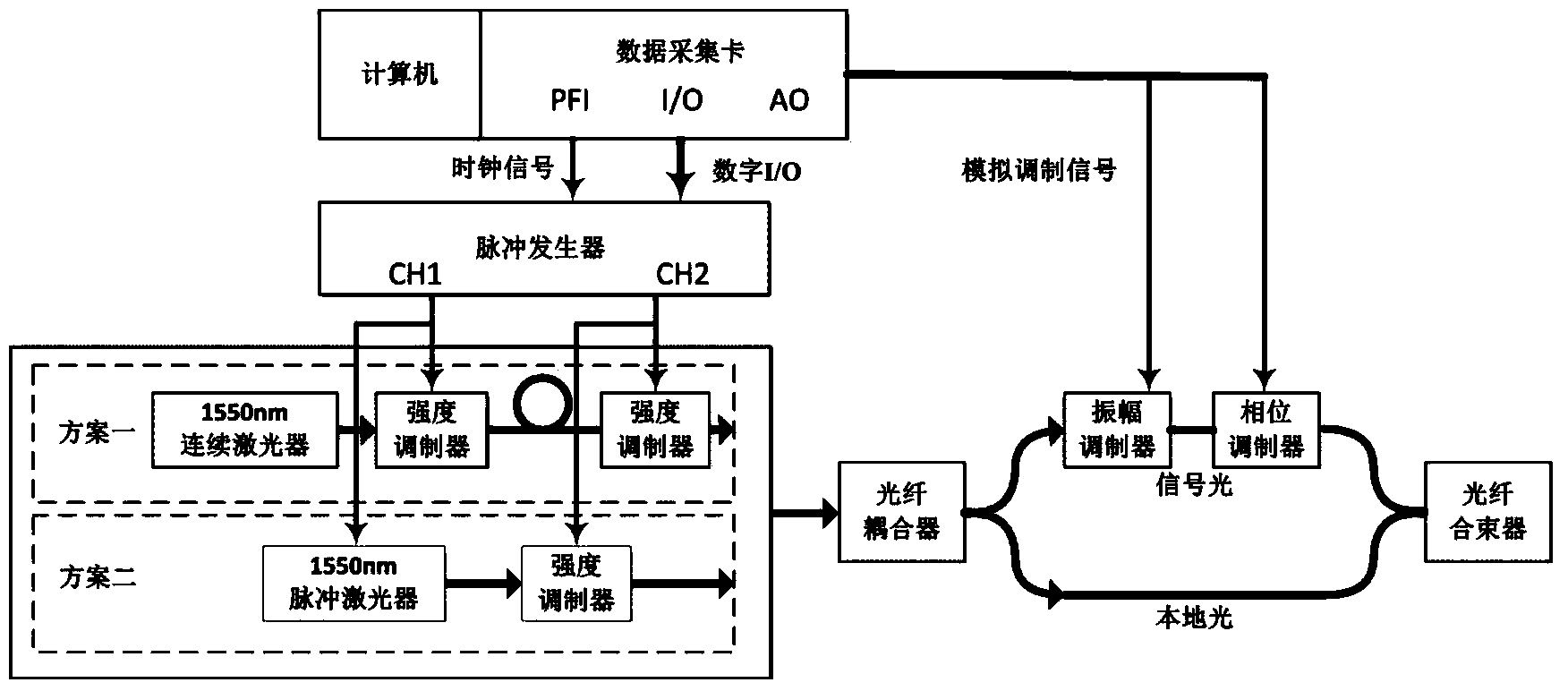

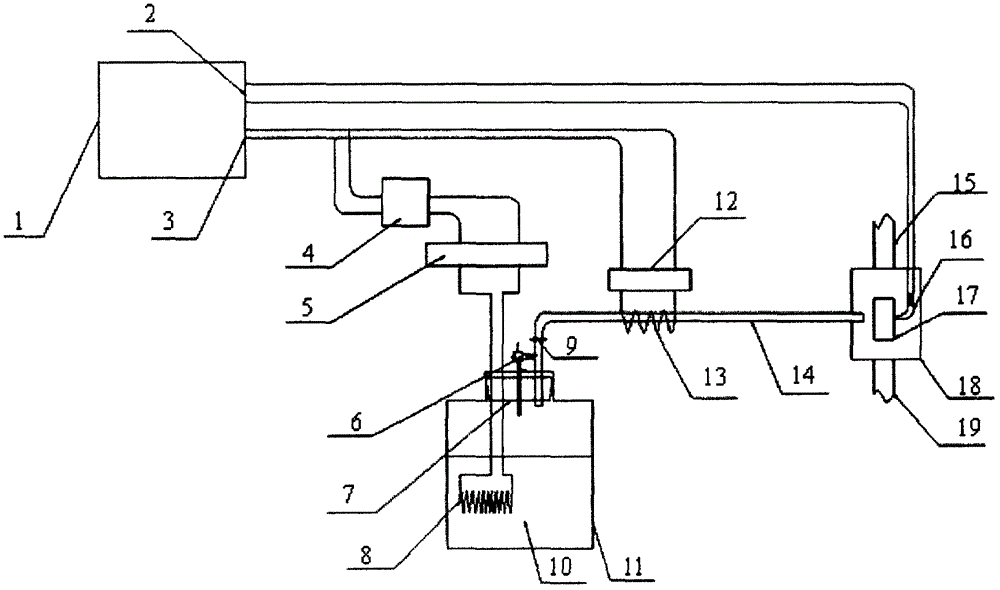

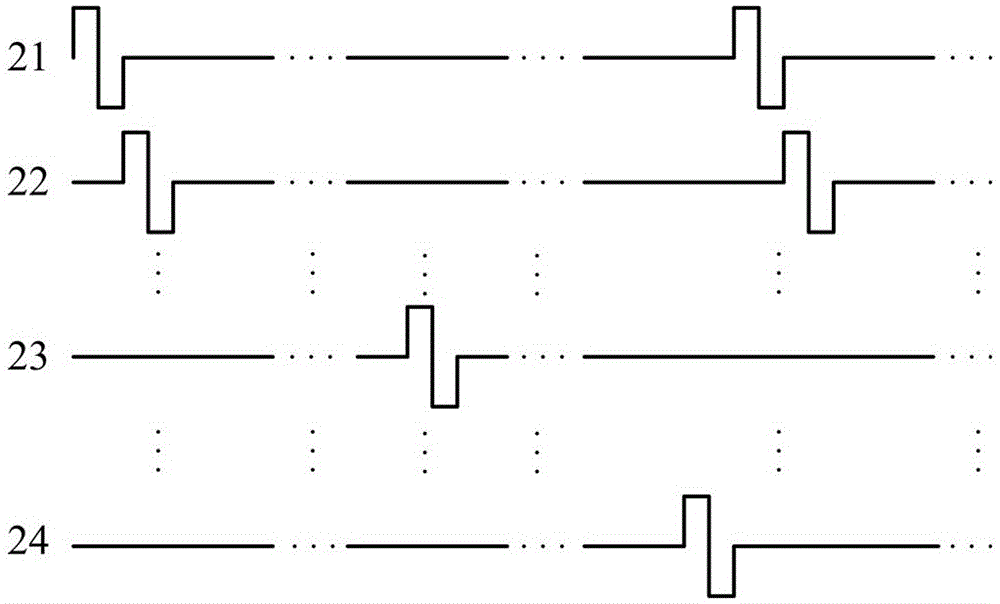

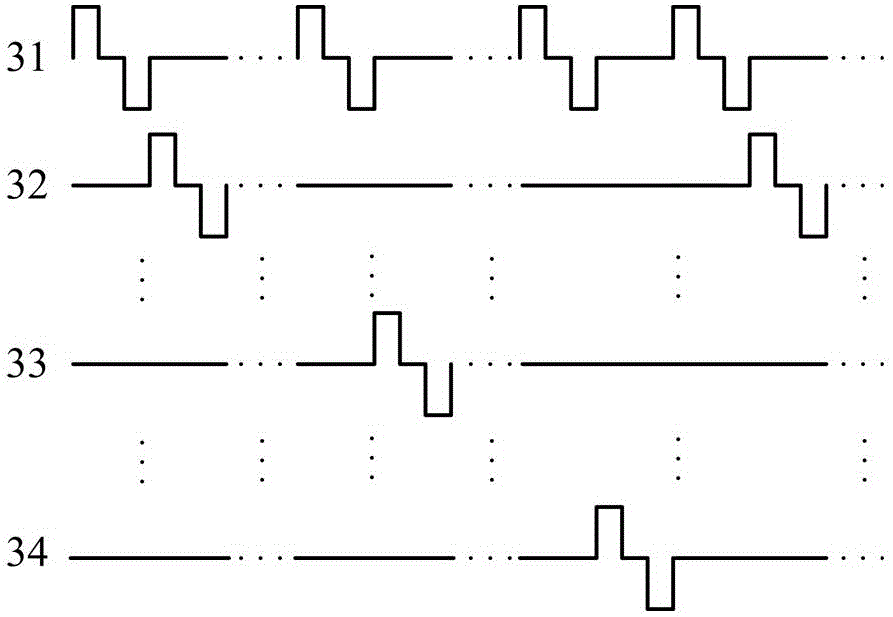

Pulse generator applied to distributing continuous variable quantum secret keys

ActiveCN103905185AShort control timeLow costKey distribution for secure communicationElectric pulse generatorPhysicsTime delays

The invention provides a pulse generator applied to distributing continuous variable quantum secret keys. The pulse generator comprises a digital circuit (1) and an analog circuit (2). The digital circuit (1) comprises a first programmable pulse width modulation chip (3) and a first programmable delay wire chip (5), a second programmable pulse width modulation chip (4) and a second programmable delay wire chip (6). The analog circuit (2) comprises a first power amplifying circuit (7) and a second power amplifying circuit (8). An externally input clock signal triggers the digital circuit (1) to generate two pulses of which the pulse and time delay can be accurately adjusted, and the two pulses are output through first power amplifying circuit (7) and the second power amplifying circuit (8) in the simulation circuit (2) respectively. The pulse generator has the advantages of being capable of accurately adjusting the pulse width, high in time delay accuracy, short in control time, high in driving capacity, small in size, low in cost and the like, and the pulse generator can be integrated in a system for distributing the continuous variable quantum secret keys very well.

Owner:SHANXI UNIV

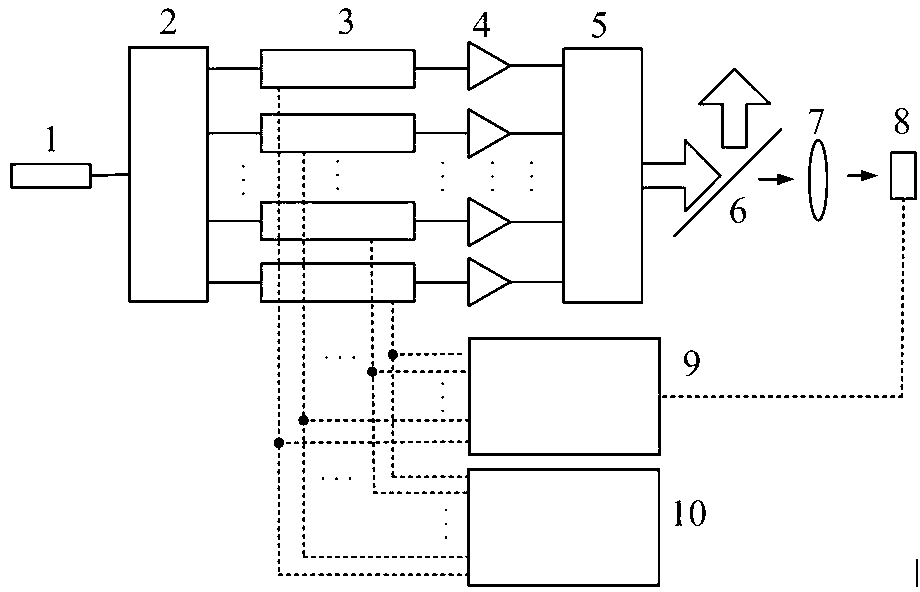

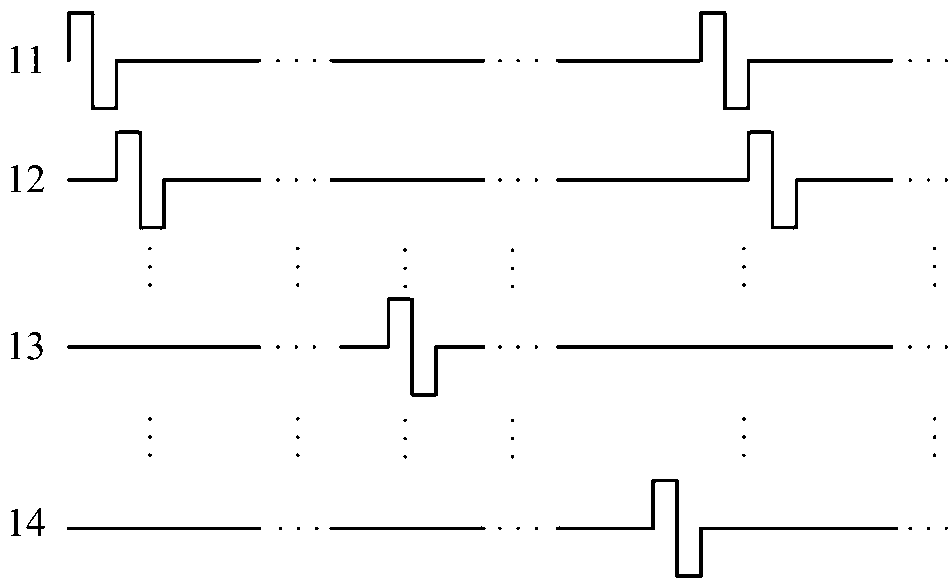

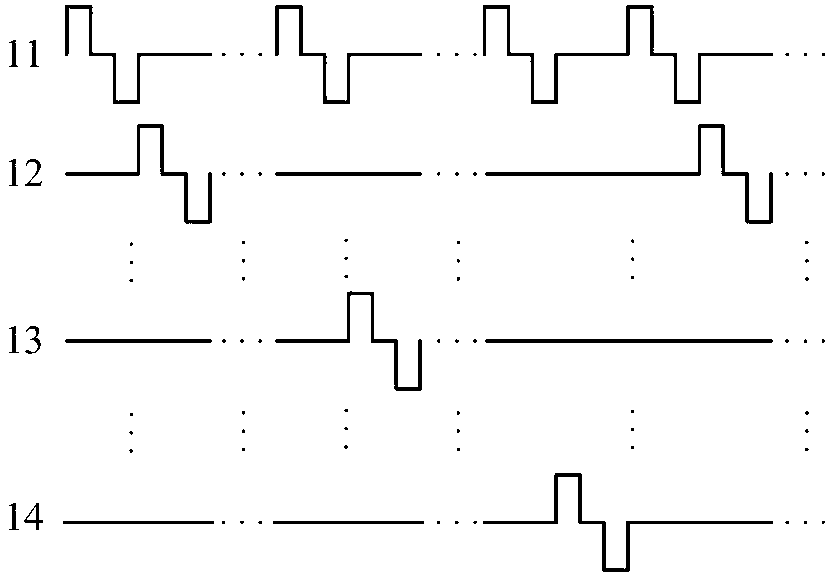

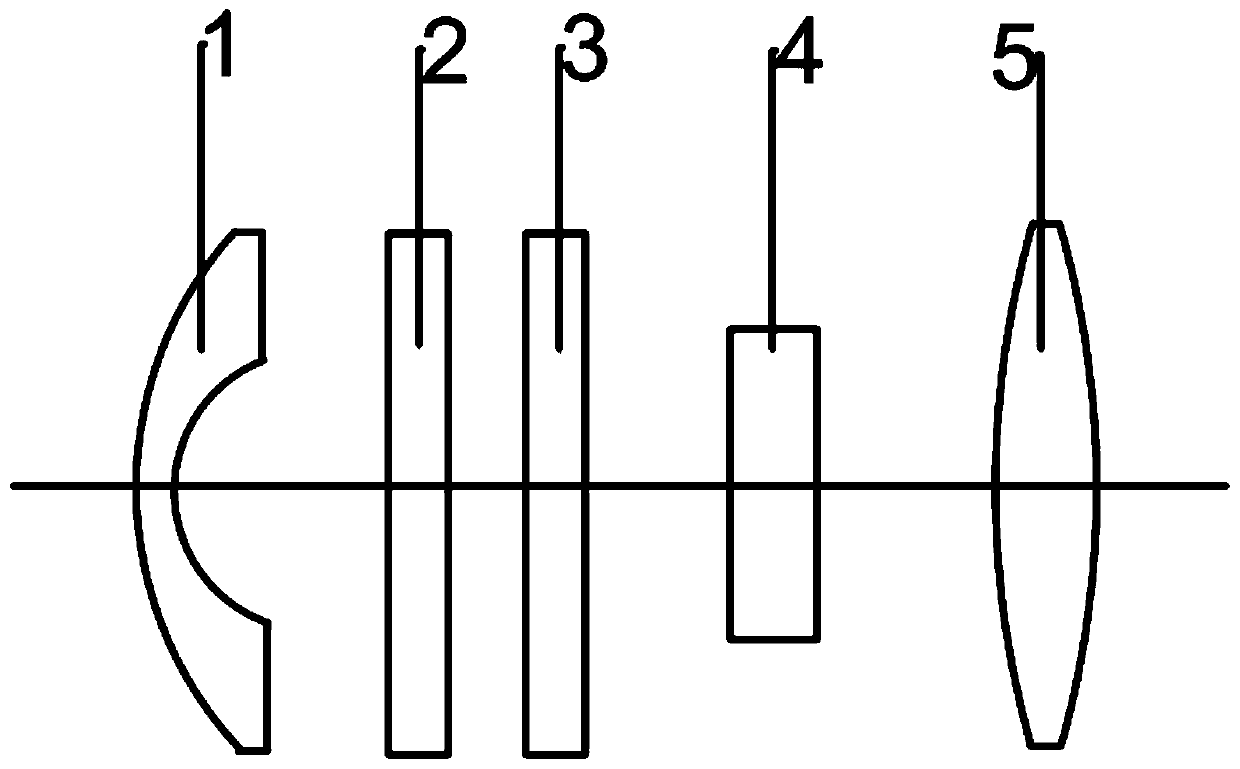

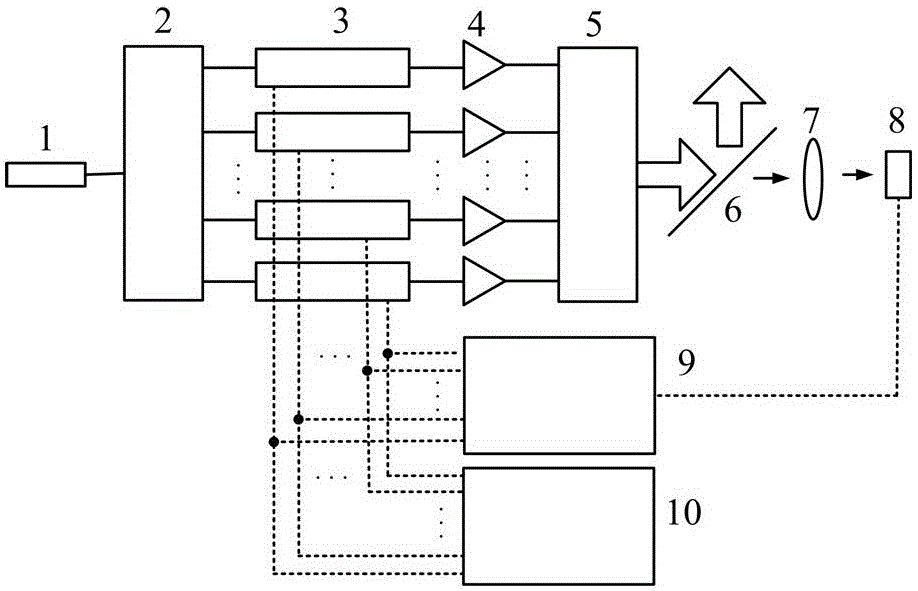

Beam array phase control system and method based on multiphase perturbation

InactiveCN103227408ASimple structureAccurately obtain the magnitude of the phase shiftLaser detailsBeam splitterControl signal

The invention provides a beam array phase control system and a method based on multiphase perturbation. Emergent laser of a laser source in the control system is input to a beam splitter; multichannel laser output by the beam splitter is input to corresponding phase controllers respectively; the phase controllers are sequentially connected with optical amplifiers and an optical collimation emitter; the optical collimation emitter is sequentially connected with an optical splitter and a far field image device; the far field image device inputs the laser into a detector; an electrical signal output by the detector is input into a phase control algorithm module; the phase control algorithm module outputs a multichannel electrical control signal to the corresponding phase controllers; and a multiphase perturbation generation module outputs a multichannel electrical modulating signal to the corresponding phase controllers. With the adoption of the system and the method, the performance of a coherent combination system can be improved, and large-scale beam combining capacity can be achieved.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS

