Automotive brake equipment with valves

A technology of automobile braking and equipment, applied in the direction of brakes, mechanical equipment, hydraulic brake transmissions, etc., can solve the problems of normal characteristics stimulating drivers, etc., and achieve the effect of avoiding invalid time, short control time and avoiding unexpected noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

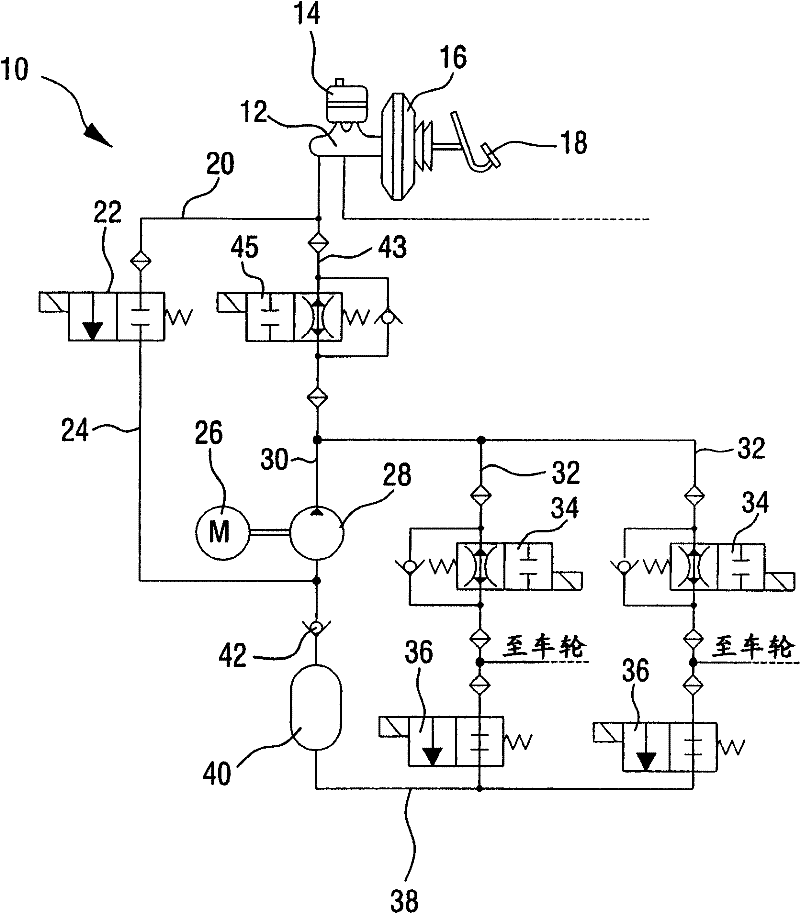

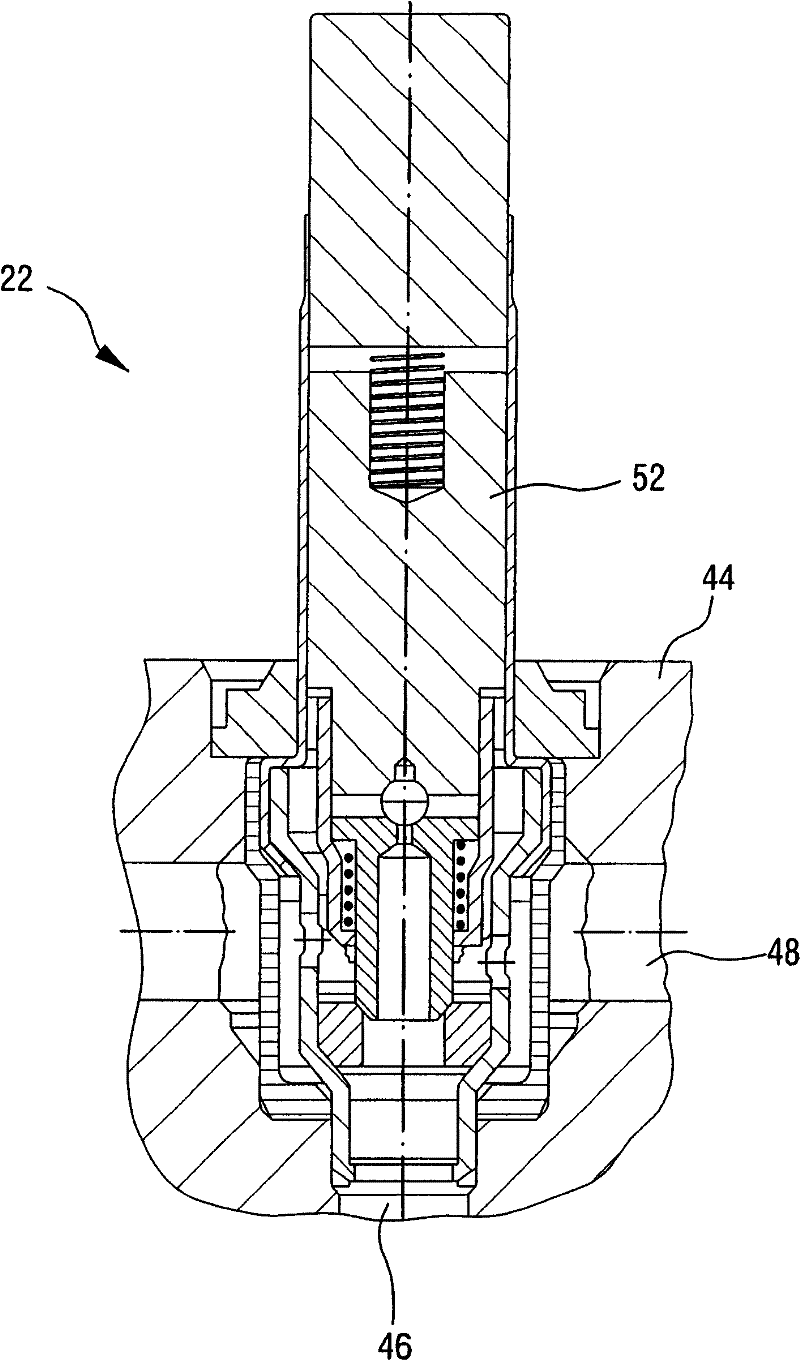

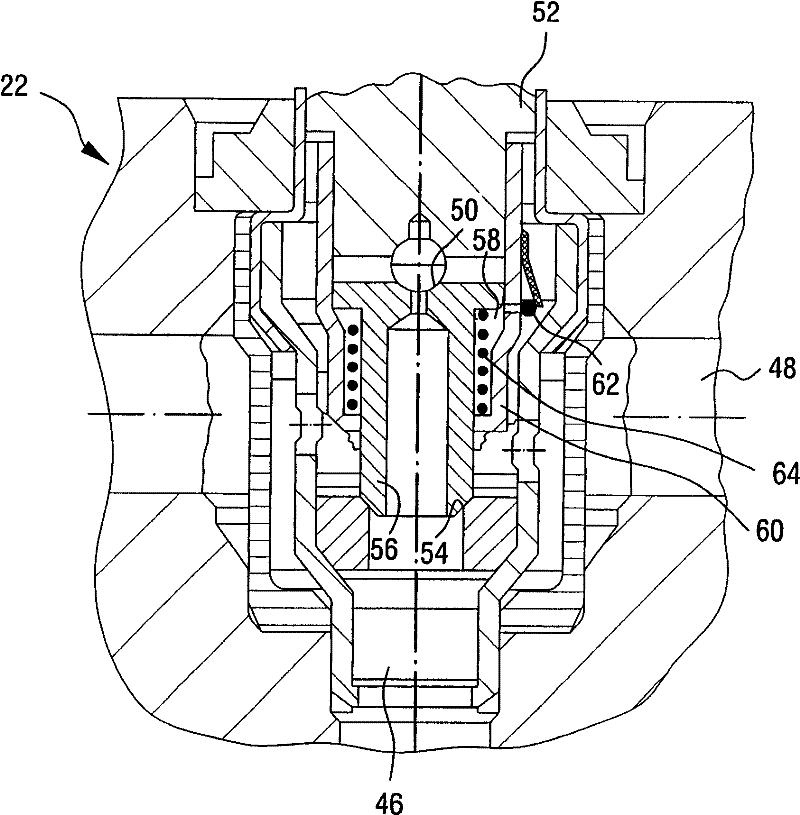

[0020] exist figure 1 A hydraulic circuit diagram of a vehicle brake system 10 is shown in , which has, as main structural components, a master brake cylinder 12 , which has a hydraulic fluid reservoir 14 arranged thereon, a brake booster 16 and a brake pedal 18 . The first and second brake circuits are connected to the master brake cylinder 12, where figure 1 Basically only the first brake circuit can be seen in it. In this brake circuit, a line 20 leads to a high-pressure directional valve 22 , behind which a suction line 24 leads to a pump 28 driven by an electric motor. The fluid conveyed in this way can be conveyed by means of a pump 28 into a pipe 30 , to which two parallel pipes 32 are connected. In each parallel line 32 a two-position / two-way valve 34 is provided, the open position of which is damped. The two-position / two-way valve 34 leads to the wheel (not shown) with the associated wheel brake cylinder and also leads to the line 32 , in which the two-position / tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com