An intelligent correction device control system for super-resolution lithography precision mask

A technology of a calibration device and a control system, which is applied to the exposure device of photoengraving process, the exposure device of microlithography, the components of the TV system, etc., can solve the problems of increasing the workload of the upper computer, reducing the alignment efficiency, and complex implementation steps. , to achieve high-efficiency image acquisition and alignment, improve alignment efficiency, and shorten the control time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited to the following examples, but should include all content in the claims. Moreover, those skilled in the art can realize all the content in the claims from the following embodiment.

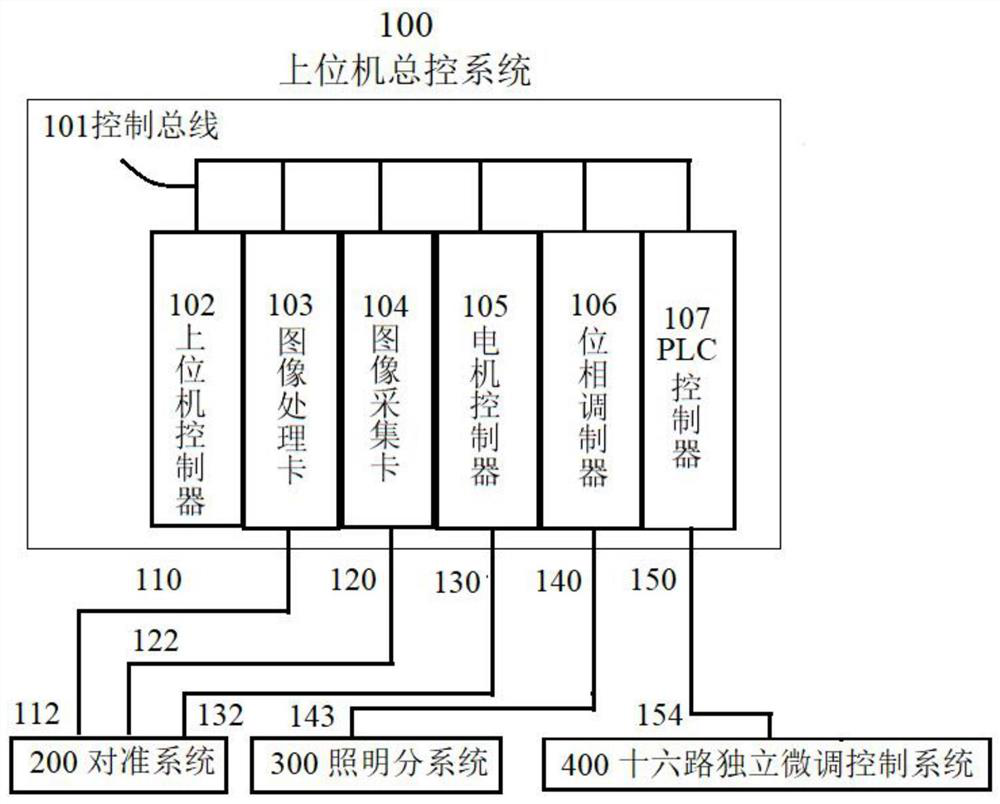

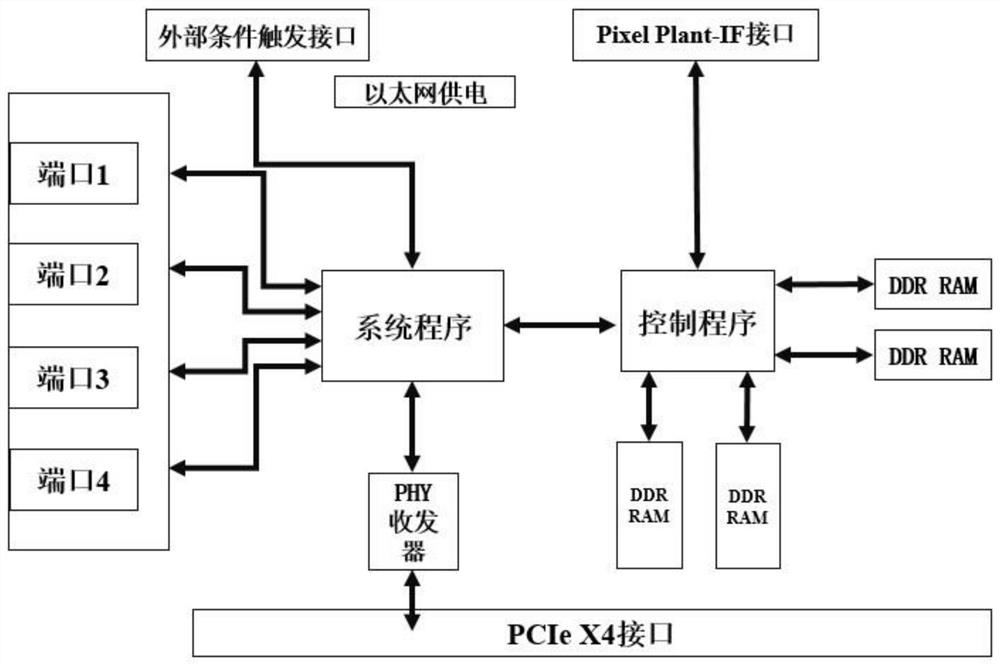

[0035] Such as figure 1 As shown, the precision mask correction device control system of the present invention includes a host computer master control system 100, a control bus 101, a host computer controller 102, an image processing card 103, an image acquisition card 104, a motor controller 105, and a phase modulator 106 , PLC controller 107; the image acquisition card 103 is connected to the outside through the PCIe transmission channel 110, and the image acquisition card 104 is connected to the outside through the Ethernet transmission channel 120; the motor controller 105 is connected to the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com