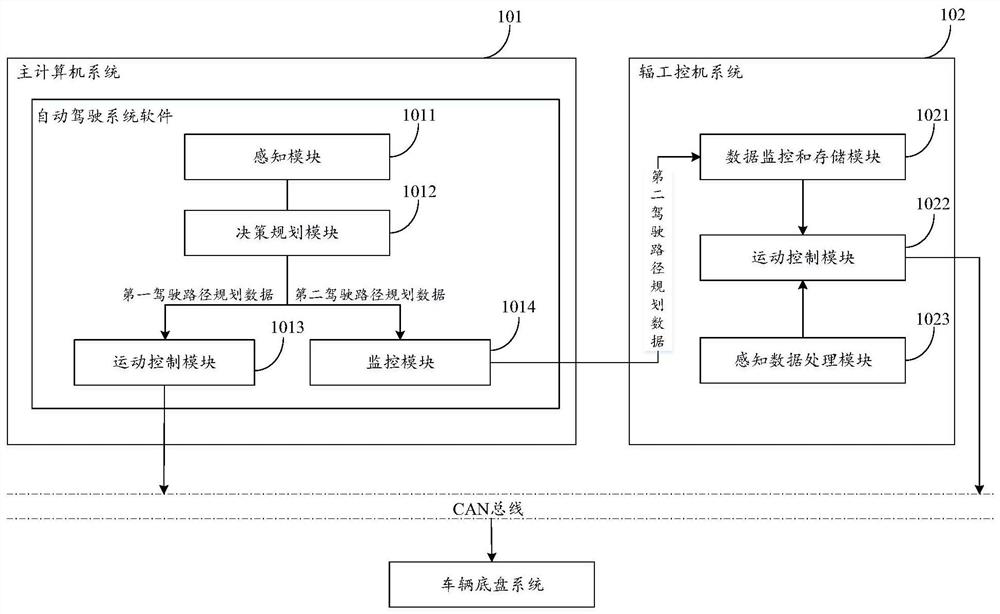

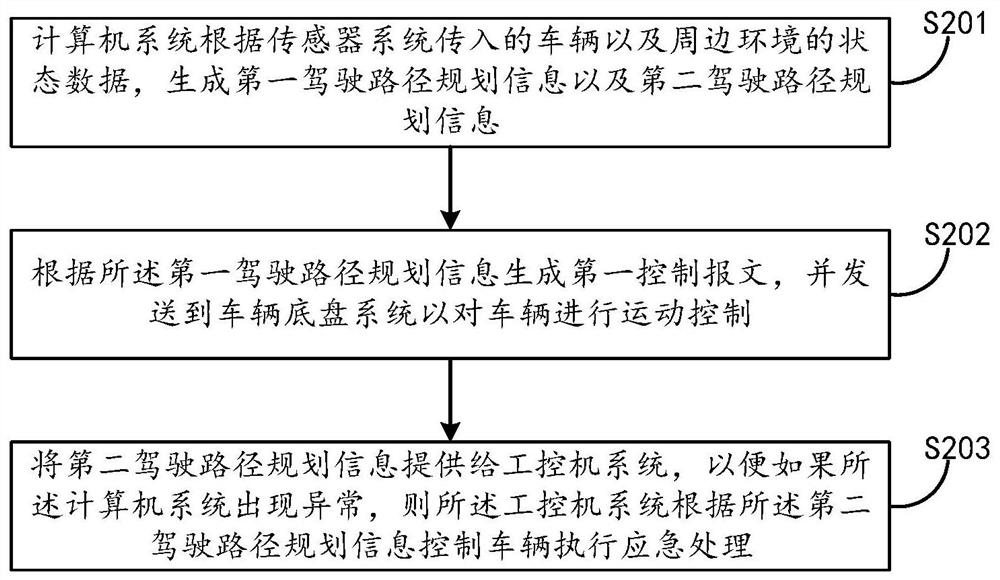

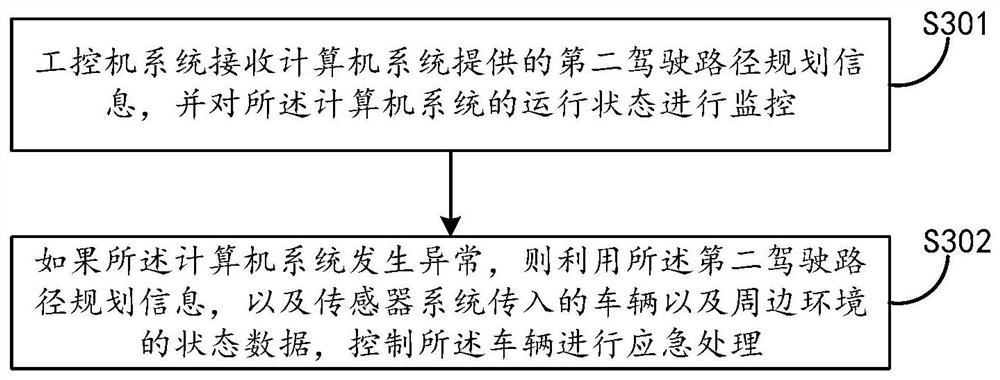

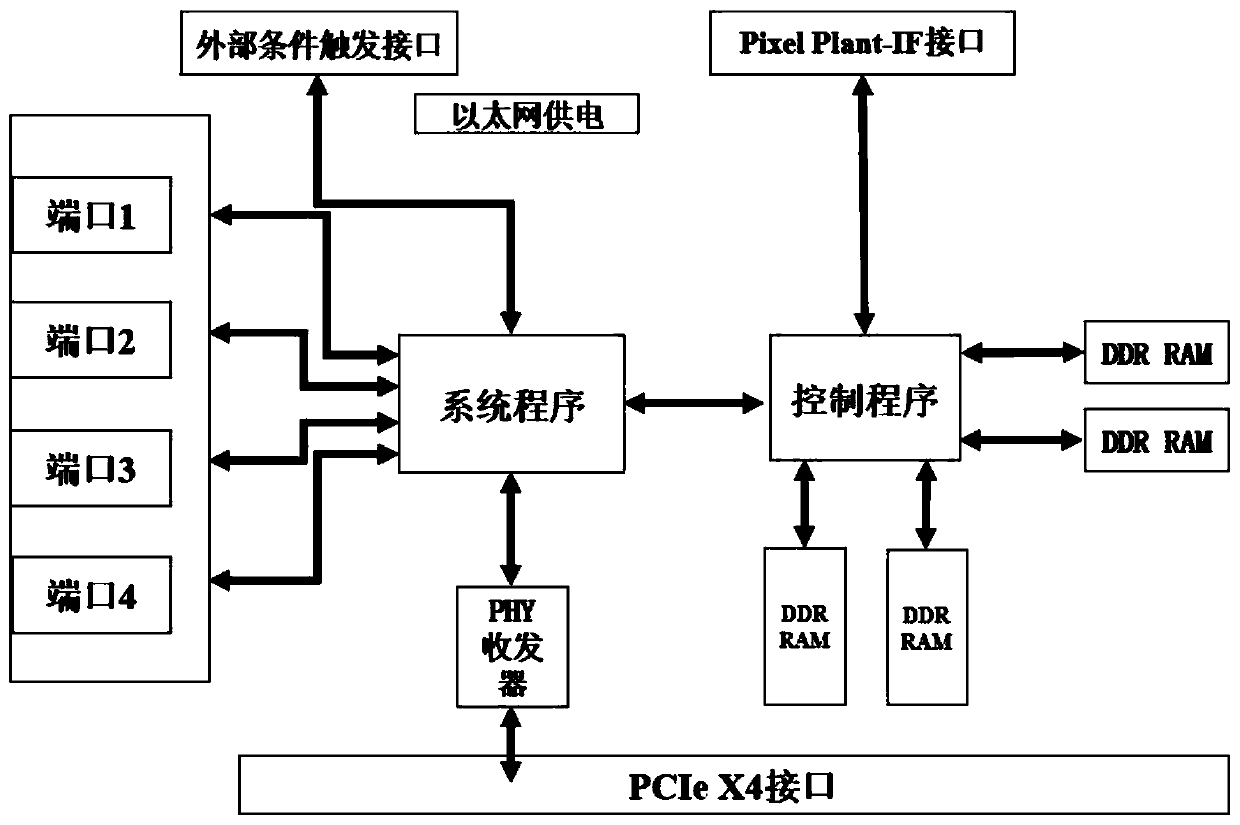

Automatic driving control method, device and system

PendingCN111661062AReduce computing power requirementsShorten the timeExternal condition input parametersData controlPersonal computer

The embodiment of the invention discloses an automatic driving control method, device and system. The system includes a processor, a computer system and an industrial personal computer system; the computer system is used for generating first driving path planning information and second driving path planning information according to the state data of a vehicle and a surrounding environment which are transmitted by a sensor system; the first driving path planning information is used for generating a control message; the control message is sent to a vehicle chassis system so as to carry out motion control on the vehicle; the second driving path planning information is provided for the industrial personal computer system in real time; the industrial personal computer system is used for storingthe second driving path planning information provided by the computer system, monitoring the running state of the computer system, and controlling the vehicle to park beside by utilizing the second driving path planning information and the state data, transmitted by the sensor system, of the vehicle and the surrounding environment when the computer system is abnormal. According to the embodimentof the invention, the reliability of an automatic driving automobile can be improved.

Owner:浙江菜鸟供应链管理有限公司

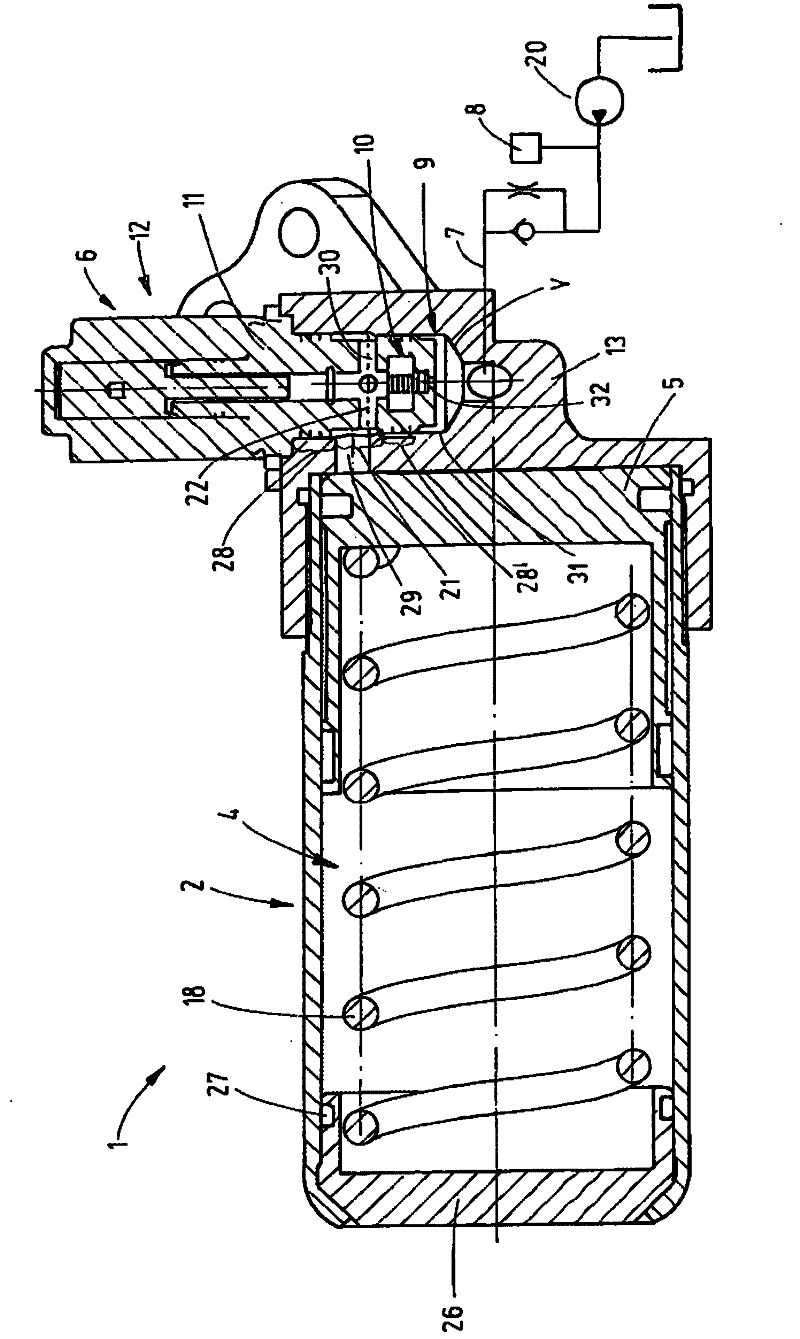

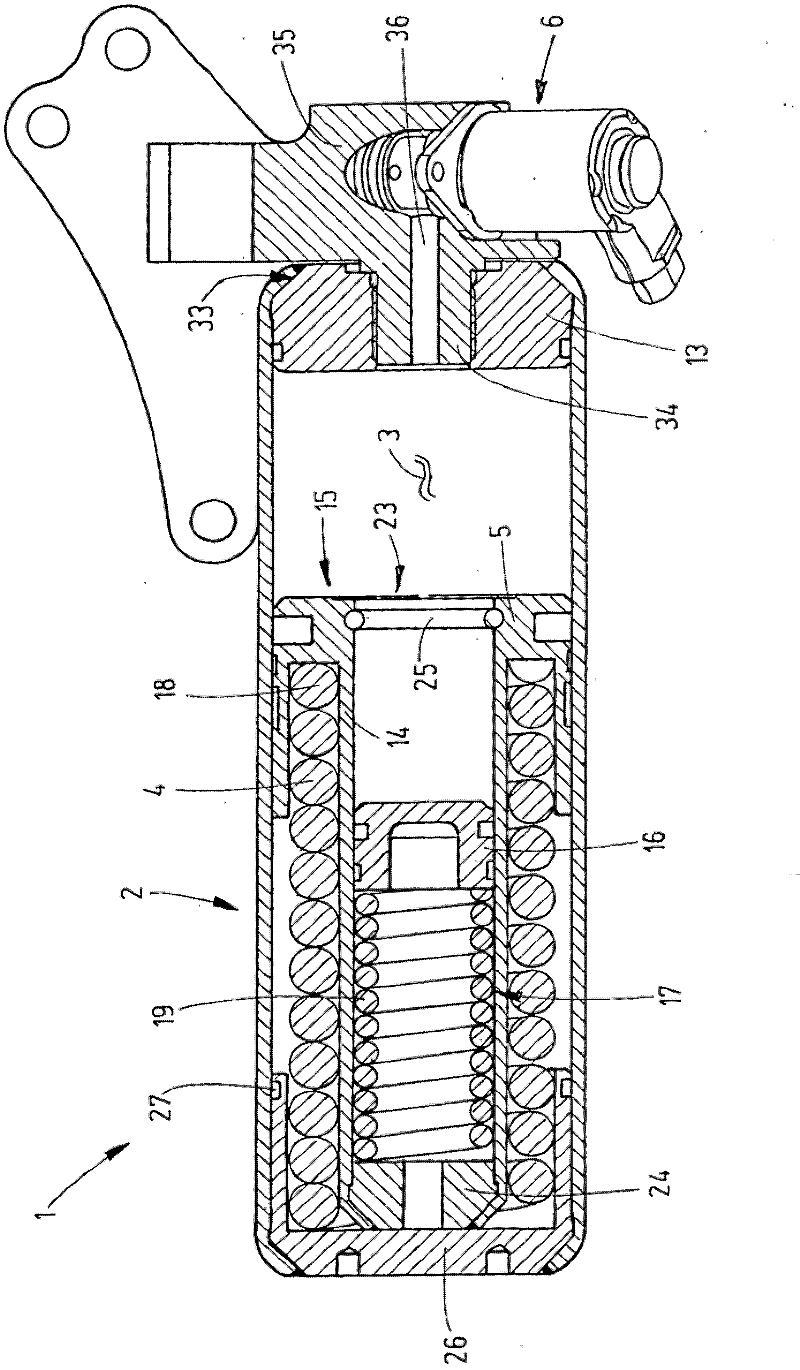

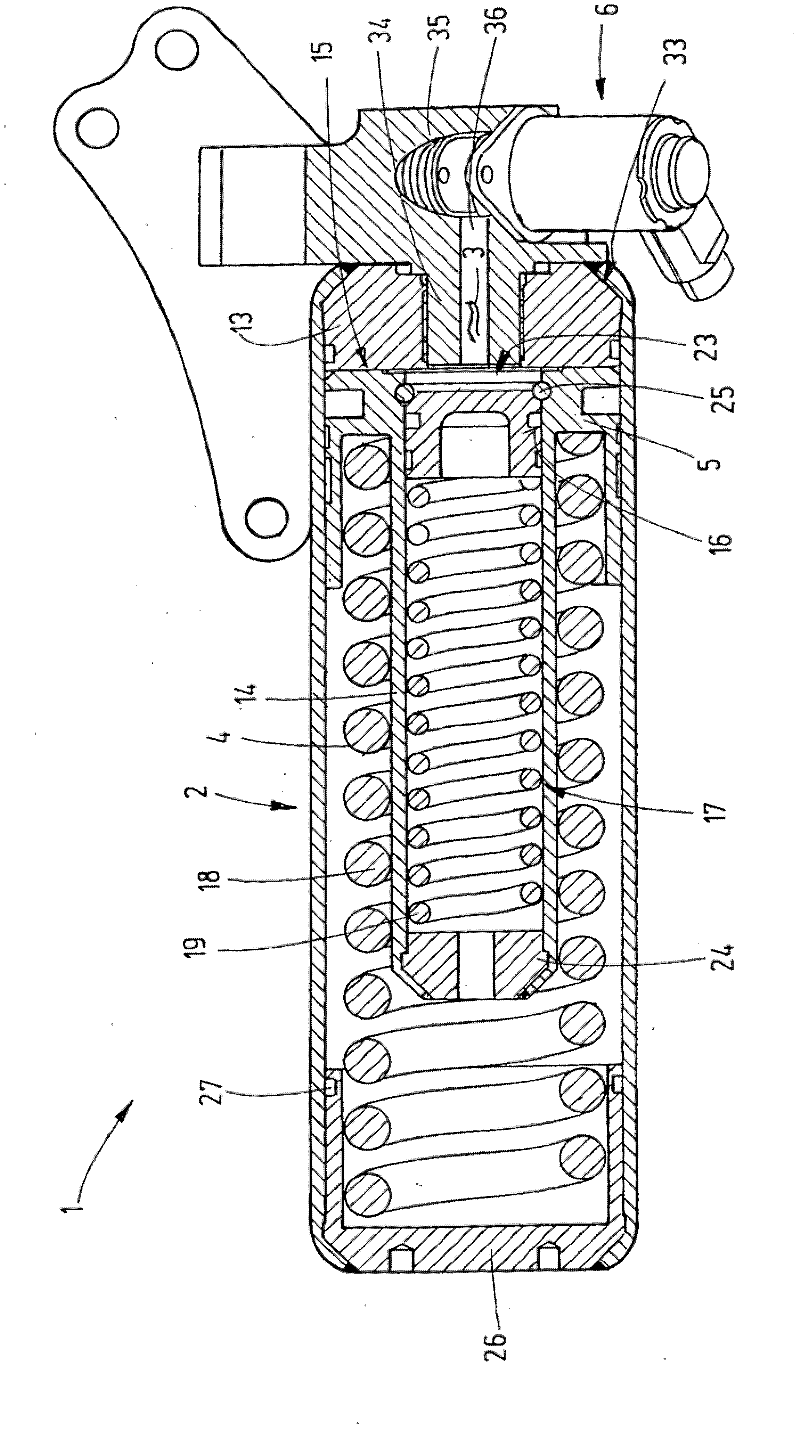

Device for releasing, in a pulsed manner, an amount of fluid that can be stored in an accumulator housing

ActiveCN102575759AQuick releaseShort control timeGearing controlActuator accumulatorsStart stopAutomatic transmission

The invention relates to a device for releasing in a pulsed manner a fluid amount (3) that can be stored in an accumulator housing (2), in particular for carrying out a start-stop function in automatic transmissions, comprising a piston (5) supported against a first energy store (4), which piston can be moved inside the accumulator housing (2) and together with said housing (2) limits the fluid amount (3) that can be accommodated, wherein the piston (5) is held by a valve unit (6) at least in a position equivalent to the maximum volume of the fluid amount (3) in the accumulator housing (2) in that a fluid-conducting connection (7) between the accumulator housing (2) and a load (8) is blocked by the valve unit (6), said device for releasing in a pulsed manner the fluid amount (3) that can be stored in the accumulator housing (2) being characterized in that the valve unit (6); is made up of at least one seat valve (9).

