Well drilling wellhead anti-overflow control system

A control system and anti-overflow technology, applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc., can solve the problems of drill pipe clamping and sealing, and ensure the safety of the well site Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

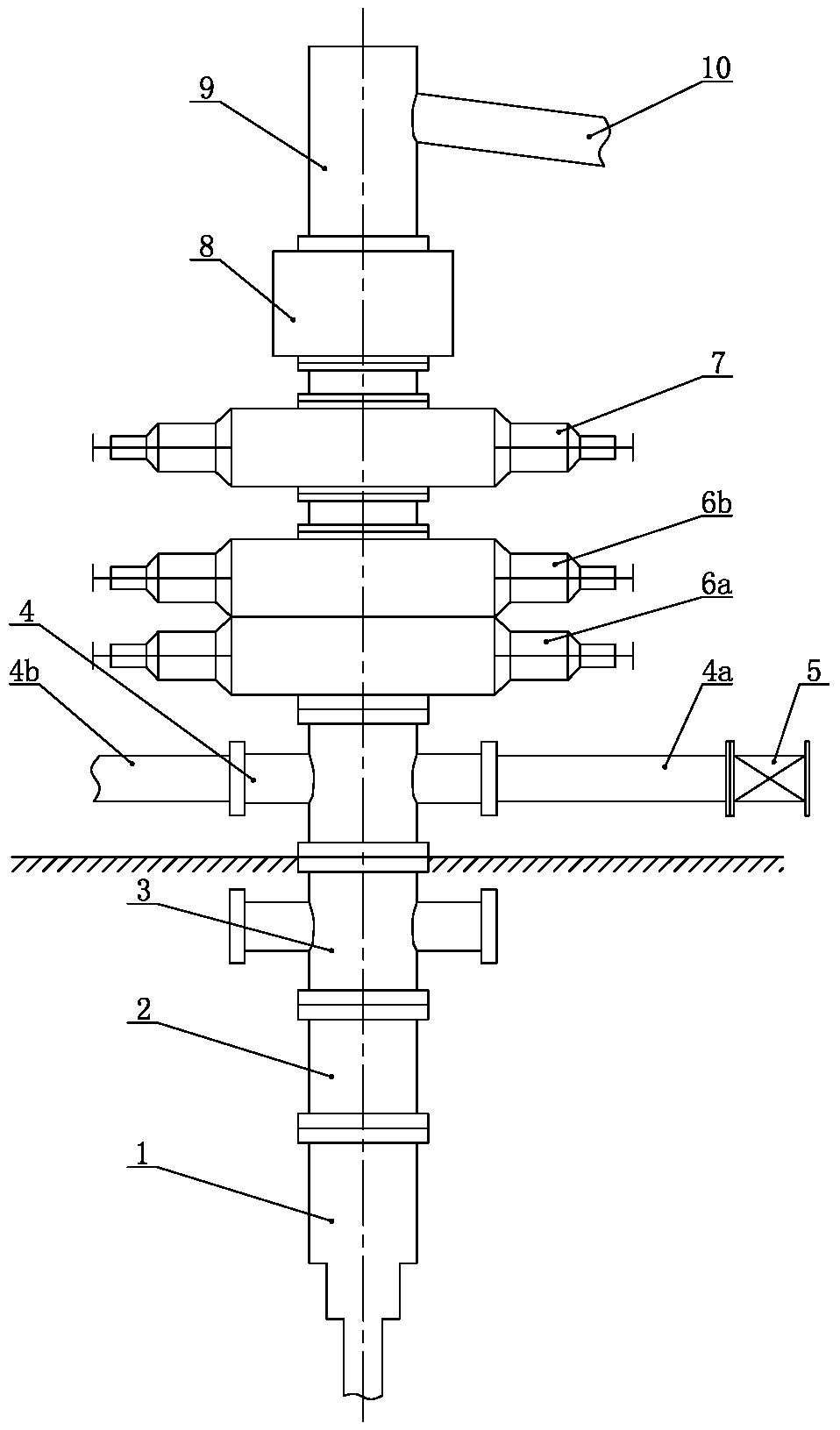

[0038] Such as figure 1 As shown, the drilling wellhead overflow prevention control system of the present invention includes a semi-sealed blowout preventer installed above the wellhead main spool 4 from bottom to top, a fully sealed single ram 7 and an annular blowout preventer 8, and the annular blowout preventer 8 The top is connected with an anti-overflow pipe 9 extending upward, and the upper end of the anti-overflow pipe 9 is connected with a return pipe 10 . The right side of the main cross 4 at the wellhead is connected with a blowout manifold 4a, the outlet of the blowout manifold 4a is connected with a throttle manifold, and a blowout plate valve 5 is installed at the entrance of the throttle manifold; the main cross 4 at the wellhead The left side of is connected with reverse circulation manifold 4b. The auxiliary cross 3 below the main cross 4 at the wellhead is located below the ground, and the rising nipple 2 below the auxiliary cross 3 is connected to the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com