Laser drilling equipment and drilling method with automatic detection of the highest point position of the sphere

An automatic detection and laser drilling technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low laser drilling efficiency, achieve a high degree of automation, reduce fitting errors, and reduce processing time Effect

Active Publication Date: 2015-08-19

HARBIN INST OF TECH

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention provides a laser drilling device and drilling method with automatic detection of the highest point position of the sphere, using image processing technology, which can improve the accuracy of laser focusing, and at the same time It can also solve the problem of low efficiency of laser drilling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] Embodiment 2:

Embodiment 2

[0029] Embodiment 3:

Embodiment 3

[0031] Embodiment 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

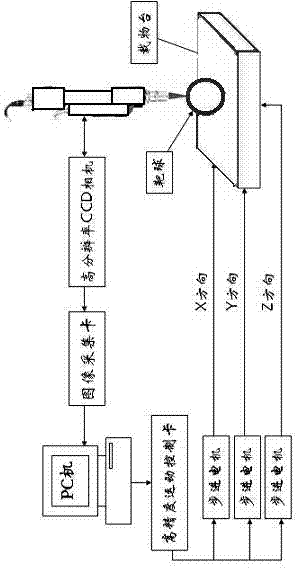

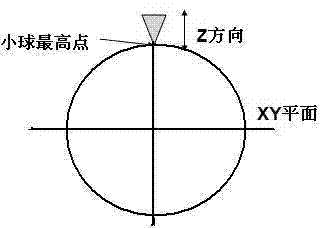

The invention discloses a laser drilling device capable of automatically detecting the highest point position of a sphere and a drilling method. At present, laser drilling is performed manually, the position of material to be machined is detected through a sensing system, the focusing position is sensed by means of the visual sense of an operator, and then a motion control system is adjusted manually to reach the designated position to perform laser drilling device. The laser drilling device capable of automatically detecting the highest point position of the sphere comprises a drilling machine, an automatic detecting system is formed by a high-resolution coaxial CCD sensor and an image collecting card and connected with a computer provided with a high-precision motion control card, the high-precision motion control card is connected with a stepping motor of the drilling machine, image processing software is installed on the computer, and the highest point position of the sphere is focused accurately and rapidly through the automatic detecting system. The laser drilling device is used for laser drilling at the highest point position of the sphere.

Description

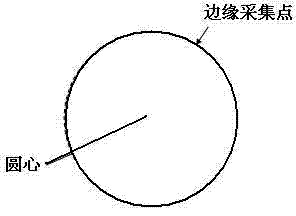

technical field [0001] The invention belongs to the technical field of automatic detection of the position of the highest point of a sphere in a laser drilling system, and in particular relates to a device and method for accurately automatically positioning the position of the highest point of a sphere and drilling holes. Background technique [0002] In the process of laser drilling, in order to ensure the shape and size requirements of the hole, it is necessary to determine the focus position of the laser and ensure that the focus position remains constant. For the laser drilling at the highest point of the sphere, the accuracy of the focus of the laser beam on the highest point of the sphere is a key factor to ensure the shape and size of the hole. [0003] At present, in the process of laser drilling, it is still mainly under human operation. The sensing system detects the position of the processed material, and relies on the operator's vision to perceive the focus posit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K26/382B23K26/046

CPCB23K26/046B23K26/382B23K26/702

Inventor 杨立军王扬张宏志侯超剑刘俊岩王懋露

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com