Owner:HYDAC TECH GMBH

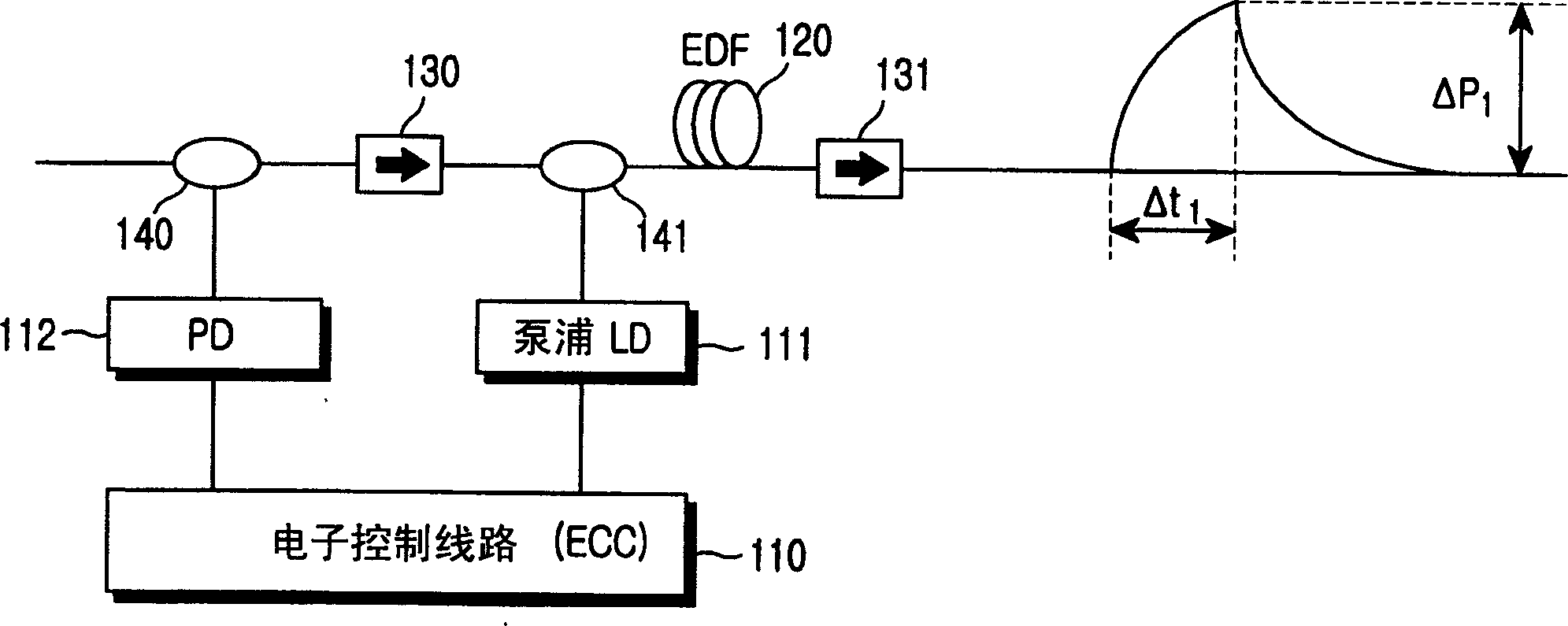

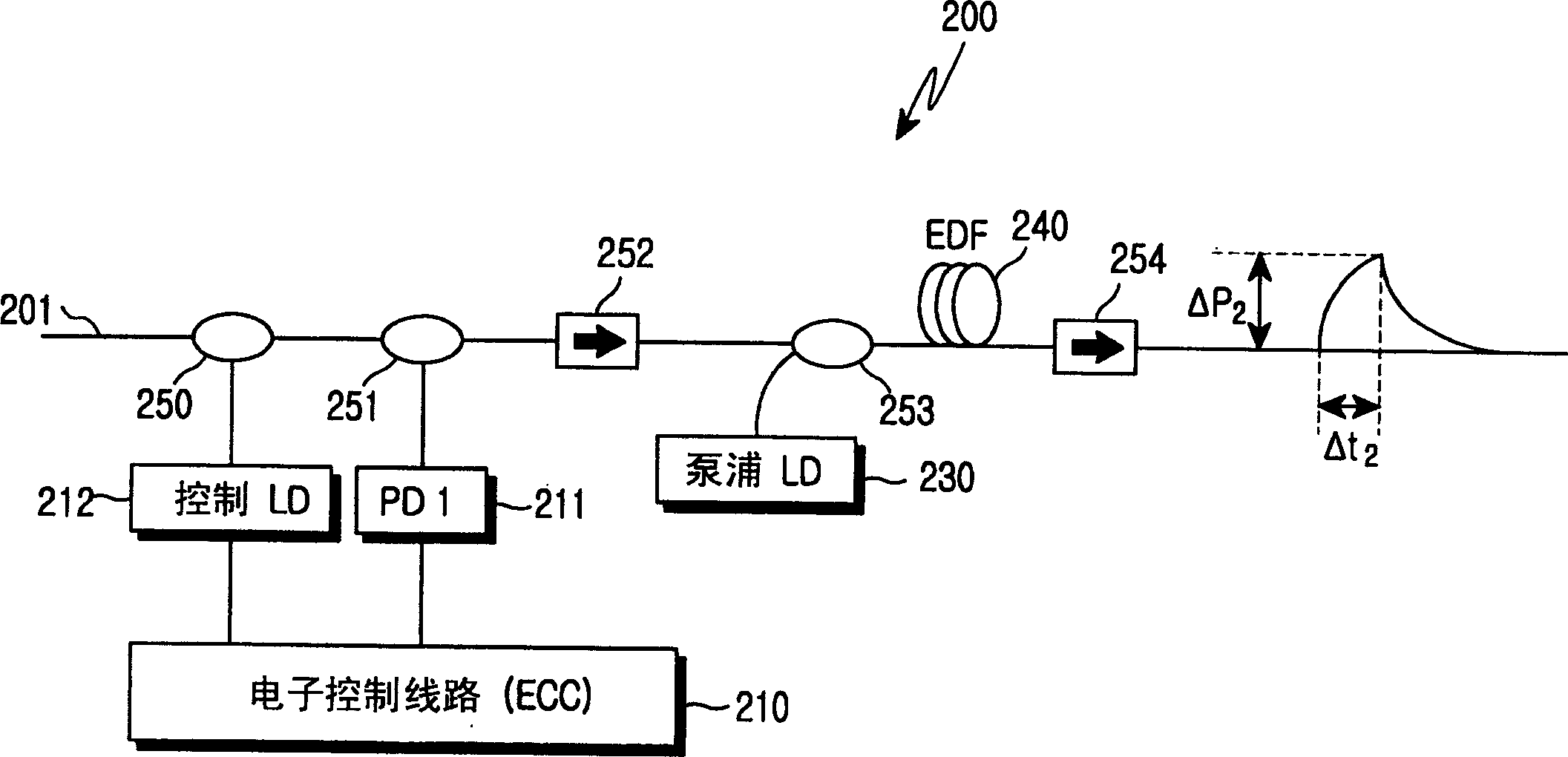

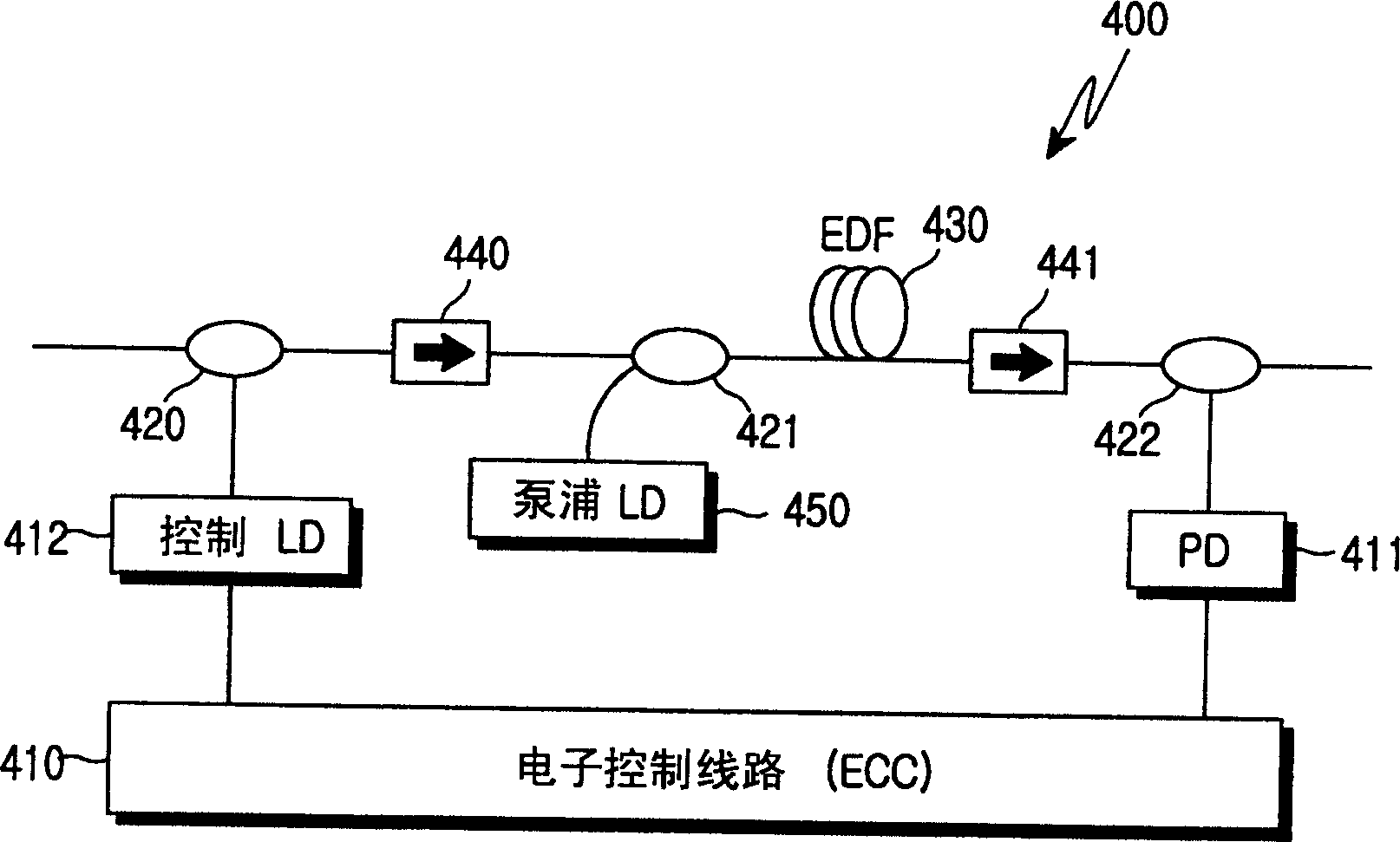

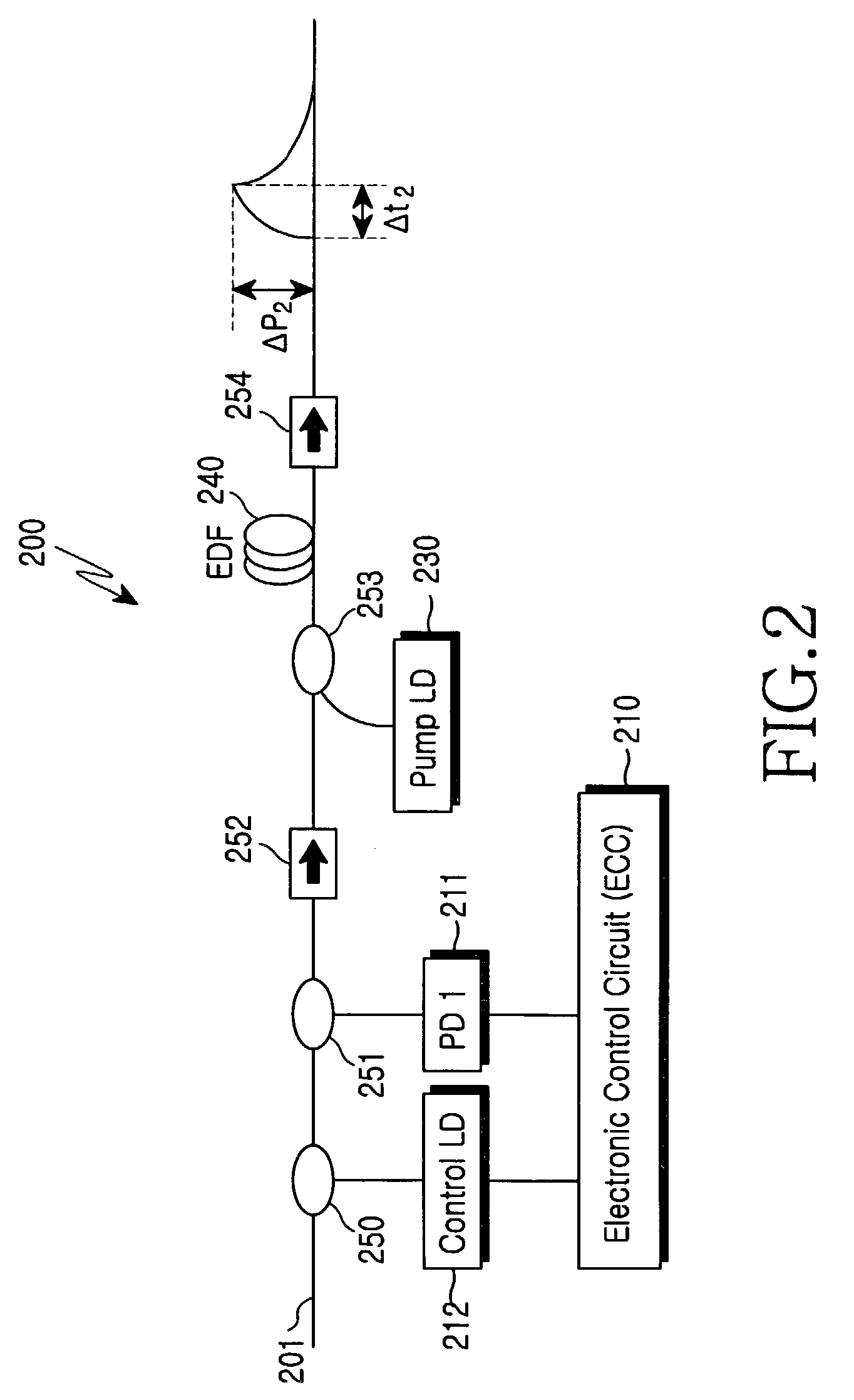

Photographing lens

InactiveCN1485670AShort control timeResponsiveActive medium shape and constructionElectromagnetic transmissionControl signalErbium doping

An optical fiber amplifier is disclosed for amplifying an input optical signal in the long wavelength band. The amplifier include first and second pumping light sources, a photo detector for detecting the intensity of the input optical signal, an erbium-doped optical fiber, and a controller. The optical fiber is brought to a first-pumped state by the first pumping light output from the first pumping light source. This generates an amplified spontaneous emission in the short wavelength band. The optical fiber is brought to a second-pumped state by the amplified spontaneous emission and outputs an induced emission light in the long wavelength band. The second pumping light source outputs a second pumping light in the same wavelength band as the amplified spontaneous emission, while controlling the intensity of the second pumping light by an output control signal, thereby controlling the intensity of the second-pumped state of the optical fiber. The controller calculates the amount of optical intensity loss and the number of channels of the input optical signal, based on the detected optical intensity, and transmits the output control signal to the second pumping light source for compensating the loss of the input optical signal.

Owner:SAMSUNG ELECTRONICS CO LTD

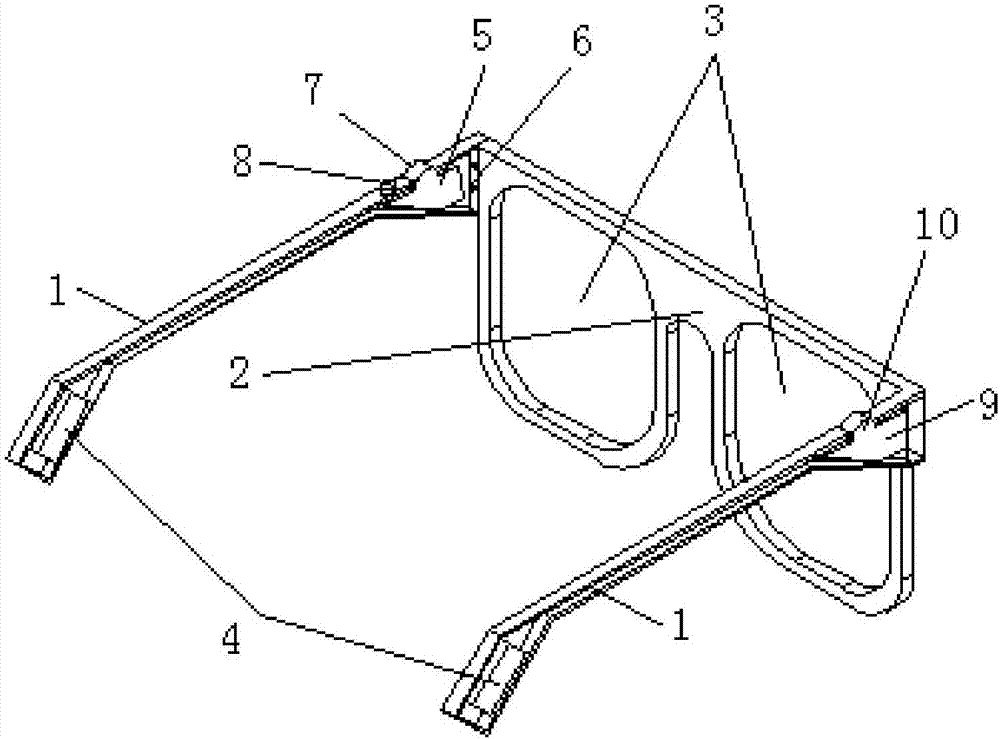

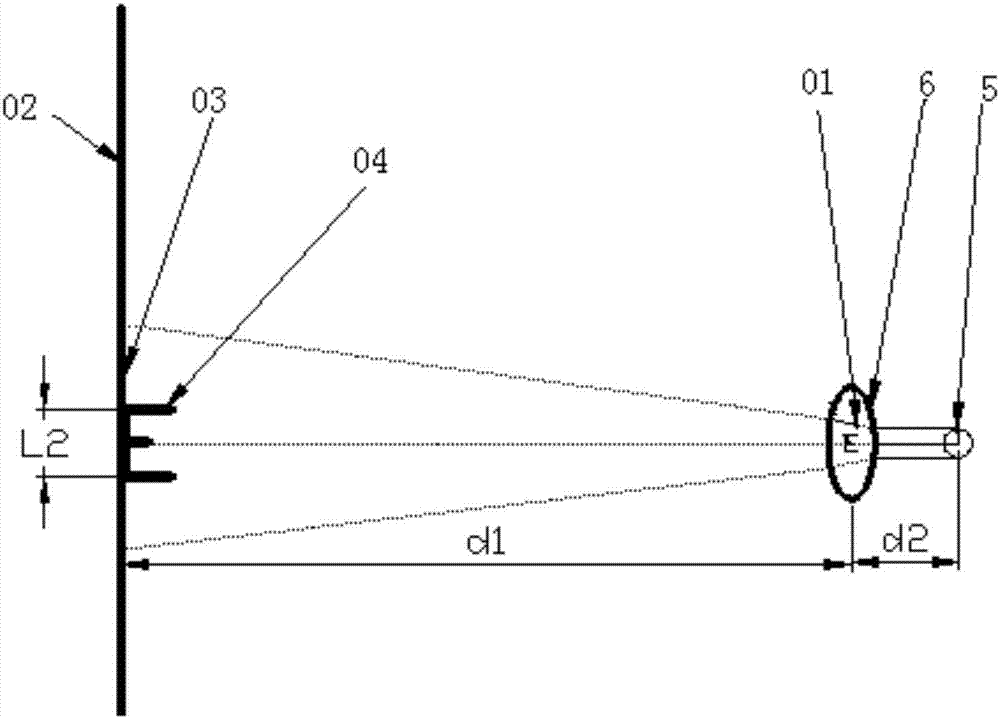

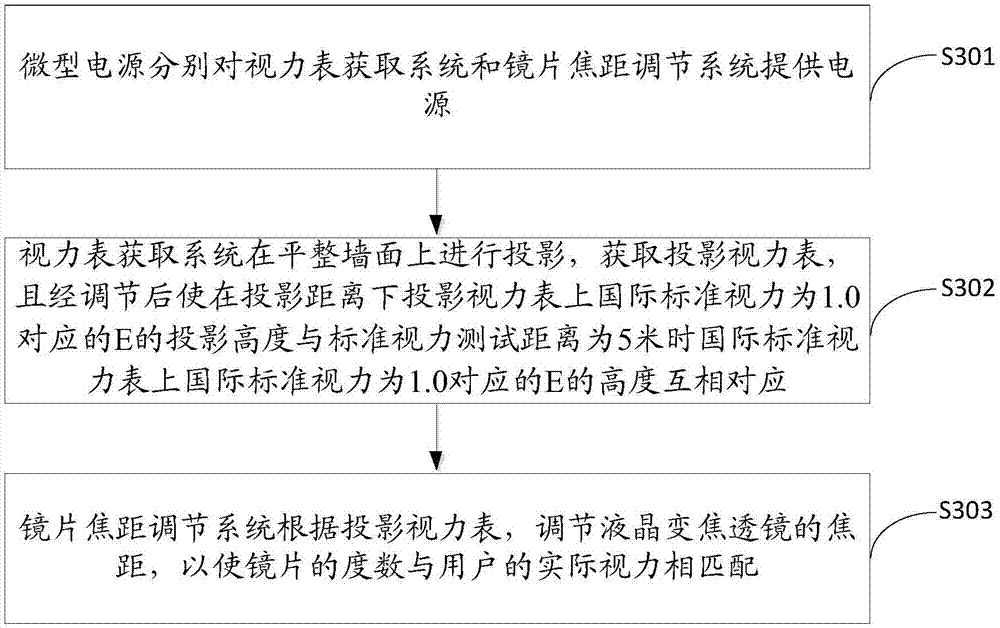

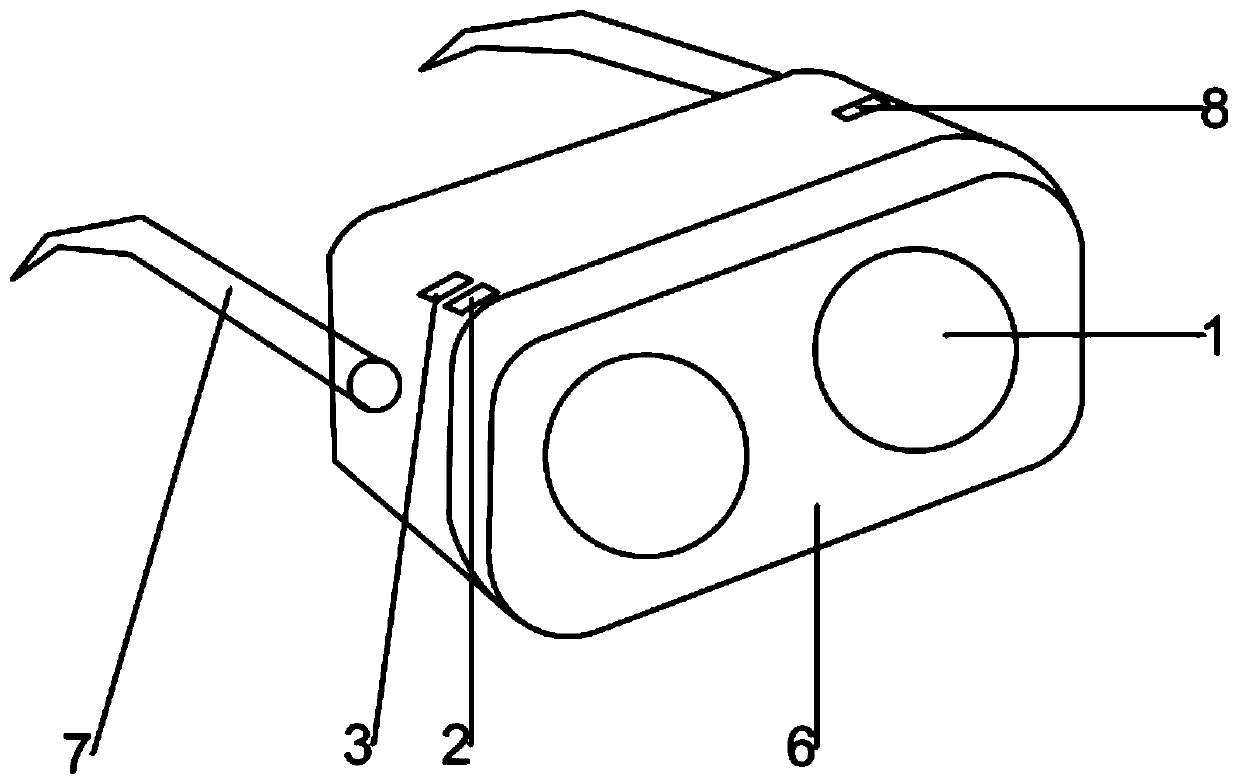

Zooming glasses and focus length adjusting method thereof

ActiveCN107991792AHigh light transmittanceShort control timeOptical partsInternational standardComputer science

The invention discloses zooming glasses and a focus length adjusting method thereof. The zooming glasses comprise a micro power supply, wherein the micro power supply is used for supplying power; a visual chart acquisition system is adopted to project on a flat wall to acquire a projection visual chart; the projection height of E corresponding to the international standard vision 1.0 on the visualchart in a projection distance corresponds to the height of E corresponding to the international standard vision 1.0 on an international visual chart in a testing distance of 5 meters after adjustment; and the focus length of a liquid crystal zooming lens can be adjusted by a user through a lens focus length adjusting system according to the projection visual chart, and thus the degree of the lens is matched with actual vision of the user. According to the zooming glasses, the projection visual chart is acquired through projection, zooming of the liquid crystal zooming lens is achieved through the lens focus length adjusting system, meanwhile the vision of the user with the zoomed lens is measured in real time, then the degree of the lens is matched with the actual vision of the user, andthe zooming glasses are short in regulation and control time, convenient to operate, accurate in zooming, small in size and good in lens light permeability.

Owner:GUANGDONG UNIV OF TECH

Freezing apparatus for separated Hopkinson pole experiment measurement

InactiveCN104390847AReduce dosageMeet control requirementsTemperatue controlStrength propertiesEngineeringElectrical and Electronics engineering

The invention discloses a freezing apparatus for separated Hopkinson pole experiment measurement, belonging to the technical field of freezing apparatuses. The freezing apparatus comprises a low-temperature environment box, a liquid nitrogen generation device and a temperature control device, wherein the temperature control device comprises a temperature controller; the temperature controller comprises a signal input interface and a signal output interface; the signal output interface is sequentially connected with a phase inverter and a solid-state relay; the solid-state relay A is connected with a heating wire A; the signal input interface is connected with a temperature measuring unit; the temperature measuring unit is used for measuring the temperature of a sample; and a heating wire B is arranged on a conduit of the liquid nitrogen generation device. According to the device, due to the combined operation of the heating wire A and the heating wire B, the aim of simultaneously controlling the liquid nitrogen ejection speed and the liquid nitrogen outlet temperature is achieved, the time in the control process is short, and the amount of liquid nitrogen is small.

Owner:SUZHOU VOCATIONAL UNIV

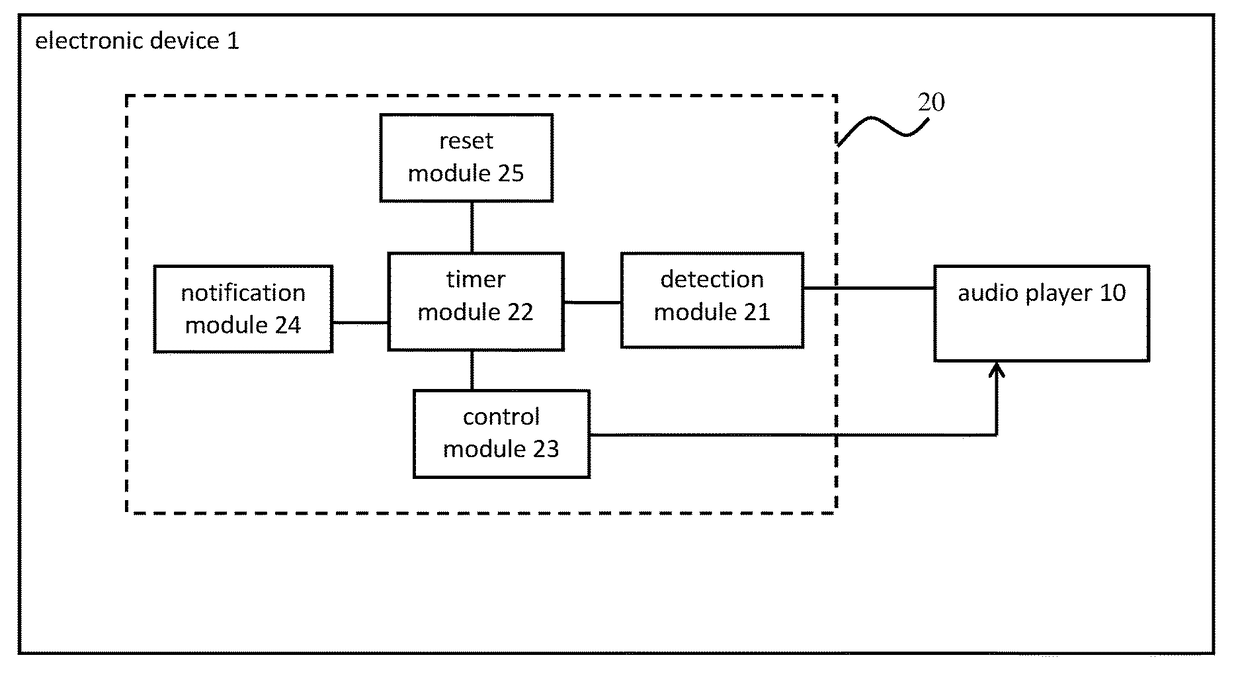

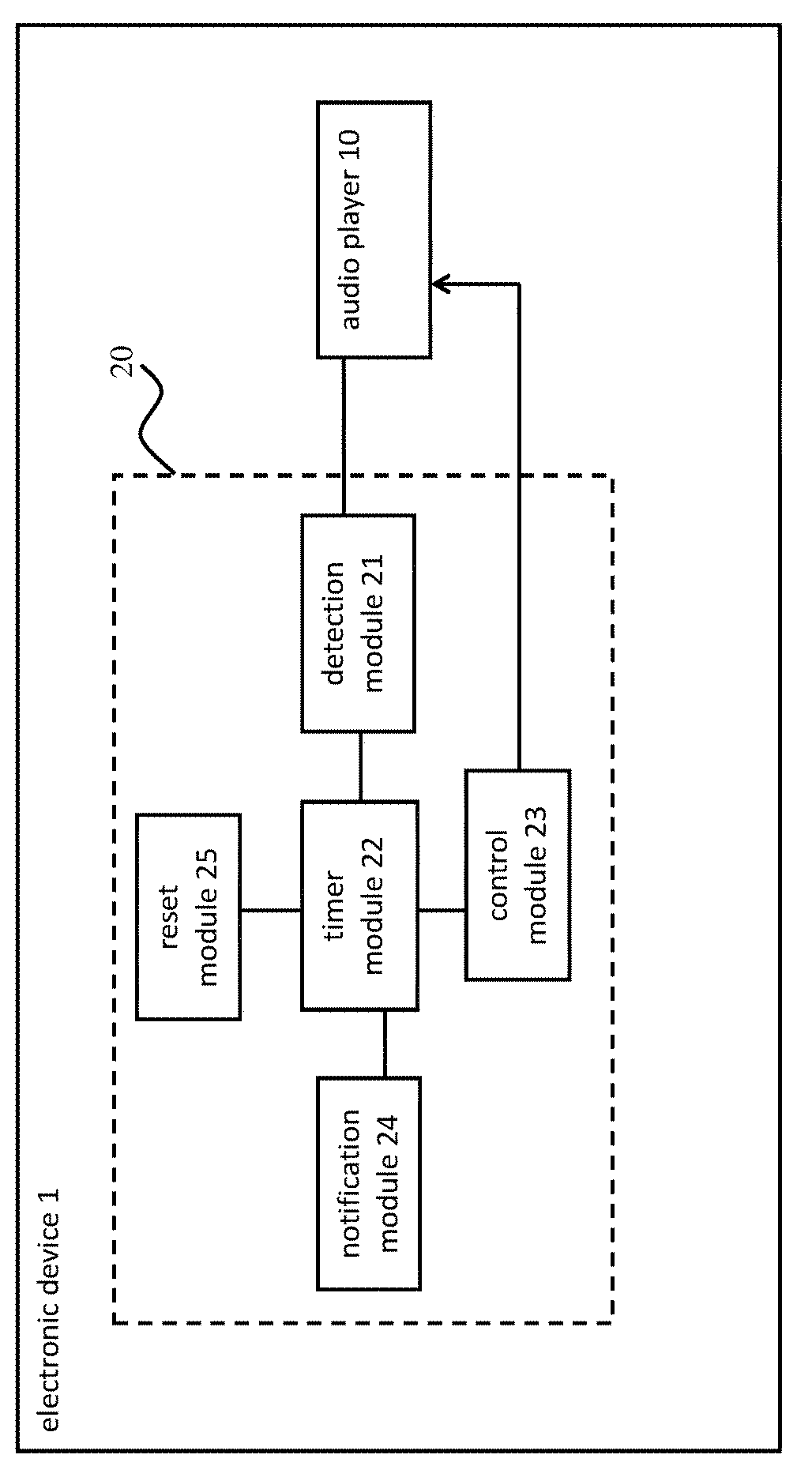

Electronic device capable of automatically adjusting an output volume

ActiveUS9832581B1Short control timeSignal processingSound input/outputAuto regulationAudio frequency

An electronic device includes an audio player and a processing unit. The processing unit includes a detection module, a timer module, and a control module. The detection module is used to detect an output volume produced currently when the audio player produces sound and to determine whether the output volume conforms to a volume control standard. The timer module is signally connected with the detection module and used to calculate the cumulative time during which the output volume produced by the audio player conforms to the volume control standard when the output volume conforms to the volume control standard and to determine whether the cumulative time equals the control time. The control module is signally connected with the timer module and used to control the audio player to decrease the volume of an output sound or to stop outputting sound when the cumulative time equals the control time.

Owner:AIROHA TECHNOLOGY CORPORATION

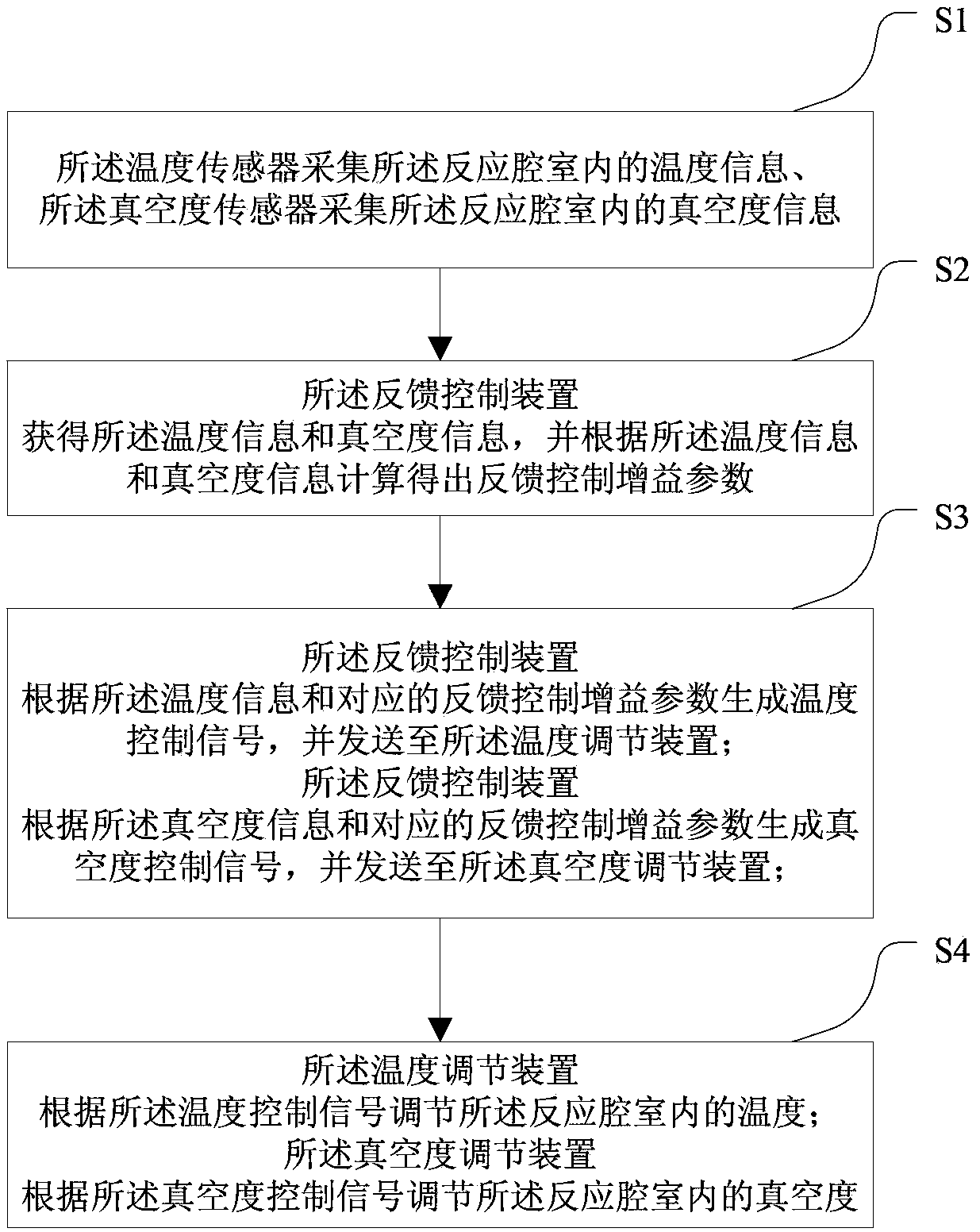

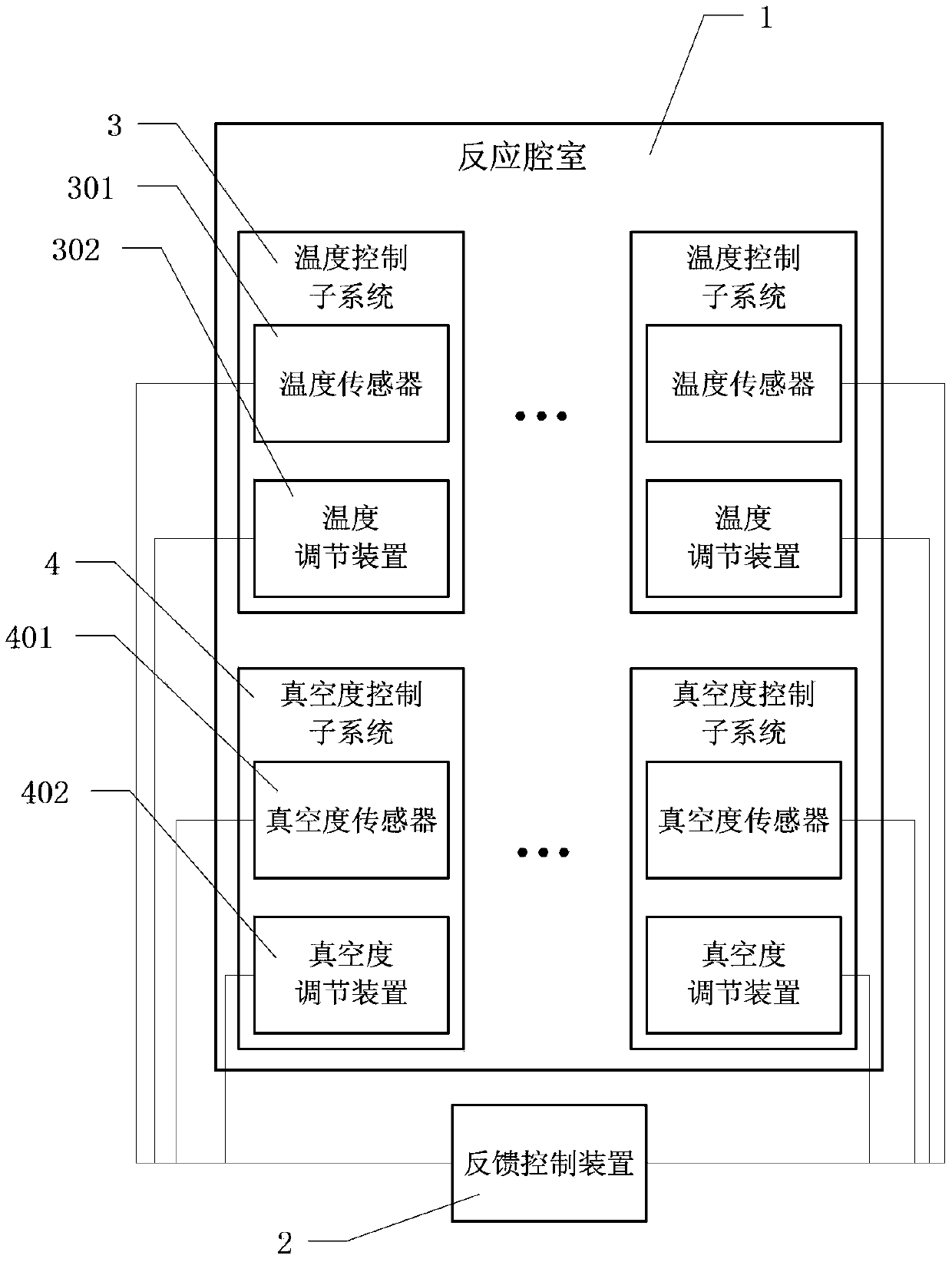

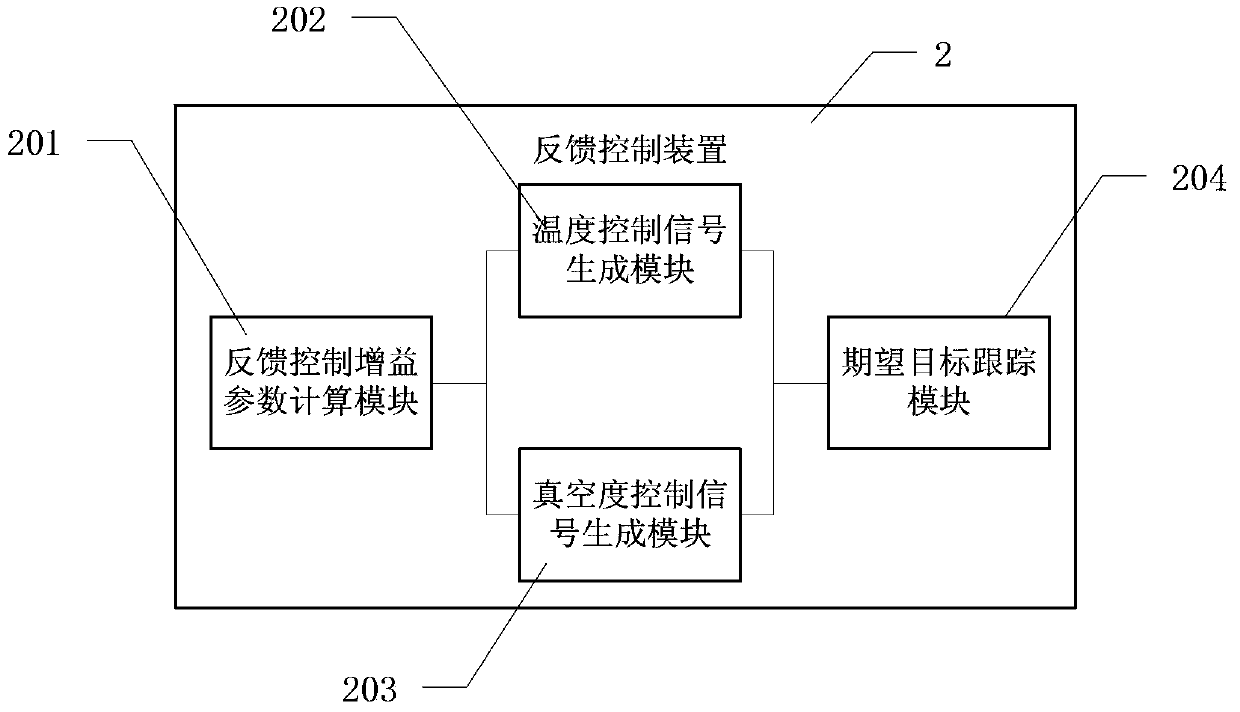

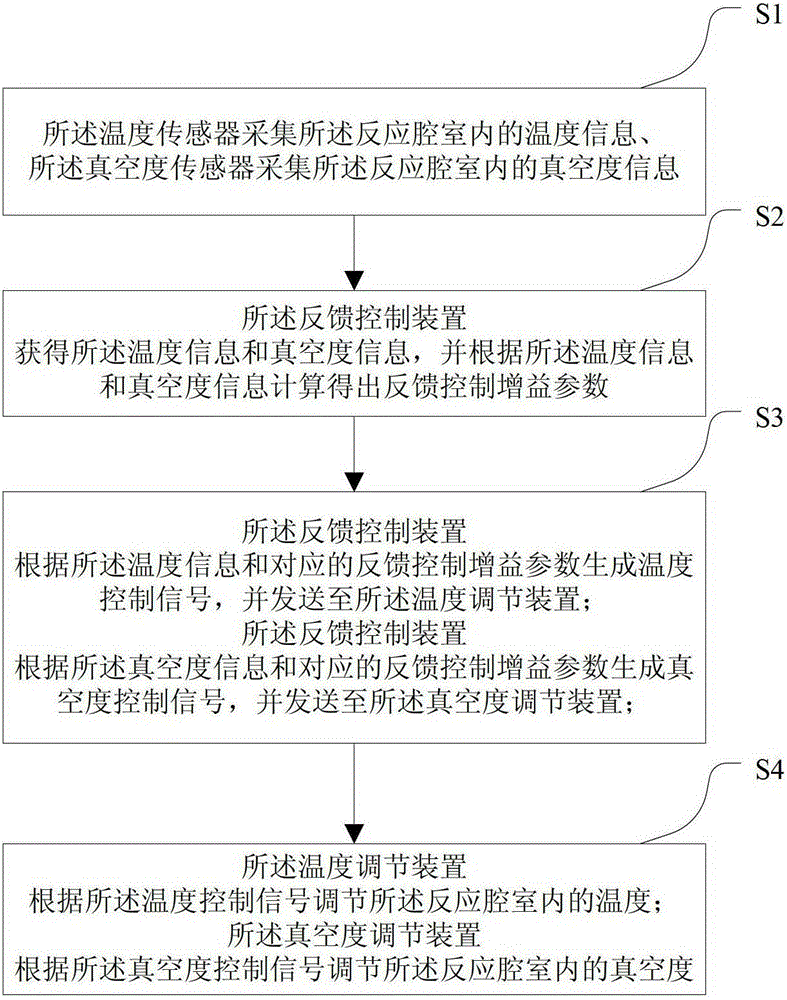

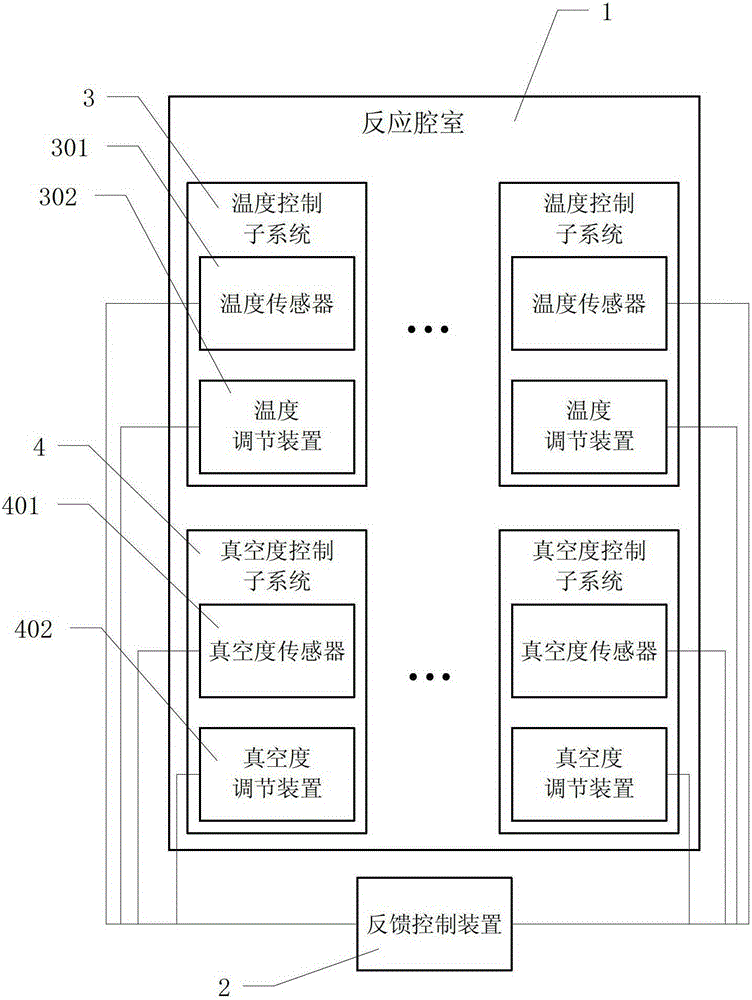

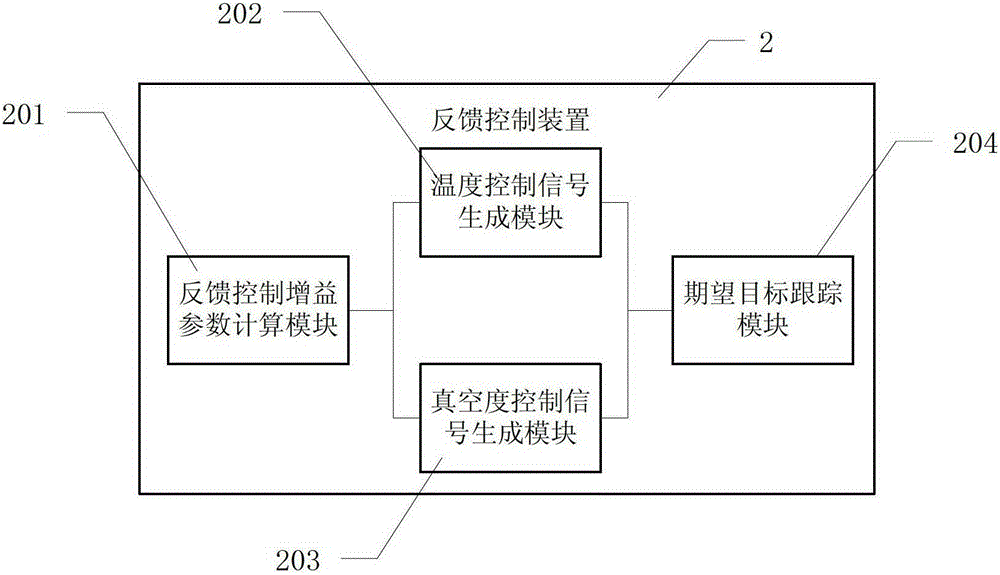

Control method and system for low pressure chemical vapor deposition (LPCVD) technical production environment

ActiveCN103397312AShorten the timeLow costChemical vapor deposition coatingTemperature controlControl signal

The invention provides a control method for a low pressure chemical vapor deposition (LPCVD) technical production environment. The control method comprises the following steps that: S1, a temperature sensor acquires temperature information in a reaction cavity, and a vacuum degree sensor acquires vacuum degree information in the reaction cavity; S2, a feedback control device acquires the temperature information and the vacuum degree information and calculates feedback control gain parameters according to the temperature information and the vacuum degree information; S3, the feedback control device generates a temperature control signal according to the temperature information and the corresponding feedback control gain parameter and a vacuum degree control signal according to the vacuum degree information and the corresponding feedback control gain parameter, and sends the temperature control signal and the vacuum degree control signal to a temperature adjustment device and a vacuum degree adjustment device; S4, the temperature adjustment device adjusts the temperature in the reaction cavity according to the temperature control signal, and the vacuum degree adjustment device adjusts the vacuum degree in the reaction cavity according to the vacuum degree control signal.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

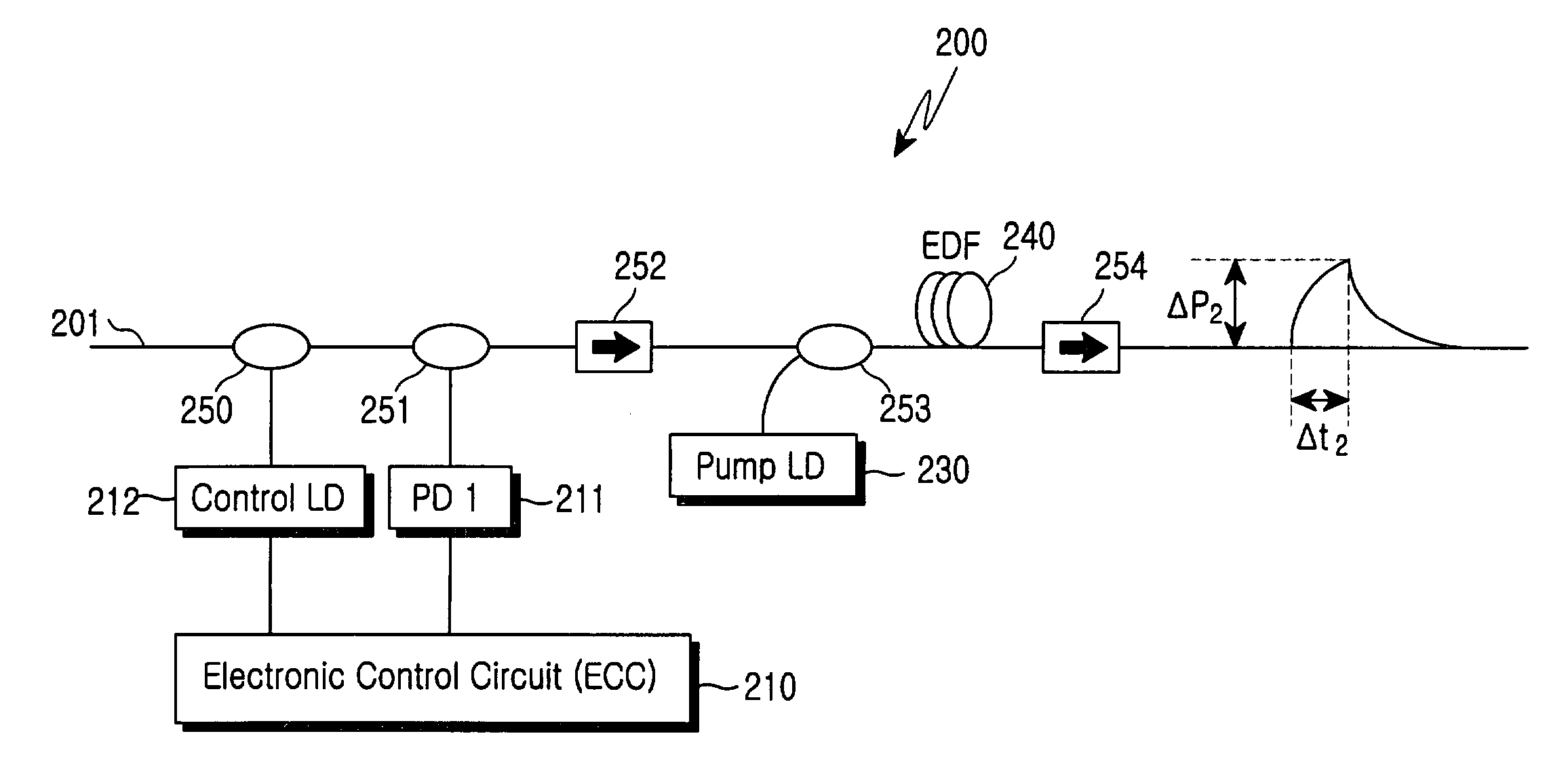

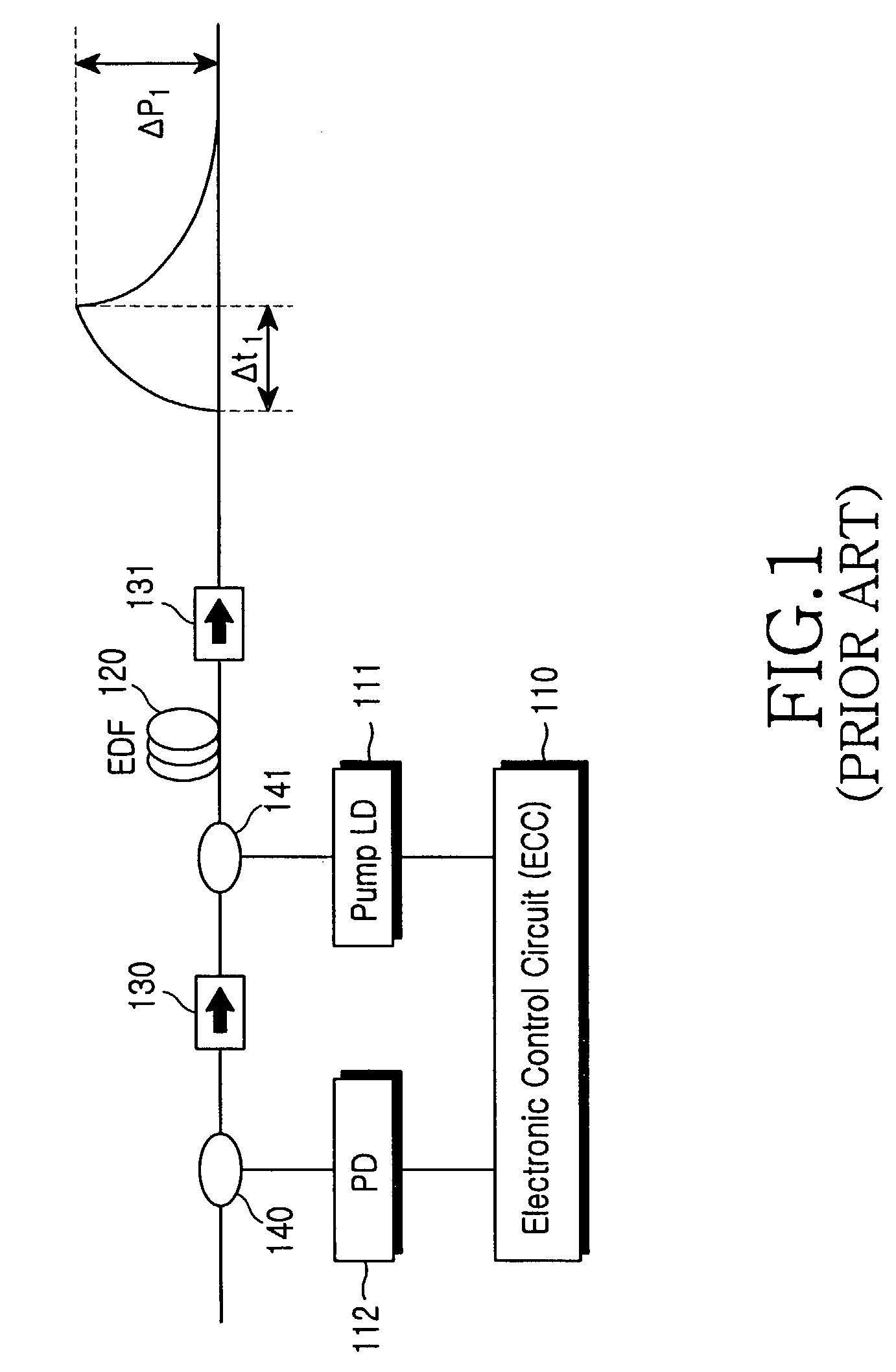

Long-wavelength optical fiber amplifier

InactiveUS6972895B2Short control timeSwift response speedFibre transmissionActive medium shape and constructionAudio power amplifierControl signal

An optical fiber amplifier is disclosed for amplifying an input optical signal in the long wavelength band. The amplifier include first and second pumping light sources, a photo detector for detecting the intensity of the input optical signal, an erbium-doped optical fiber, and a controller. The optical fiber is brought to a first-pumped state by the first pumping light output from the first pumping light source. This generates an amplified spontaneous emission in the short wavelength band. The optical fiber is brought to a second-pumped state by the amplified spontaneous emission and outputs an induced emission light in the long wavelength band. The second pumping light source outputs a second pumping light in the same wavelength band as the amplified spontaneous emission, while controlling the intensity of the second pumping light by an output control signal, thereby controlling the intensity of the second-pumped state of the optical fiber. The controller calculates the amount of optical intensity loss and the number of channels of the input optical signal, based on the detected optical intensity, and transmits the output control signal to the second pumping light source for compensating the loss of the input optical signal.

Owner:SAMSUNG ELECTRONICS CO LTD

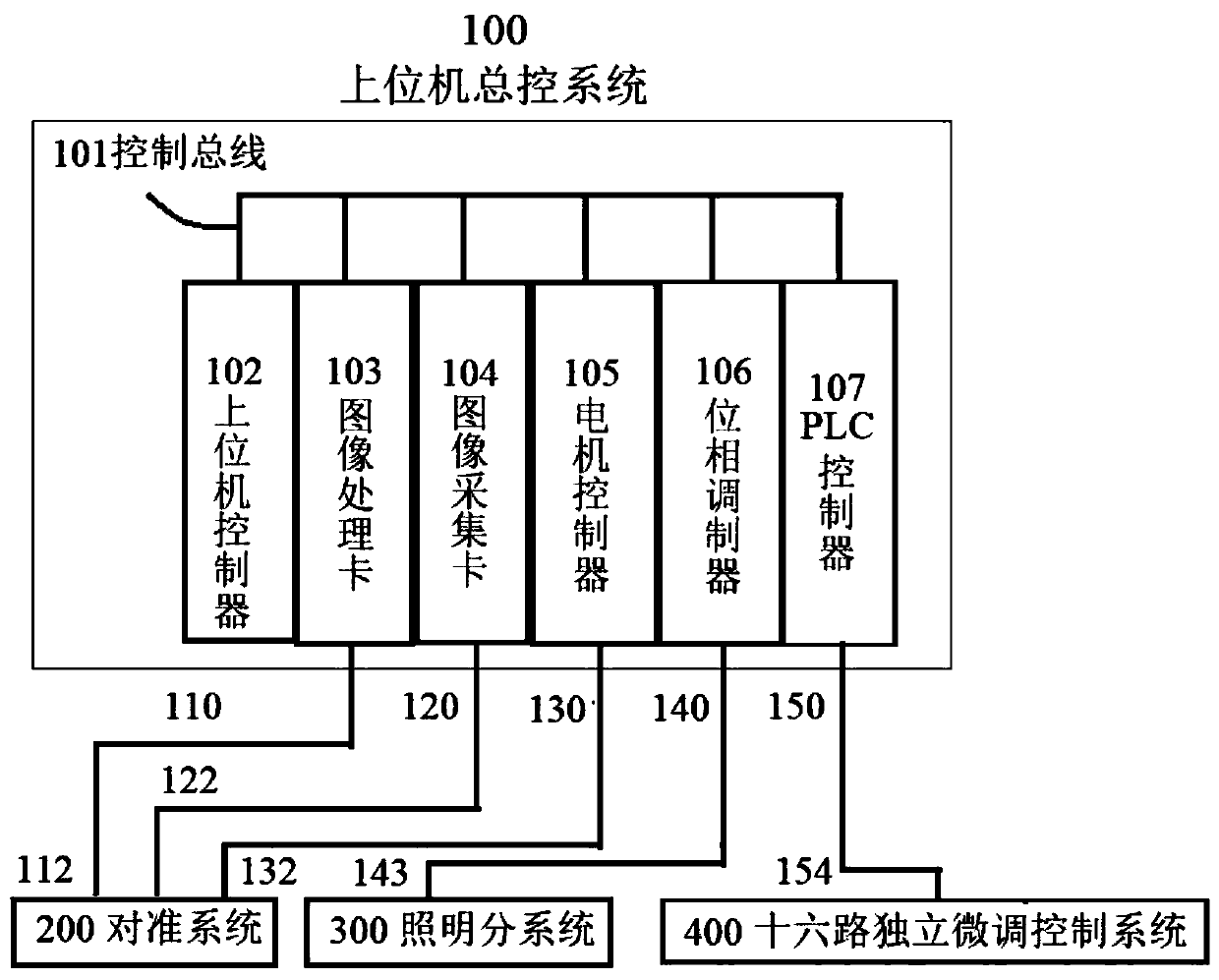

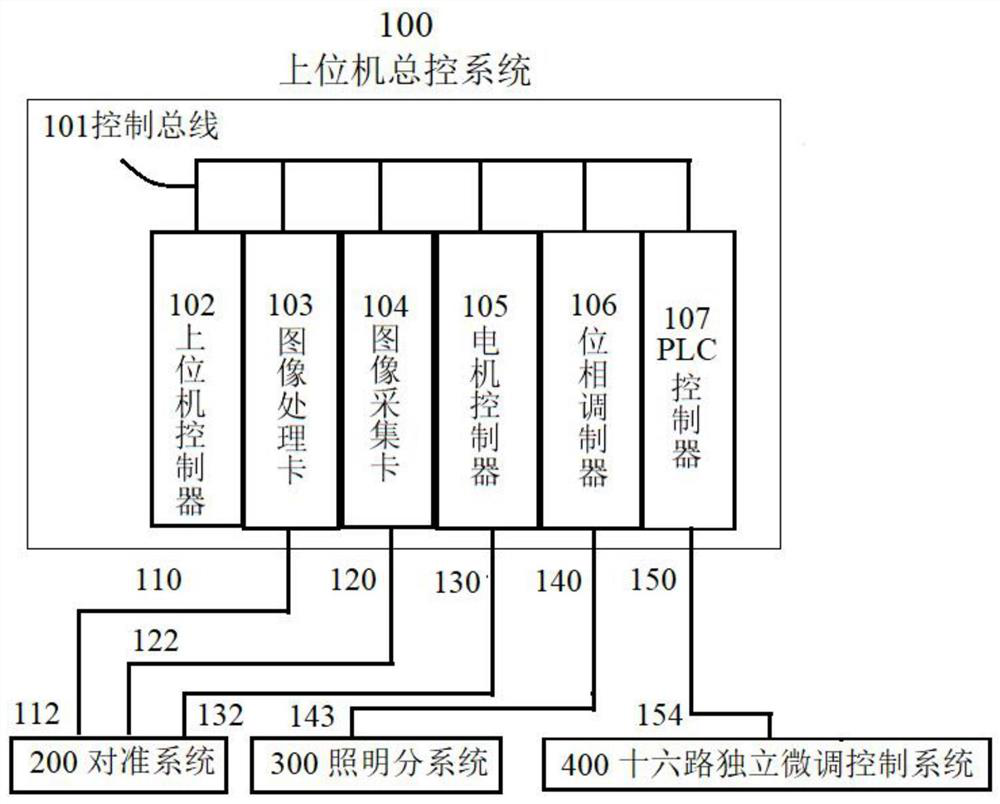

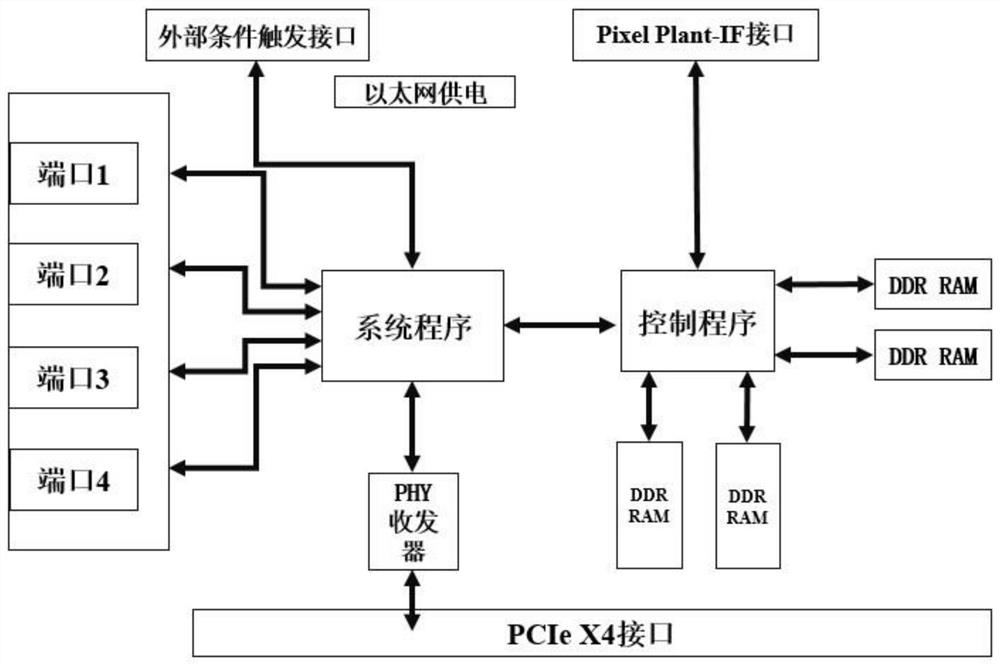

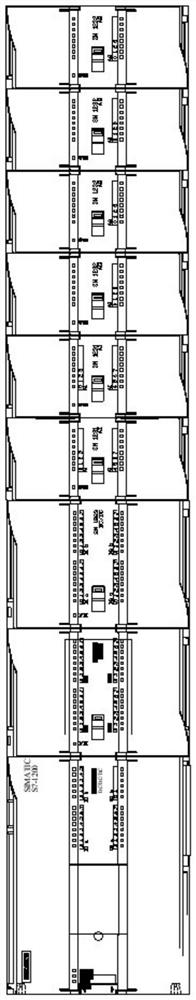

Intelligent correction device control system for super-resolution photoetching precision mask

ActiveCN111580359AEconomic realizationQuick responseProgramme controlTelevision system detailsComputer control systemImaging processing

The invention discloses an intelligent correction device control system for a super-resolution photoetching precision mask. The control system is combined with an optical system to realize accurate expected mask deformation control. The master control of the intelligent control system is completed through a high-performance industrial personal computer, and the intelligent control system comprisesan upper computer control system, an image acquisition subsystem, an image processing subsystem, an alignment subsystem, an illumination subsystem and a sixteen-path independent fine adjustment maskdeformation control subsystem. Through combined control of all subsystems of the control system, expected precise mask deformation control can be achieved, and compared with an existing implementationmethod, the steps are simpler and more convenient, and implementation of the control system is more economical. In addition, the control system adopts a PCIe channel and an independent display card to transmit and process an alignment image signal, and mask precision deformation control adopts a PID closed-loop control algorithm to realize precision regulation and control, so that the subsystem efficiency is improved, and the system can realize mask deformation control and alignment more quickly and accurately.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

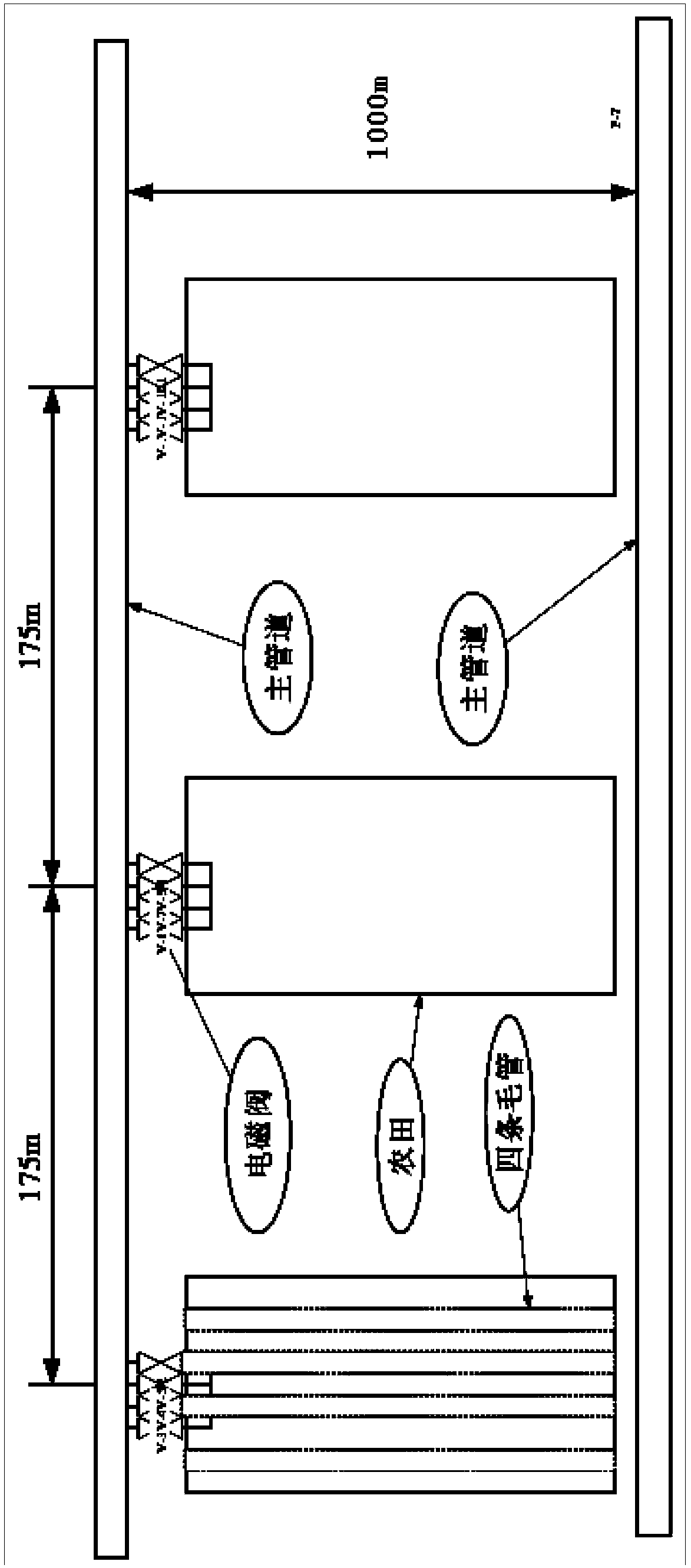

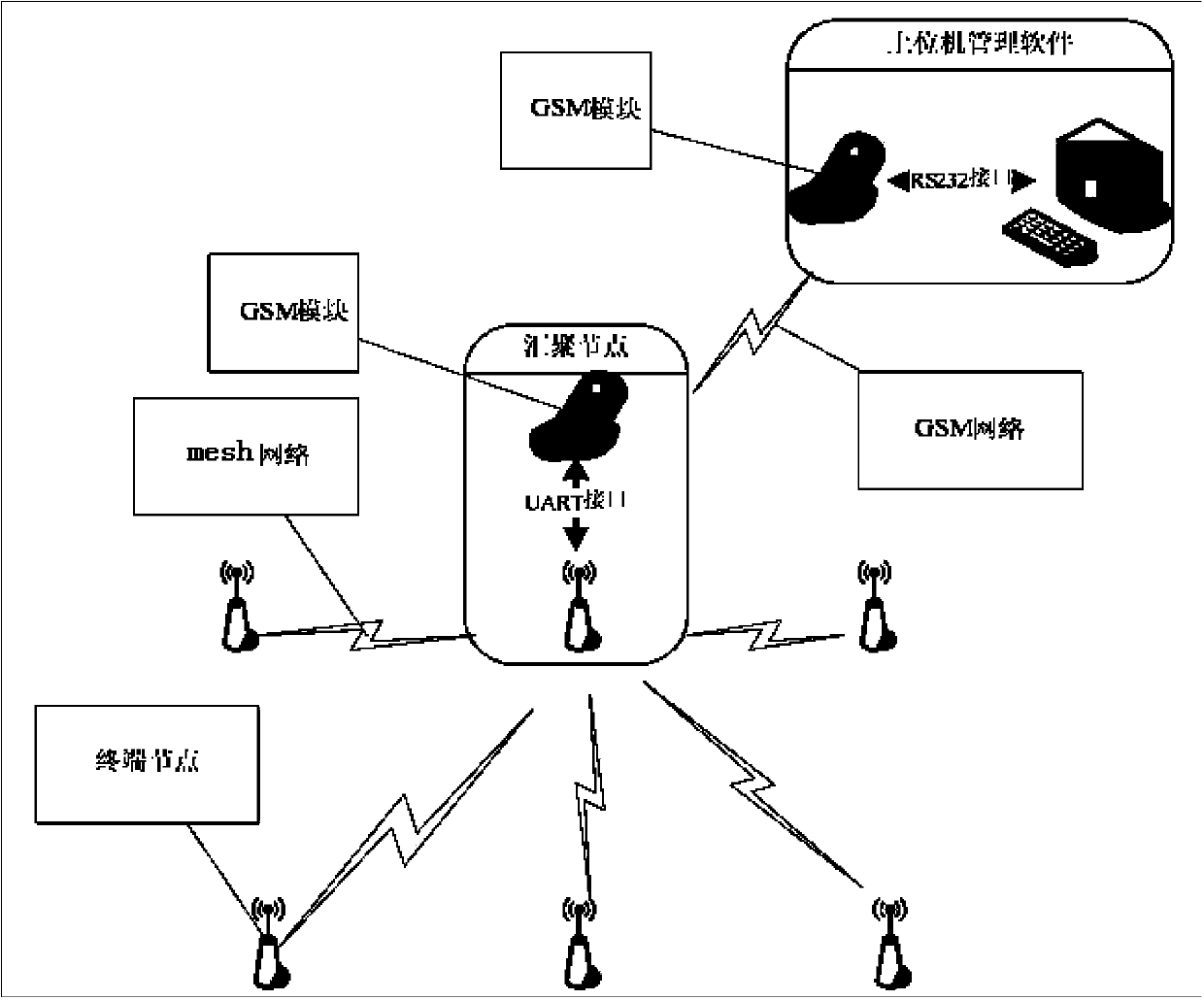

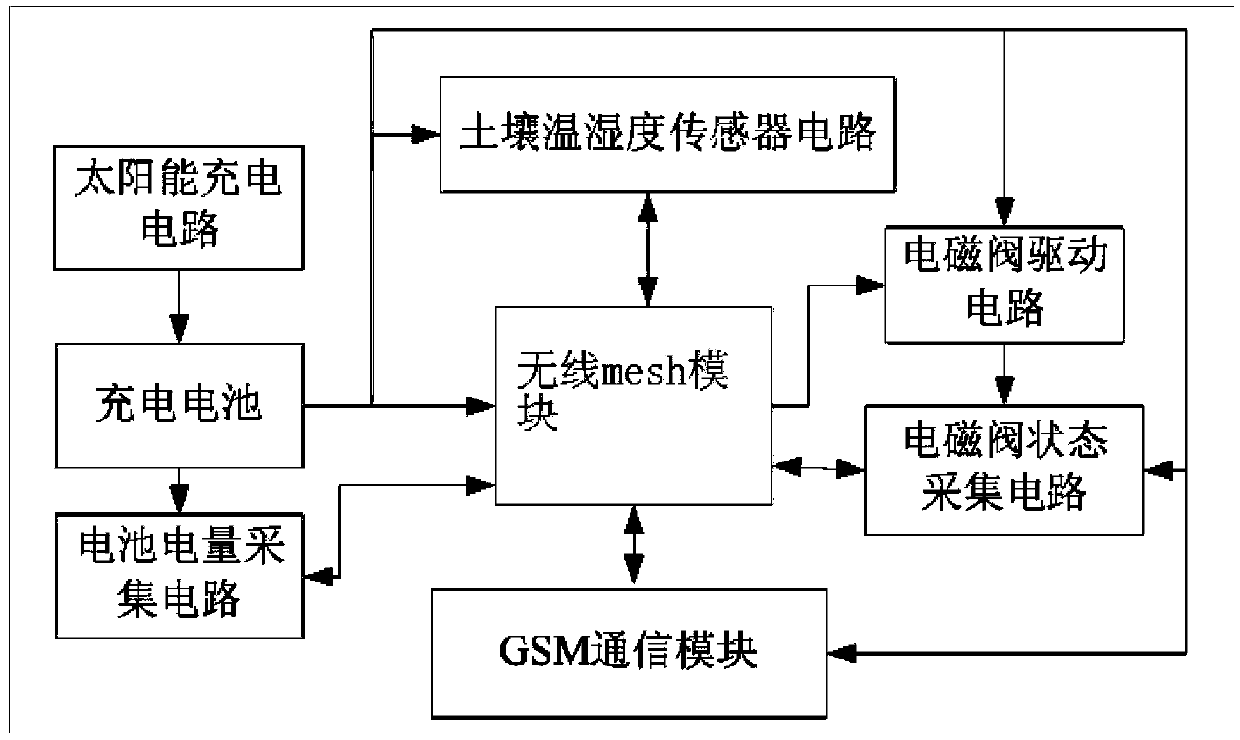

Farmland irrigation system

InactiveCN104206234AShow status informationIncrease costWatering devicesCultivating equipmentsEngineeringSubmarine pipeline

The invention discloses a farmland irrigation system, which comprises electromagnetic valves, capillary pipes and main pipeline equipment, wherein the electromagnetic valves are respectively connected with the capillary pipes and the main pipeline, in one piece of farmland, one end opening of each capillary pipe of the four capillary pipes is respectively provided with one electromagnetic valve, one end of the main pipeline is connected with one electromagnetic valve, and the other end of the main pipeline is respectively connected with the electromagnetic valves of the four capillary pipes. The farmland irrigation system has the characteristics that the energy consumption is low, and the control is easy. The farmland irrigation system is suitable for being popularized and applied.

Owner:HUANGHE S & T COLLEGE

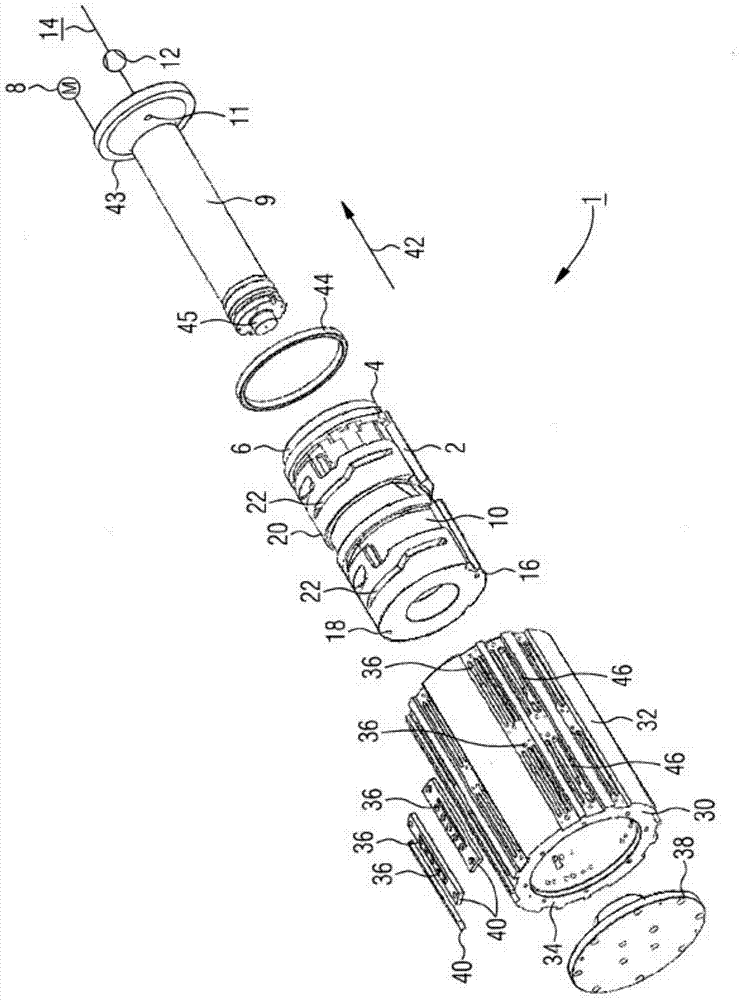

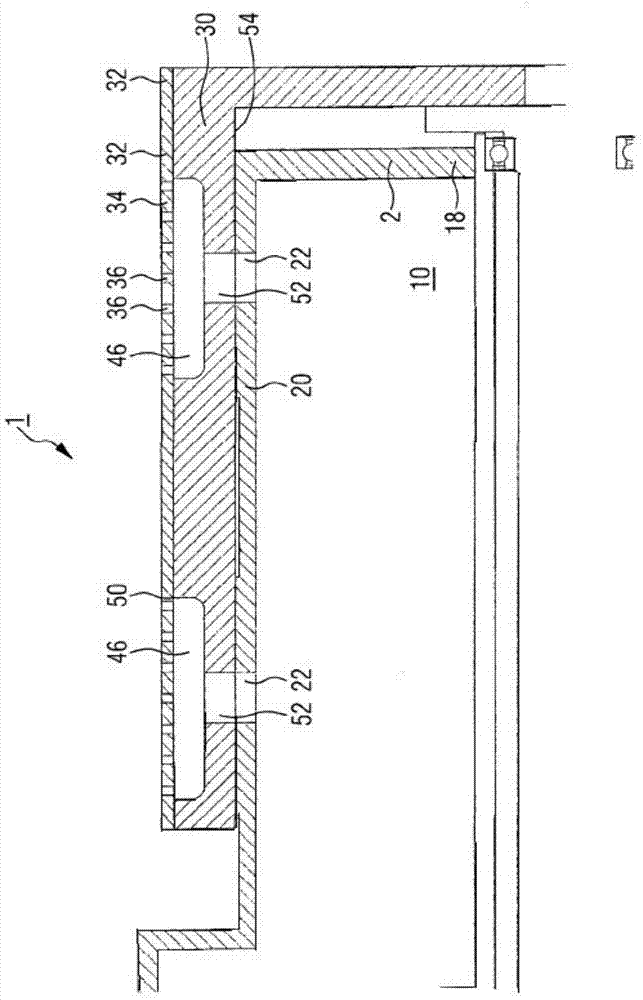

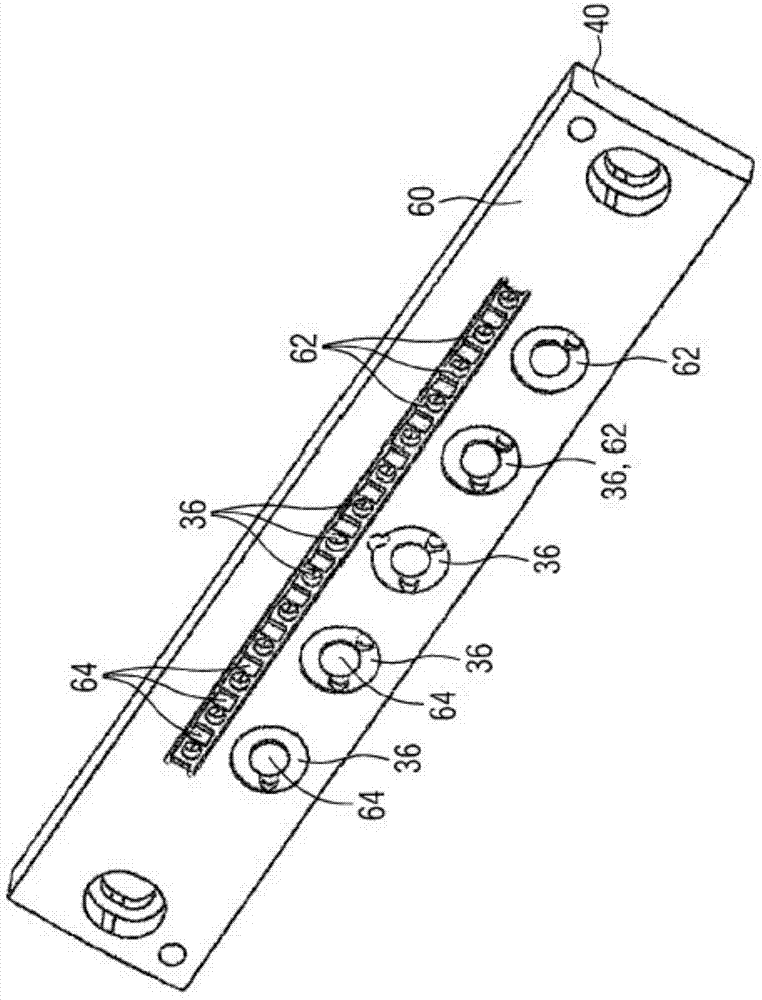

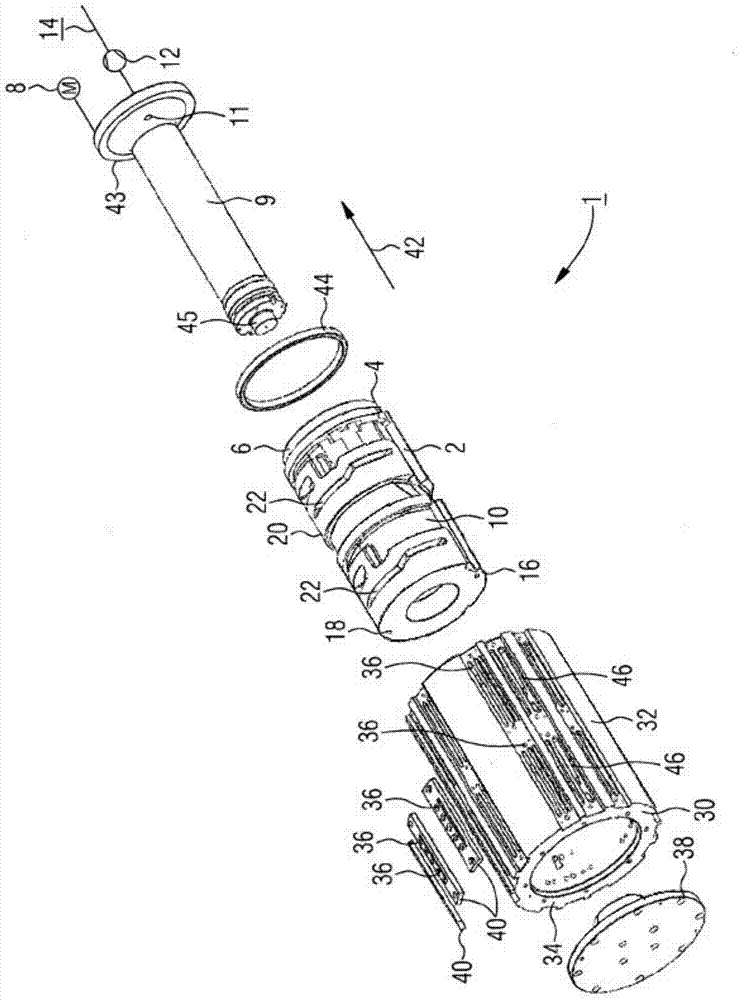

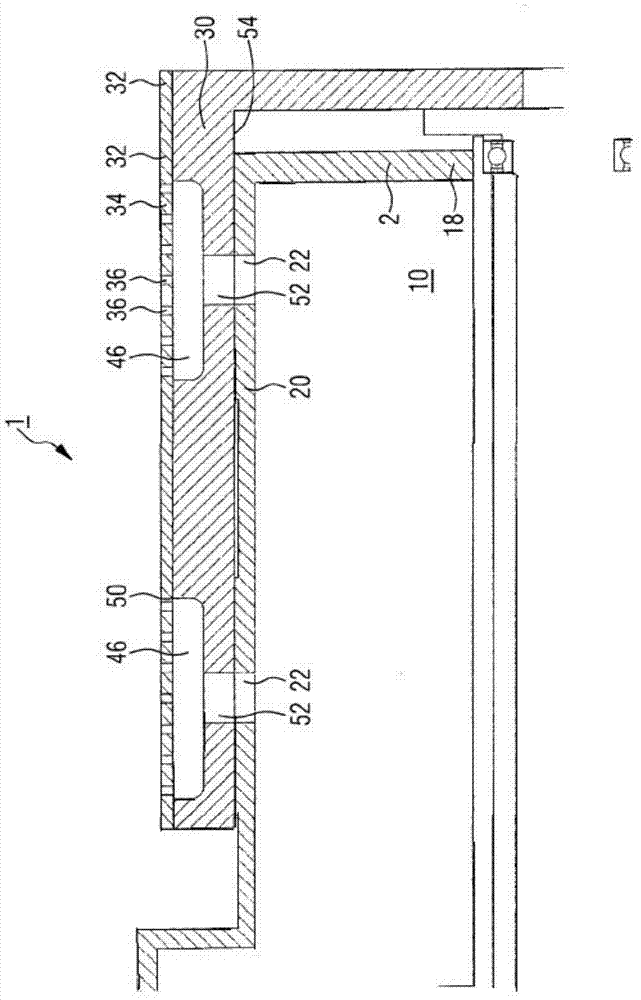

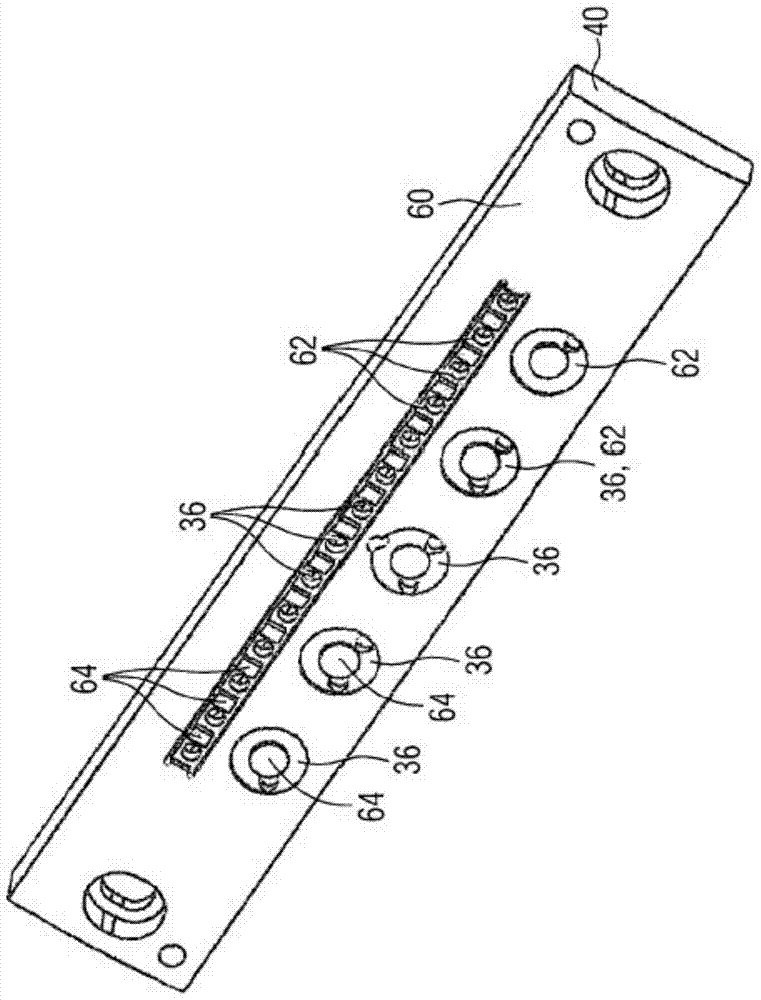

Suction roll system

ActiveCN104812539AEasy to replaceCutting costsPress sectionMetal working apparatusControl systemEngineering

A suction roll system (1) with a rotatably mounted cylindrical suction roll (32), the cylinder jacket (34) of which is provided with a plurality of suction holes (36), which can be selectively connected via a control system individually or in groups to a vacuum system (14), is intended to make possible, in a reliable fashion, particularly short switchover times and also high flexibility, even when groups of a plurality of suction holes (36) are actuated. To this end, according to the invention, the control system comprises a fixedly mounted hollow cylinder (2) projecting into the suction roll (32) and connected by its interior volume (10) to the vacuum system (14), the cylinder jacket (20) of which is penetrated by a number of control slots (22).

Owner:WINKLER DUNNEBIER GMBH

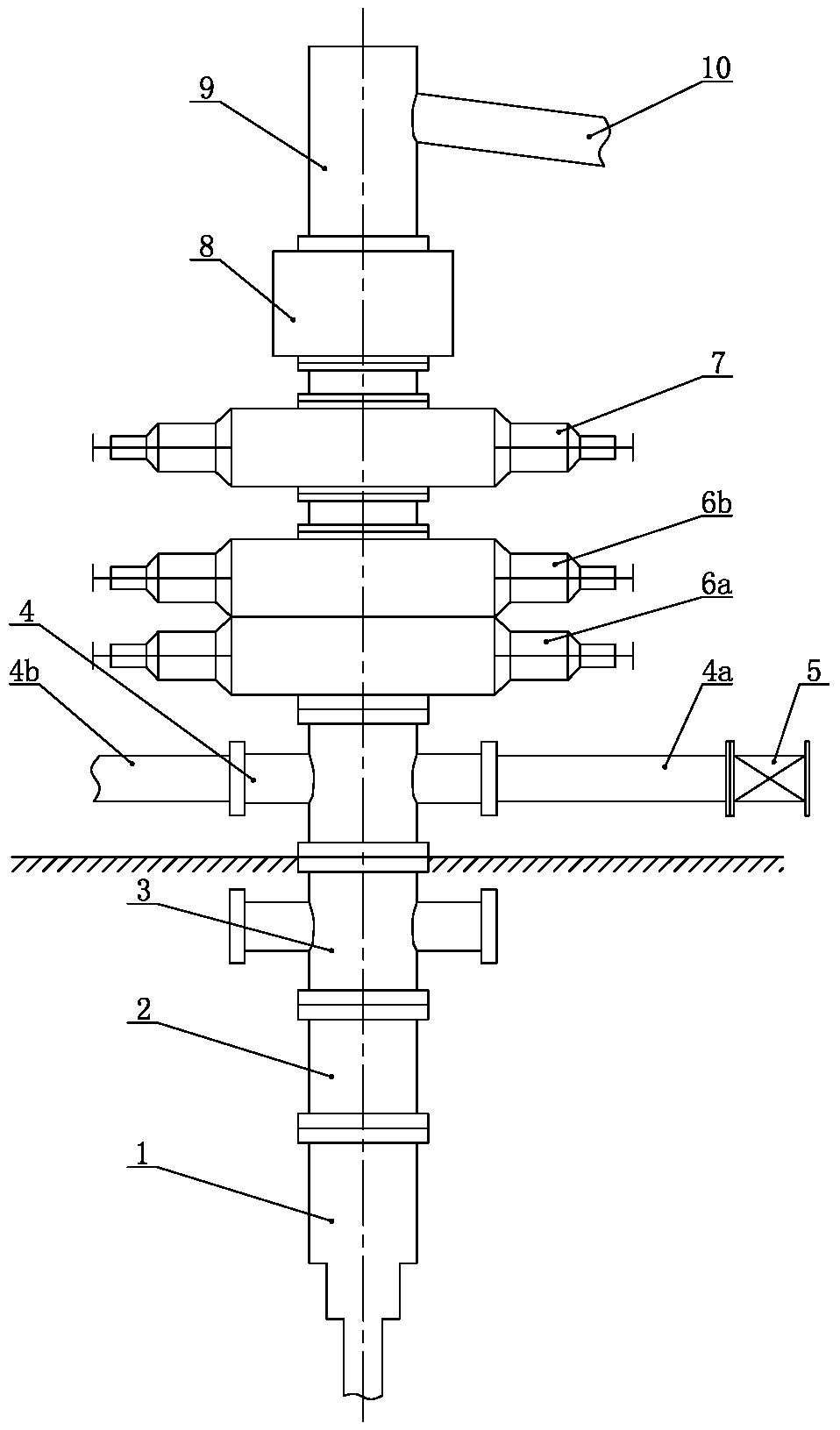

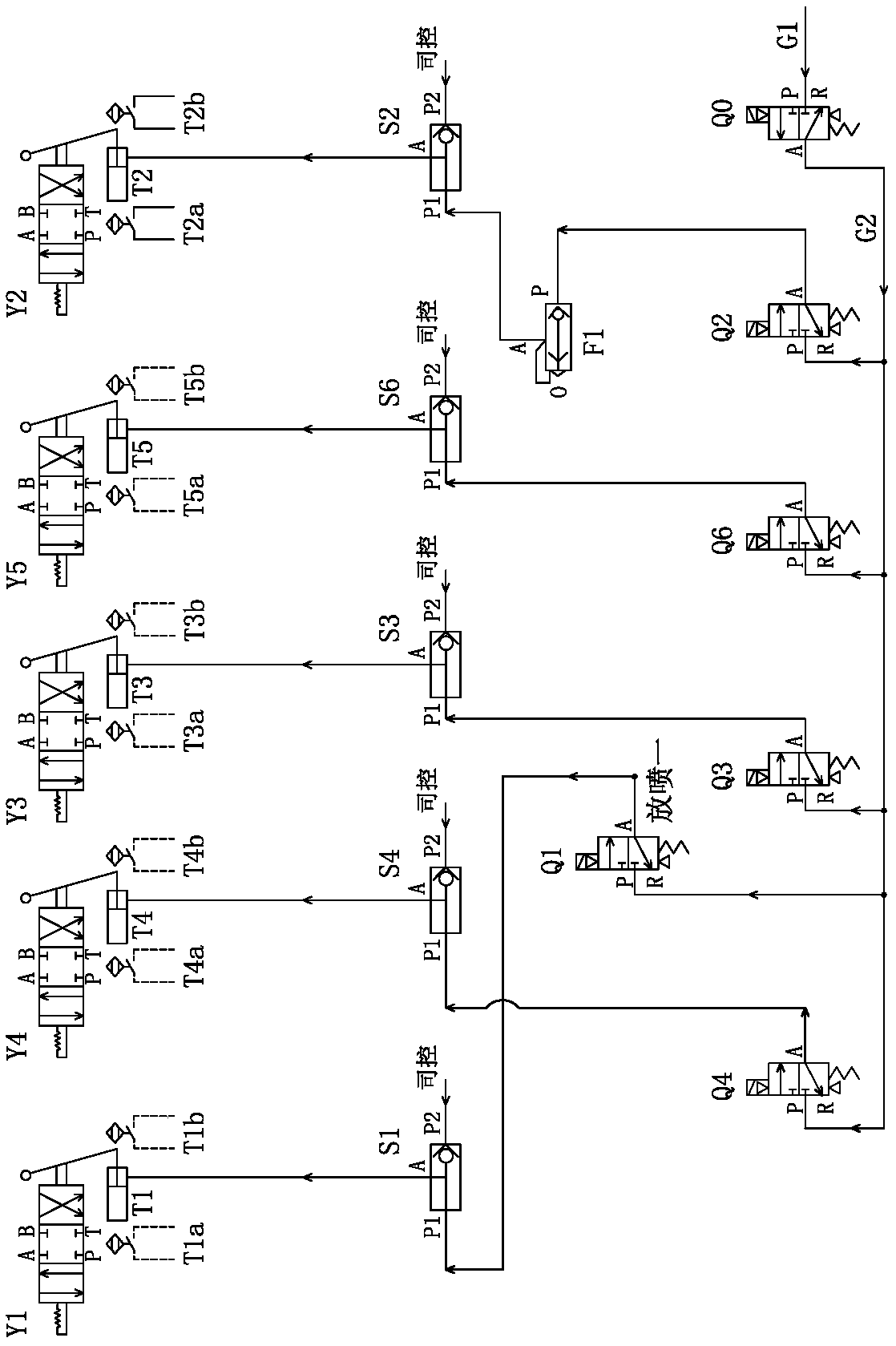

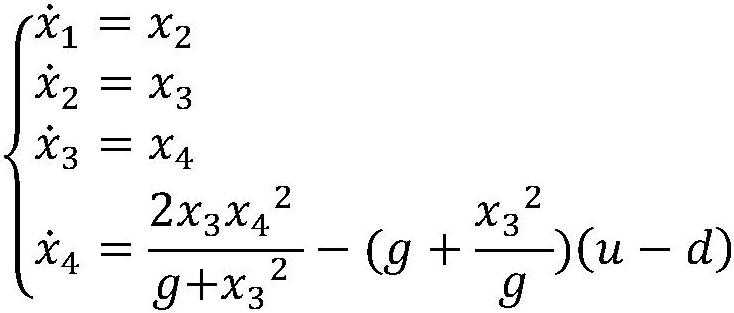

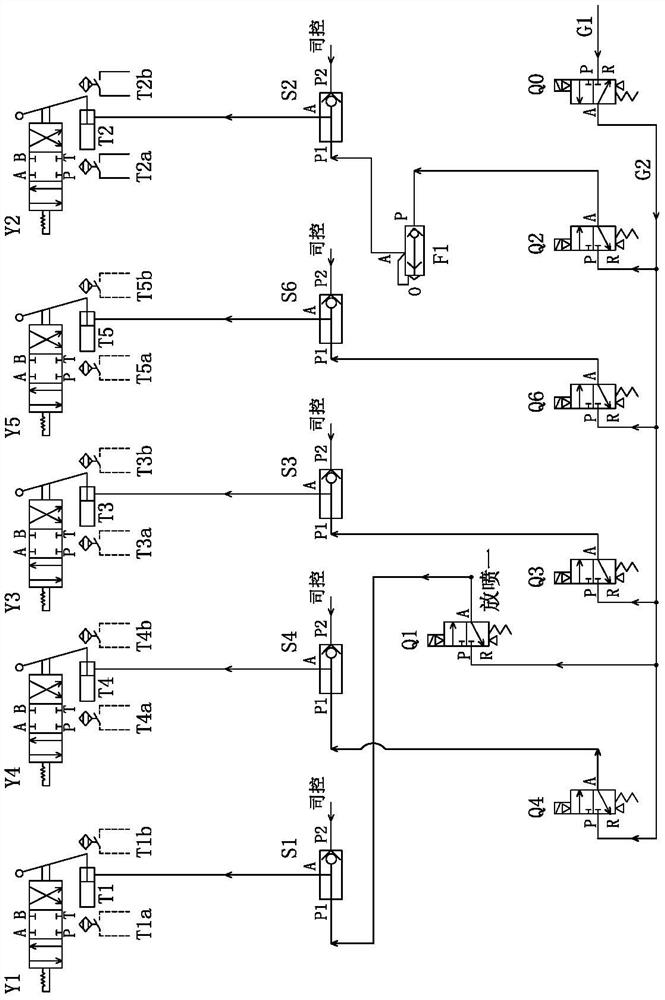

Well drilling wellhead anti-overflow control system

ActiveCN111535772AImprove protectionGuaranteed resetWell/borehole valve arrangementsSealing/packingControl systemWell drilling

The invention relates to a well drilling wellhead anti-overflow control system which comprises a semi-sealing large valve element flashboard and a semi-sealing small valve element flashboard on a wellhead main four way, a full-sealing singe flashboard and an annular bop; the top of the annular bop is connected with an anti-overflow pipe; a blowoff manifold is connected with the right side of the wellhead main four way; the outlet of the blowoff manifold is connected with a throttling manifold; a blowoff flat valve is arranged at the inlet of the throttling manifold; a reverse circulation manifold is connected with the left side of the wellhead main four way; a semi-sealing bop is a double gate disc bop composed of the semi-sealing large valve element flashboard and the semi-sealing small valve element flashboard; the large and small valve element flashboards are controlled by large and small valve element liquid rotary valves; an operating handle is connected with the piston rod of a semi-sealing air cylinder; compressed air is connected with a blowoff pneumatic control valve I, an annular pneumatic control valve and the ports P of semi-sealing large and small valve element pneumatic control valves; and the ports A of the semi-sealing large and small valve element pneumatic control valves are connected with the upper cavity gas ports of semi-sealing large and small valve element air cylinders through semi-sealing large and small valve element shuttle valves. The well drilling wellhead anti-overflow control system can realize soft closing for underground drilling tools withdifferent specifications.

Owner:中石化石油工程技术服务有限公司 +1

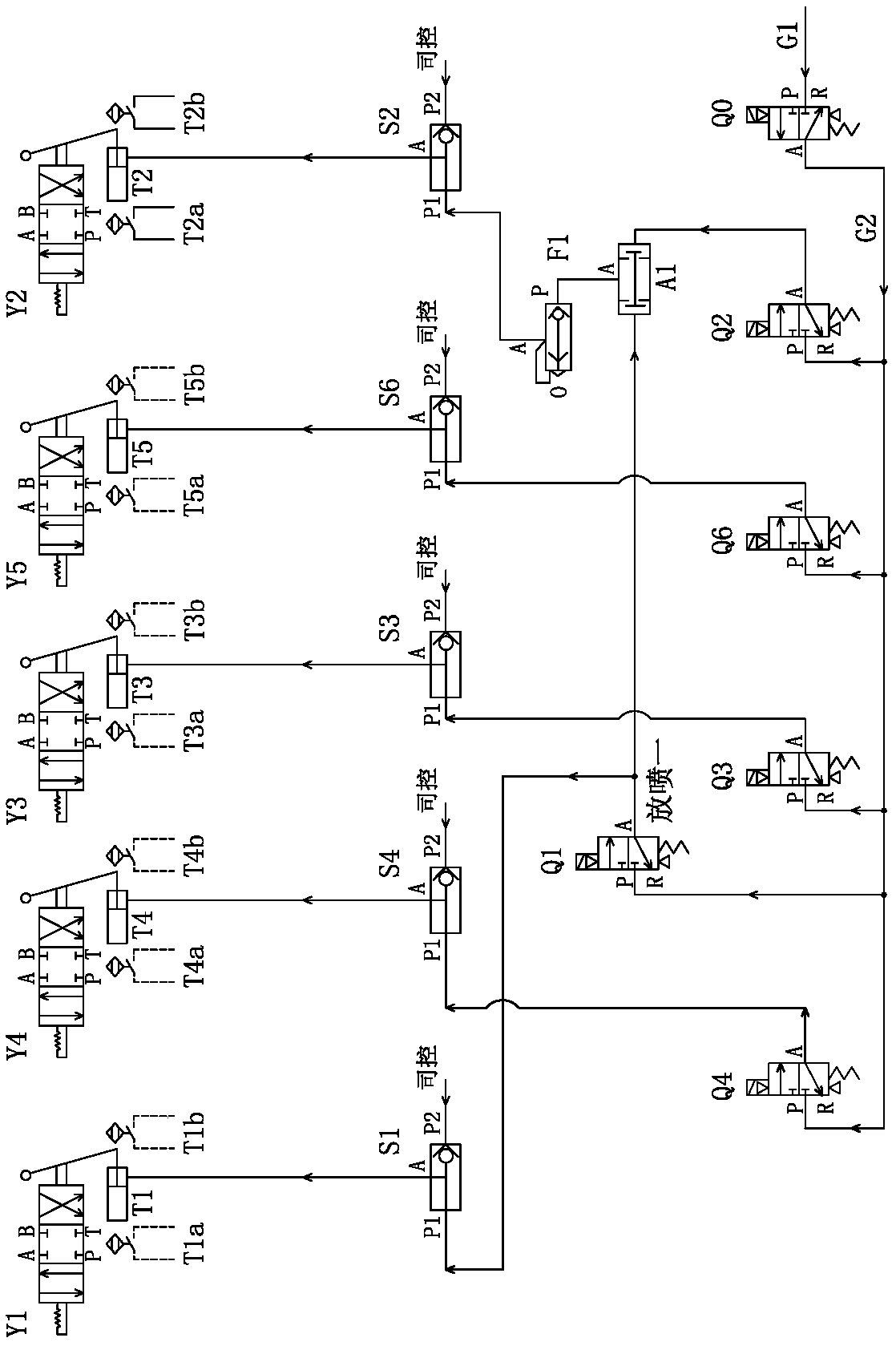

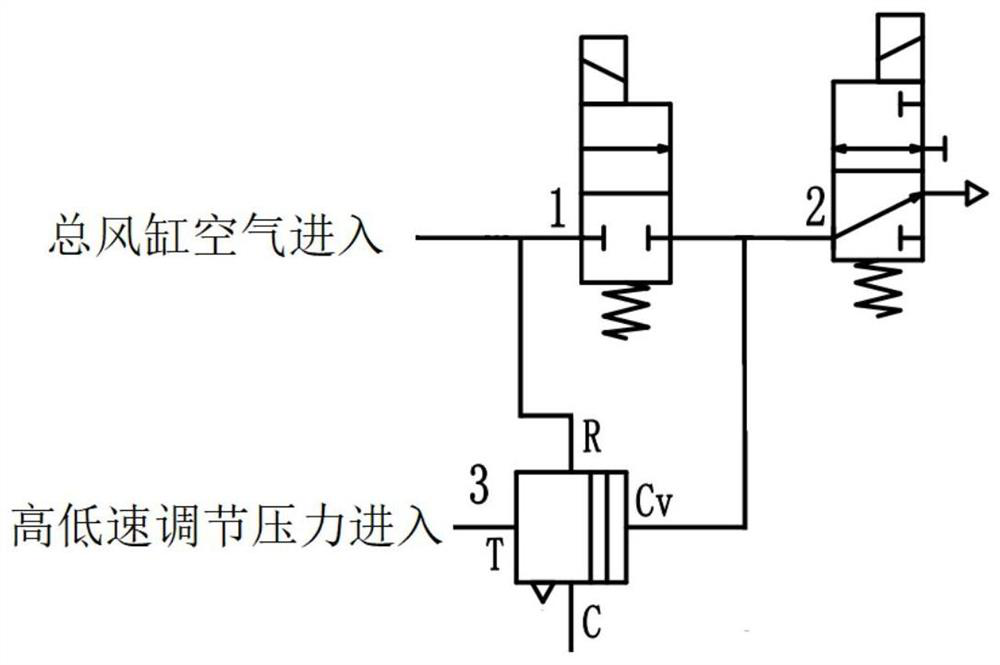

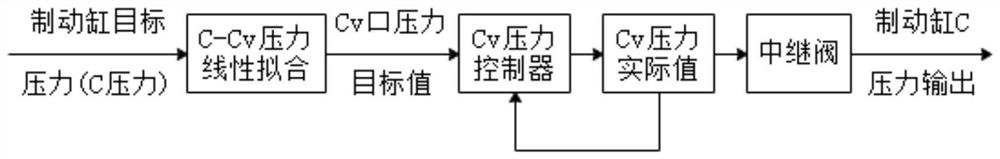

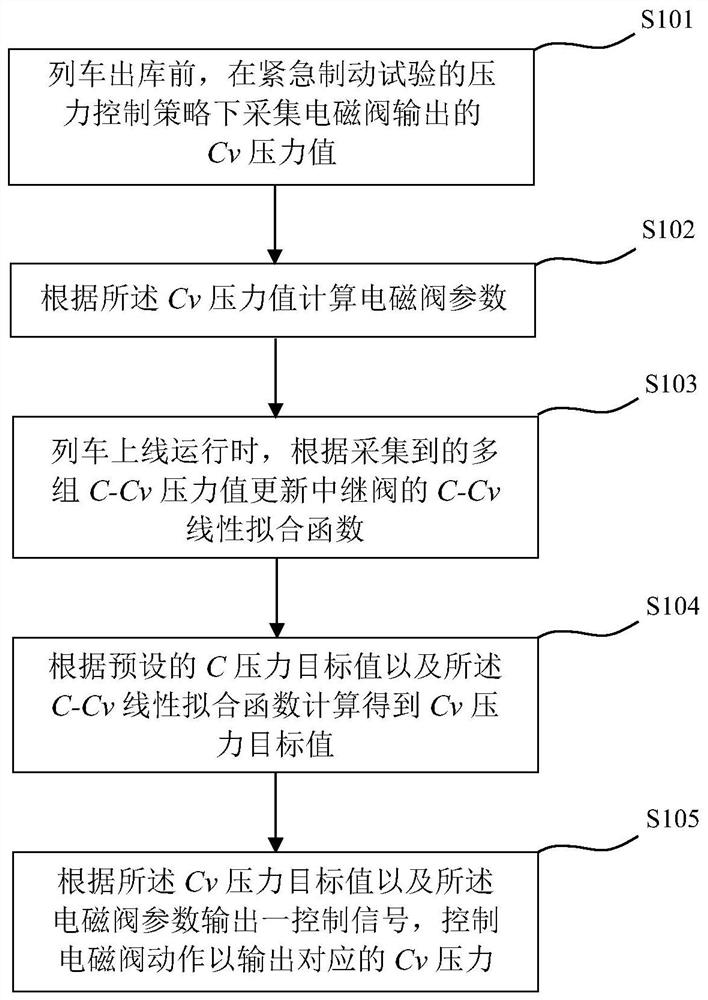

Train brake cylinder pressure control method and system

ActiveCN112937628AReduce the number of movementsExtended service lifeBraking action transmissionAerodynamic brakesRelay valveControl signal

The invention provides a train brake cylinder pressure control method and system, and the method comprises the steps: collecting a Cv pressure value outputted by an electromagnetic valve under a control strategy of an emergency brake test before a train leaves a garage; calculating electromagnetic valve parameters according to the Cv pressure value; when the train runs on line, the C-Cv linear fitting function of the relay valve is updated according to the collected multiple groups of C-Cv pressure values; calculating a Cv pressure target value according to a preset C pressure target value and the C-Cv linear fitting function; and outputting a control signal according to the Cv pressure target value and the electromagnetic valve parameter, and controlling an electromagnetic valve to act so as to output the corresponding Cv pressure. By estimating the parameters of the electromagnetic valve and the relay valve and controlling the pressure of the brake cylinder according to the parameters, higher accuracy, higher control speed and fewer action times of the electromagnetic valve are achieved, and the service life of the valve is greatly prolonged.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

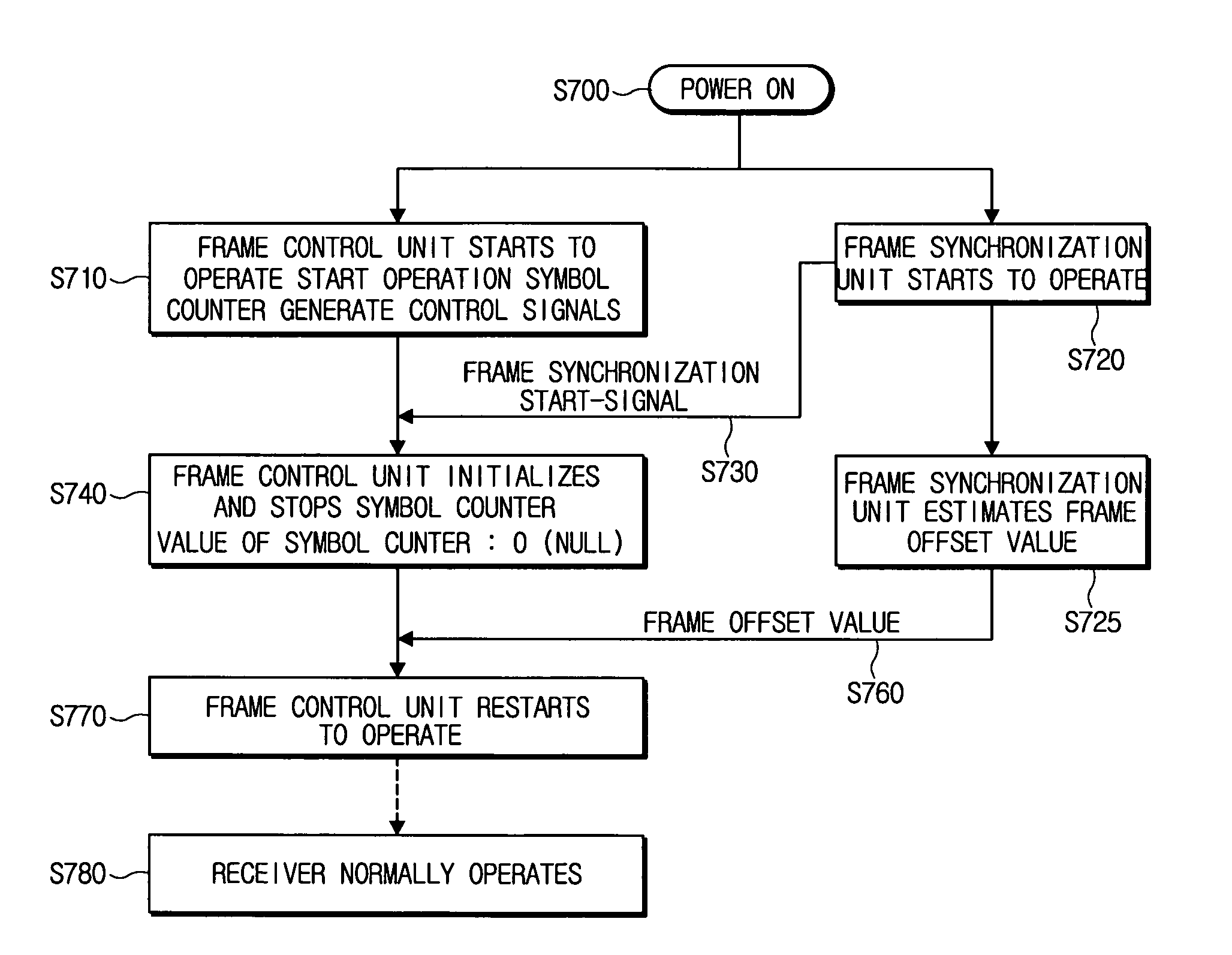

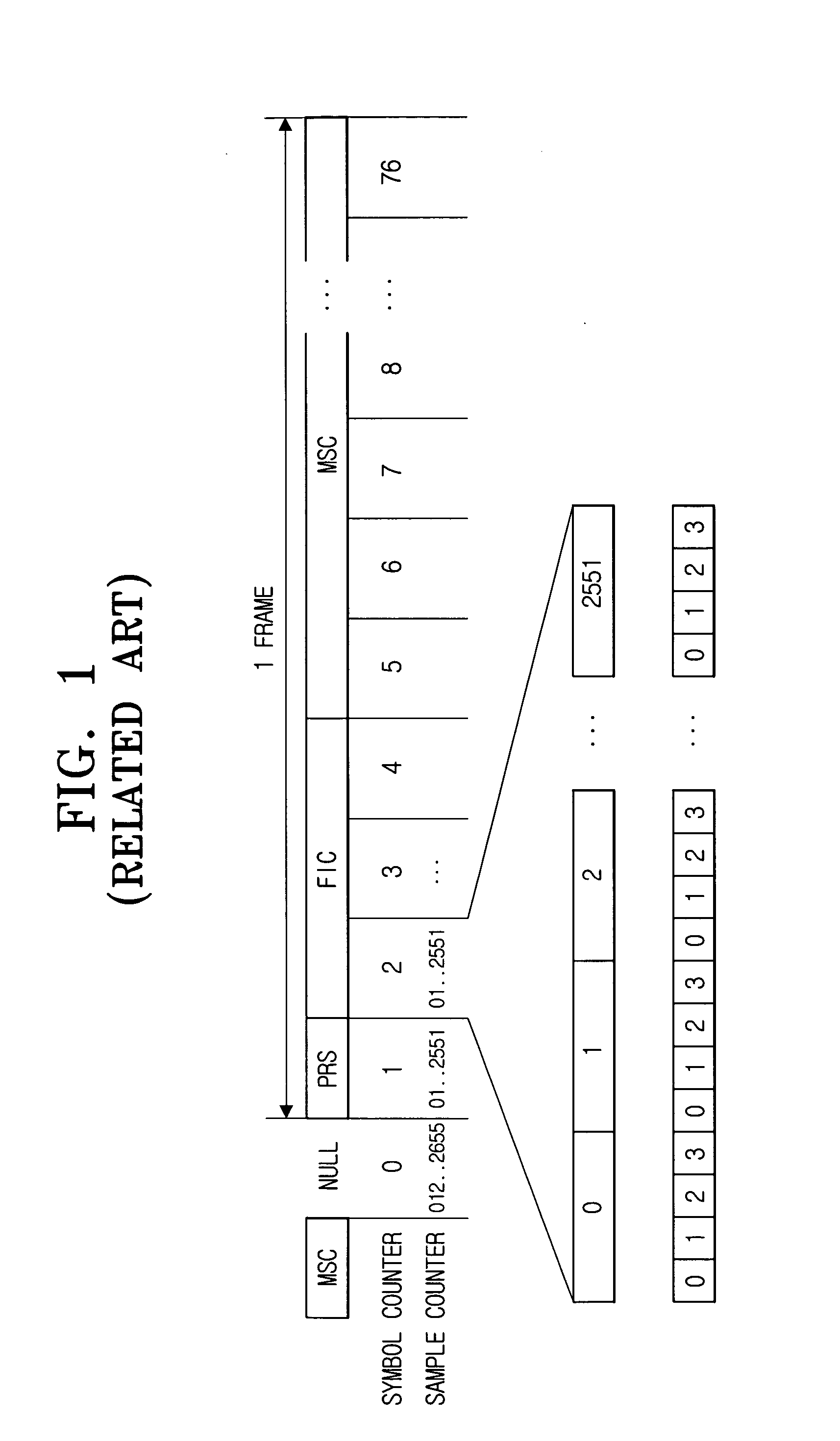

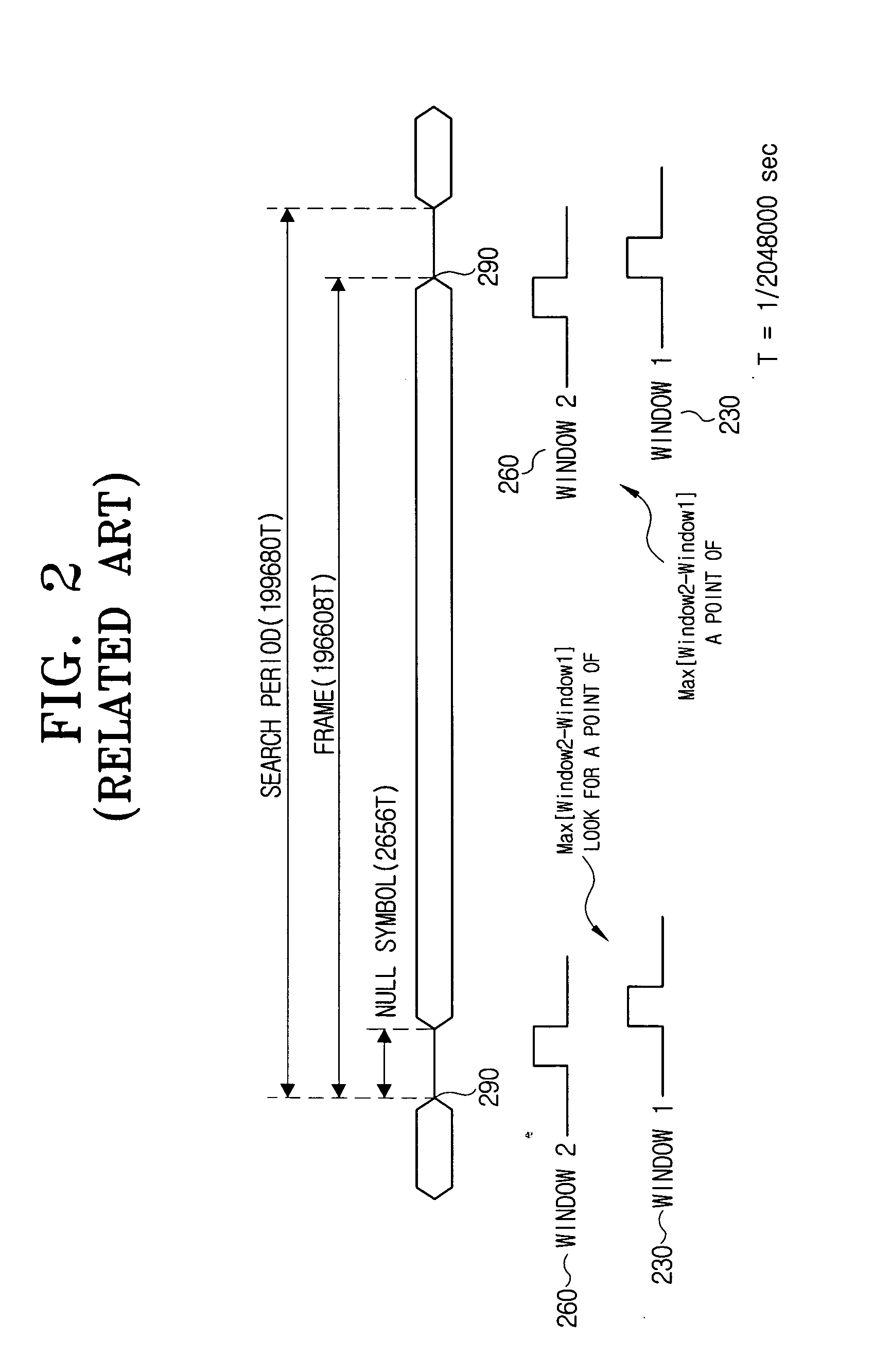

Method of and system for controlling frame synchronization for European Digital Audio Broadcasting

InactiveUS20060188049A1Short control timeControl frameTelevision system detailsModulated-carrier systemsStart signalLaunch Time

Disclosed are a method of and a system for controlling frame synchronization for European Digital Audio Broadcast (DAB), the method including the steps of generating a frame synchronization start-signal with respect to an incoming signal which is input when power is supplied, keeping symbol count values with the value “0” after the frame synchronization start-signal is input, transmitting a frame offset value with respect to the incoming signal, and restarting symbol counting for frame synchronization depending on the frame offset value after the frame offset value is input, wherein the frame synchronization unit may preferably transmit the frame offset value after estimating the frame offset value. In accordance with the method and system described herein, it is possible to achieve frame synchronization in short time, thereby reducing a startup time of a DAB receiver and power consumption which is needed for the frame synchronization.

Owner:SAMSUNG ELECTRONICS CO LTD

Suction Roll System

ActiveCN104812539BEasy to replaceCutting costsPress sectionMetal working apparatusControl systemEngineering

A suction roll system (1) with a rotatably mounted cylindrical suction roll (32), the cylinder jacket (34) of which is provided with a plurality of suction holes (36), which can be selectively connected via a control system individually or in groups to a vacuum system (14), is intended to make possible, in a reliable fashion, particularly short switchover times and also high flexibility, even when groups of a plurality of suction holes (36) are actuated. To this end, according to the invention, the control system comprises a fixedly mounted hollow cylinder (2) projecting into the suction roll (32) and connected by its interior volume (10) to the vacuum system (14), the cylinder jacket (20) of which is penetrated by a number of control slots (22).

Owner:WINKLER DUNNEBIER GMBH

A control method and control system for the production environment of lpcvd process

ActiveCN103397312BShorten the timeLow costChemical vapor deposition coatingTemperature controlControl system

The invention provides a control method for a low pressure chemical vapor deposition (LPCVD) technical production environment. The control method comprises the following steps that: S1, a temperature sensor acquires temperature information in a reaction cavity, and a vacuum degree sensor acquires vacuum degree information in the reaction cavity; S2, a feedback control device acquires the temperature information and the vacuum degree information and calculates feedback control gain parameters according to the temperature information and the vacuum degree information; S3, the feedback control device generates a temperature control signal according to the temperature information and the corresponding feedback control gain parameter and a vacuum degree control signal according to the vacuum degree information and the corresponding feedback control gain parameter, and sends the temperature control signal and the vacuum degree control signal to a temperature adjustment device and a vacuum degree adjustment device; S4, the temperature adjustment device adjusts the temperature in the reaction cavity according to the temperature control signal, and the vacuum degree adjustment device adjusts the vacuum degree in the reaction cavity according to the vacuum degree control signal.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Vision auxiliary tool

PendingCN110572619AImprove practicalitySimple structureTelevision system detailsColor television detailsEngineeringMicro power source

The invention relates to a vision auxiliary tool. The vision assisting tool comprises a shell worn on the head; a camera, a display screen, a micro power source, a zooming system and a circuit board are arranged in the shell, and a switch button is arranged on the shell; the camera is fixed at the front end of the shell and is far away from one end of the eyes; the display screen is fixed behind the camera; the circuit board is fixed in the shell and at the upper part of the display screen, and is electrically connected with the camera, the display screen, the micro power supply, the zoom system and the switch; the micro power supply is integrated in the shell and at the rear part of the circuit board; the zooming part is arranged in the shell; and the switch button is connected with the micro power supply. The vision auxiliary tool is easy to operate, convenient to use and practical.

Owner:冀成

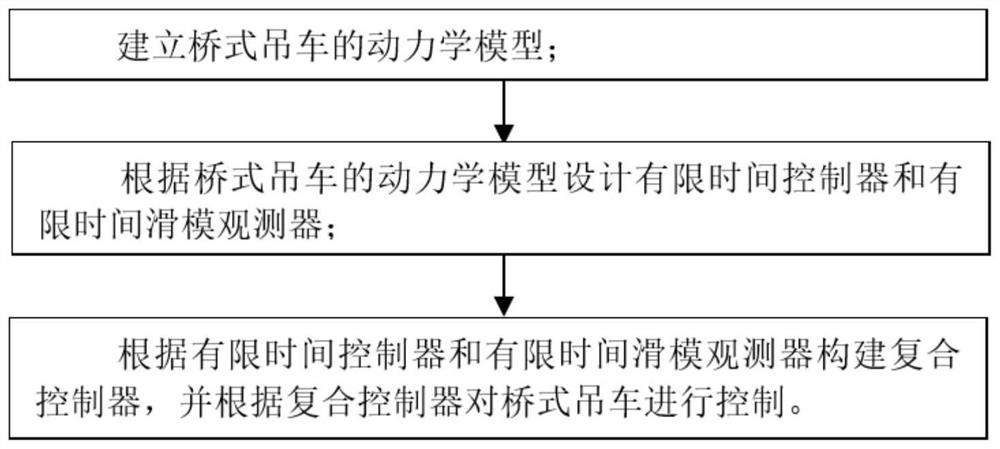

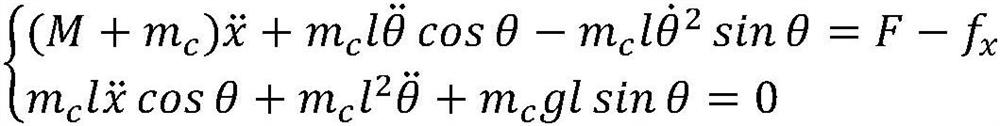

Bridge crane control method based on finite time composition

ActiveCN114280937AImprove anti-interference abilityImprove anti-swing effectTotal factory controlLoad-engaging elementsDynamic modelsControl engineering

The invention discloses a bridge crane control method based on finite time composition, and belongs to the technical field of crane control. The method comprises the following steps: firstly, establishing a dynamic model of the bridge crane, and then designing a finite time controller and a finite time sliding mode observer according to the dynamic model of the bridge crane; and then a composite controller is constructed according to the finite time controller and the finite time sliding mode observer, and the bridge crane is controlled according to the composite controller. The problem that in the prior art, the anti-swing control effect is poor is solved, the bridge crane control method based on finite time composition is provided, interference caused by parameter uncertainty, modeling errors and the like is restrained through combination of the finite time sliding mode observer and the finite time controller, and the anti-swing control effect of the bridge crane is improved. And the anti-swing performance and the anti-interference capability of the bridge crane are improved.

Owner:NANJING UNIV OF TECH

Drilling wellhead overflow prevention control system

ActiveCN111535772BImprove protectionGuaranteed resetWell/borehole valve arrangementsSealing/packingControl systemWell drilling

The invention relates to a wellhead overflow prevention control system for drilling, which comprises semi-sealed large and small spool double rams located on the main cross of the wellhead, a fully-sealed single ram and an annular blowout preventer, the top of which is connected with an overflow prevention pipe ;The right side of the main cross at the wellhead is connected with a discharge manifold, the outlet of the discharge manifold is connected with a throttle manifold, and the entrance of the throttle manifold is equipped with a discharge flat valve; the left side of the main cross at the wellhead is connected There is a reverse circulation manifold; the semi-sealed blowout preventer is a double-slide preventer composed of a semi-sealed large spool gate and a semi-sealed small spool gate. The large and small spool gates are controlled by the large and small spool liquid rotation valve, its operating handle is connected with the piston rod of the semi-sealed cylinder; the compressed air is respectively connected with the P port of the spray air control valve 1, the annular air control valve, and the semi-sealed large and small spool air control valve; the semi-sealed large and small spool air The A port of the control valve is connected with the upper cavity air port of the semi-sealed large and small spool cylinder through the semi-sealed large and small spool shuttle valves. The device can realize soft shut-in for drilling tools of different specifications downhole.

Owner:中石化石油工程技术服务有限公司 +1

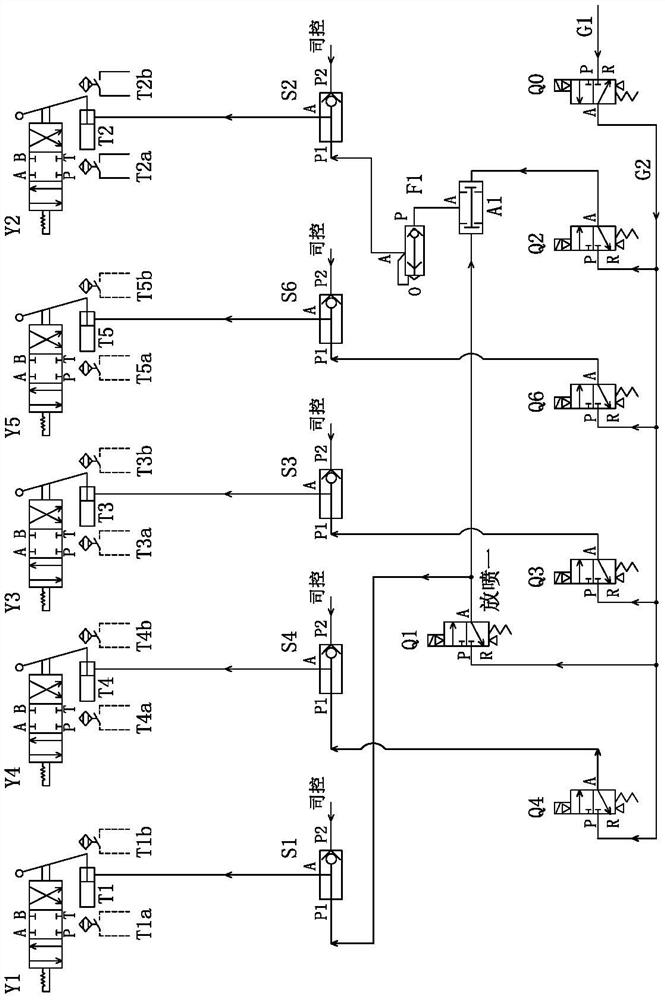

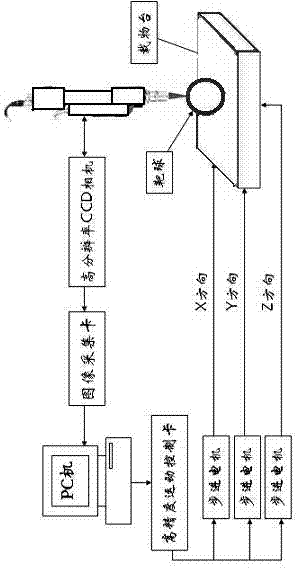

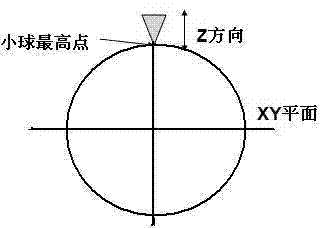

Laser drilling equipment and drilling method with automatic detection of the highest point position of the sphere

ActiveCN103785956BEasy extractionShorten detection timeLaser beam welding apparatusImage manipulationVisual perception

The invention discloses a laser drilling device capable of automatically detecting the highest point position of a sphere and a drilling method. At present, laser drilling is performed manually, the position of material to be machined is detected through a sensing system, the focusing position is sensed by means of the visual sense of an operator, and then a motion control system is adjusted manually to reach the designated position to perform laser drilling device. The laser drilling device capable of automatically detecting the highest point position of the sphere comprises a drilling machine, an automatic detecting system is formed by a high-resolution coaxial CCD sensor and an image collecting card and connected with a computer provided with a high-precision motion control card, the high-precision motion control card is connected with a stepping motor of the drilling machine, image processing software is installed on the computer, and the highest point position of the sphere is focused accurately and rapidly through the automatic detecting system. The laser drilling device is used for laser drilling at the highest point position of the sphere.

Owner:HARBIN INST OF TECH

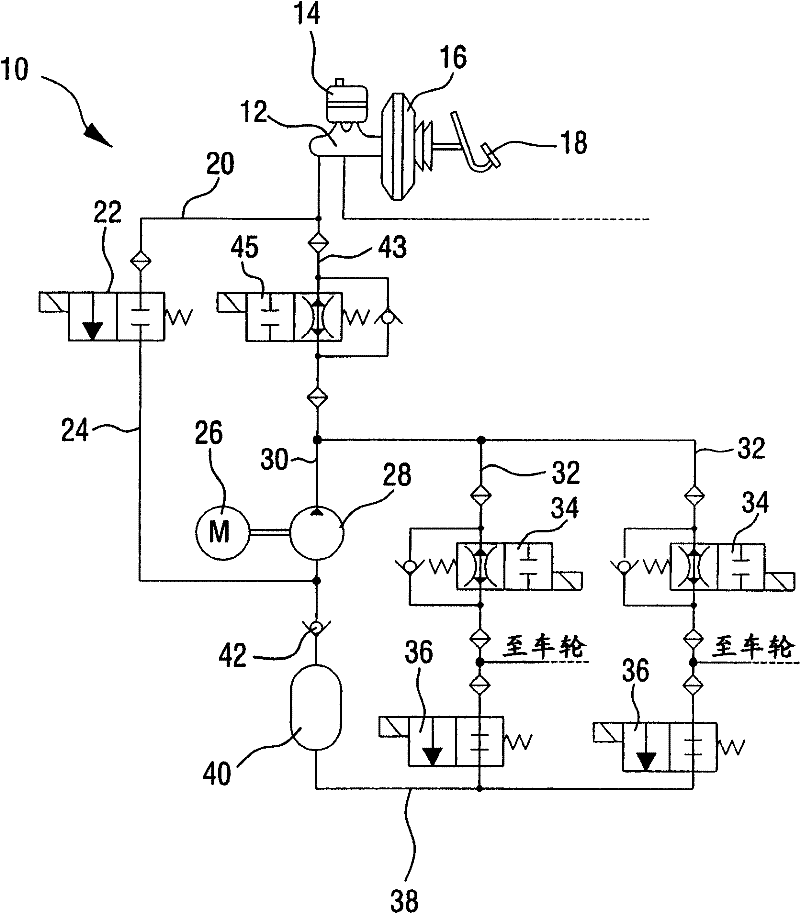

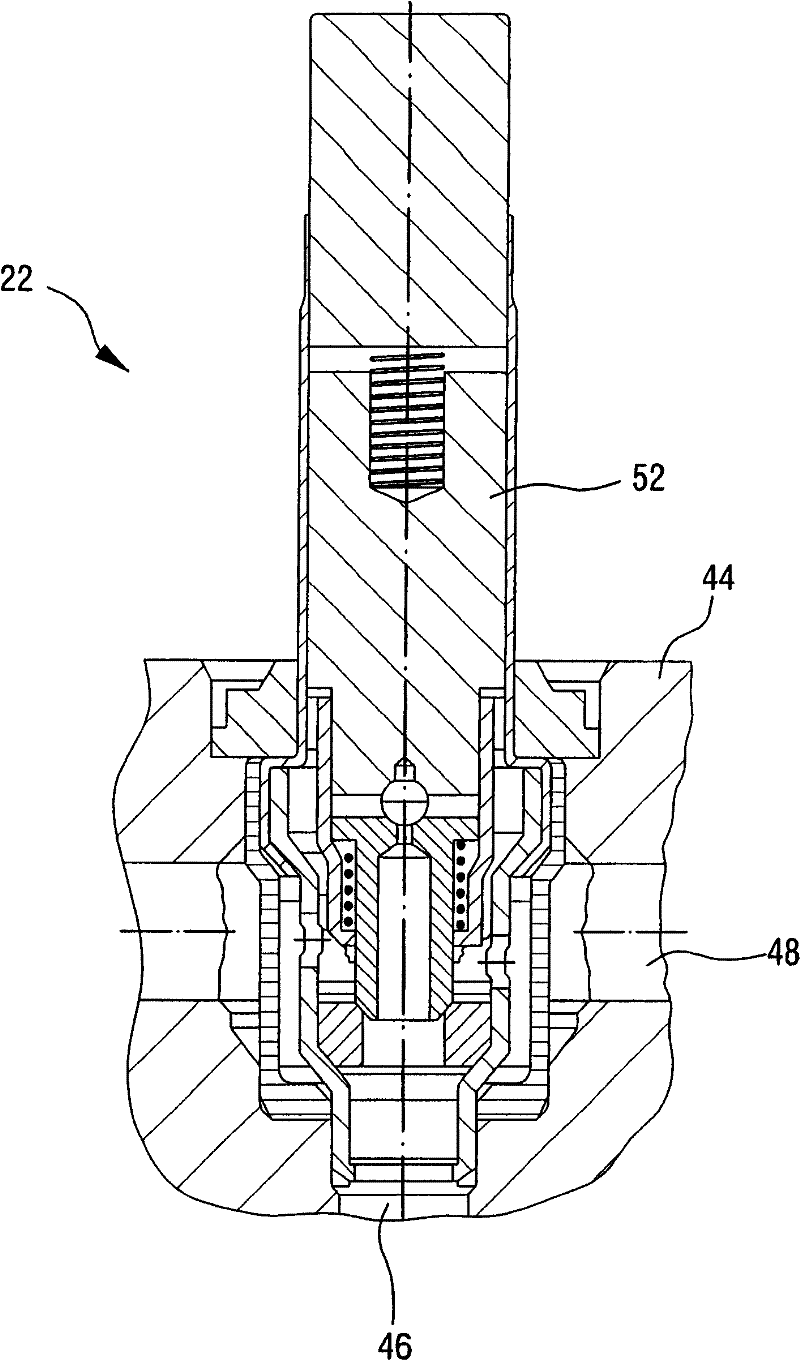

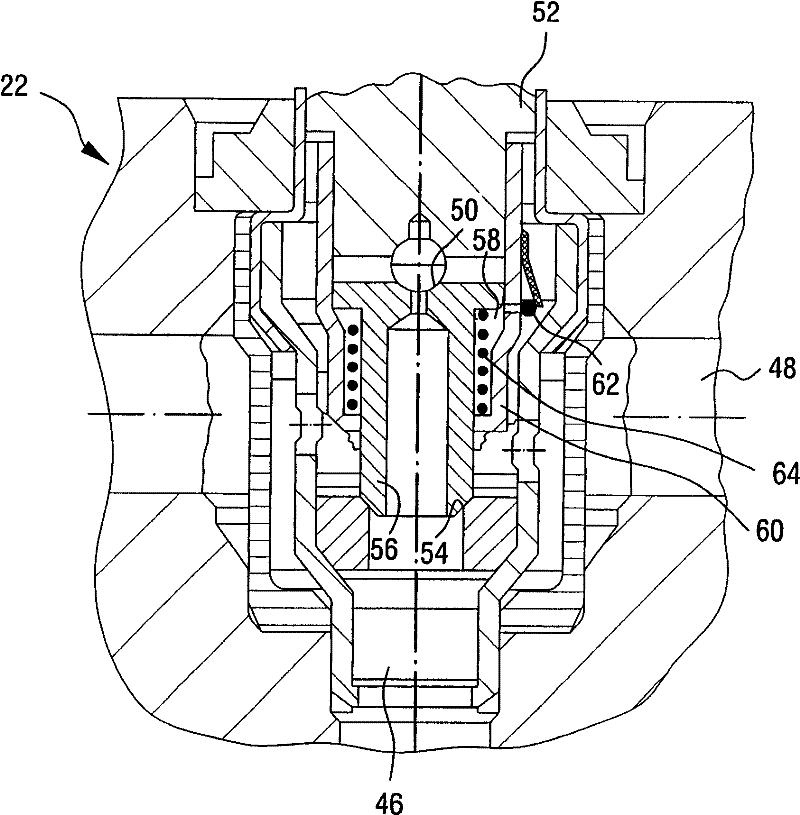

Automotive brake equipment with valves

InactiveCN1935568BAvoid shock-type pressure equalization processShort control timeOperating means/releasing devices for valvesFluid braking transmissionEngineeringFluid level

Owner:ROBERT BOSCH GMBH

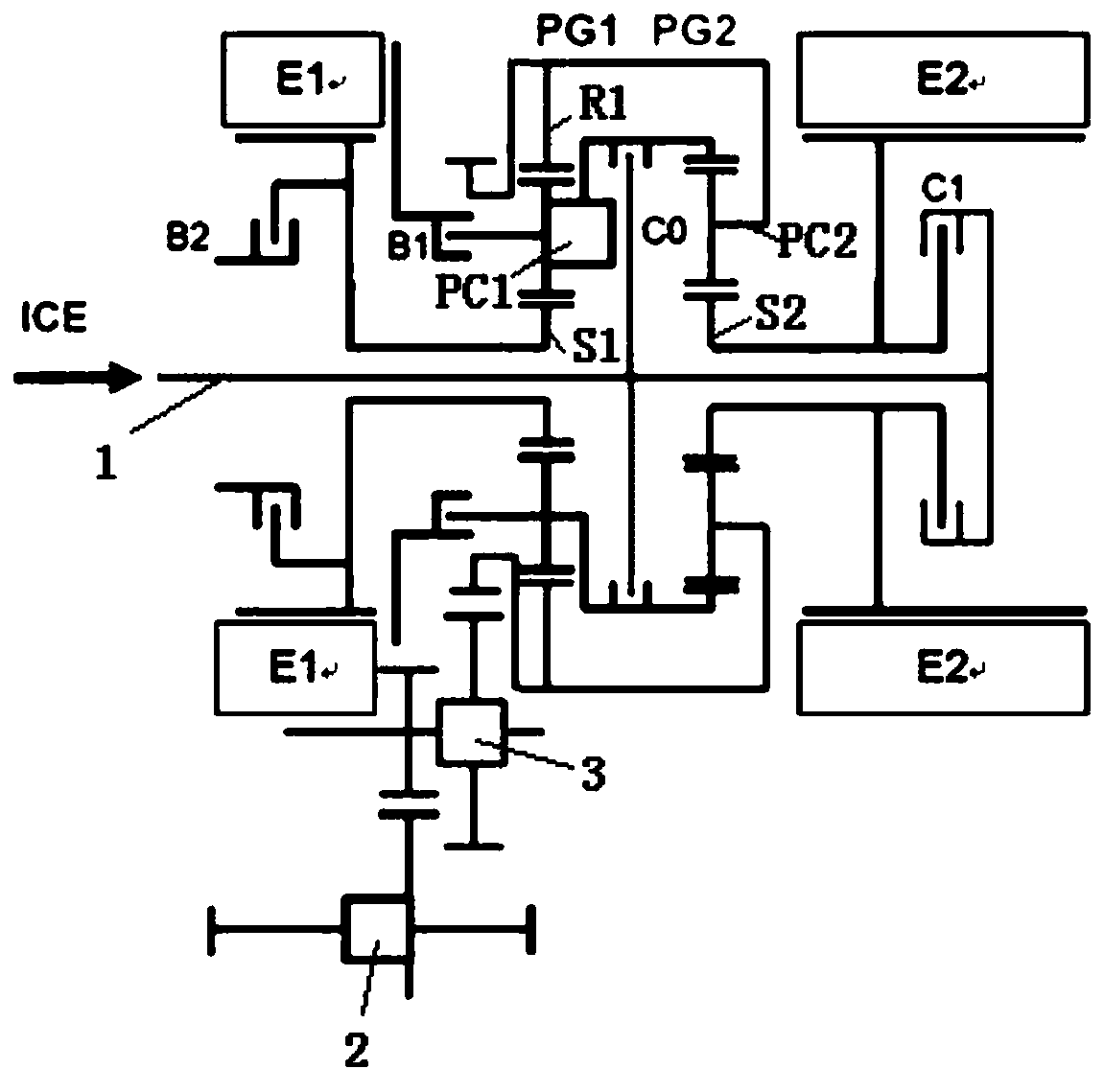

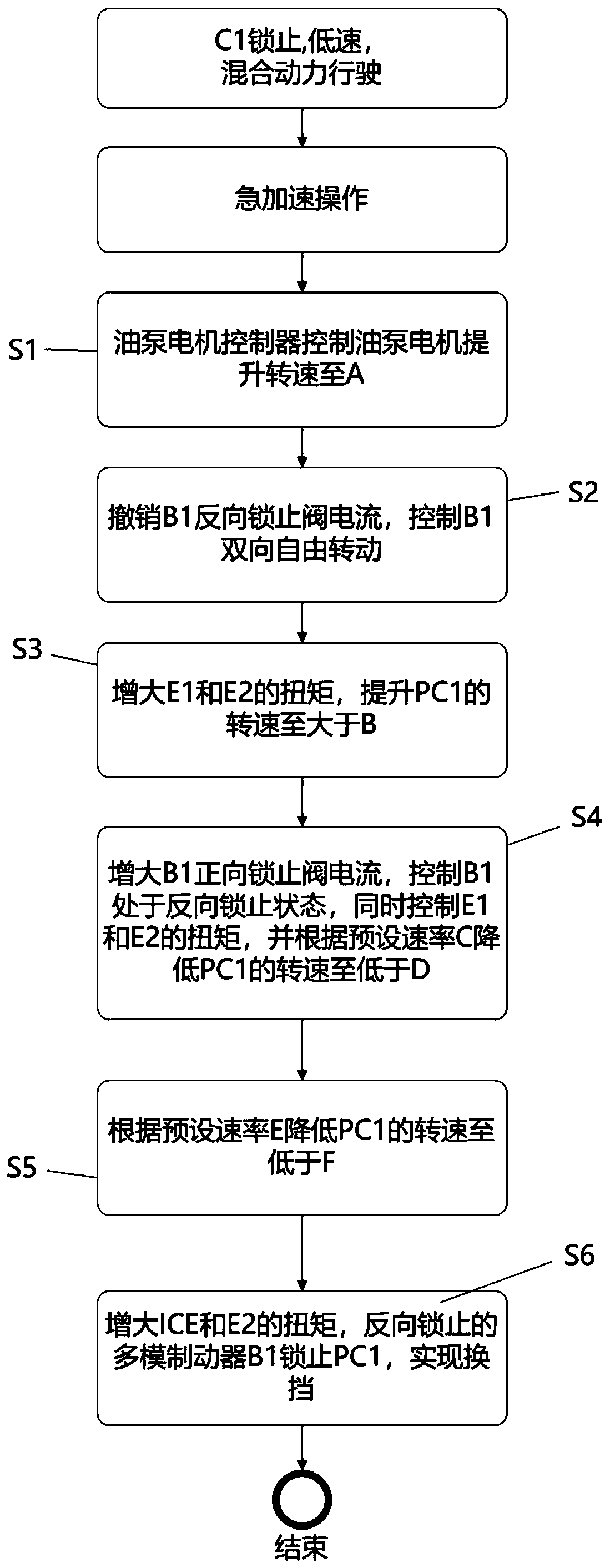

Shift control method of hybrid electric vehicle based on multi-mode brake

ActiveCN109552311BShorten shift timeImprove driving comfortHybrid vehiclesElectric machineryHybrid electrical vehicle

Owner:江西鼎盛新材料科技有限公司

Two-point active control method for asymmetrical voltage in non-effectively grounded neutral system

InactiveCN104092228BReduced amplificationSlow controlPolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionPower gridVoltage drop

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

System and method for beam array phase control based on multi-phase perturbation

InactiveCN103227408BSimple structureAccurately obtain the magnitude of the phase shiftLaser detailsBeam splitterControl signal

The invention provides a beam array phase control system and a method based on multiphase perturbation. Emergent laser of a laser source in the control system is input to a beam splitter; multichannel laser output by the beam splitter is input to corresponding phase controllers respectively; the phase controllers are sequentially connected with optical amplifiers and an optical collimation emitter; the optical collimation emitter is sequentially connected with an optical splitter and a far field image device; the far field image device inputs the laser into a detector; an electrical signal output by the detector is input into a phase control algorithm module; the phase control algorithm module outputs a multichannel electrical control signal to the corresponding phase controllers; and a multiphase perturbation generation module outputs a multichannel electrical modulating signal to the corresponding phase controllers. With the adoption of the system and the method, the performance of a coherent combination system can be improved, and large-scale beam combining capacity can be achieved.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS

An intelligent correction device control system for super-resolution lithography precision mask

ActiveCN111580359BEconomic realizationQuick responseProgramme controlTelevision system detailsGraphic cardPhotolithography

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

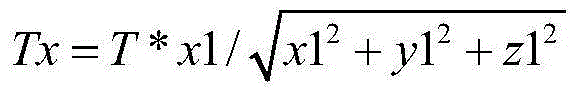

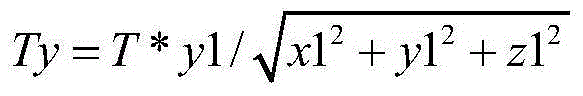

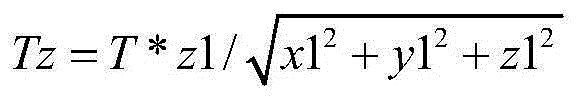

The temperature control method of the diamond six-sided top press

InactiveCN104275125BEasily distinguish temperature trendsDifferentiate temperature trendsUltra-high pressure processesCENBOLTemperature control

The invention relates to a temperature control method of a diamond cubic press. The temperature control method comprises the following steps: 1, establishing a three-axis three-dimensional coordinate system by using a center point of a cavity inside the diamond cubic press as an original point, setting s heat sources in the cavity inside the diamond cubic press, wherein each heat source has a coordinate P in the coordinate system, the temperature value of each heat source is T, and the T is decomposed onto an x axis, a y axis and a z axis to form three temperature components; setting three particle swarms, wherein the three particle swarms are respectively sets of the temperature components of the s heat sources in directions of the three axes; the temperature components in the particle swarms are called as particles, the three particle swarms internally comprise s particles; 2, respectively optimizing the three particle swarms by using a particle swarm optimizing algorithm; and 3, controlling the heating intensity of the s heat sources by adopting a PID algorithm according to data in the three optimized particle swarms, so as to achieve the purpose of controlling the temperature of the cavity inside the diamond cubic press. The temperature control method is short in control time, accurate in control and stable in effect.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com